ASTM F2945-12a

(Specification)Standard Specification for Polyamide 11 Gas Pressure Pipe, Tubing, and Fittings

Standard Specification for Polyamide 11 Gas Pressure Pipe, Tubing, and Fittings

ABSTRACT

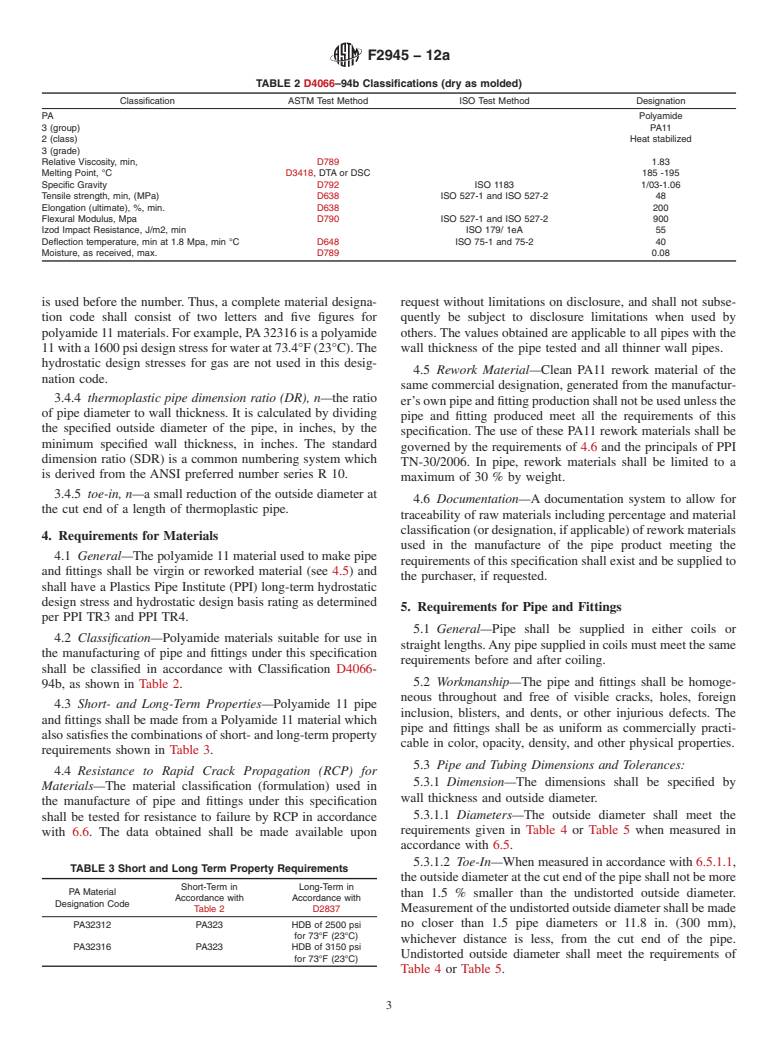

This specification covers requirements and test methods for the characterization of polyamide 11 pipe, tubing, and fittings for use in fuel gas piping. The pipe and fittings covered by this specification are intended for use in the transport of fuel gases. This specification does not cover threaded pipe. The polyamide 11 material used to make pipe and fittings shall be virgin or reworked material and shall have a Plastics Pipe Institute (PPI) long-term hydrostatic design stress and hydrostatic design basis rating as determined per PPI TR3 and PPI TR4. This specification deals with requirements for materials, requirements for pipe and fittings, test methods, marking, and quality Assurance.

SCOPE

1.1 This specification covers requirements and test methods for the characterization of polyamide 11 pipe, tubing, and fittings for use in fuel gas piping. The pipe and fittings covered by this specification are intended for use in the transport of fuel gases.

1.1.1 This specification does not cover threaded pipe. Generic fusion guidelines are given in Appendix X1. Design considerations are discussed in Appendix X2. In-plant quality control programs are specified in Annex A1.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following is an index of the annexes and appendixes in this specification:

Annexes

Subject

Annex A1

In-Plant Quality Control for sizes up to 12 in.

