ASTM D2112-15(2023)

(Test Method)Standard Test Method for Oxidation Stability of Inhibited Mineral Insulating Oil by Pressure Vessel

Standard Test Method for Oxidation Stability of Inhibited Mineral Insulating Oil by Pressure Vessel

SCOPE

1.1 This test method covers and is intended as a rapid method for the evaluation of the oxidation stability of new mineral insulating oils containing a synthetic oxidation inhibitor. This test is considered of value in checking the oxidation stability of new mineral insulating oils containing 2,6-ditertiary-butyl para-cresol or 2,6-ditertiary-butyl phenol, or both, in order to control the continuity of this property from shipment to shipment. The applicability of this procedure for use with inhibited mineral insulating oils of more than 12 cSt at 40 °C (approximately 65 SUS at 100 °F) has not been established.

1.2 The values stated in SI units are to be regarded as standard except where there is no direct equivalent for hardware designed on the inch-pound unit basis.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (See warning in 6.7.)

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2112 − 15 (Reapproved 2023)

Standard Test Method for

Oxidation Stability of Inhibited Mineral Insulating Oil by

Pressure Vessel

This standard is issued under the fixed designation D2112; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E1 Specification for ASTM Liquid-in-Glass Thermometers

1.1 This test method covers and is intended as a rapid

3. Summary of Test Method

method for the evaluation of the oxidation stability of new

3.1 The test specimen is agitated by rotating axially at

mineral insulating oils containing a synthetic oxidation inhibi-

100 r ⁄min at an angle of 30° from the horizontal, under an

tor. This test is considered of value in checking the oxidation

initial oxygen pressure of 620 kPa (90 psi), in a stainless steel

stability of new mineral insulating oils containing 2,6-

or copper vessel (for rapid temperature equilibrium), with a

ditertiary-butyl para-cresol or 2,6-ditertiary-butyl phenol, or

glass test specimen container and copper catalyst coil, in the

both, in order to control the continuity of this property from

presence of water, at a bath temperature of 140 °C. The time

shipment to shipment. The applicability of this procedure for

for an oil to react with a given volume of oxygen is measured;

use with inhibited mineral insulating oils of more than 12 cSt

completion of the test is indicated by a specific drop in

at 40 °C (approximately 65 SUS at 100 °F) has not been

pressure.

established.

1.2 The values stated in SI units are to be regarded as

4. Significance and Use

standard except where there is no direct equivalent for hard-

4.1 This is a control test of oxidation stability of new,

ware designed on the inch-pound unit basis.

inhibited mineral insulating oils for determining the induction

1.3 This standard does not purport to address all of the

period of oxidation inhibitors under prescribed accelerated

safety concerns, if any, associated with its use. It is the

aging conditions. There is no proven correlation between oil

responsibility of the user of this standard to establish appro-

performance in this test and performance in service. However,

priate safety, health, and environmental practices and deter-

the test method may be used to check the continuity of

mine the applicability of regulatory limitations prior to use.

oxidation stability of production oils.

(See warning in 6.7.)

