ASTM B250/B250M-16

(Specification)Standard Specification for General Requirements for Wrought Copper Alloy Wire

Standard Specification for General Requirements for Wrought Copper Alloy Wire

ABSTRACT

This specification establishes the general requirements common to wrought copper and copper alloy wires. The materials for manufacture shall be a cast bar, billet, rod, or other form of such purity and soundness as to be suitable for processing by hot working, cold working, and subsequent annealing to produce finished products that meet the specified temper properties and have a uniform wrought structure. Products shall be sampled and prepared, then tested accordingly to examine their conformance to dimensional (diameter, thickness, specific and stock lengths, width, straightness, and edge contour), mechanical (tensile, yield and bend strengths, elongation, and Rockwell hardness), electrical (resistivity and conductivity), chemical composition, and grain size requirements. In the event of conflict between this specification and the individual casting product specifications, the requirements of the casting specification shall take precedence.

SIGNIFICANCE AND USE

12.1 For the purpose of determining compliance with the specified limits for requirements of the properties listed in the following table, an observed value or calculated value shall be rounded as indicated in accordance with the rounding method of Practice E29.

Property

Rounded Unit for Observed

or Calculated Value

Dimensions

Chemical composition

Hardness

Electrical resistivity/conductivity

nearest unit in the last

right-hand significant

digit used in expressing

the limiting value

Tensile strength

Yield strength

nearest ksi [5 MPa]

Elongation

Below 5 %

nearest multiple of 0.5 %

5 % and over

nearest 1 %

Grain size

Under 0.060 mm

nearest multiple of 0.005 mm

0.060 mm and over

nearest 0.01 mm

SCOPE

1.1 This specification establishes requirements common to wrought copper and copper alloy wire and shall apply to Specifications B16/B16M, B99/B99M, B134/B134M, B159/B159M, B197/B197M, B206/B206M, B272, B301/B301M, B453/B453M, B967/B967M, and B974/B974M to the extent referenced therein.

1.2 The chemical composition, physical and mechanical properties, and all other requirements not included in this specification shall be prescribed in the product specification.

1.3 Units—Values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B250/B250M −16

Standard Specification for

1

General Requirements for Wrought Copper Alloy Wire

This standard is issued under the fixed designation B250/B250M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B159/B159MSpecification for Phosphor Bronze Wire

B193Test Method for Resistivity of Electrical Conductor

1.1 This specification establishes requirements common to

Materials

wrought copper and copper alloy wire and shall apply to

B194SpecificationforCopper-BerylliumAlloyPlate,Sheet,

Specifications B16/B16M, B99/B99M, B134/B134M, B159/

Strip, and Rolled Bar

B159M, B197/B197M, B206/B206M, B272, B301/B301M,

B197/B197M Specification for Copper-Beryllium Alloy

B453/B453M, B967/B967M, and B974/B974M to the extent

Wire

referenced therein.

B206/B206MSpecification for Copper-Nickel-Zinc (Nickel

1.2 The chemical composition, physical and mechanical

Silver) Wire and Copper-Nickel Alloy Wire

properties, and all other requirements not included in this

B272Specification for Copper Flat Products with Finished

specification shall be prescribed in the product specification.

(Rolled or Drawn) Edges (Flat Wire and Strip)

B301/B301MSpecification for Free-Cutting Copper Rod,

1.3 Units—Values stated in either SI units or inch-pound

units are to be regarded separately as standard.Within the text, Bar, Wire, and Shapes

B453/B453M Specification for Copper-Zinc-Lead Alloy

SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system (Leaded-Brass) Rod, Bar, and Shapes

B846Terminology for Copper and Copper Alloys

shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the B900Practice for Packaging of Copper and Copper Alloy

Mill Products for U.S. Government Agencies

standard.

B967/B967M Specification for Copper-Zinc-Tin-Bismuth

1.4 The following safety hazard caveat pertains only to the

Alloy Rod, Bar and Wire

testmethodsdescribedinthisspecification.Thisstandarddoes

B974/B974MSpecification for Free-Cutting Bismuth Brass

not purport to address all of the safety concerns, if any,

Rod, Bar and Wire

associatedwithitsuse.Itistheresponsibilityoftheuserofthis

E3Guide for Preparation of Metallographic Specimens

standard to establish appropriate safety and health practices

E8/E8MTest Methods for Tension Testing of Metallic Ma-

and to determine the applicability of regulatory limitations

terials

prior to use.

