ASTM E2726/E2726M-12

(Test Method)Standard Test Method for Evaluating the Fire-Test-Response of Deck Structures to Burning Brands

Standard Test Method for Evaluating the Fire-Test-Response of Deck Structures to Burning Brands

SIGNIFICANCE AND USE

This test method is intended to establish the test protocol for decking materials and systems. This test method is intended to address a fire caused by exterior sources that involves the upper surface of the deck or structure.

This test is a practical assessment of fire-test-response characteristics under a prescribed fire loading. This test method is a variation of Test Method E108.

SCOPE

1.1 This test method determines the fire-test-response characteristics of deck structures attached to or in close proximity to primary structures. The burning brand exposures test is intended to determine the surface spread of flame and degradation modes of decking materials when exposed to a burning brand on the upper surface of a deck structure.

1.2 The use of paints, coatings, stains, or other surface treatments for fire protection purposes are beyond the scope of this test method. This test method excludes the use of paints, stains, or coatings for this fire-test-response determination.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 Fire testing of products and materials is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2726/E2726M–12

Standard Test Method for

Evaluating the Fire-Test-Response of Deck Structures to

Burning Brands

ThisstandardisissuedunderthefixeddesignationE2726/E2726M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2898 Practice for Accelerated Weathering of Fire-

Retardant-Treated Wood for Fire Testing

1.1 This test method determines the fire-test-response char-

D6662 Specification for Polyolefin-Based Plastic Lumber

acteristics of deck structures attached to or in close proximity

Decking Boards

to primary structures. The burning brand exposures test is

D7032 Specification for Establishing Performance Ratings

intended to determine the surface spread of flame and degra-

for Wood-Plastic Composite Deck Boards and Guardrail

dation modes of decking materials when exposed to a burning

Systems (Guards or Handrails)

brand on the upper surface of a deck structure.

E84 Test Method for Surface Burning Characteristics of

1.2 The use of paints, coatings, stains, or other surface

Building Materials

treatments for fire protection purposes are beyond the scope of

E108 Test Methods for Fire Tests of Roof Coverings

this test method. This test method excludes the use of paints,

E176 Terminology of Fire Standards

stains, or coatings for this fire-test-response determination.

2.2 ICC Evaluation Services, Inc.:

1.3 The values stated in either SI units or inch-pound units

AC 109 Acceptance Criteria for Thermoplastic Composite

are to be regarded separately as standard. The values stated in

Lumber Products

each system may not be exact equivalents; therefore, each

AC 174 Acceptance Criteria for Deck Board Span Ratings

system shall be used independently of the other. Combining

and Guardrail Systems (Guards and Handrails)

values from the two systems may result in non-conformance

with the standard.

3. Terminology

1.4 This standard is used to measure and describe the

3.1 Definitions—For definitions of terms used in this test

response of materials, products, or assemblies to heat and

method, refer to Terminology E176.

flame under controlled conditions, but does not by itself

3.2 Definitions of Terms Specific to This Standard:

incorporate all factors required for fire-hazard or fire-risk

3.2.1 deck structure, n—exterior structures comprised of

assessment of the materials, products, or assemblies under

deck boards or panels, stair treads, risers, and landings of

actual fire conditions.

decks, porches, and balconies.

1.5 Fire testing of products and materials is inherently

3.2.2 test material, n—members that constitute the exposed

hazardous. Adequate safeguards for personnel and property

surface of the deck structures.

shall be employed in conducting these tests.

1.6 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 Thistestmethodisintendedtoestablishthetestprotocol

responsibility of the user of this standard to establish appro-

fordeckingmaterialsandsystems.Thistestmethodisintended

priate safety and health practices and determine the applica-

to address a fire caused by exterior sources that involves the

bility of regulatory limitations prior to use.

upper surface of the deck or structure.

4.2 This test is a practical assessment of fire-test-response

2. Referenced Documents

characteristicsunderaprescribedfireloading.Thistestmethod

2.1 ASTM Standards:

is a variation of Test Method E108.

