ASTM C110-14

(Test Method)Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone

Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone

ABSTRACT

These test methods cover physical testing of quicklime, hydrated lime, and limestone. Plastic property testing shall include test methods for standard consistency and plasticity of lime putty, water retention of hydrated lime, and air entrainment. Soundness testing shall include test methods for autoclave expansion, and popping and pitting of hydrated lime. Application testing shall include test methods for slaking rate of quicklime, dry brightness of pulverized limestone, limestone grindability determination by the laboratory ball mill method, and settling rate of hydrated lime. Particle size analysis shall include test methods for residue and sieve analysis, fineness of pulverized quicklime and hydrated lime by air permeability, particle size of pulverized limestone, and dry screening of hydrated lime, pulverized quicklime, and limestone by air jet sieving. Density measurement shall include the following test methods: apparent loose density, and apparent packed density of hydrated lime, pulverized quicklime, and limestone; specific gravity of hydrated lime products; and wet sieve analysis of agricultural liming materials.

SCOPE

1.1 These test methods cover physical testing of quicklime and hydrated lime, and of limestone not otherwise covered in ASTM standards.2

Note 1: Quicklime and hydrated lime have a high affinity for moisture and carbon dioxide. Caution should be taken to protect both hydrated and quicklime during sampling, storage, and testing (see Practice C50).

1.2 The test procedures appear in the following order:

Plastic Property Testing

Section

Standard Consistency of Lime Putty

5

Plasticity of Lime Putty

6

Water Retention of Hydrated Lime

7

Air Entrainment

8

Soundness Testing

Autoclave Expansion of Hydrated and Hydraulic Lime

9

Popping and Pitting of Hydrated Lime

10

Application Testing

Slaking Rate of Quicklime

11

Dry Brightness of Pulverized Limestone

12

Limestone Grindability Determination by the Laboratory Ball Mill Method

13

Settling Rate of Hydrated Lime

14

Particle Size Analysis

Residue and Sieve Analysis

15

Sieve Analysis of Dry Limestone, Quicklime, and Hydrated Lime

16

Fineness of Pulverized Quicklime and Hydrated Lime by Air Permeabiity

17

Particle Size of Pulverized Limestone

18

Dry Screening of Hydrated Lime, Pulverized Quicklime, and Limestone by Air Jet Sieving

19

Wet Sieve Analysis of Agricultural Liming Materials

20

Density Measurement

Apparent Loose Density of Hydrated Lime, Pulverized Quicklime, and Limestone

21

Apparent Packed Density of Hydrated Lime, Pulverized Quicklime, and Limestone

22

Relative Density (Specific Gravity) of Hydrated Lime Products

23

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C110 −14

StandardTest Methods for

Physical Testing of Quicklime, Hydrated Lime, and

Limestone

This standard is issued under the fixed designation C110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope conversions to inch-pound units that are provided for informa-

tion only and are not considered standard.

1.1 These test methods cover physical testing of quicklime

1.4 This standard does not purport to address all of the

and hydrated lime, and of limestone not otherwise covered in

safety concerns, if any, associated with its use. It is the

ASTM standards.

responsibility of the user of this standard to establish appro-

NOTE1—Quicklimeandhydratedlimehaveahighaffinityformoisture

priate safety and health practices and determine the applica-

and carbon dioxide. Caution should be taken to protect both hydrated and

bility of regulatory limitations prior to use.

quicklime during sampling, storage, and testing (see Practice C50).

1.2 The test procedures appear in the following order:

2. Referenced Documents

Plastic Property Testing Section

2.1 ASTM Standards:

Standard Consistency of Lime Putty 5

Plasticity of Lime Putty 6

C28/C28MSpecification for Gypsum Plasters

Water Retention of Hydrated Lime 7

C50Practice for Sampling, Sample Preparation, Packaging,

Air Entrainment 8

and Marking of Lime and Limestone Products

Soundness Testing

Autoclave Expansion of Hydrated and Hydraulic Lime 9

C51Terminology Relating to Lime and Limestone (as used

Popping and Pitting of Hydrated Lime 10

by the Industry)

Application Testing

C91Specification for Masonry Cement

Slaking Rate of Quicklime 11

Dry Brightness of Pulverized Limestone 12

C109/C109MTest Method for Compressive Strength of

Limestone Grindability Determination by the Laboratory Ball Mill 13

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

Method

Specimens)

