ASTM D2232-23

(Test Method)Standard Test Method for Evaporating Residue of Naphthalene

Standard Test Method for Evaporating Residue of Naphthalene

SIGNIFICANCE AND USE

5.1 Evaporation residue is an empirical measure of nonvolatile impurities in naphthalene. This test method is suitable for setting specifications and for use as an internal quality control tool.

SCOPE

1.1 This test method covers the determination of the evaporation residue of naphthalene.

1.2 This test method has been found applicable to determining residue in the range of 0.3 and 1.5 wt %.

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7, 8.1, 9.2, and 9.3.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2232 − 23

Standard Test Method for

1

Evaporating Residue of Naphthalene

This standard is issued under the fixed designation D2232; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Procedures for Aromatic Hydrocarbons and Related Ma-

terials

1.1 This test method covers the determination of the evapo-

E29 Practice for Using Significant Digits in Test Data to

ration residue of naphthalene.

Determine Conformance with Specifications

1.2 This test method has been found applicable to determin-

E145 Specification for Gravity-Convection and Forced-

ing residue in the range of 0.3 and 1.5 wt %.

Ventilation Ovens

1.3 In determining the conformance of the test results using E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

this method to applicable specifications, results shall be

rounded off in accordance with the rounding-off method of

2.2 Other Document:

Practice E29. OSHA Regulations, 29 CFR 1910.1000 and

1910.1200 Toxic and Hazardous Substances – Air con-

1.4 The values stated in SI units are to be regarded as

3

taminants; Hazard Communication

standard. No other units of measurement are included in this

standard.

3. Terminology

1.5 This standard does not purport to address all of the

3.1 See Terminology D4790 for the definition of terms used

safety concerns, if any, associated with its use. It is the

in this test method.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4. Summary of Test Method

mine the applicability of regulatory limitations prior to use.

4.1 A weighed quantity of naphthalene is heated in a tared

For specific hazard statements, see Section 7, 8.1, 9.2, and 9.3.

dish for 3 h at 105 °C in a forced-draft oven and the residue is

1.6 This international standard was developed in accor-

weighed.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

5.1 Evaporation residue is an empirical measure of nonvola-

mendations issued by the World Trade Organization Technical

tile impurities in naphthalene. This test method is suitable for

Barriers to Trade (TBT) Committee.

setting specifications and for use as an internal quality control

2. Referenced Documents tool.

2

2.1 ASTM Standards:

6. Apparatus

D3438 Practice for Sampling and Handling Naphthalene,

6.1 Evaporating Dishes, porcelain, shallow form or alumi-

Maleic Anhydride, and Phthalic Anhydride

num weighing dishes, low form, fluted, 60 mm diameter, 15

D4790 Terminology of Aromatic Hydrocarbons and Related

mm high, 42 mL capacity.

Chemicals

D6809 Guide for Quality Control and Quality Assurance

6.2 Drying Oven, forced-ventilation, conforming to Speci-

fication E145 Type II, Grade A or B.

1

This test method is under the jurisdiction of ASTM Committee D16 on

7. Hazards

Aromatic, Industrial, Specialty and Related Chemicals and is the direct responsi-

bility of Subcommittee D16.07 on Styrene, Ethylbenzene and C9 and C10 Aromatic

7.1 Consult current OSHA regulations, supplier’s Safety

Hydrocarbons.

Data Sheets and local regulations for all materials used in this

Current edition approved April 1, 2023. Published June 2023. Originally

test method.

approved in 1967. Last previous edition approved in 2018 as D2232 – 14 (2018).

DOI: 10.1520/D2232-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from U.S. Government Printing Office Superintendent of Documents,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2232 − 23

4

TABLE 1 Evaporation Residue (wt. %)

