ASTM D2402-94

(Test Method)Standard Test Method for Water Retention of Textile Fibers (Centrifuge Procedure)

Standard Test Method for Water Retention of Textile Fibers (Centrifuge Procedure)

SCOPE

1.1 This test method covers the measurement of water retention of man-made and natural fibers as staple, tow, or filament and spun yarns. It is intended to give a measure of the amount of water which cannot be removed from thoroughly wetted fiber solely by mechanical means as applied by centrifugal force (see 3.1.2.).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2402 – 94

Standard Test Method for

Water Retention of Textile Fibers (Centrifuge Procedure)

This standard is issued under the fixed designation D 2402; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

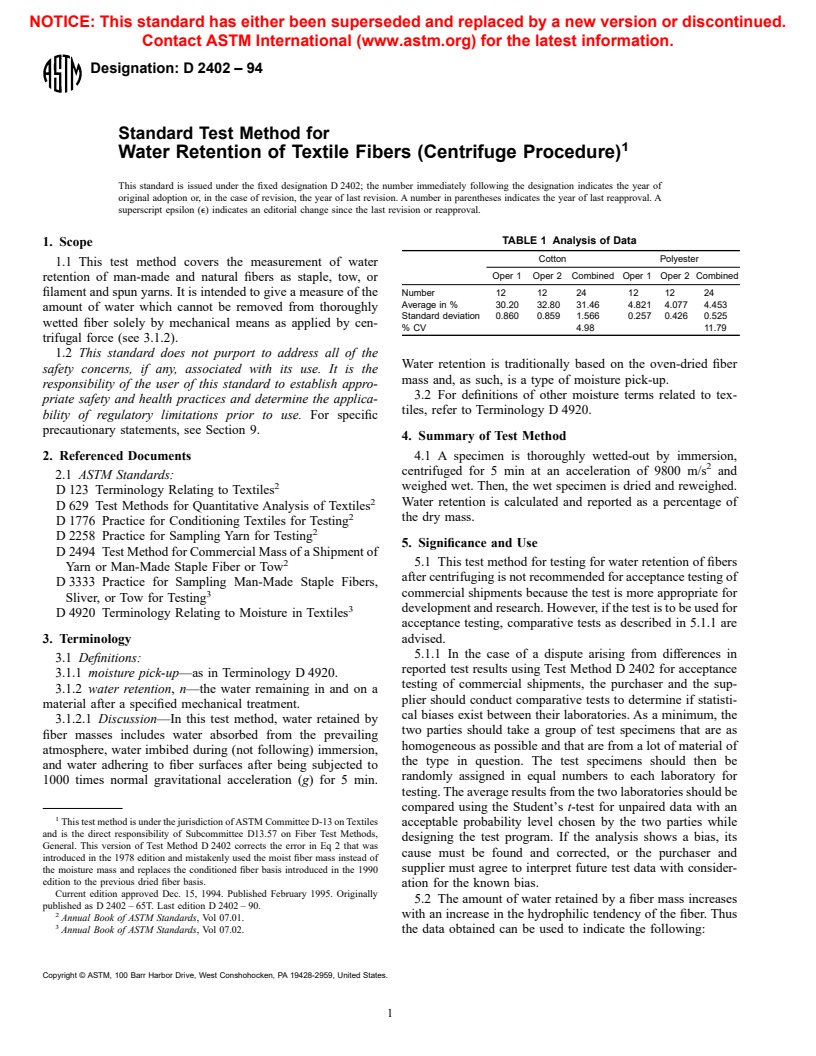

TABLE 1 Analysis of Data

1. Scope

Cotton Polyester

1.1 This test method covers the measurement of water

Oper 1 Oper 2 Combined Oper 1 Oper 2 Combined

retention of man-made and natural fibers as staple, tow, or

filament and spun yarns. It is intended to give a measure of the Number 12 12 24 12 12 24

Average in % 30.20 32.80 31.46 4.821 4.077 4.453

amount of water which cannot be removed from thoroughly

Standard deviation 0.860 0.859 1.566 0.257 0.426 0.525

wetted fiber solely by mechanical means as applied by cen-

% CV 4.98 11.79

trifugal force (see 3.1.2).

1.2 This standard does not purport to address all of the

Water retention is traditionally based on the oven-dried fiber

safety concerns, if any, associated with its use. It is the

mass and, as such, is a type of moisture pick-up.

responsibility of the user of this standard to establish appro-

3.2 For definitions of other moisture terms related to tex-

priate safety and health practices and determine the applica-

tiles, refer to Terminology D 4920.

bility of regulatory limitations prior to use. For specific

precautionary statements, see Section 9.