Settling Rate of Hydrated Lime 14

Particle Size Analysis

C136Test Method for Sieve Analysis of Fine and Coarse

Residue and Sieve Analysis 15

Aggregates

Sieve Analysis of Dry Limestone, Quicklime, and Hydrated Lime 16

C150Specification for Portland Cement

Fineness of Pulverized Quicklime and Hydrated Lime by Air 17

Permeabiity

C185Test Method for Air Content of Hydraulic Cement

Particle Size of Pulverized Limestone 18

Mortar

Dry Screening of Hydrated Lime, Pulverized Quicklime, and 19

Limestone by Air Jet Sieving C188Test Method for Density of Hydraulic Cement

Wet Sieve Analysis of Agricultural Liming Materials 20

C192/C192MPracticeforMakingandCuringConcreteTest

Density Measurement

Specimens in the Laboratory

Apparent Loose Density of Hydrated Lime, Pulverized Quicklime, 21

and Limestone C204Test Methods for Fineness of Hydraulic Cement by

Apparent Packed Density of Hydrated Lime, Pulverized 22

Air-Permeability Apparatus

Quicklime, and Limestone

C207Specification for Hydrated Lime for Masonry Pur-

Relative Density (Specific Gravity) of Hydrated Lime Products 23

poses

1.3 The values stated in SI units are to be regarded as

C230/C230MSpecification for Flow Table for Use in Tests

standard. The values given in parentheses are mathematical

of Hydraulic Cement

C231Test Method for Air Content of Freshly Mixed Con-

These test methods are under the jurisdiction of ASTM Committee C07 on

crete by the Pressure Method

Lime and Limestone and are the direct responsibility of Subcommittee C07.06 on

C305Practice for Mechanical Mixing of Hydraulic Cement

Physical Tests.

Current edition approved Dec. 1, 2014. Published December 2014. Originally

approved in 1934. Last previous edition approved in 2011 as C110–11. DOI:

10.1520/C0110-14. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fortestsonlimestoneasaggregate,seeVol04.02ofthe Annual Book of ASTM contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards. For tests on limestone as building stone, see Vol 04.05 of the Annual Standards volume information, refer to the standard’s Document Summary page on

Book of ASTM Standards. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C110−14

Pastes and Mortars of Plastic Consistency 5.1.1 In order to measure certain physical properties of a

C430Test Method for Fineness of Hydraulic Cement by the lime putty, such as plasticity, it is necessary to have a uniform

45-µm (No. 325) Sieve or standard consistency (viscosity), since the property mea-

C472Test Methods for Physical Testing of Gypsum, Gyp- surement is affected by the consistency level.

