ASTM D6210-17

(Specification)Standard Specification for Fully-Formulated Glycol Base Engine Coolant for Heavy-Duty Engines

Standard Specification for Fully-Formulated Glycol Base Engine Coolant for Heavy-Duty Engines<rangeref></rangeref >

ABSTRACT

This specification covers the requirements for fully-formulated glycol base coolants for cooling systems of heavy-duty engines. When concentrates are used at 40 to 60 % glycol concentration by volume in water of suitable quality, or when prediluted glycol base engine coolants (50 volume % minimum) are used without further dilution, they will function effectively during both winter and summer to provide protection against corrosion, cavitation, freezing, and boiling. The coolant concentrate mixed with water or the prediluted coolant, when maintained with maintenance doses of supplemental coolant additives (SCA), shall be suitable for use in a properly maintained cooling system in normal service for a minimum of two years. In addition, the coolant concentrate or prediluted coolant shall provide protection in operating engines against cavitation corrosion (also termed liner pitting) and against scaling of internal engine hot surfaces. Hot surfaces typically are within the engine head, head spacer, upper cylinder liner, or liquid cooled exhaust manifold.

SCOPE

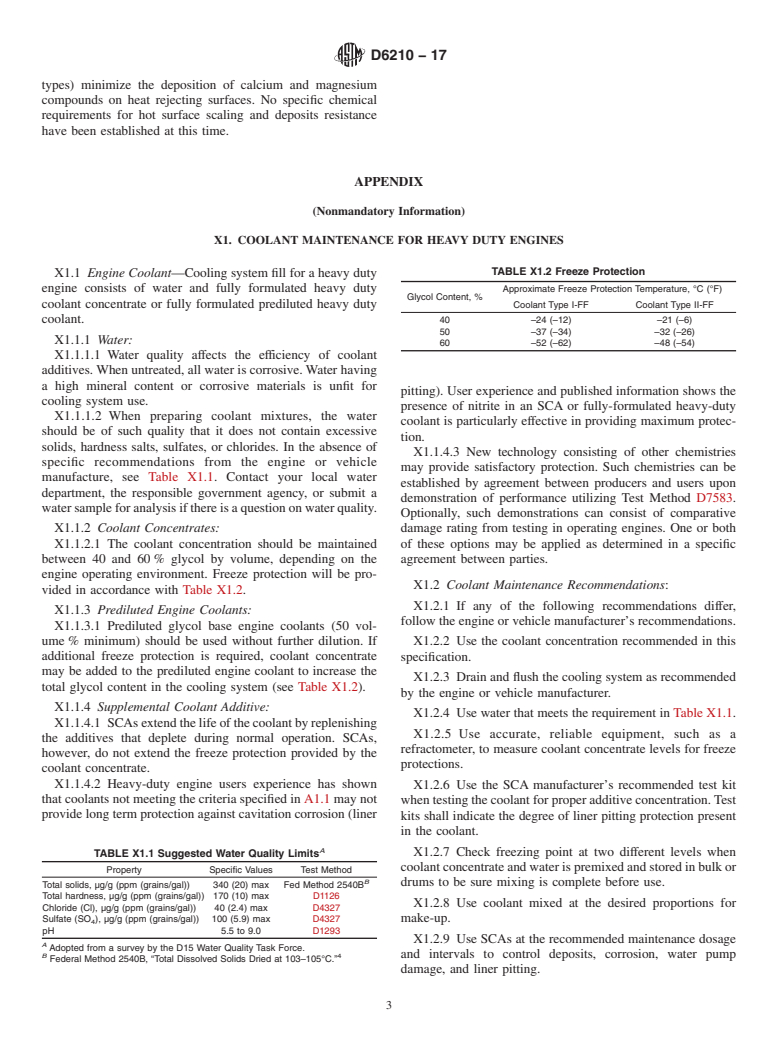

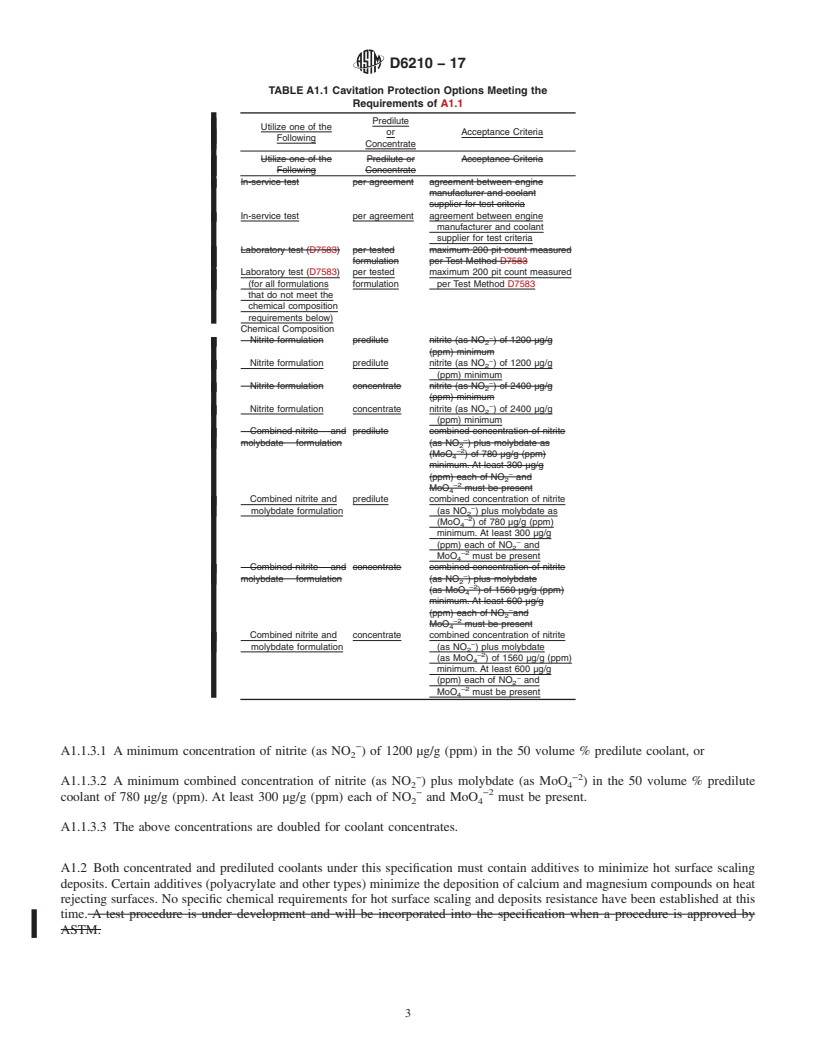

1.1 This specification covers the requirements for fully-formulated glycol base coolants for cooling systems of heavy-duty engines. When concentrates are used at 40 to 60 % glycol concentration by volume in water of suitable quality, (see Appendix X1), or when prediluted glycol base engine coolants (50 volume % minimum) are used without further dilution, they will function effectively during both winter and summer to provide protection against corrosion, cavitation, freezing, and boiling.

1.2 This specification is intended to cover the requirements for engine coolants prepared from virgin or recycled ethylene or propylene glycol.

Note 1: Committee D15 has not substantially studied the impact of using recycled glycols from sources such as:

• glycol bottoms

• polyester manufacturing waste

• aircraft and runway deicers

• medical waste to prepare engine coolants. However, several serious cases of very poor performance have been reported and substantiated in heavy duty fleets when recycled glycols from sources such as above have been used to prepare engine coolants. Efforts are underway to more clearly define the purity requirements for glycols used to prepare engine coolants meeting this specification, whether from recycled engine coolants or other sources.

