ASTM F363-99

(Test Method)Standard Test Method for Corrosion Testing of Gaskets

Standard Test Method for Corrosion Testing of Gaskets

SCOPE

1.1 This test method covers the evaluation of gaskets under corrosive conditions at varying temperature and pressure levels. The test unit may be glass lined if the flanges are sufficiently plane (industry accepted), thus providing resistance to all chemicals, except hydrofluoric acid, from cryogenic temperatures to 260°C (500°F) at pressures from full vacuum to the allowable pressure rating of the unit, or made of other suitable material. The test unit described (Fig. 1) has an internal design pressure rating of 1034 kPa (150 psi) at 260°C (500°F).

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 363 – 99

Standard Test Method for

Corrosion Testing of Gaskets

This standard is issued under the fixed designation F 363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

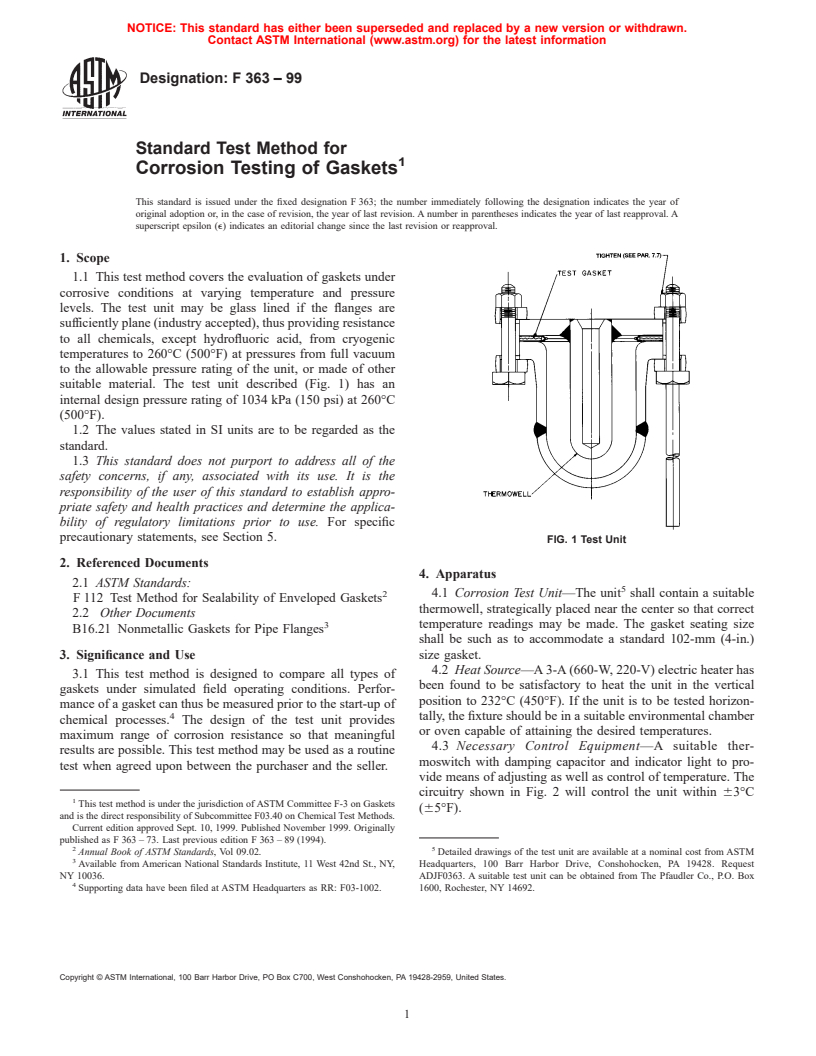

1.1 This test method covers the evaluation of gaskets under

corrosive conditions at varying temperature and pressure

levels. The test unit may be glass lined if the flanges are

sufficiently plane (industry accepted), thus providing resistance

to all chemicals, except hydrofluoric acid, from cryogenic

temperatures to 260°C (500°F) at pressures from full vacuum

to the allowable pressure rating of the unit, or made of other

suitable material. The test unit described (Fig. 1) has an

internal design pressure rating of 1034 kPa (150 psi) at 260°C

(500°F).

1.2 The values stated in SI units are to be regarded as the

standard.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific

precautionary statements, see Section 5.

FIG. 1 Test Unit

2. Referenced Documents

4. Apparatus

2.1 ASTM Standards:

4.1 Corrosion Test Unit—The unit shall contain a suitable

F 112 Test Method for Sealability of Enveloped Gaskets

thermowell, strategically placed near the center so that correct

2.2 Other Documents

temperature readings may be made. The gasket seating size

B16.21 Nonmetallic Gaskets for Pipe Flanges

shall be such as to accommodate a standard 102-mm (4-in.)

3. Significance and Use size gasket.

4.2 Heat Source—A 3-A (660-W, 220-V) electric heater has

3.1 This test method is designed to compare all types of

been found to be satisfactory to heat the unit in the vertical

gaskets under simulated field operating conditions. Perfor-

position to 232°C (450°F). If the unit is to be tested horizon-

mance of a gasket can thus be measured prior to the start-up of

4 tally, the fixture should be in a suitable environmental chamber

chemical processes. The design of the test unit provides

or oven capable of attaining the desired temperatures.

maximum range of corrosion resistance so that meaningful

4.3 Necessary Control Equipment—A suitable ther-

results are possible. This test method may be used as a routine

moswitch with damping capacitor and indicator light to pro-

test when agreed upon between the purchaser and the seller.

vide means of adjusting as well as control of temperature. The

circuitry shown in Fig. 2 will control the unit within 63°C

This test method is under the jurisdiction of ASTM Committee F-3 on Gaskets

(65°F).

and is the direct responsibility of Subcommittee F03.40 on Chemical Test Methods.

Current edition approved Sept. 10, 1999. Published November 1999. Originally

published as F 363 – 73. Last previous edition F 363 – 89 (1994).

2 5

Annual Book of ASTM Standards, Vol 09.02. Detailed drawings of the test unit are available at a nominal cost from ASTM

Available from American National Standards Institute, 11 West 42nd St., NY, Headquarters, 100 Barr Harbor Drive, Conshohocken, PA 19428. Request

NY 10036. ADJF0363. A suitable test unit can be obtained from The Pfaudler Co., P.O. Box

Supporting data have been filed at ASTM Headquarters as RR: F03-1002. 1600, Rochester, NY 14692.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 363

Fig. 3. Progression of the tightening on each bolt should be in

approximately 20N · m (15 lbf · ft) increments.

7.8 If both vapor and liquid phase test results are desired,

place the bolted and assembled test unit on its side in an oven

or environmental chamber.

7.9 If only vapor phase results are required, place the test

unit in an upright position. Use the electric heater to bring the

unit to the desired temperature and adjust the thermoswitch as

shown by the indicator light.

FIG. 2 Control Circuit

7.10 Retighten the bolts to the final torque previously used

after2hatthe regulated temperature.

4.4 Thermometer, having 0.5°C graduations.

7.11 Continue the test for approximately 24 h; turn off the

heat supply for an 8 h period during each of the next three days.

5. Safety Precautions

Continue the test at the desired temperature without cycling for

5.1 Since the test unit is not vented, corrosive liquids that

the remainder of the prescribed test period.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.