sum Plasters and Gypsum Concrete

5.2 Apparatus:

C595Specification for Blended Hydraulic Cements

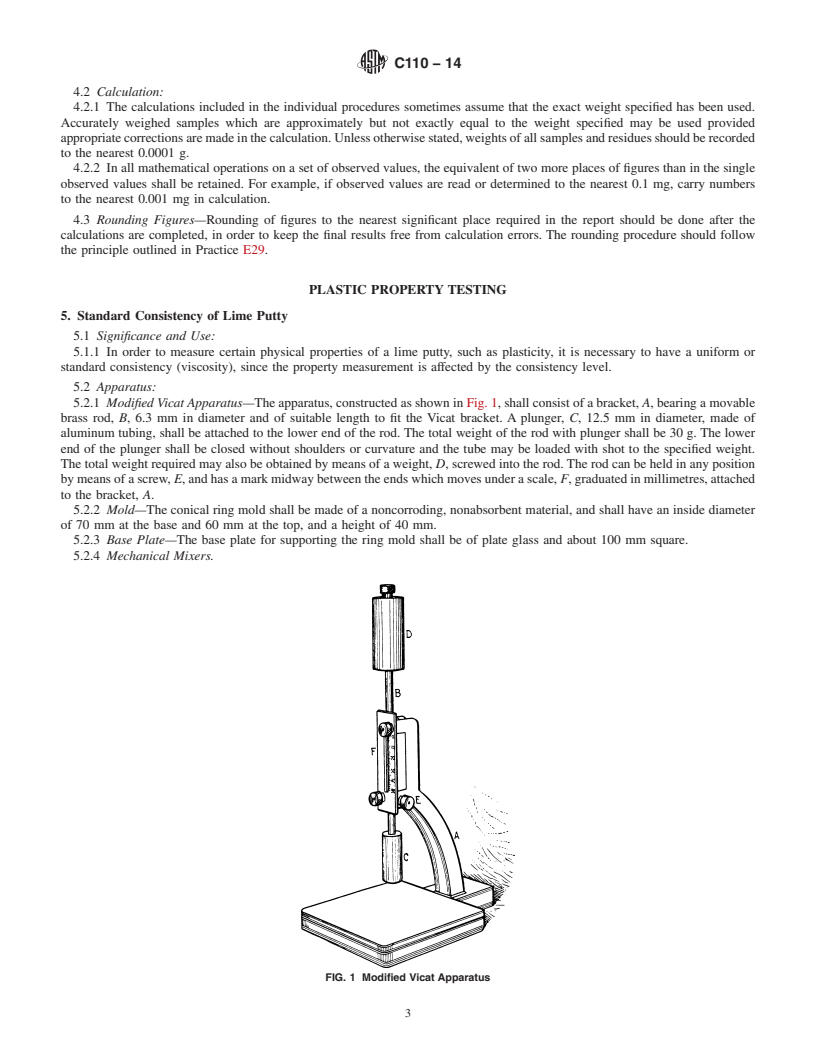

5.2.1 Modified Vicat Apparatus—The apparatus, con-

C670Practice for Preparing Precision and Bias Statements

structed as shown in Fig. 1, shall consist of a bracket, A,

for Test Methods for Construction Materials

bearing a movable brass rod, B, 6.3 mm in diameter and of

C702PracticeforReducingSamplesofAggregatetoTesting

suitable length to fit the Vicat bracket.Aplunger, C, 12.5 mm

Size

in diameter, made of aluminum tubing, shall be attached to the

C778Specification for Sand

lower end of the rod. The total weight of the rod with plunger

C1005Specification for Reference Masses and Devices for

shall be 30 g. The lower end of the plunger shall be closed

Determining Mass and Volume for Use in the Physical

withoutshouldersorcurvatureandthetubemaybeloadedwith

Testing of Hydraulic Cements

shottothespecifiedweight.Thetotalweightrequiredmayalso

C1107Specification for Packaged Dry, Hydraulic-Cement

beobtainedbymeansofaweight, D,screwedintotherod.The

Grout (Nonshrink)

rodcanbeheldinanypositionbymeansofascrew, E,andhas

D75Practice for Sampling Aggregates

a mark midway between the ends which moves under a scale,

E11Specification forWovenWireTest Sieve Cloth andTest

F, graduated in millimetres, attached to the bracket, A.

Sieves

5.2.2 Mold—The conical ring mold shall be made of a

E29Practice for Using Significant Digits in Test Data to

noncorroding, nonabsorbent material, and shall have an inside

Determine Conformance with Specifications

diameter of 70 mm at the base and 60 mm at the top, and a

E177Practice for Use of the Terms Precision and Bias in

height of 40 mm.

ASTM Test Methods

5.2.3 Base Plate—The base plate for supporting the ring

E691Practice for Conducting an Interlaboratory Study to

mold shall be of plate glass and about 100 mm square.

Determine the Precision of a Test Method

5.2.4 Mechanical Mixers.

3. Terminology

5.3 Standard Consistency Determination:

5.3.1 Mechanical Mixing Procedure Using the Vac-U-

3.1 Definitions—Unless otherwise specified, for definitions

Mixer—To a measured amount of water contained in an

of terms used in this standard see Terminology C51.

800-cm Vac-U-Mix bowl, add 300 g of hydrated lime and

4. General Procedures

hand mix for 10s with a stiff spatula (Note 2). Cover putty to

4.1 Sampling—Samples of lime and limestone for physical

analysis shall be taken and prepared in accordance with the

requirements of Practice C50 applicable to the material to be

tested.

4.2 Calculation:

4.2.1 Thecalculationsincludedintheindividualprocedures

sometimes assume that the exact weight specified has been

used. Accurately weighed samples which are approximately

but not exactly equal to the weight specified may be used

provided appropriate corrections are made in the calculation.

Unless otherwise stated, weights of all samples and residues

should be recorded to the nearest 0.0001 g.