1.3 The coolants governed by this specification are categorized as follows:

Coolant Type

Description

I-FF

Ethylene glycol base concentrate

II-FF

Propylene glycol base concentrate

III-FF

Ethylene glycol predilute (50 vol %)

IV-FF

Propylene glycol predilute (50 vol %)

1.4 Coolant concentrates meeting this specification do not require any addition of Supplemental Coolant Additive (SCA) until the first maintenance interval when a maintenance dose of SCA is required to continue protection in certain heavy duty engine cooling systems, particularly those of the wet cylinder liner-in-block design. The SCA additions are defined by and are the primary responsibility of the engine manufacturer or vehicle manufacturer. If they provide no instructions, follow the SCA supplier's instructions.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D6210 −17

Standard Specification for

Fully-Formulated Glycol Base Engine Coolant for Heavy-

1,2

Duty Engines

This standard is issued under the fixed designation D6210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* SCA is required to continue protection in certain heavy duty

engine cooling systems, particularly those of the wet cylinder

1.1 This specification covers the requirements for fully-

liner-in-block design. The SCA additions are defined by and

formulated glycol base coolants for cooling systems of heavy-

are the primary responsibility of the engine manufacturer or

duty engines.When concentrates are used at 40 to 60% glycol

vehicle manufacturer. If they provide no instructions, follow

concentration by volume in water of suitable quality, (see

the SCA supplier’s instructions.

Appendix X1), or when prediluted glycol base engine coolants

(50 volume% minimum) are used without further dilution, 1.5 The values stated in SI units are to be regarded as

theywillfunctioneffectivelyduringbothwinterandsummerto standard. The values given in parentheses are for information

provide protection against corrosion, cavitation, freezing, and only.

boiling.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.2 This specification is intended to cover the requirements

responsibility of the user of this standard to establish appro-

for engine coolants prepared from virgin or recycled ethylene

priate safety, health, and environmental practices and deter-

or propylene glycol.

