ASTM D4985-10

(Specification)Standard Specification for Low Silicate Ethylene Glycol Base Engine Coolant for Heavy Duty Engines Requiring a Pre-Charge of Supplemental Coolant Additive (SCA)

Standard Specification for Low Silicate Ethylene Glycol Base Engine Coolant for Heavy Duty Engines Requiring a Pre-Charge of Supplemental Coolant Additive (SCA)

ABSTRACT

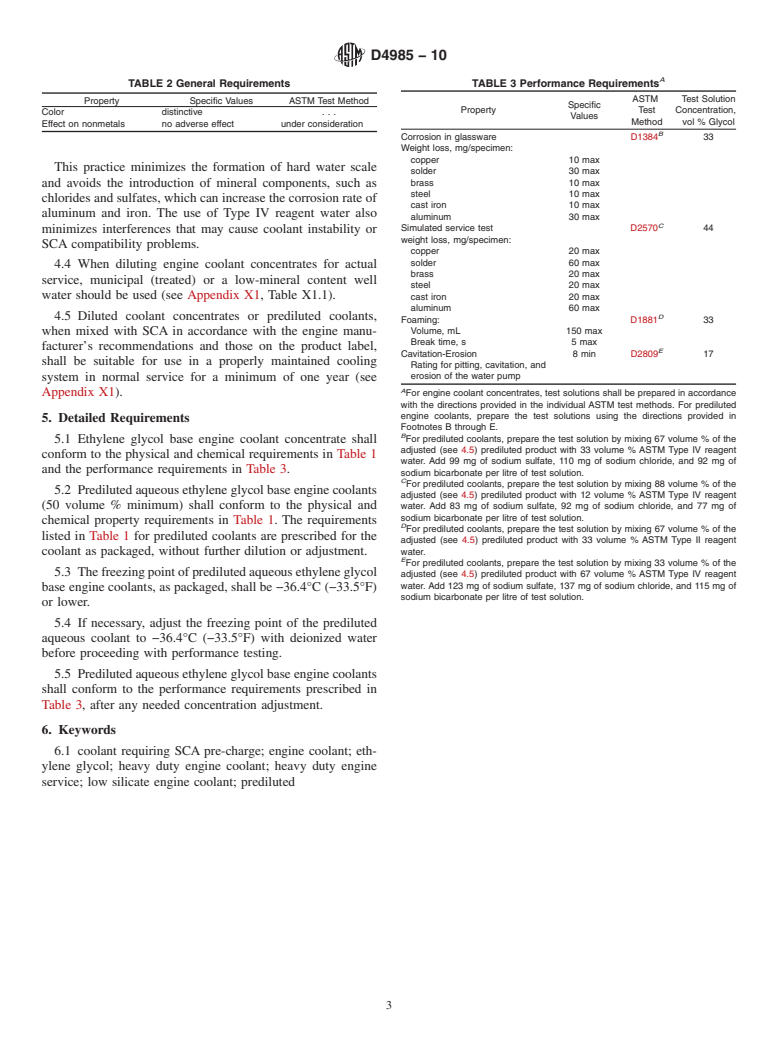

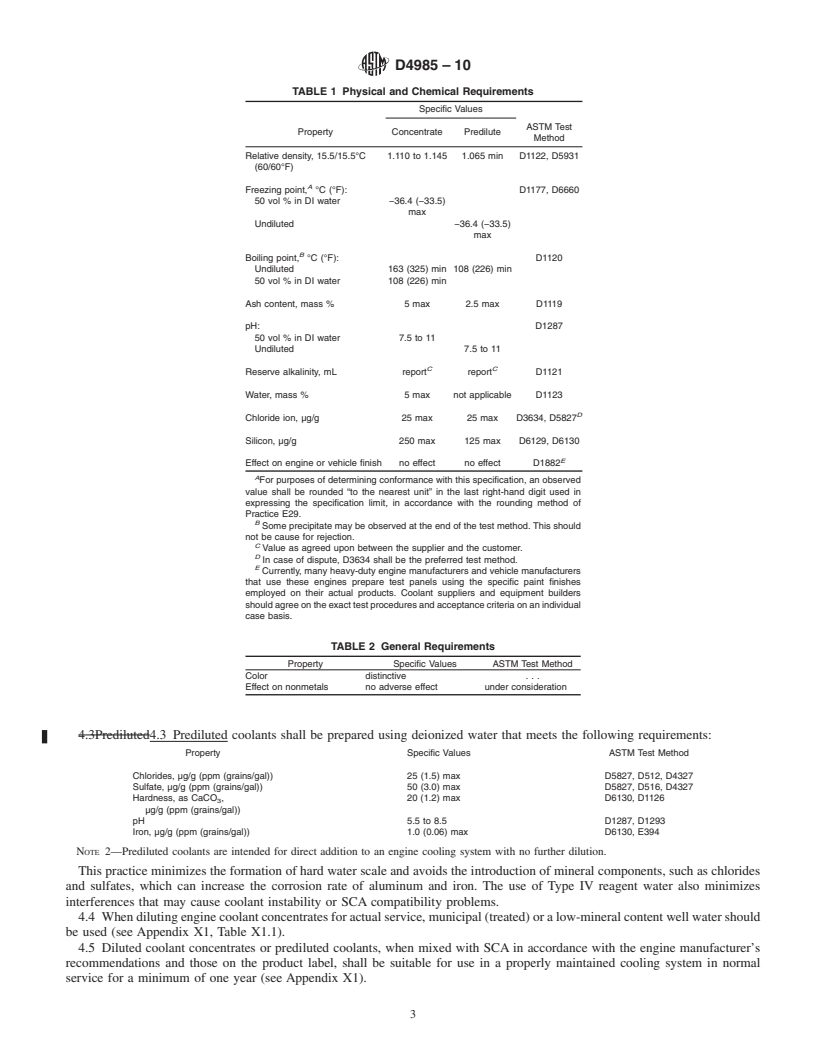

This specification covers the requirements for low silicate ethylene glycol base engine coolants for cooling systems of heavy-duty engines. Such engines are typically used in off-highway machinery for agriculture, mining, earth-moving, and construction; Class 5 to 8 over the road trucks and buses; high output stationary engine installations; and locomotive and marine installations. Prediluted coolants shall be prepared using deionized Ethylene glycol base engine coolant concentrates or prediluted ethylene glycol base engine coolants shall be formulated with ethylene glycol. The coolants shall conform to the prescribed physical, chemical, and performance requirements, which include relative density, freezing point, boiling point, ash content, pH, reserve alkalinity, water content, chloride ion content, silicon content, corrosion in glassware, simulated service test, foaming, and cavitation. The color and effect of nonmetals of the coolant shall be evaluated. Prediluted coolant shall also meet the required content of sulfate and iron. Its CaCO3 content shall be tested to determine its hardness.

SCOPE

1.1 This specification covers the requirements for low silicate ethylene glycol base engine coolants for cooling systems of heavy-duty engines. When concentrates are used at 40 to 60 % concentration by volume in water, or when prediluted glycol base engine coolants (50 volume % minimum) are used without further dilution, they will function effectively to provide protection against corrosion, freezing to at least −36.4°C (−33.5°F), and boiling to at least 108°C (226°F).

Note 1—This specification is based on the knowledge of the performance of engine coolants prepared from new or virgin ingredients. A separate specification exists (D6210) for heavy-duty engine coolants which may be prepared from recycled or reprocessed used coolant or reprocessed industrial-source ethylene glycol.

1.2 Coolants meeting this specification require an initial charge of a supplemental coolant additive (SCA) and require regular maintenance doses of an SCA to continue the protection in certain operating heavy-duty engine cooling systems, particularly those of the wet cylinder liner-in-block design. The SCA additions are defined by and are the primary responsibility of the engine manufacturer or vehicle manufacturer. If they provide no instructions, follow the SCA supplier's recommended instructions.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4985 −10