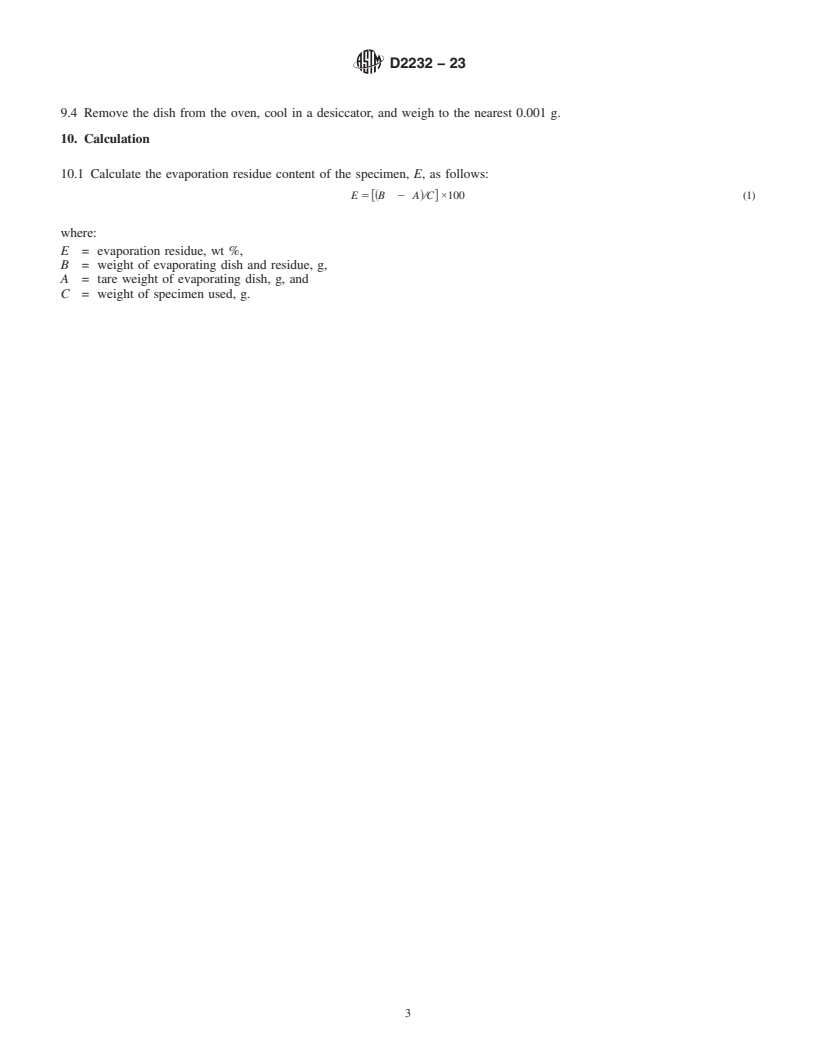

11. Precision and Bias

Repeatability Reproducibility

11.1 An ILS was conducted which included six laboratories

A

Average

Material Limit Limit

¯ analyzing four samples three times. Practice E691 was fol-

X r R

lowed for the design and analysis of the data. The details are

A 0.07 0.09 0.0

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2232 − 14 (Reapproved 2018) D2232 − 23

Standard Test Method for

1

Evaporating Residue of Naphthalene

This standard is issued under the fixed designation D2232; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination of the evaporation residue of naphthalene.

1.2 This test method has been found applicable to determining residue in the range of 0.3 and 1.5 wt %.

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off

in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific hazard statements, see Section 7, 8.1, 9.2, and 9.3.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D3438 Practice for Sampling and Handling Naphthalene, Maleic Anhydride, and Phthalic Anhydride

D4790 Terminology of Aromatic Hydrocarbons and Related Chemicals

D6809 Guide for Quality Control and Quality Assurance Procedures for Aromatic Hydrocarbons and Related Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E145 Specification for Gravity-Convection and Forced-Ventilation Ovens

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 Other Document:

OSHA Regulations, 29 CFR 1910.1000 and 1910.1200 paragraphs 1910.1000 and 1910.1200Toxic and Hazardous Substances

3

– Air contaminants; Hazard Communication

1

This test method is under the jurisdiction of ASTM Committee D16 on Aromatic, Industrial, Specialty and Related Chemicals and is the direct responsibility of

Subcommittee D16.07 on Styrene, Ethylbenzene and C9 and C10 Aromatic Hydrocarbons.

Current edition approved June 1, 2018April 1, 2023. Published June 2018June 2023. Originally approved in 1967. Last previous edition approved in 20142018 as

D2232 – 14.D2232 – 14 (2018). DOI: 10.1520/D2232-14R18.10.1520/D2232-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2232 − 23

3. Terminology

3.1 See Terminology D4790 for the definition of terms used in this test method.

4. Summary of Test Method

4.1 A weighed quantity of naphthalene is heated in a tared dish for 3 h at 105°C105 °C in a forced-draft oven and the residue is

weighed.

5. Significance and Use

5.1 Evaporation residue is an empirical measure of nonvolatile impurities in naphthalene. This test method is suitable for setting

specifications and for use as an internal quality control tool.

6. Apparatus

6.1 Evaporating Dishes, porcelain, shallow form or aluminum weighing dishes, low form, fluted, 60 mm diameter, 15 mm high,

42 mL capacity.

6.2 Drying Oven, forced-ventilation, conforming to Specification E145 Type II, Grade A or B.

7. Hazards

7.1 Consult current OSHA regulations, supplier’s Safety Data Sheets and local regulations for all materials used in this test

method.

8. Sampling and Handling

8.1 Refer to Practice D3438 for proper sampling and handling of this produc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.