ASTM E317-21

(Practice)Standard Practice for Evaluating Performance Characteristics of Ultrasonic Pulse-Echo Testing Instruments and Systems without the Use of Electronic Measurement Instruments

Standard Practice for Evaluating Performance Characteristics of Ultrasonic Pulse-Echo Testing Instruments and Systems without the Use of Electronic Measurement Instruments

SIGNIFICANCE AND USE

5.1 This practice describes procedures applicable to both shop and field conditions. More comprehensive or precise measurements of the characteristics of complete systems and their components will generally require laboratory techniques and electronic equipment such as oscilloscopes and signal generators. Substitution of these methods is not precluded where appropriate; however, their usage is not within the scope of this practice.

5.2 This document does not establish system acceptance limits, nor is it intended as a comprehensive equipment specification.

5.3 While several important characteristics are included, others of possible significance in some applications are not covered.

5.4 Since the parameters to be evaluated and the applicable test conditions must be specified, this practice shall be prescribed only by those familiar with ultrasonic NDT technology and the required tests shall be performed either by such a qualified person or under his supervision.

5.5 Implementation may require more detailed procedural instructions in the format of the using facility.

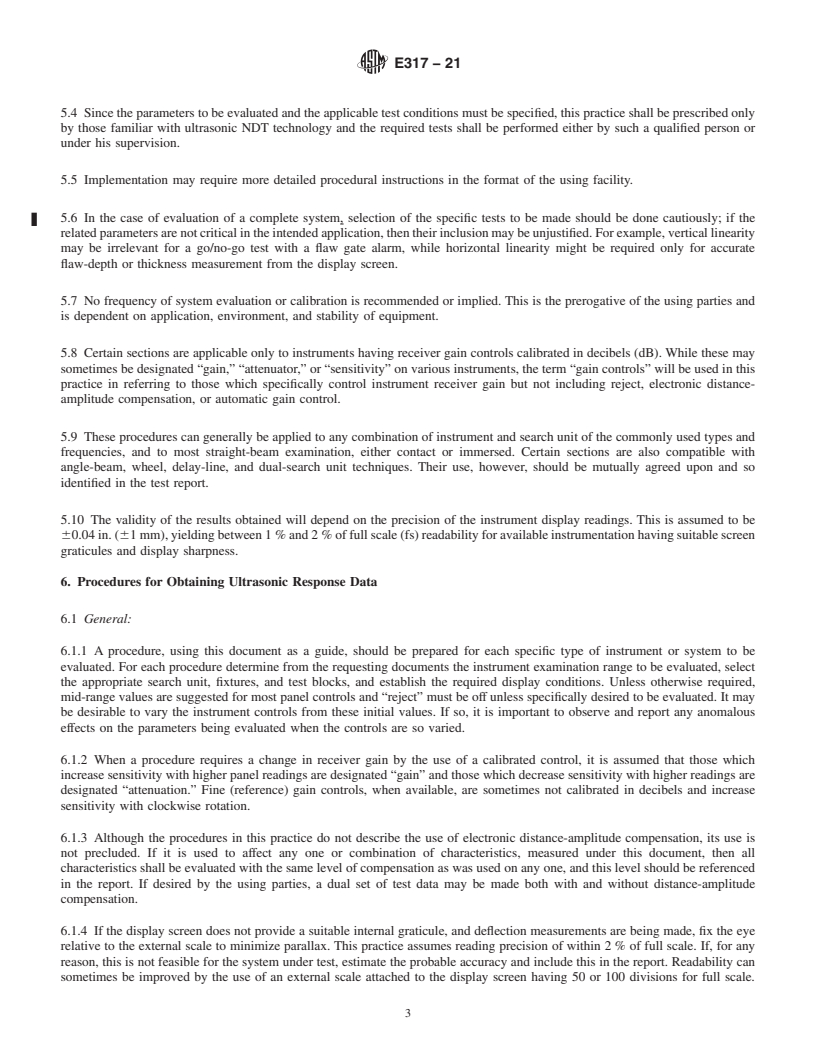

5.6 In the case of evaluation of a complete system, selection of the specific tests to be made should be done cautiously; if the related parameters are not critical in the intended application, then their inclusion may be unjustified. For example, vertical linearity may be irrelevant for a go/no-go test with a flaw gate alarm, while horizontal linearity might be required only for accurate flaw-depth or thickness measurement from the display screen.