4.2.2 In all mathematical operations on a set of observed

values,theequivalentoftwomoreplacesoffiguresthaninthe

single observed values shall be retained. For example, if

observed values are read or determined to the nearest 0.1 mg,

carry numbers to the nearest 0.001 mg in calculation.

4.3 Rounding Figures—Rounding of figures to the nearest

significantplacerequiredinthereportshouldbedoneafterthe

calculations are completed, in order to keep the final results

free from calculation errors. The rounding procedure should

follow the principle outlined in Practice E29.

PLASTIC PROPERTY TESTING

5. Standard Consistency of Lime Putty

5.1 Significance and Use: FIG. 1 Modified Vicat Apparatus

C110−14

prevent evaporation of water. After the applicable soaking

period, 30 min maximum for Type S, special hydrated lime,

and not less than 16 h nor more than 24 h for Type N, normal

hydratedlime,insertthepaddleassemblyandmixtheputtyfor

30 s with the mechanical mixer. Remove the paddle assembly

andscrapedownanyputtyadheringtoitandtothesidesofthe

mixing bowl. Remix for 30 s and determine the consistency as

prescribed in 5.3. If the penetration is less than 15 mm, return

all of the material to the mixer bowl, add additional water, and

remix for 15 s. If the penetration is greater than 25 mm, repeat

the test.

NOTE 2—Most lime hydrates will require 250 to 300 mL of water to

produceaputtyofproperconsistencyforthistestif300goflimeareused.

5.3.2 Mechanical Mixing Procedure Using the Hobart N-50

Mixer—To a measured amount of water contained in the N-50

mixingbowl,add600gofhydratedlimeandhandmixfor10s

withastiffspatula(Note3).Coverputtytopreventevaporation

ofwater.Aftertheapplicablesoakingperiod,30minmaximum

for Type S, special hydrated lime, and not less than 16 h nor

more than 24 h for Type N, normal hydrated lime, insert the

paddle assembly and mix the putty for 1 min at a slow speed.

Stopthemixerandscrapedownthepaddleandthesidesofthe

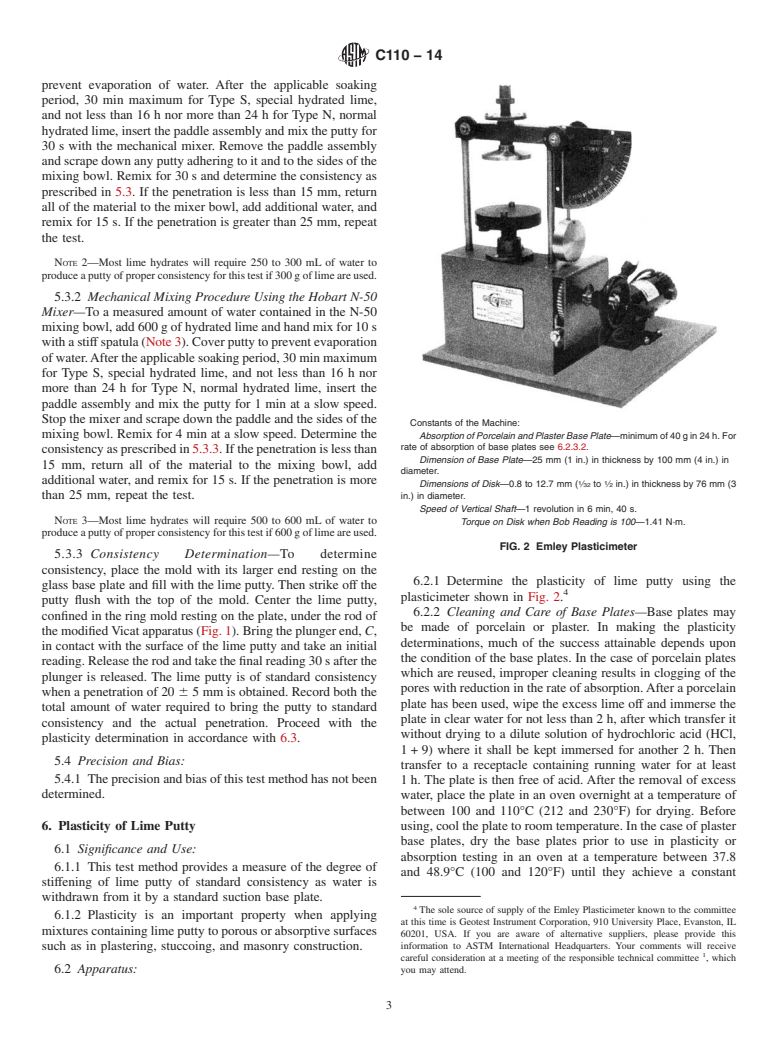

Constants of the Machine:

mixing bowl. Remix for 4 min at a slow speed. Determine the Absorption of Porcelain and Plaster Base Plate—minimumof40gin24h.For

rate of absorption of base plates see 6.2.3.2.

