ASTM D3950-06e1

(Specification)Standard Specification for Strapping, Nonmetallic (and Joining Methods)

Standard Specification for Strapping, Nonmetallic (and Joining Methods)

SCOPE

1.1 This specification covers nonmetallic strapping and joining methods intended for use in closing, reinforcing, and bundling articles for shipment, unitizing, palletizing, and bracing for car loading and truck loading.

1.2 The values stated in inch-pound units are to be regarded as standard.

The following safety hazards caveat pertains only to the test method portion, Section 12, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 3950 – 06

Standard Specification for

1

Strapping, Nonmetallic (and Joining Methods)

This standard is issued under the fixed designation D 3950; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—The term “polyolefin” was replaced with “polypropylene” throughout editorially in January 2007.

1. Scope 3. Terminology

1.1 This specification covers nonmetallic strapping and 3.1 For general definitions of packaging and distribution

joining methods intended for use in closing, reinforcing, and environments, see Terminology D 996.

bundling articles for shipment, unitizing, palletizing, and

4. Classification

bracing for car loading and truck loading.

1.2 The values stated in inch-pound units are to be regarded 4.1 Types and Grades:

as standard.

1.3 The following safety hazards caveat pertains only to the

Type I — Strapping, bonded rayon cord.

Grade 1—Light duty.

test method portion, Section 12, of this specification: This

Grade 2—Regular duty.

standard does not purport to address all of the safety concerns,

Grade 3—Heavy duty.

if any, associated with its use. It is the responsibility of the user Type IA — Strapping, bonded, or woven polyester cord.

Grade 1—Light duty.

of this standard to establish appropriate safety and health

Grade 2—Regular duty.

practices and determine the applicability of regulatory limita-

Grade 3—Heavy duty.

tions prior to use. Grade 4—Extra heavy duty.

Grade 5—Special duty.

Grade 6—Special duty.

2. Referenced Documents

Grade 7—Special duty.

2

2.1 ASTM Standards: Type II — Strapping, polypropylene plastic.

Type III — Strapping, nylon plastic.

D 996 Terminology of Packaging and Distribution Environ-

Type IV — Strapping, polyester plastic.

ments

D 3951 Practice for Commercial Packaging

5. Ordering Information

D 4332 Practice for Conditioning Containers, Packages, or

5.1 The inquiry and order shall indicate the following:

Packaging Components for Testing

5.1.1 Type, grade, and dimensions required (see 4.1 and

2.2 Other Standards:

7.1),

ANSI/ASQC Z 1.4 Sampling Procedures and Tables for

5.1.2 Length per coil (see 8.1),

3

Inspection by Attributes

5.1.3 Joining method (see 6.2), type and size required (if

ANSI/ASQC Z 1.9 Sampling Procedures and Tables for

needed),

3

Inspection by Variables for Percent Nonconforming

5.1.4 If an embossed finish on strapping is desired or

allowed (see Footnote in Table 1),

5.1.5 Make and model of strapping equipment that the

1

strapping and joining method must work in, if applicable,

This specification is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.25 on Palletizing

5.1.6 Coil dimensions (see 8.1),

and Unitizing of Loads.

5.1.7 Level of packaging and packing if other than commer-

Current edition approved Oct. 1, 2006. Published October 2006. Originally

cial (see Section 15), and

approved in 1980. Last previous edition approved in 2005 as D 3950 – 05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5.1.8 ASTM designation and date of issue.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6. Materials and Manufacture

the ASTM website.

3

6.1 Materials shall be of the quality necessary to meet the

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036. physical requirements within the allowable dimensions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

D3950–06

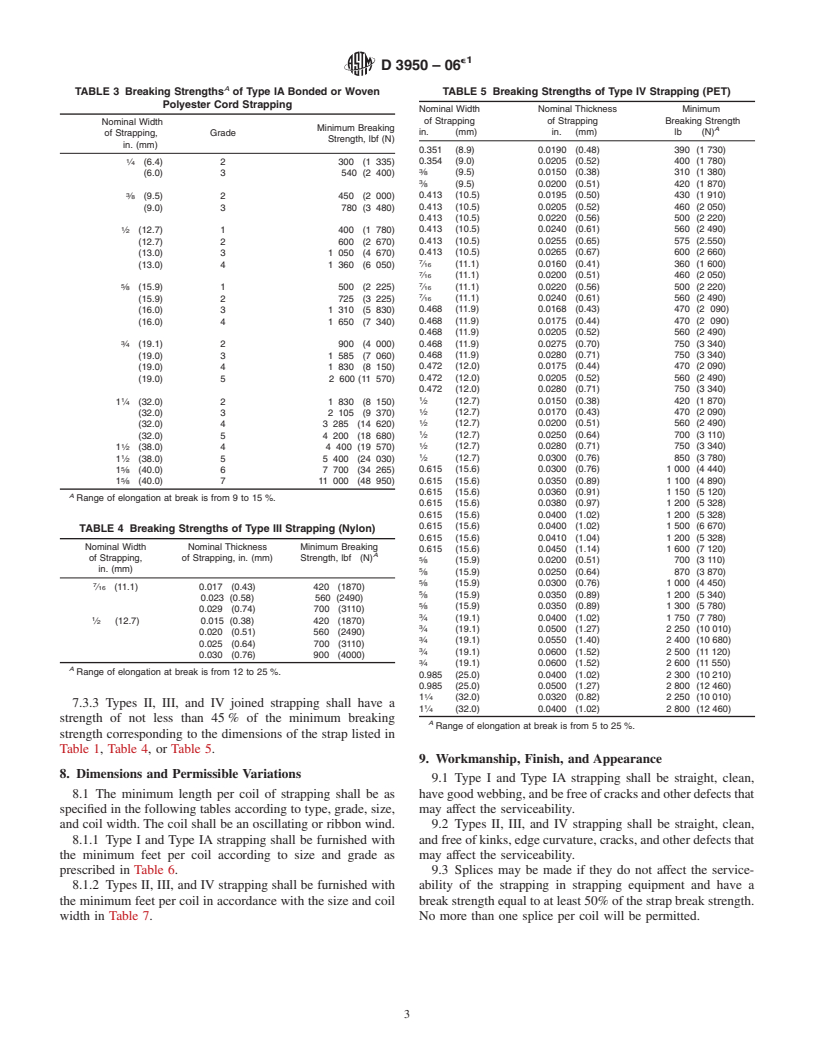

TABLE 1 Breaking Strengths of Type II Strapping (PP)

nonwoven material or longitudinal polyester cords woven with

Nominal Width Nominal Thickness Minimum a weft thread and treated with a plastic binder to form a woven

of Strapping of Strapping Breaking Strength

material.

A B

in. (mm) in. (mm) lb (N)

6.1.2 Type II—Strapping shall be an extruded, oriented

0.197 (5.0) 0.0120 (0.30) 80 (360)

polypropylene.

0.197 (5.0) 0.0145 (0.37) 100 (440)

6.1.3 Type III—Strapping shall be an extruded, oriented

0.234 (5.9) 0.0135 (0.34) 130 (580)

0.234 (5.9) 0.0140 (0.36) 155 (690)

nylon.

0.236 (6.0) 0.0130 (0.33) 135 (600)

6.1.4 Type IV—Strapping shall be an extruded, oriented

0.234 (5.9) 0.0160 (0.41) 180 (800)

polyester.

0.236 (6.0) 0.0173 (0.44) 190 (850)

1

⁄4 (6.4) 0.0135 (0.34) 134 (600)

6.2 Joining Methods—If seals or buckles are to be used,

1

⁄4 (6.4) 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.