StandardSpecification for

Low Silicate Ethylene Glycol Base Engine Coolant for Heavy

Duty Engines Requiring a Pre-Charge of Supplemental

1

Coolant Additive (SCA)

This standard is issued under the fixed designation D4985; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers the requirements for low 2.1 ASTM Standards:

silicate ethylene glycol base engine coolants for cooling D512Test Methods for Chloride Ion In Water

systems of heavy-duty engines.When concentrates are used at D516Test Method for Sulfate Ion in Water

40 to 60% concentration by volume in water, or when D1119Test Method for Percent Ash Content of Engine

prediluted glycol base engine coolants (50 volume % mini- Coolants

mum) are used without further dilution, they will function

D1120Test Method for Boiling Point of Engine Coolants

effectively to provide protection against corrosion, freezing to D1121Test Method for ReserveAlkalinity of Engine Cool-

at least −36.4°C (−33.5°F), and boiling to at least 108°C

ants and Antirusts

(226°F). D1122Test Method for Density or Relative Density of

EngineCoolantConcentratesandEngineCoolantsByThe

NOTE 1—This specification is based on the knowledge of the perfor-

Hydrometer

mance of engine coolants prepared from new or virgin ingredients. A

D1123Test Methods for Water in Engine Coolant Concen-

separate specification exists (D6210) for heavy-duty engine coolants

which may be prepared from recycled or reprocessed used coolant or trate by the Karl Fischer Reagent Method

reprocessed industrial-source ethylene glycol.

D1126Test Method for Hardness in Water

D1177Test Method for Freezing Point of Aqueous Engine

1.2 Coolants meeting this specification require an initial

Coolants

charge of a supplemental coolant additive (SCA) and require

D1287TestMethodforpHofEngineCoolantsandAntirusts

regular maintenance doses of an SCA to continue the protec-

D1293Test Methods for pH of Water

tion in certain operating heavy-duty engine cooling systems,

D1384Test Method for Corrosion Test for Engine Coolants

particularlythoseofthewetcylinderliner-in-blockdesign.The

in Glassware

SCAadditionsaredefinedbyandaretheprimaryresponsibility

D1881Test Method for Foaming Tendencies of Engine

of the engine manufacturer or vehicle manufacturer. If they

Coolants in Glassware

provide no instructions, follow the SCA supplier’s recom-

D1882Test Method for Effect of Cooling System Chemical

mended instructions.