NOTE 1—Committee D15 has not substantially studied the impact of mine the applicability of regulatory limitations prior to use.

using recycled glycols from sources such as:

1.7 This international standard was developed in accor-

glycol bottoms

dance with internationally recognized principles on standard-

polyester manufacturing waste

ization established in the Decision on Principles for the

aircraft and runway deicers

Development of International Standards, Guides and Recom-

medical waste

mendations issued by the World Trade Organization Technical

to prepare engine coolants. However, several serious cases of very poor

Barriers to Trade (TBT) Committee.

performance have been reported and substantiated in heavy duty fleets

when recycled glycols from sources such as above have been used to

prepare engine coolants. Efforts are underway to more clearly define 2. Referenced Documents

the purity requirements for glycols used to prepare engine coolants

3

2.1 ASTM Standards:

meeting this specification, whether from recycled engine coolants or

other sources.

D1126Test Method for Hardness in Water

D1293Test Methods for pH of Water

1.3 The coolants governed by this specification are catego-

D3306Specification for Glycol Base Engine Coolant for

rized as follows:

Automobile and Light-Duty Service

Coolant Type Description

D4327Test Method forAnions in Water by Suppressed Ion

I-FF Ethylene glycol base concentrate

Chromatography

II-FF Propylene glycol base concentrate

D5828Test Method for Compatibility of Supplemental

III-FF Ethylene glycol predilute (50 vol %)

IV-FF Propylene glycol predilute (50 vol %) Coolant Additives (SCAs) and Engine Coolant Concen-

trates

1.4 Coolant concentrates meeting this specification do not

D7583Test Method for John Deere Coolant Cavitation Test

require any addition of Supplemental CoolantAdditive (SCA)

4

2.2 Other Standard:

untilthefirstmaintenanceintervalwhenamaintenancedoseof

Federal Method 2540BTotal Dissolved Solids Dried at

103–105°C

1

ThisspecificationisunderthejurisdictionofASTMCommitteeD15onEngine

Coolants and Related Fluids and is the direct responsibility of Subcommittee

3

D15.07 on Specifications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2017. PublishedDecember 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1998. Last previous edition approved in 2010 as D6210-10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6210-17. the ASTM website.

2 4

Aresearch report is available fromASTM International Headquarters. Request Standard Method for the Examination of Water and Wastewater, American

RR:D15-1023. PublicHealthAssociation(APHA),etal,800IStreet,NW,Washington,DC20001.

*A Summary of Changes section appears at the end of this st

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6210 − 10 D6210 − 17

Standard Specification for

Fully-Formulated Glycol Base Engine Coolant for Heavy-

1,2

Duty Engines

This standard is issued under the fixed designation D6210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers the requirements for fully-formulated glycol base coolants for cooling systems of heavy-duty

engines. When concentrates are used at 40 to 60 % glycol concentration by volume in water of suitable quality, (see Appendix X1),

or when prediluted glycol base engine coolants (50 volume % minimum) are used without further dilution, they will function

effectively during both winter and summer to provide protection against corrosion, cavitation, freezing, and boiling.

1.2 This specification is intended to cover the requirements for engine coolants prepared from virgin or recycled ethylene or

propylene glycol.

NOTE 1—Committee D15 has not substantially studied the impact of using recycled glycols from sources such as:

• glycol bottoms

• polyester manufacturing waste

• aircraft and runway deicers

• medical waste

to prepare engine coolants. However, several serious cases of very poor performance have been reported and substantiated in heavy duty fleets when

recycled glycols from sources such as above have been used to prepare engine coolants. Efforts are underway to more clearly define the purity

requirements for glycols used to prepare engine coolants meeting this specification, whether from recycled engine coolants or other sources.

1.3 The coolants governed by this specification are categorized as follows:

Coolant Type Description

I-FF Ethylene glycol base concentrate

II-FF Propylene glycol base concentrate

III-FF Ethylene glycol predilute (50 vol %)

IV-FF Propylene glycol predilute (50 vol %)

1.4 Coolant concentrates meeting this specification do not require any addition of Supplemental Coolant Additive (SCA) until

the first maintenance interval when a maintenance dose of SCA is required to continue protection in certain heavy duty engine

cooling systems, particularly those of the wet cylinder liner-in-block design. The SCA additions are defined by and are the primary

responsibility of the engine manufacturer or vehicle manufacturer. If they provide no instructions, follow the SCA supplier’s

instructions.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

D1126 Test Method for Hardness in Water

1

This specification is under the jurisdiction of ASTM Committee D15 on Engine Coolants and Related Fluids and is the direct responsibility of Subcommittee D15.07

on Specifications.

Current edition approved Dec. 1, 2010Nov. 1, 2017. Published January 2011December 2017. Originally approved in 1998. Last previous edition approved in 20082010

as D6210 - 08.D6210 - 10. DOI: 10.1520/D6210-10.10.1520/D6210-17.

2

A research report is available from ASTM International Headquarters. Request RR:D15-1023.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6210 − 17

D1293 Test Methods for pH of Water

D3306 Specification for Glycol Base Engine Coolant for Automobile and Light-Duty Service

D4327 Test Method for Anions in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.