5.7 No frequency of system evaluation or calibration is recommended or implied. This is the prerogative of the using parties and is dependent on application, environment, and stability of equipment.

5.8 Certain sections are applicable only to instruments having receiver gain controls calibrated in decibels (dB). While these may sometimes be designated “gain,” “attenuator,” or “sensitivity” on various instruments, the term “gain controls” wil...

SCOPE

1.1 This practice describes procedures for evaluating the following performance characteristics of ultrasonic pulse-echo examination instruments and systems: Horizontal Limit and Linearity; Vertical Limit and Linearity; Resolution - Entry Surface and Far Surface; Sensitivity and Noise; Accuracy of Calibrated Gain Controls. Evaluation of these characteristics is intended to be used for comparing instruments and systems or, by periodic repetition, for detecting long-term changes in the characteristics of a given instrument or system that may be indicative of impending failure, and which, if beyond certain limits, will require corrective maintenance. Instrument characteristics measured in accordance with this practice are expressed in terms that relate to their potential usefulness for ultrasonic testing. Instrument characteristics expressed in purely electronic terms may be measured as described in Guide E1324.

1.2 Ultrasonic examination systems using pulsed-wave trains and A-scan presentation (rf or video) may be evaluated.

1.3 The procedures are applicable to shop or field conditions; additional electronic measurement instrumentation is not required.

1.4 This practice establishes no performance limits for examination systems; if such acceptance criteria are required, these must be specified by the using parties. Where acceptance criteria are implied herein, they are for example only and are subject to more or less restrictive limits imposed by customer's and end user's controlling documents.

1.5 The specific parameters to be evaluated, conditions and frequency of test, and report data required must also be determined by the user.

1.6 This practice may be used for the evaluation of a complete examination system, including search unit, instrument, interconnections, fixtures and connected alarm and auxiliary devices, primarily in cases where such a system is used repetitively without change or substitution. T...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E317 − 21

Standard Practice for

Evaluating Performance Characteristics of Ultrasonic Pulse-

Echo Testing Instruments and Systems without the Use of

1

Electronic Measurement Instruments

This standard is issued under the fixed designation E317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.5 The specific parameters to be evaluated, conditions and

frequency of test, and report data required must also be

1.1 This practice describes procedures for evaluating the

determined by the user.

following performance characteristics of ultrasonic pulse-echo

1.6 This practice may be used for the evaluation of a

examination instruments and systems: Horizontal Limit and

Linearity; Vertical Limit and Linearity; Resolution - Entry complete examination system, including search unit,

instrument, interconnections, fixtures and connected alarm and

Surface and Far Surface; Sensitivity and Noise; Accuracy of

Calibrated Gain Controls. Evaluation of these characteristics is auxiliary devices, primarily in cases where such a system is

used repetitively without change or substitution. This practice

intended to be used for comparing instruments and systems or,

by periodic repetition, for detecting long-term changes in the is not intended to be used as a substitute for calibration or

standardizationofaninstrumentorsystemtoinspectanygiven

characteristics of a given instrument or system that may be

indicative of impending failure, and which, if beyond certain material. There are limitations to the use of standard reference

2

blocks for that purpose.

limits, will require corrective maintenance. Instrument charac-

teristics measured in accordance with this practice are ex-

1.7 Requiredtestapparatusincludesselectedtestblocksand

pressed in terms that relate to their potential usefulness for

a precision external attenuator (where specified) in addition to

ultrasonic testing. Instrument characteristics expressed in

the instrument or system to be evaluated.

purelyelectronictermsmaybemeasuredasdescribedinGuide

1.8 Precautions relating to the applicability of the proce-

E1324.

dures and interpretation of the results are included.

1.2 Ultrasonic examination systems using pulsed-wave

1.9 Alternateprocedures,suchasexamplesdescribedinthis

trains and A-scan presentation (rf or video) may be evaluated.

document,orothers,mayonlybeusedwithcustomerapproval.