consistencyasprescribedin5.3.3.Ifthepenetrationislessthan

Dimension of Base Plate—25 mm (1 in.) in thickness by 100 mm (4 in.) in

15 mm, return all of the material to the mixing bowl, add

diameter.

additional water, and remix for 15 s. If the penetration is more

1 1

Dimensions of Disk—0.8to12.7mm( ⁄32 to ⁄2 in.) in thickness by 76 mm (3

than 25 mm, repeat the test. in.) in diameter.

Speed of Vertical Shaft—1 revolution in 6 min, 40 s.

NOTE 3—Most lime hydrates will require 500 to 600 mL of water to Torque on Disk when Bob Reading is 100—1.41 N·m.

produceaputtyofproperconsistencyforthistestif600goflimeareused.

FIG. 2 Emley Plasticimeter

5.3.3 Consistency Determination—To determine

consistency, place the mold with its larger end resting on the

6.2.1 Determine the plasticity of lime putty using the

glass base plate and fill with the lime putty.Then strike off the

plasticimeter shown in Fig. 2.

putty flush with the top of the mold. Center the lime putty,

6.2.2 Cleaning and Care of Base Plates—Base plates may

confined in the ring mold resting on the plate, under the rod of

be made of porcelain or plaster. In making the plasticity

themodifiedVicatapparatus(Fig.1).Bringtheplungerend, C,

determinations, much of the success attainable depends upon

in contact with the surface of the lime putty and take an initial

the condition of the base plates. In the case of porcelain plates

reading.Releasetherodandtakethefinalreading30safterthe

which are reused, improper cleaning results in clogging of the

plunger is released. The lime putty is of standard consistency

poreswithreductionintherateofabsorption.Afteraporcelain

whenapenetrationof20 65mmisobtained.Recordboththe

plate has been used, wipe the excess lime off and immerse the

total amount of water required to bring the putty to standard

plate in clear water for not less than 2 h, after which transfer it

consistency and the actual penetration. Proceed with the

without drying to a dilute solution of hydrochloric acid (HCl,

plasticity determination in accordance with 6.3.

1+9) where it shall be kept immersed for another 2 h. Then

5.4 Precision and Bias:

transfer to a receptacle containing running water for at least

5.4.1 Theprecisionandbiasofthistestmethodhasnotbeen

1h. The plate is then free of acid.After the removal of excess

determined.

water, place the plate in an oven overnight at a temperature of

between 100 and 110°C (212 and 230°F) for drying. Before

6. Plasticity of Lime Putty

using,cooltheplatetoroomtemperature.Inthecaseofplaster

base plates, dry the base plates prior to use in plasticity or

6.1 Significance and Use:

absorption testing in an oven at a temperature between 37.8

6.1.1 This test method provides a measure of the degree of

and 48.9°C (100 and 120°F) until they achieve a constant

stiffening of lime putty of standard consistency as water is

withdrawn from it by a standard suction base plate.

The sole source of supply of the Emley Plasticimeter known to the committee

6.1.2 Plasticity is an important property when applying

at this time is Geotest Instrument Corporation, 910 University Place, Evanston, IL

mixturescontaininglimeputtytoporousorabsorptivesurfaces

60201, USA. If you are aware of alternative suppliers, please provide this

information to ASTM International Headquarters. Your comments will receive

such as in plastering, stuccoing, and masonry construction.

careful consideration at a meeting of the responsible technical committee , which

6.2 Apparatus: you may attend.

C110−14

weight. Before using, cool the plaster plate to room tempera- and start the motor. It is essential that the motor be started

ture in a dessicator charged with a drying agent. If the plate is exactly120safterthefirstportionofthepastehasbeenplaced

not to be used immediately after reaching room temperature, in the mold. Record the time when the first portion of paste is

continue to store the plate in the dessicator until such time that placed in the mold as zero time; the motor is therefore started

it is to be used. Plaster base plates shall not be reused after at 2 min. Take care to protect the specimen from drafts during

plasticity, total absorption or rate of absorption testing (see the test.

