ASTM E1917-97

(Test Method)Standard Test Method for Determination of Phosphorous in Nickel, Ferronickel, and Nickel Alloys by Phosphovanadomolybdate Molecular Absorption Spectrometric Method

Standard Test Method for Determination of Phosphorous in Nickel, Ferronickel, and Nickel Alloys by Phosphovanadomolybdate Molecular Absorption Spectrometric Method

SCOPE

1.1 This test method covers the determination of phosphorus in nickel, ferronickel, and nickel alloys in the 0.0007% through 0.05% range.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1917 – 97

Standard Test Method for

Determination of Phosphorus in Nickel, Ferronickel, and

Nickel Alloys by Phosphovanadomolybdate Molecular

Absorption Spectrometric Method

This standard is issued under the fixed designation E 1917; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ISO 11400:1992(E) Nickel, Ferronickel and Nickel

Alloys—Determination of Phosphorus Content—

1.1 This test method covers the determination of phospho-

Phosphovanadomolybdate Molecular Absorption Spectro-

rus in nickel, ferronickel, and nickel alloys in the 0.0007 %

metric Method

through 0.05 % range.

1.2 Arsenic, chromium, hafnium, niobium, silicon, tanta-

3. Summary of Test Method

lum, titanium, and tungsten interfere, but the interference can

3.1 The sample is dissolved in a mixture of hydrochloric

be avoided by complexation or volatilization (for Cr). The

acid and nitric acid. The solution is evaporated to perchloric

lowest phosphorus content (0.0007 %) can be reached only in

acid fumes and chromium is removed as volatile chromyl

samples with low contents of interfering elements.

chloride. Silicon and refractory elements are complexed with

1.3 This standard does not purport to address all of the

fluoride ions. The phosphorus is converted to phosphovanado-

safety concerns, if any, associated with its use. It is the

molybdic acid in a perchloric and nitric acid solution. The

responsibility of the user of this standard to establish appro-

phosphovanadomolybdic acid is extracted with 2-methyl-2-

priate safety and health practices and determine the applica-

pentanone in the presence of citric acid to complex arsenic.

bility of regulatory limitations prior to use. For specific hazards

Absorbance is measured at 355 nm.

associated with the use of this practice see Practices E 50.

Refer to specific warning notes given throughout this test

4. Significance and Use

method.

4.1 This test method is used for the analysis of nickel,

2. Referenced Documents ferronickel, and nickel base alloy samples by molecular ab-

sorption spectrometry to check compliance with compositional

2.1 ASTM Standards:

specifications. It is assumed that all who use the procedure will

E 50 Practices for Apparatus, Reagents, and Safety Precau-

2 be trained analysts capable of performing common laboratory

tions for Chemical Analysis of Metals

procedures skillfully and safely. It is expected that the work

E 882 Guide for Accountability and Quality Control in the

3 will be performed in a properly equipped laboratory and that

Chemical Analysis Laboratory

proper waste disposal procedures will be followed. Appropriate

E 1452 Practice for Preparation of Calibration Solutions for

quality control practices must be followed, such as those

Spectrophotometric and for Spectroscopic Atomic Analy-

3 described in Guide E 882.

sis

E 1601 Practice for Conducting Interlaboratory Study to

5. Apparatus

Evaluate the Performance of an Analytical Method

5.1 Spectrophotometer—Capable of measuring absorbance

2.2 ISO Standards:

at a wavelength of 355 nm.

ISO 5725:1986 Precision of Test Methods—Determination

5.2 Cells—To fit spectrophotometer, having an optical path

of Repeatability and Reproducibility for a Standard Test

4 of 1 cm.

Method by Inter-laboratory Tests

NOTE 1—Cells having other dimensions can be used, provided suitable

adjustments can be made in the amount of sample and reagents used.

This practice is under the jurisdiction of ASTM Committee E-1 on Analytical

Chemistry of Metals, Ores and Related Materials and is the direct responsibility of

6. Reagents

Subcommittee E01.08 on Nickel, Cobalt and High Temperature Alloys.

6.1 Purity and Concentration of Reagents—The purity and

Current edition approved November 10, 1997. Published June 1998.

Annual Book of ASTM Standards, Vol 03.05. concentration of common chemical reagents shall conform to

Annual Book of ASTM Standards, Vol 03.06.

Practices E 50. The reagents should be free of or contain only

Available from American National Standards Institute, 11 West 42nd Street,

New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1917–97

minimal amounts (<0.1 μg/g) of phosphorus. Calibration solu- 9. Procedure

tions shall be prepared in accordance with Practice E 1452.

9.1 Test Portion and Preparation of Test Solution:

6.1.1 Verify the absence of phosphorus in the reagents using

9.1.1 Weigh to the nearest 0.1 mg a test portion of the

the blank test (9.6.1). Reagents giving high blank values are

sample in accordance with Table 1.

unsuitable and should not be used. The blank value for all

9.1.2 Transfer the test portion to a polytetrafluoroethylene

reagents should be below 0.0005 % P calculated fora1g

(PTFE) beaker and add 5 mL of HNO and then 5 mL of HCl.

sample.

For samples with high contents of Nb, Si, Ta, or Hf, also add

6.2 Ammonium Metavanadate Solution—Dissolve 2.5 g of

7 mL of HF. Cover the beaker with a PTFE cover and heat

ammonium metavanadate (NH VO ) in water and dilute to 1 L.

4 3 gently until the reaction ceases. Use a sandbath or other means

6.3 Citric Acid Solution—Dissolve 500 g citric acid mono-

to avoid direct contact of the PTFE beaker with a metal

hydrate (C H O ·H O) in water and dilute to 1 L.