5. Test Apparatus

This test method is under the jurisdiction of ASTM Committee E05 on Fire

5.1 The essential elements of the fire test apparatus are

Standards and is the direct responsibility of Subcommittee E05.14 on External Fire

Exposures. illustrated in Fig. 1. They include a test deck, an adjustable

Current edition approved Jan. 1, 2012. Published January 2012. DOI:10.1520/

frame on which the test deck is mounted, a wind tunnel, an air

E2726_E2726M–12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from International Code Council Evaluation Service, 5600 Workman

the ASTM website. Mill Road, Whittier, CA.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2726/E2726M–12

FIG. 1 Deck Structure Test Specimen and Test Apparatus (Burning-Brand)

velocity meter with or without the use of a timing device and test material’s individual deck board width; the length of the

an adjustable air supply. During the test: test material shall be 610 64mm[24 6 ⁄16 in.].

5.1.1 Providefreeoutlettooutsideairbeyondandabovethe 6.3 Joists—The test material shall be supported by two

test apparatus to exhaust air introduced into the test room by nominal 50 by 150 mm [2 by 6-in.] joists running perpendicu-

the blower, and

lar to the test material’s deck boards with a 406 64mm[16

5.1.2 Close all openings into the test room other than those in.]center-to-centerspacing,creatinga90 64mm[3.5 60.16

mentioned in 5.1.1, such as doors and windows.

in.] overhang on the outer side of each edge joist. Joist length

5.2 The temperature of the air supplied by the blower shall shall meet the requirements specified in 6.2.

be maintained between 10 and 32°C [50 and 90°F].

6.4 Test Material:

5.3 Wind Tunnel (see Fig. 1)—The wind tunnel shall deliver 6.4.1 All test materials shall be representative of the as-

5.3 6 0.2 m/s [12 6 0.5 mph] airflow at zero incline over the

manufactured product including the cross sectional dimen-

width of the test specimen. Test Method E108 Burning Brand sions.

Roof Test apparatus shall be used, with the following modifi-

6.4.2 Test material shall be sampled to meet the intended

cations: end-use of the test data.

5.3.1 Test Specimen Support—The test specimen shall be

6.4.3 Prior to testing, all test material and joists shall be

supported horizontally with its leading edge 838.2 mm [33 in.] conditioned to a constant weight or for a minimum of 30 days

from the front opening of the wind tunnel with the joists

at21 62°C[70 64°F]and50%RH 65%,whichevercomes

parallel to the airflow and resting on two transverse metal first. Constant weight shall be defined as a change in test

supports. The top surfaces of these supports, which shall be no

material weight less than or equal to2%ina 24-h period.

more than 76 mm [3 in.] wide, are at the same height as the 6.4.4 Edge-to-edge spacing and method of attachment shall

floor of the wind tunnel.

conform to the manufacturer’s installation recommendations.

5.3.2 Fragments—Burning fragments shall be free to fall to The test material shall be flush with the ends of the joists at the

the floor of the room.

front of the test specimen (that is, the edge of the test specimen

5.4 Anemometer—A device for measuring airflow across

facing the front opening of the wind tunnel). Test material at

the deck shall be provided.

the back of the test specimen (that is, the edge of the test

specimen furthest away from the front opening of the wind

NOTE 1—Any direct reading instrument with scale graduated in incre-

tunnel) manufactured with tongue-and-groove edge connec-

ments of not more than 6 m/min [20 ft/min] or any timed instrument with

tions shall be spaced and attached according to the manufac-

scalegraduated(fora1mintimedreading)inincrementsofnotmorethan

1.5 m/min (5 ft/min) will be suitable. turer’s recommendations.

5.5 Burner—Gas-fueled burner for brand ignition. The

7. Calibration

flame temperature of the igniting flame shall be 888 6 28°C

[1630 6 50°F] measured 59 mm [2 ⁄16 in.] above the top of the 7.1 Calibrating Air Current:

burner, which is shielded from drafts. 7.1.1 Set up the test apparatus and position a smooth deck,