5. Apparatus

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

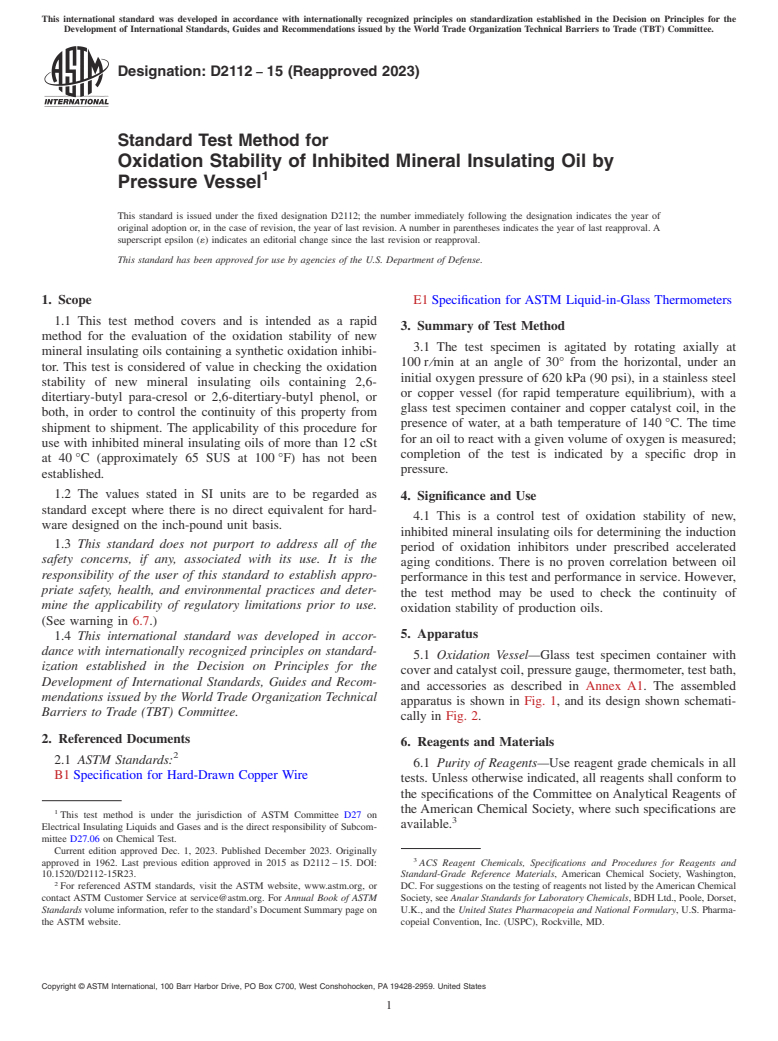

5.1 Oxidation Vessel—Glass test specimen container with

ization established in the Decision on Principles for the

cover and catalyst coil, pressure gauge, thermometer, test bath,

Development of International Standards, Guides and Recom-

and accessories as described in Annex A1. The assembled

mendations issued by the World Trade Organization Technical

apparatus is shown in Fig. 1, and its design shown schemati-

Barriers to Trade (TBT) Committee.

cally in Fig. 2.

2. Referenced Documents

6. Reagents and Materials

2.1 ASTM Standards:

6.1 Purity of Reagents—Use reagent grade chemicals in all

B1 Specification for Hard-Drawn Copper Wire

tests. Unless otherwise indicated, all reagents shall conform to

the specifications of the Committee on Analytical Reagents of

the American Chemical Society, where such specifications are

This test method is under the jurisdiction of ASTM Committee D27 on

available.

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

mittee D27.06 on Chemical Test.

Current edition approved Dec. 1, 2023. Published December 2023. Originally

approved in 1962. Last previous edition approved in 2015 as D2112 – 15. DOI: ACS Reagent Chemicals, Specifications and Procedures for Reagents and

10.1520/D2112-15R23. Standard-Grade Reference Materials, American Chemical Society, Washington,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or DC. For suggestions on the testing of reagents not listed by the American Chemical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

Standards volume information, refer to the standard’s Document Summary page on U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

the ASTM website. copeial Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2112 − 15 (2023)

and container to the nearest 0.1 g and record the weight. Wash

the coil by filling the container above the level of the coil with

10 % hydrochloric acid by volume for 30 s. Discard the acid

and rinse the coils three times with tap water followed by three

times with distilled water. Reweigh the coil and container and

determine by difference the water retained in the system. The

coils are now ready for use. This procedure has been found to

be acceptable for treatment of commercially available,

prepackaged, preformed coils that meet the requirement de-

scribed in this test method. Use a new coil for each test

specimen.

8.3 Cleaning of Vessel—Wash the vessel body, lid, and

inside of vessel stem with hot detergent solution and with

water. Rinse inside of stem with 2–propanol and blow dry with

clean dry air. An alternative cleaning solution is the use of a

50/50 volumetric blend of methanol and acetone; it has been

FIG. 1 Rotating Vessel Oxidation Test Apparatus

found to be effective in cleaning sludge from the vessel. If the

vessel body, lid, or inside of stem smells sour after simple

cleaning, wash with alcoholic KOH solution and repeat as

6.2 Hydrochloric Acid, 10 vol %.

before (see Note 1).

6.3 Silicon Carbide Abrasive Cloth, 100-grit with cloth

backing. NOTE 1—Insufficient cleaning of the vessel may adversely affect test

results.

6.4 Acetone, ACS grade.

6.5 2-Propanol, 99 vol %, refined.

9. Procedure

6.6 Liquid Detergent.

9.1 Charging—Weigh 50 g 6 0.5 g of oil sample into the

container, add 5 mL of distilled water, and cover with a 51 mm

6.7 Oxygen, 99.5 %, with pressure regulation above 620 kPa

(2-in.) watch glass or a 57.2 mm (2 ⁄4-in.) PTFE disk with one

(90 psi). (Warning—Oxygen vigorously accelerates combus-

or four holes and retaining spring. If rinse water is present in

tion.)

the container, compensate for it by using less added water

6.8 Potassium Hydroxide, Alcohol Solution (1 mass %)—

based on the water retention determined in 8.2. Add 5 mL of

Dissolve 7.93 g of potassium hydroxide (KOH) pellets in 1 L

distilled water to the vessel and slide the test specimen

of 99 % refined 2-propanol.

container and cover lid into the vessel body (see Note 2). Apply

6.9 Silicone Stopcock Grease.

a thin coating of silicone stopcock grease to the O-ring vessel

seal located in the gasket groove of the vessel lid to provide

6.10 Wire Catalyst—AWG No. 14 (approximately

lubrication, and insert the lid into the vessel body. Place the

1.628 mm diameter) electrolytic copper wire 99.9 % purity,

vessel cap over the vessel stem, and tighten by hand. Cover the

conforming to Specification B1. Soft-drawn copper wire of an

threads of the gauge-nipple with a thin coating of stopcock

equivalent grade may also be used.

grease or TFE-fluorocarbon, or both, and screw the gauge into

the top-center tap of the vessel stem. A pressure transducer can

7. Hazards

also be used. Flush the vessel twice with oxygen supplied to

7.1 Consult Safety Data Sheets for all materials used in this

the vessel at 620 kPa (90 psi) and release to the atmosphere.

test method.