Solutions on Organic Finishes for Automotive Vehicles

1.3 The values stated in SI units are to be regarded as the

D2570TestMethodforSimulatedServiceCorrosionTesting

standard. The values given in parentheses are for information

of Engine Coolants

only.

D2809Test Method for Cavitation Corrosion and Erosion-

Corrosion Characteristics of Aluminum Pumps With En-

1.4 This standard does not purport to address all of the

gine Coolants

safety concerns, if any, associated with its use. It is the

D3306Specification for Glycol Base Engine Coolant for

responsibility of the user of this standard to establish appro-

Automobile and Light-Duty Service

priate safety and health practices and determine the applica-

D3634Test Method for Trace Chloride Ion in Engine Cool-

bility of regulatory limitations prior to use.

ants

1

ThisspecificationisunderthejurisdictionofASTMCommitteeD15onEngine

2

CoolantsandisthedirectresponsibilityofSubcommitteeD15.07onSpecifications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2010. Published May 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1989. Last previous edition approved in 2009 as D4985–09. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4985-10. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4985−10

D4327Test Method forAnions in Water by Suppressed Ion water, and shall contain suitable corrosion inhibitors, dye, and

Chromatography a foam suppressor. Other glycols, such as propylene and

D4725Terminology for Engine Coolants diethylene, may be included in concentrates up to a maximum

D5827Test Method for Analysis of Engine Coolant for of 15% (7.5% for prediluted coolants) if the physical and

Chloride a

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately,ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4985–09 Designation: D4985 – 10

Standard Specification for

Low Silicate Ethylene Glycol Base Engine Coolant for Heavy

Duty Engines Requiring a Pre-Charge of Supplemental

1

Coolant Additive (SCA)

This standard is issued under the fixed designation D4985; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers the requirements for low silicate ethylene glycol base engine coolants for cooling systems of

heavy-duty engines. When concentrates are used at 40 to 60% concentration by volume in water, or when prediluted glycol base

engine coolants (50 volume % minimum) are used without further dilution, they will function effectively to provide protection

against corrosion, freezing to at least −36.4°C (−33.5°F), and boiling to at least 108°C (226°F).

NOTE 1—This specification is based on the knowledge of the performance of engine coolants prepared from new or virgin ingredients. A separate

specification exists (D6210) for heavy-duty engine coolants which may be prepared from recycled or reprocessed used coolant or reprocessed

industrial-source ethylene glycol.

1.2 Coolants meeting this specification require an initial charge of a supplemental coolant additive (SCA) and require regular

maintenancedosesofanSCAtocontinuetheprotectionincertainoperatingheavy-dutyenginecoolingsystems,particularlythose

of the wet cylinder liner-in-block design. The SCA additions are defined by and are the primary responsibility of the engine

manufacturer or vehicle manufacturer. If they provide no instructions, follow the SCA supplier’s recommended instructions.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D512 Test Methods for Chloride Ion In Water

D516 Test Method for Sulfate Ion in Water

D1119 Test Method for Percent Ash Content of Engine Coolants

D1120 Test Method for Boiling Point of Engine Coolants

D1121 Test Method for Reserve Alkalinity of Engine Coolants and Antirusts

D1122 Test Method for Density or Relative Density of Engine Coolant Concentrates and Engine Coolants ByThe Hydrometer

D1123 Test Methods for Water in Engine Coolant Concentrate by the Karl Fischer Reagent Method

D1126 Test Method for Hardness in Water

D1177 Test Method for Freezing Point of Aqueous Engine Coolants

D1287 Test Method for pH of Engine Coolants and Antirusts

D1293 Test Methods for pH of Water

D1384 Test Method for Corrosion Test for Engine Coolants in Glassware

D1881 Test Method for Foaming Tendencies of Engine Coolants in Glassware

D1882 Test Method for Effect of Cooling System Chemical Solutions on Organic Finishes for Automotive Vehicles

D1888Method of Test for Particulate and Dissolved Matter in Water

D2570 Test Method for Simulated Service Corrosion Testing of Engine Coolants

D2809 TestMethodforCavitationCorrosionandErosion-CorrosionCharacteristicsofAluminumPumpsWithEngineCoolants

1

This specification is under the jurisdiction of ASTM Committee D15 on Engine Coolants and is the direct responsibility of Subcommittee D15.07 on Specifications.

CurrenteditionapprovedMarchApril1,2009.2010.PublishedMay2009.2010.Originallyapprovedin1989.Lastpreviouseditionapprovedin20052009asD4985–059.

DOI: 10.1520/D4985-109.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4985 – 10

D3306 Specification for Glycol Base Engine Coolant for Automobile and Light-Duty Service

D3634 Test Method for Trace Chloride Ion in Engine Coolants

D4327 Test Method for Anio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.