1.3 m [4 ft-4 in.] long on the framework at a 127 mm per 304.8

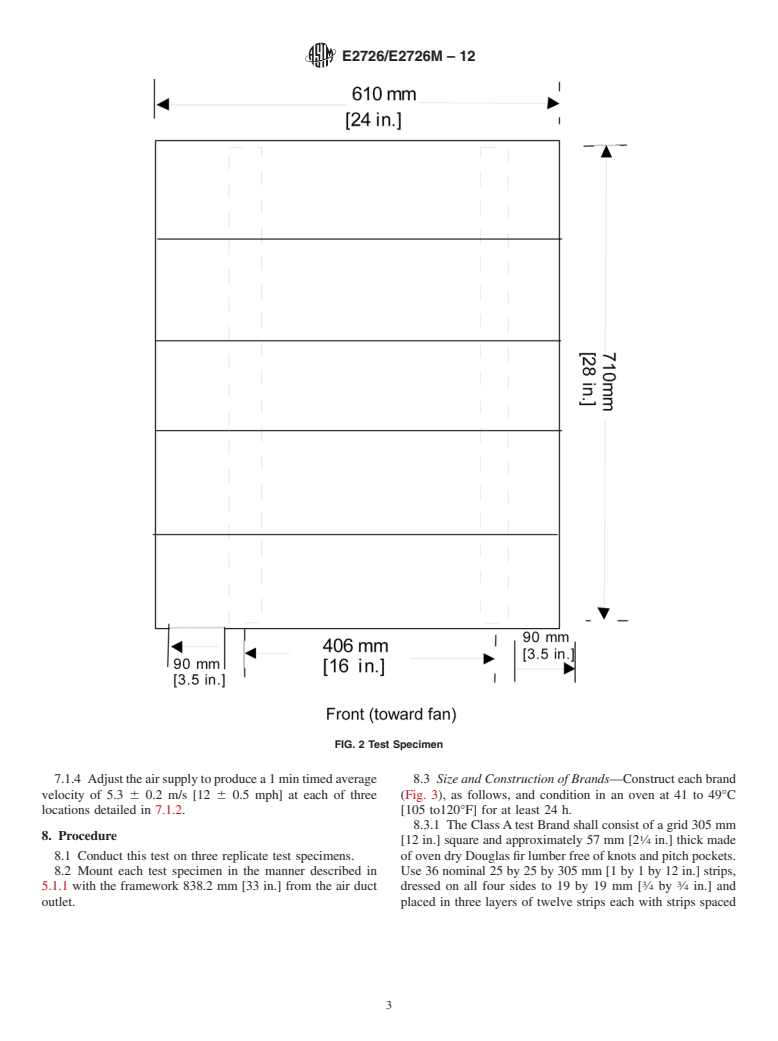

6. Test Specimens (see Fig. 2)

mm [5 in. per 12 in.] horizontal incline.

6.1 The test specimen shall consist of joists as specified in 7.1.2 Measure the air velocity at the center and 76 mm [3

6.3 and test material as specified in 6.4. in.] from the edges of the deck.

6.2 Test Specimen Size—The overall size of the test speci- 7.1.3 Position the center of the air measuring device 95 6 3

3 1

men shall be nominally 610 by 710 mm [24 by 28 in.]. The mm [3 ⁄4 6 ⁄8 in.] above the surface. The air flow through and

overalltestspecimenlength(thatis,directionofjoists)shallbe around the instrument shall be as free and undisturbed as

710 6 51 mm [28 6 2 in.] to accommodate variations in the possible.

E2726/E2726M–12

FIG. 2 Test Specimen

7.1.4 Adjusttheairsupplytoproducea1mintimedaverage 8.3 Size and Construction of Brands—Construct each brand

velocity of 5.3 6 0.2 m/s [12 6 0.5 mph] at each of three (Fig. 3), as follows, and condition in an oven at 41 to 49°C

locations detailed in 7.1.2. [105 to120°F] for at least 24 h.

8.3.1 The ClassAtest Brand shall consist of a grid 305 mm

8. Procedure

[12 in.] square and approximately 57 mm [2 ⁄4 in.] thick made

8.1 Conduct this test on three replicate test specimens. of oven dry Douglas fir lumber free of knots and pitch pockets.

8.2 Mount each test specimen in the manner described in Use 36 nominal 25 by 25 by 305 mm [1 by 1 by 12 in.] strips,

3 3

5.1.1 with the framework 838.2 mm [33 in.] from the air duct dressed on all four sides to 19 by 19 mm [ ⁄4 by ⁄4 in.] and

outlet. placed in three layers of twelve strips each with strips spaced

E2726/E2726M–12

FIG. 3 Class A & B Brands

1 1

6.35mm[ ⁄4in.]apart.Placethesestripsatrightanglestothose by 152-mm [6 by 6-in.] face for 30 s, each 57 by 152-mm [2 ⁄4

in adjoining layers and nail (Note 2) at each end of each strip by 6-in.] face for 30 s, and each 152 by 152-mm [6 by 6-in.]

on one face (Fig. 3). The dry weight of the finished brand shall face again for 30 s.

be 2000 6 150 g at the time of test.