Annex A2

PA-11 Butt Fusion Fittings

Appendixes

Subject

Appendix X1

Butt Fusion Guidelines for PA-11 Piping

Appendix X2

Design Consideration

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1—Heat fusion joining of PA11 pipe and fittings meeting the requirements of this standard is limited to PA11 pipe and fittings meeting the requirements of this Standard. Heat Fusion joining of PA11 pipe and fittings meeting the requirements of this standard is not allowed to pipes and fittings made from any other thermoplastic materials (for example, PA12, PEs, PVCs, etc.).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2945 −12a

StandardSpecification for

1

Polyamide 11 Gas Pressure Pipe, Tubing, and Fittings

This standard is issued under the fixed designation F2945; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

Balloted changes were added, and the year date was changed on November 27, 2012.

1. Scope 2. Referenced Documents

2

1.1 This specification covers requirements and test methods 2.1 ASTM Standards:

for the characterization of polyamide 11 pipe, tubing, and D543Practices for Evaluating the Resistance of Plastics to

fittingsforuseinfuelgaspiping.Thepipeandfittingscovered Chemical Reagents

bythisspecificationareintendedforuseinthetransportoffuel D618Practice for Conditioning Plastics for Testing

gases. D638Test Method for Tensile Properties of Plastics

1.1.1 This specification does not cover threaded pipe. Ge- D648Test Method for Deflection Temperature of Plastics

neric fusion guidelines are given in Appendix X1. Design Under Flexural Load in the Edgewise Position

considerations are discussed in Appendix X2. In-plant quality D789Test Methods for Determination of Solution Viscosi-

control programs are specified in Annex A1. ties of Polyamide (PA)

D790Test Methods for Flexural Properties of Unreinforced

1.2 Thetextofthisspecificationreferencesnotes,footnotes,

and Reinforced Plastics and Electrical Insulating Materi-

and appendixes which provide explanatory material. These

als

notesandfootnotes(excludingthoseintablesandfigures)shall

D792Test Methods for Density and Specific Gravity (Rela-

not be considered as requirements of the specification.

tive Density) of Plastics by Displacement

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

D1598Test Method for Time-to-Failure of Plastic Pipe

as standard. The values given in parentheses are mathematical

Under Constant Internal Pressure

conversions to SI units that are provided for information only

D1599Test Method for Resistance to Short-Time Hydraulic

and are not considered standard.

Pressure of Plastic Pipe, Tubing, and Fittings

1.4 Thefollowingisanindexoftheannexesandappendixes D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics

in this specification:

3

D1898Practice for Sampling of Plastics (Withdrawn 1998)

Annexes Subject

Annex A1 In-Plant Quality Control for sizes up to 12 in. D2122Test Method for Determining Dimensions of Ther-

Annex A2 PA-11 Butt Fusion Fittings

moplastic Pipe and Fittings

Appendixes Subject

D2290Test Method for Apparent Hoop Tensile Strength of

Appendix X1 Butt Fusion Guidelines for PA-11 Piping

Appendix X2 Design Consideration

Plastic or Reinforced Plastic Pipe

D2774PracticeforUndergroundInstallationofThermoplas-

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the tic Pressure Piping

D2837Test Method for Obtaining Hydrostatic Design Basis

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- forThermoplasticPipeMaterialsorPressureDesignBasis

for Thermoplastic Pipe Products

bility of regulatory limitations prior to use.

D3418Test Method for Transition Temperatures and En-

NOTE 1—Heat fusion joining of PA11 pipe and fittings meeting the

thalpies of Fusion and Crystallization of Polymers by

requirements of this standard is limited to PA11 pipe and fittings meeting

Differential Scanning Calorimetry

the requirements of this Standard. Heat Fusion joining of PA11 pipe and

fittings meeting the requirements of this standard is not allowed to pipes D4066Classification System for Nylon Injection and Extru-

and fittings made from any other thermoplastic materials (for example,

sion Materials (PA)

PA12, PEs, PVCs, etc.).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction ofASTM Committee F17 on Plastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 27, 2012. Published December 2012. Orginally the ASTM website.

3

approved in 2012. Last previous edition approved in 2012 as F2945–12. DOI: The last approved version of this historical standard is referenced on

10.1520/D2945–12A. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2945−12a

F412Terminology Relating to Plastic Piping Systems ISO 22621 Part 1Plastics

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.