6.2.3). 6.3.2 Record the scale reading at 1-min intervals until the

6.2.3 Absorption of Plasticimeter Base Plates: test is completed. Consider the test complete when: (1) the

6.2.3.1 Total Absorption—Plasticimeter base plates when scale reading reaches 100, (2) any reading is less than the one

immersed in water at room temperature for a period of 24 h before, or (3) the scale reading remains constant for three

shall absorb not less than 40 g of water. Before making the consecutive readings (2 min) and the specimen has vi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C110 − 11 C110 − 14

Standard Test Methods for

Physical Testing of Quicklime, Hydrated Lime, and

Limestone

This standard is issued under the fixed designation C110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 These test methods cover physical testing of quicklime and hydrated lime, and of limestone not otherwise covered in ASTM

standards.

NOTE 1—Quicklime and hydrated lime have a high affinity for moisture and carbon dioxide. Caution should be taken to protect both hydrated and

quicklime during sampling, storage, and testing (see Practice C50).

NOTE 1—Quicklime and hydrated lime have a high affinity for moisture and carbon dioxide. Caution should be taken to protect both hydrated and

quicklime during sampling, storage, and testing (see Practice C50).

1.2 The test procedures appear in the following order:

Plastic Property Testing Section

Standard Consistency of Lime Putty 5

Plasticity of Lime Putty 6

Water Retention of Hydrated Lime 7

Air Entrainment 8

Apparent Loose Density of Hydrated Lime, Pulverized 20

Quicklime, and Limestone

Soundness Testing

Apparent Packed Density of Hydrated Lime, Pulverized 21

Quicklime, and Limestone

Autoclave Expansion of Hydrated 9

and Hydraulic Lime

Autoclave Expansion of Hydrated Lime 9

Popping and Pitting of Hydrated Lime 10

Application Testing

Slaking Rate of Quicklime 11

Dry Brightness of Pulverized Limestone 12

Limestone Grindability Determination by the Laboratory Ball Mill 13

Method

Settling Rate of Hydrated Lime 14

Particle Size Analysis

Dry Screening by Air Jet Sieve 18

Residue and Sieve Analysis 15

Fineness of Pulverized Quicklime and Hydrated Lime by Air 16

Permeability

Sieve Analysis of Dry Limestone, Quicklime, and Hydrated Lime 16

Limestone Grindability 13

Fineness of Pulverized Quicklime and Hydrated Lime by Air 17

Permeabiity

Particle Size of Pulverized Limestone 17

Particle Size of Pulverized Limestone 18

Plasticity of Lime Putty 6

Dry Screening of Hydrated Lime, Pulverized Quicklime, and 19

Limestone by Air Jet Sieving

Popping and Pitting of Hydrated Lime 10

These test methods are under the jurisdiction of ASTM Committee C07 on Lime and Limestone and are the direct responsibility of Subcommittee C07.06 on Physical

Tests.

Current edition approved June 1, 2011Dec. 1, 2014. Published August 2011December 2014. Originally approved in 1934. Last previous edition approved in 20102011

as C110C110 – 11.–10. DOI: 10.1520/C0110-11.10.1520/C0110-14.

For tests on limestone as aggregate, see Vol 04.02 of the Annual Book of ASTM Standards. For tests on limestone as building stone, see Vol 04.05 of the Annual Book

of ASTM Standards.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C110 − 14

Wet Sieve Analysis of Agricultural Liming Materials 20

Residue and Sieve Analysis 15

Density Measurement

Settling Rate of Hydrated Lime 14

Apparent Loose Density of Hydrated Lime, Pulverized Quicklime, 21

and Limestone

Slaking Rate of Quicklime 11

Specific Gravity of Hydrated Lime Products 22

Apparent Packed Density of Hydrated Lime, Pulverized 22

Quicklime, and Limestone

Standard Consistency of Lime Putty 5

Water Retention of Hydrated Lime 7

Relative Density (Specific Gravity) of Hydrated Lime Products 23

Wet Sieve Analysis of Agricultural Liming Materials 19

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C28/C28M Specification for Gypsum Plasters