8.5 Brand Placement:

8.3.2 The Class B test brand shall consist of a grid 152 mm

8.5.1 Class A Brand—Place a brand on the surface of each

[6in.]squareandapproximately57mm[2 ⁄4in.]thickmadeof

test deck at the location considered most vulnerable (point of

dry Douglas fir lumber free of knots and pitch pockets. Use 18

minimum coverage over deck joint) with respect to ignition of

nominal 25 by 25 by 152 mm [1 by 1 by 6 in.] strips, dressed

the deck but in no case closer than 101 mm [4 in.] from either

3 3

on all four sides to 19 by 19 mm [ ⁄4 by ⁄4 in.], and placed in

sideor305mm[12in.]fromtheedgeofthedeckclosesttothe

three layers of six strips each with strips spaced 6.35 mm ([ ⁄4

wind source. Place the brand so that the strips in both the upper

in.]apart.Placethesestripsatrightanglestothoseinadjoining

and bottom layers are parallel to the direction of air flow and

layers and nail (Note 2) at each end of each strip on one face

with the upper edge of the brand located 76 mm [3 in.] above

(Fig. 3). The dry weight of the finished brand shall be 500 6

thehorizontaljointinthetestdeck.SecuretothedeckbyaNo.

150 g at the time of test.

18B&S gage soft iron wire.

8.5.2 Class B Brand—Place a brand on the surface of the

NOTE 2—NailsusedintheconstructionofClassAandBbrandsareNo.

test deck at the location considered most vulnerable (point of

16, 38 mm [1 ⁄2 in.] long bright, flat head, diamond point, wire nails. 68

nails weighing approximately 42 g are used for Class A brand. 32 nails

minimum coverage over deck joint) with respect to ignition of

weighing approximately 21 g are used for Class B brand. 1

the deck. Position the brand with its upper edge 38 mm [1 ⁄2

in.] above the selected joint in the deck boards, but in no case

8.4 Ignition of Brand—Before application to the test speci-

closer than 152 mm [6 in.] from each side or 305 mm [12 in.]

men, the brand shall be ignited by subjecting it, for the

from the edge of the deck closest to the wind source. Place the

following required periods of time, to the flame of a gas burner

brand so that the bottom layers are parallel to the direction of

of such size that, during the process of ignition, the brands are

air flow. Secure to the deck by a 1.02 mm [No. 18B&S gage]

enveloped in the burner flame. The flame temperature of the

soft iron wire.

igniting flame shall be 888 6 28°C [1630 6 50°F] measured

8.6 Duration of Test—Continuetheexposureuntilthebrand

59 mm [2 ⁄16 in.] above the top of the burner, which is shielded

is totally consumed and until all evidence of flame, glow and

from drafts.

smoke has disappeared from both the exposed surface of the

8.4.1 Expose Class A test brand to the flame for 5 min,

test material and the underside of the test material, but not for

during which time it shall be rotated to present each surface to

more than 1 ⁄2 h. Disregard the results of tests in which the

the flame in the following manner and sequence: Each 305 by

brand does not show progressive and substantially complete

305-mm [12 by 12-in.] face for 30 s, each 57 by 305-mm [2 ⁄4

consumption after application to the test specimen. If results

by 12-in.] face for 45 s, and each 305 by 305-mm [12 by

are disregarded, the procedure shall be repeated using a new

12-in.] face again for 30 s.

test specimen.

8.4.2 Expose Class B test brand to the flame for 4 min,

during which time they shall be rotated to present each surface 8.7 Recordthefurthestdistancetowhichflaminghasspread

to the flame in the following manner and sequence: Each 152 as measured by the furthest extent of the char to a depth of 3

E2726/E2726M–12

mm [0.125 in.]. This measurement shall be in centimeters 10.1.1 Description of the test material, the test specimen

[inches] from the front edge of the test specimen. including construction details of the application of the test

8.8 Observations—During and after the burning brand test, material to the joists.

observe for deformation from the horizontal plane, location of 10.1.2 Storage conditions of test specimens,

flaming or glowing combustion, displacement of the test 10.1.3 Describe the pre-test accelerated aging / weathering

material, flaming drops or particles falling from the deck that procedure and exposure used (if applicable),

continue to burn on the floor and any generated flying brands, 10.1.4 Moisture content of the test specimen at the time of

and flaming or smoke at the end of 1 ⁄2 h test period.The entire testing,

test shall be recorded with a video or digital recorder to allow 10.1.5 Details of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.