6 8 7 2

hotplate surface. Add 10 mL of HClO and, leaving a small

6.4 Fluoroboric Acid Solution—Disperse 75 g of boric acid

opening to release the vapors, evaporate to dense HClO

(H BO ) in 600 mL of hot water in a plastic beaker. Add 50 mL

3 3

fumes.

HF (40 %) and dilute to 1 L. Digest over medium heat until the

NOTE 3—Nickel and some copper bearing nickel alloys, such as monel,

boric acid is dissolved. Store in plastic bottle. The solution

will dissolve more readily in HNO (1+1).

should be gently heated if the boric acid forms crystals.

NOTE 4—Warning: Fuming HClO is a powerful oxidant and can

cause explosions when in contact with organic materials. All evaporations

NOTE 2—Warning: HF and fluoroboric acid are extremely irritating

must be carried out in the presence of HNO and in a fume hood suitable

and corrosive to skin and mucous membranes, producing severe skin

for use with HClO .

burns that are slow to heal. In case of contact with skin, wash well with

water and seek medical advice. When using HF and fluoroboric acid,

9.1.3 For samples containing less than 0.1 % chromium,

always wear appropriate safety gear, such as goggles and gloves.

omit the next step and proceed directly to 9.3.

6.5 Hexaammonium Heptamolybdate Solution—Dissolve

9.2 Removal of Chromium:

15 g of hexaammonium heptamolybdate tetrahydrate

9.2.1 Continue fuming for 3 min. Cautiously begin adding

[(NH ) Mo O ·4H O] in warm water and dilute to 100 mL.

HCl drop by drop to the fuming solution in the partly covered

4 6 7 24 2

Prepare fresh solution each day. If high and unstable blank

beaker until colored fumes are no longer liberated. Then

values appear, there might be a problem with the salt used. In

resume fuming to re-oxidize the remaining chromium. Repeat

such a case, switch to another lot.

the treatment until no brown fumes appear when the HCl is

6.6 4-methyl-2-pentanone—methylisobutyl ketone.

added. Cool to room temperature.

6.7 Phosphorus Stock Calibration Solution (1.000 g/L)—

9.3 Complexation:

Transfer 4.3942 g of potassium dihydrogenorthophosphate

9.3.1 Add 25 mL HNO (1+4) and 4 mL HF to the solution

(KH PO ) (which has been previously dried at 110°C to

2 4 and heat for 8 to 10 minutes until the precipitate is dissolved.

constant weight and cooled in a desiccator) toa1L volumetric

NOTE 5—It is important that the precipitated refractory oxides dissolve

flask. Dissolve in water, dilute to the mark and mix.

completely. If this does not happen, add another 2 mL HF and repeat the

6.8 Phosphorus Calibration Solution (10 mg/L)—Transfer

boiling. If the precipitate still remains undissolved, a new test sample of

10.0 mL of the phosphorus stock calibration solution toa1L

a smaller weight must be taken for the analysis.

volumetric flask. Dilute t

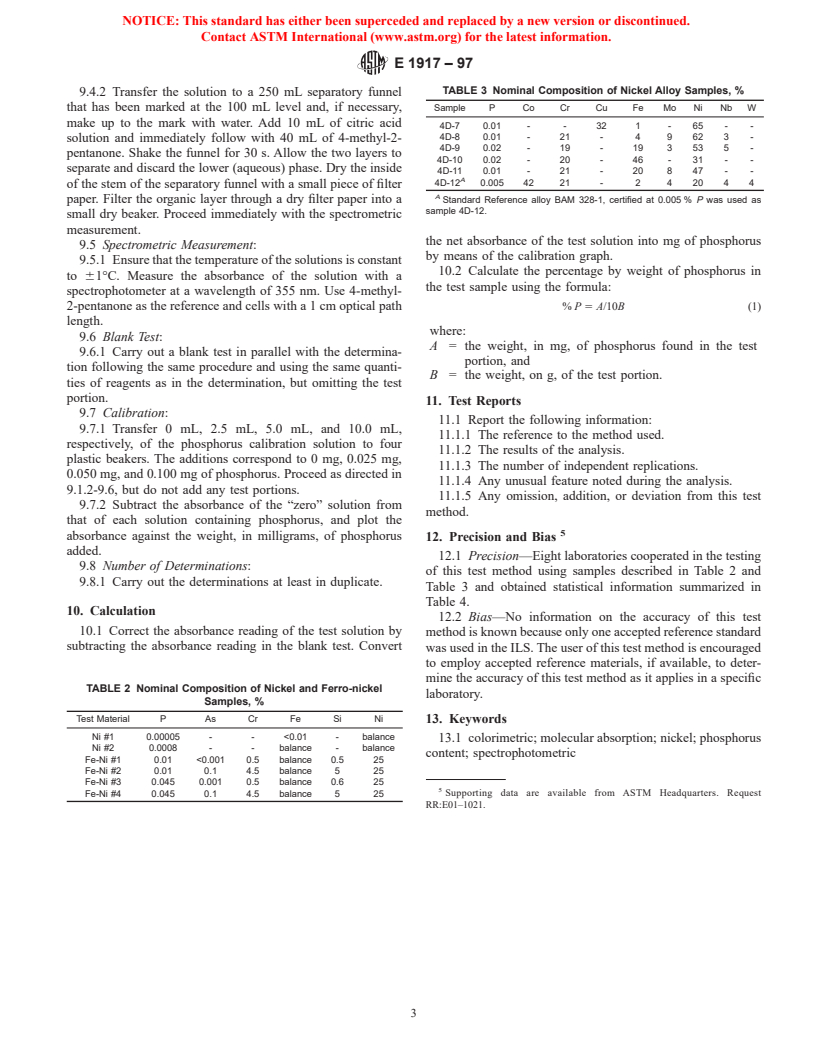

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.