C50 Practice for Sampling, Sample Preparation, Packaging, and Marking of Lime and Limestone Products

C51 Terminology Relating to Lime and Limestone (as used by the Industry)

C91 Specification for Masonry Cement

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C136 Test Method for Sieve Analysis of Fine and Coarse Aggregates

C150 Specification for Portland Cement

C185 Test Method for Air Content of Hydraulic Cement Mortar

C188 Test Method for Density of Hydraulic Cement

C192/C192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C204 Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus

C207 Specification for Hydrated Lime for Masonry Purposes

C230/C230M Specification for Flow Table for Use in Tests of Hydraulic Cement

C231 Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method

C305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

C430 Test Method for Fineness of Hydraulic Cement by the 45-μm (No. 325) Sieve

C472 Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete

C595 Specification for Blended Hydraulic Cements

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

C702 Practice for Reducing Samples of Aggregate to Testing Size

C778 Specification for Sand

C1005 Specification for Reference Masses and Devices for Determining Mass and Volume for Use in the Physical Testing of

Hydraulic Cements

C1107 Specification for Packaged Dry, Hydraulic-Cement Grout (Nonshrink)

D75 Practice for Sampling Aggregates

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—Unless otherwise specified, for definitions of terms used in this standard see Terminology C51.

4. General Procedures

4.1 Sampling—Samples of lime and limestone for physical analysis shall be taken and prepared in accordance with the

requirements of Practice C50 applicable to the material to be tested.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

C110 − 14

4.2 Calculation:

4.2.1 The calculations included in the individual procedures sometimes assume that the exact weight specified has been used.

Accurately weighed samples which are approximately but not exactly equal to the weight specified may be used provided

appropriate corrections are made in the calculation. Unless otherwise stated, weights of all samples and residues should be recorded

to the nearest 0.0001 g.

4.2.2 In all mathematical operations on a set of observed values, the equivalent of two more places of figures than in the single

observed values shall be retained. For example, if observed values are read or determined to the nearest 0.1 mg, carry numbers

to the nearest 0.001 mg in calculation.

4.3 Rounding Figures—Rounding of figures to the nearest significant place required in the report should be done after the

calculations are completed, in order to keep the final results free from calculation errors. The rounding procedure should follow

the principle outlined in Practice E29.

PLASTIC PROPERTY TESTING

5. Standard Consistency of Lime Putty

5.1 Significance and Use:

5.1.1 In order to measure certain physical properties of a lime putty, such as plasticity, it is necessary to have a uniform or

standard consistency (viscosity), since the property measurement is affected by the consistency level.

5.2 Apparatus:

5.2.1 Modified Vicat Apparatus—The apparatus, constructed as shown in Fig. 1, shall consist of a bracket, A, bearing a movable

brass rod, B, 6.3 mm in diameter and of suitable length to fit the Vicat bracket. A plunger, C, 12.5 mm in diameter, made of

aluminum tubing, shall be attached to the lower end of the rod. The total weight of the rod with plunger shall be 30 g. The lower

end of the plunger shall be closed without shoulders or curvature and the tube may be loaded with shot to the specified weight.

The total weight required may also be obtained by means of a weight, D, screwed into the rod. The rod can be held in any position

by means of a screw, E, and has a mark midway between the ends which moves under a scale, F, graduated in millimetres, attached

to the bracket, A.

5.2.2 Mold—The conical ring mold shall be made of a noncorroding, nonabsorbent material, and shall have an inside diameter

of 70 mm at the base and 60 mm at the top, and a height of 40 mm.

5.2.3 Base Plate—The base plate for supporting the ring mold shall be of plate glass and about 100 mm square.

5.2.4 Mechanical Mixers.

FIG. 1 Modified Vicat Apparatus

C110 − 14

5.3 Standard Consistency Determination:

5.3.1 Mechanical Mixing Procedure Using the Vac-U-Mixer—To a measured amount of water contained in an 800-cm

Vac-U-Mix bowl, add 300 g of hydrated lime and hand mix for 10 s 10 s with a stiff spatula (Note 2). Cover putty to prevent

evaporation of water. After the applicable soaking period, 30 min maximum for Type S, special hydrated lime, and not less than

16 h nor more than 24 h for Type N, normal hydrated lime, insert the paddle assembly and mix the putty for 30 s with the

mechanical mixer. Remove the paddle assembly and scrape down any putty adhering to it and to the sides of the mixing bowl.