Adjust the regulating valve on the oxygen supply tank to

620 kPa (90 psi) at a room temperature of 25 °C. For each

8. Preparation of Apparatus

2.8 °C above or below this temperature, add or subtract 7 kPa

8.1 Catalyst Preparation—Immediately before use, polish

(1 psi) unit to attain the required initial pressure. Fill the vessel

the copper wire with silicon carbide abrasive cloth and wipe

to this required pressure and close the inlet valve securely by

free from abrasives with a clean dry cloth. Wind approximately

hand. If desired, test the vessel for leaks by immersion in water

3 m of the wire into a coil having an outside diameter of 44 mm

(see Note 3). Prepare a duplicate test specimen in exactly the

to 48 mm and stretched to a height of 40 mm to 42 mm. Clean

same way.

the coil thoroughly with acetone and allow it to air-dry.

NOTE 2—The water between the vessel well and the test specimen

Immediately after air drying, insert the coil with a twisting

container aids heat transfer.

motion into the glass test specimen container. Handle the coil

NOTE 3—If the vessel was immersed in water to check for leaks, dry the

only with clean tongs to avoid contamination. Weigh the coil

outside of the wet vessel by any convenient means such as an air blast or

and the container to the nearest 0.1 g and record the weight.

a towel. Such drying is advisable to prevent subsequent introduction of

Prepare a new coil for each test specimen. free water into the hot oil bath, which would cause sputtering.

8.2 Alternative Method of Catalyst Preparation—Wind ap- 9.2 Oxidation—Bring the heating bath to the test tempera-

proximately 3 m of copper wire into a coil of the dimensions ture of 140 °C while the stirrer is in operation. Insert the

specified in 8.1, and add to the glass container. Weigh the coil vessels into the rotating carriages and note the time. If an

D2112 − 15 (2023)

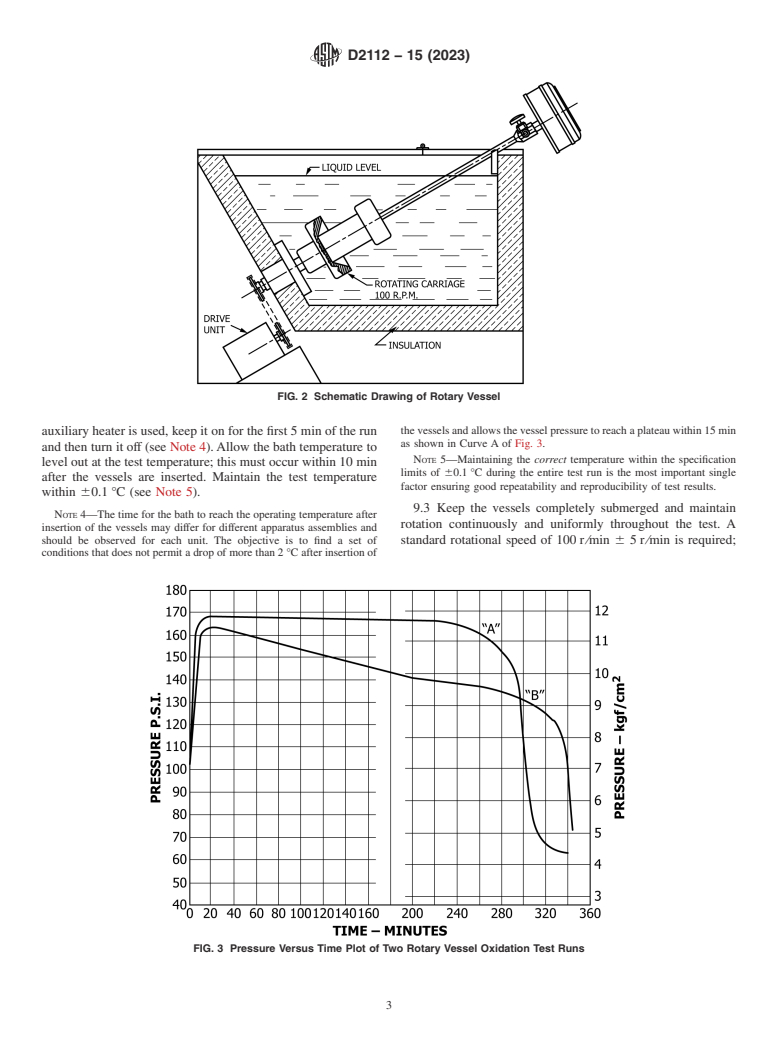

FIG. 2 Schematic Drawing of Rotary Vessel

the vessels and allows the vessel pressure to reach a plateau within 15 min

auxiliary heater is used, keep it on for the first 5 min of the run

as shown in Curve A o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.