4. Summary of Test Method

2. Referenced Documents 4.1 A specimen is thoroughly wetted-out by immersion,

centrifuged for 5 min at an acceleration of 9800 m/s and

2.1 ASTM Standards:

2 weighed wet. Then, the wet specimen is dried and reweighed.

D 123 Terminology Relating to Textiles

Water retention is calculated and reported as a percentage of

D 629 Test Methods for Quantitative Analysis of Textiles

2 the dry mass.

D 1776 Practice for Conditioning Textiles for Testing

D 2258 Practice for Sampling Yarn for Testing

5. Significance and Use

D 2494 Test Method for Commercial Mass of a Shipment of

2 5.1 This test method for testing for water retention of fibers

Yarn or Man-Made Staple Fiber or Tow

after centrifuging is not recommended for acceptance testing of

D 3333 Practice for Sampling Man-Made Staple Fibers,

3 commercial shipments because the test is more appropriate for

Sliver, or Tow for Testing

3 development and research. However, if the test is to be used for

D 4920 Terminology Relating to Moisture in Textiles

acceptance testing, comparative tests as described in 5.1.1 are

advised.

3. Terminology

5.1.1 In the case of a dispute arising from differences in

3.1 Definitions:

reported test results using Test Method D 2402 for acceptance

3.1.1 moisture pick-up—as in Terminology D 4920.

testing of commercial shipments, the purchaser and the sup-

3.1.2 water retention, n—the water remaining in and on a

plier should conduct comparative tests to determine if statisti-

material after a specified mechanical treatment.

cal biases exist between their laboratories. As a minimum, the

3.1.2.1 Discussion—In this test method, water retained by

two parties should take a group of test specimens that are as

fiber masses includes water absorbed from the prevailing

homogeneous as possible and that are from a lot of material of

atmosphere, water imbibed during (not following) immersion,

the type in question. The test specimens should then be

and water adhering to fiber surfaces after being subjected to

randomly assigned in equal numbers to each laboratory for

1000 times normal gravitational acceleration (g) for 5 min.

testing. The average results from the two laboratories should be

compared using the Student’s t-test for unpaired data with an

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles acceptable probability level chosen by the two parties while

and is the direct responsibility of Subcommittee D13.57 on Fiber Test Methods,

designing the test program. If the analysis shows a bias, its

General. This version of Test Method D 2402 corrects the error in Eq 2 that was

cause must be found and corrected, or the purchaser and

introduced in the 1978 edition and mistakenly used the moist fiber mass instead of

the moisture mass and replaces the conditioned fiber basis introduced in the 1990 supplier must agree to interpret future test data with consider-

edition to the previous dried fiber basis.

ation for the known bias.

Current edition approved Dec. 15, 1994. Published February 1995. Originally

5.2 The amount of water retained by a fiber mass increases

published as D 2402 – 65T. Last edition D 2402 – 90.

with an increase in the hydrophilic tendency of the fiber. Thus

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 07.02. the data obtained can be used to indicate the following:

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2402

take at random the number of shipping containers directed in

the applicable material specification or other agreement be-

tween the purchaser and supplier, such as an agreement to use

Practice D 3333 for staple fiber, sliver, top or tow, or to use

Practice D 2258 for yarn. Consider the shipping containers to

be the primary sampling units.

NOTE 1—An adequate specification or other agreement between the

purchaser and supplier requires taking into account the variability between

shipping containers, between laboratory samples within the shipping

container, and between test specimens within a laboratory sample, to

provide a sampling plan with a meaningful producer’s risk, consumer’s

risk, acceptable quality level, and limiting quality level.

8.2 Laboratory Sample—As a laboratory sample for accep-

tance testing, proceed as follows:

8.2.1 For Staple Fiber—Systematically take five laboratory

sample subunits from each bale in the lot sample as directed in

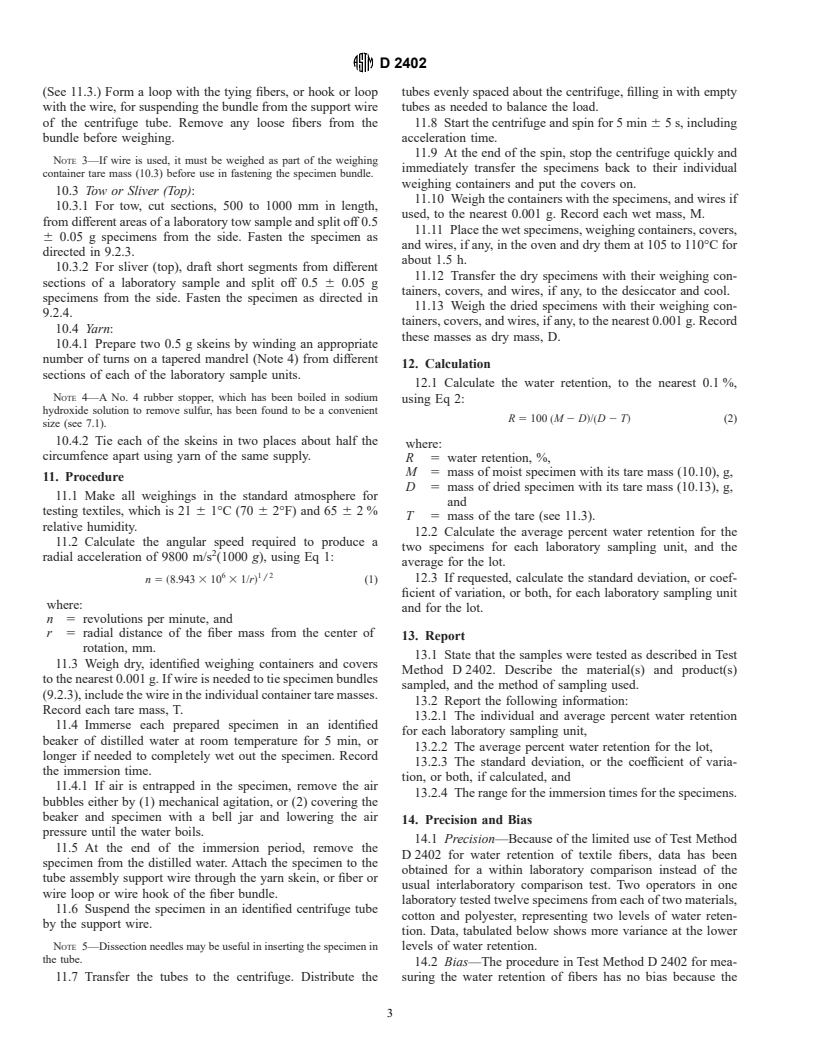

FIG. 1 Cross-section View of Centrifuge Tube Assembly

Practice D 3333.

8.2.2 For Tow and Sliver (or Top)—From each shipping

5.2.1 Differences in water retention between the various

container in the lot sample, take at least a metre, or yard, of

man-made and natural fibers,

material from the leading end of the textile strand that has a

5.2.2 Degree of cross-linking in cellulosic fibers,

clean uniform appearance. If the shipping container has mul-

5.2.3 Damage incurred by wool and silk fibers due to

tiple packages, take one package drawn at random from the

alkaline processing, and

container for that laboratory sample.

5.2.4 Persistence of water-repellent treatments.

8.2.3 For Yarn in Cases—Take ten yarn packages as di-

6. Apparatus

rected in Practice D 2258. Remove enough traverses of yarn to

obtain a surface free of visible damage or soil, and then remove

6.1 Stationary Coarse Comb , approximately 63 mm long

at least a gram of yarn for the laboratory sample from each

and having needles approximately 12.5 mm long and spaced 19

laboratory sampling unit.

needles to the 10 mm, or

8.2.4 For Yarn on Beams—Sample as agreed upon between

6.2 Hand Cards.

the purchaser and supplier.

6.3 Centrifuge, with trunnions capable of holding at least 2

8.3 Test Specimens—Test two 0.5 g specimens from each

tube assemblies. The centrifuge must be capable of operating

laboratory sampling unit, preferably from different sections of

to develop an angular speed that will produce a radial accel-

the laboratory sample units.

eration of 9800 m/s (1000 g) on the specimen within 5 min.

6.4 Tube Assemblies, each consisting of a 15-mL, polypro-

9. Conditioning

pylene, centrifuge tube with draining holes, shell and support

9.1 Specimens may be tested without any conditioning.

wire (see Fig. 1).

6.5 Timer, suitable for controlling immersion time and

10. Specimen Preparation

centrifuge time to 61s.

6.6 Balance, with sensitivity of 0.5 mg and a capacity of 10.1 Foreign Matter and Extractable Matter—If the labo-

2000 g. ratory sample units contain foreign matter, remove the latter by

6.7 Weighing Containers, air-tight, large enough to hold a mechanical means (such as hand carding). For samples con-

specimen basket. taining n

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.