Remix for 30 s and determine the consistency as prescribed in 5.3. If the penetration is less than 15 mm, return all of the material

to the mixer bowl, add additional water, and remix for 15 s. If the penetration is greater than 25 mm, repeat the test.

NOTE 2—Most lime hydrates will require 250 to 300 mL of water to produce a putty of proper consistency for this test if 300 g of lime are used.

5.3.2 Mechanical Mixing Procedure Using the Hobart N-50 Mixer—To a measured amount of water contained in the N-50

mixing bowl, add 600 g of hydrated lime and hand mix for 10 s 10 s with a stiff spatula (Note 3). Cover putty to prevent

evaporation of water. After the applicable soaking period, 30 min 30 min maximum for Type S, special hydrated lime, and not less

than 16 h nor more than 24 h for Type N, normal hydrated lime, insert the paddle assembly and mix the putty for 1 min at a slow

speed. Stop the mixer and scrape down the paddle and the sides of the mixing bowl. Remix for 4 min at a slow speed. Determine

the consistency as prescribed in 5.3.3. If the penetration is less than 15 mm, return all of the material to the mixing bowl, add

additional water, and remix for 15 s. If the penetration is more than 25 mm, repeat the test.

NOTE 3—Most lime hydrates will require 500 to 600 mL of water to produce a putty of proper consistency for this test if 600 g of lime are used.

5.3.3 Consistency Determination—To determine consistency, place the mold with its larger end resting on the glass base plate

and fill with the lime putty. Then strike off the putty flush with the top of the mold. Center the lime putty, confined in the ring mold

resting on the plate, under the rod of the modified Vicat apparatus (Fig. 1). Bring the plunger end, C, in contact with the surface

of the lime putty and take an initial reading. Release the rod and take the final reading 30 s after the plunger is released. The lime

putty is of standard consistency when a penetration of 20 6 5 mm is obtained. Record both the total amount of water required to

bring the putty to standard consistency and the actual penetration. Proceed with the plasticity determination in accordance with 6.3.

5.4 Precision and Bias:

5.4.1 The precision and bias of this test method has not been determined.

Constants of the Machine:

Absorption of Porcelain and Plaster Base Plate—minimum of 40 g in 24 h. For rate of

absorption of base plates see 6.2.3.2.

Dimension of Base Plate—25 mm (1 in.) in thickness by 100 mm (4 in.) in

diameter.

1 1

Dimensions of Disk—0.8 to 12.7 mm ( ⁄32 to ⁄2 in.) in thickness by 76 mm (3 in.) in diameter.

Speed of Vertical Shaft—1 revolution in 6 min, 40 s.

Torque on Disk when Bob Reading is 100—1.41 N·m.

FIG. 2 Emley Plasticimeter

C110 − 14

6. Plasticity of Lime Putty

6.1 Significance and Use:

6.1.1 This test method provides a measure of the degree of stiffening of lime putty of standard consistency as water is withdrawn

from it by a standard suction base plate.

6.1.2 Plasticity is an important property when applying mixtures containing lime putty to porous or absorptive surfaces such

as in plastering, stuccoing, and masonry construction.

6.2 Apparatus:

6.2.1 Determine the plasticity of lime putty using the plasticimeter shown in Fig. 2.

6.2.2 Cleaning and Care of Base Plates—Base plates may be made of porcelain or plaster. In making the plasticity

determinations, much of the success attainable depends upon the condition of the base plates. In the case of porcelain plates which

are reused, improper cleaning results in clogging of the pores with reduction in the rate of absorption. After a porcelain plate has

been used, wipe the excess lime off and immerse the plate in clear water for not less than 2 h, after which transfer it without drying

to a dilute solution of hydrochloric acid (HCl, 1 + 9) where it shall be kept immersed for another 2 h. Then transfer to a receptacle

containing running water for at least 1 h. 1 h. The plate is then free of acid. After the removal of excess water, place the plate in

an oven overnight at a temperature of between 100 and 110 °C 110°C (212 and 230 °F) 230°F) for drying. Before using, cool the

plate to room temperature. In the case of plaster base plates, dry the base plates prior to use in p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.