1.3 The procedures are applicable to shop or field condi-

1.10 Units—The values stated in inch-pound units are to be

tions; additional electronic measurement instrumentation is not

regarded as standard. The values given in parentheses are

required.

mathematical conversions to SI units that are provided for

1.4 This practice establishes no performance limits for

information only and are not considered standard.

examination systems; if such acceptance criteria are required,

1.11 This standard does not purport to address all of the

these must be specified by the using parties. Where acceptance

safety concerns, if any, associated with its use. It is the

criteria are implied herein, they are for example only and are

responsibility of the user of this standard to establish appro-

subjecttomoreorlessrestrictivelimitsimposedbycustomer’s

priate safety, health, and environmental practices and deter-

and end user’s controlling documents.

mine the applicability of regulatory limitations prior to use.

1.12 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- ization established in the Decision on Principles for the

structive Testing and is the direct responsibility of Subcommittee E07.06 on

Ultrasonic Method.

2

Current edition approved June 1, 2021. Published June 2021. Originally Beck, K. H., “Limitations to the Use of Reference Blocks for Periodic and

approved in 1967. Last previous edition approved in 2016 as E317 – 16. DOI: Preinspection Calibration of Ultrasonic Inspection Instruments and Systems,”

10.1520/E0317-21. Materials Evaluation, Vol 57, No. 3, March 1999.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E317 − 21

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E317 − 16 E317 − 21

Standard Practice for

Evaluating Performance Characteristics of Ultrasonic Pulse-

Echo Testing Instruments and Systems without the Use of

1

Electronic Measurement Instruments

This standard is issued under the fixed designation E317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This practice describes procedures for evaluating the following performance characteristics of ultrasonic pulse-echo

examination instruments and systems: Horizontal Limit and Linearity; Vertical Limit and Linearity; Resolution - Entry Surface and

Far Surface; Sensitivity and Noise; Accuracy of Calibrated Gain Controls. Evaluation of these characteristics is intended to be used

for comparing instruments and systems or, by periodic repetition, for detecting long-term changes in the characteristics of a given

instrument or system that may be indicative of impending failure, and which, if beyond certain limits, will require corrective

maintenance. Instrument characteristics measured in accordance with this practice are expressed in terms that relate to their

potential usefulness for ultrasonic testing. Instrument characteristics expressed in purely electronic terms may be measured as

described in Guide E1324.

1.2 Ultrasonic examination systems using pulsed-wave trains and A-scan presentation (rf or video) may be evaluated.

1.3 The procedures are applicable to shop or field conditions; additional electronic measurement instrumentation is not required.

1.4 This practice establishes no performance limits for examination systems; if such acceptance criteria are required, these must

be specified by the using parties. Where acceptance criteria are implied herein, they are for example only and are subject to more

or less restrictive limits imposed by customer’s and end user’s controlling documents.

1.5 The specific parameters to be evaluated, conditions and frequency of test, and report data required,required must also be

determined by the user.

1.6 This practice may be used for the evaluation of a complete examination system, including search unit, instrument,

interconnections, fixtures and connected alarm and auxiliary devices, primarily in cases where such a system is used repetitively

without change or substitution. This practice is not intended to be used as a substitute for calibration or standardization of an

2

instrument or system to inspect any given material. There are limitations to the use of standard reference blocks for that purpose.

1.7 Required test apparatus includes selected test blocks and a precision external attenuator (where specified) in addition to the

instrument or system to be evaluated.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic Method.

Current edition approved June 1, 2016June 1, 2021. Published June 2016June 2021. Originally approved in 1967. Last previous edition approved in 20112016 as

E317 - 11.E317 – 16. DOI: 10.1520/E0317-16.10.1520/E0317-21.

2

Beck, K. H., “Limitations to the Use of Reference Blocks for Periodic and Preinspection Calibration of Ultrasonic Inspection Instruments and Systems,” Materials

Evaluation, Vol 57, No. 3, March 1999.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E317 − 21

1.8 Precautions relating to the applicability of the procedures and interpretation of the results are included.

1.9 Alternate procedures, such as examples described in this document, or others, may only be used with customer approval.

1.10 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.11 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.