E18Test Methods for Rockwell Hardness of Metallic Ma-

terials

2. Referenced Documents

2 E29Practice for Using Significant Digits in Test Data to

2.1 ASTM Standards:

Determine Conformance with Specifications

B16/B16MSpecification for Free-Cutting Brass Rod, Bar

E54Test Methods for ChemicalAnalysis of Special Brasses

and Shapes for Use in Screw Machines

3

and Bronzes (Withdrawn 2002)

B99/B99MSpecification for Copper-Silicon Alloy Wire for

E62Test Methods for Chemical Analysis of Copper and

General Applications

3

CopperAlloys(PhotometricMethods)(Withdrawn2010)

B134/B134MSpecification for Brass Wire

E75Test Methods for Chemical Analysis of Copper-Nickel

3

and Copper-Nickel-Zinc Alloys (Withdrawn 2010)

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

E112Test Methods for Determining Average Grain Size

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

E118 Test Methods for Chemical Analysis of Copper-

Bar, Wire, Shapes and Forgings.

3

Chromium Alloys (Withdrawn 2010)

Current edition approved Oct. 1, 2016. Published October 2016. Originally

E121Test Methods for Chemical Analysis of Copper-

approved in 1951. Last previous edition approved in 2013 as B250/B250M–13.

3

DOI: 10.1520/B0250_B0250M-16.

Tellurium Alloys (Withdrawn 2010)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B250/B250M−16

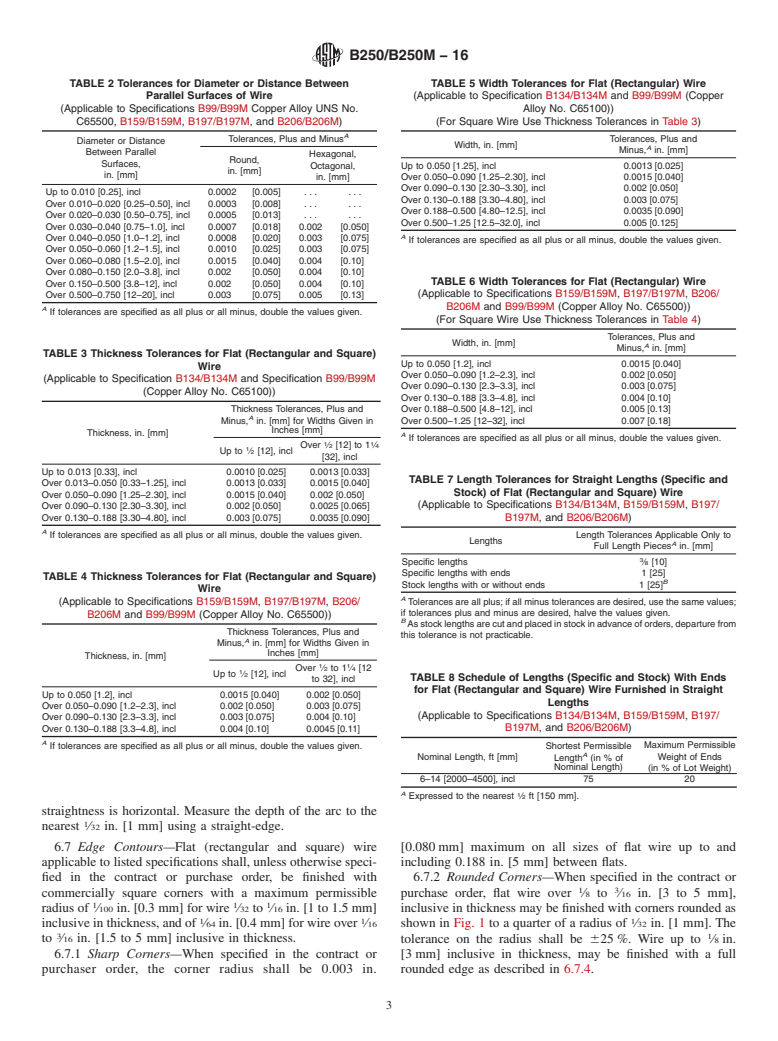

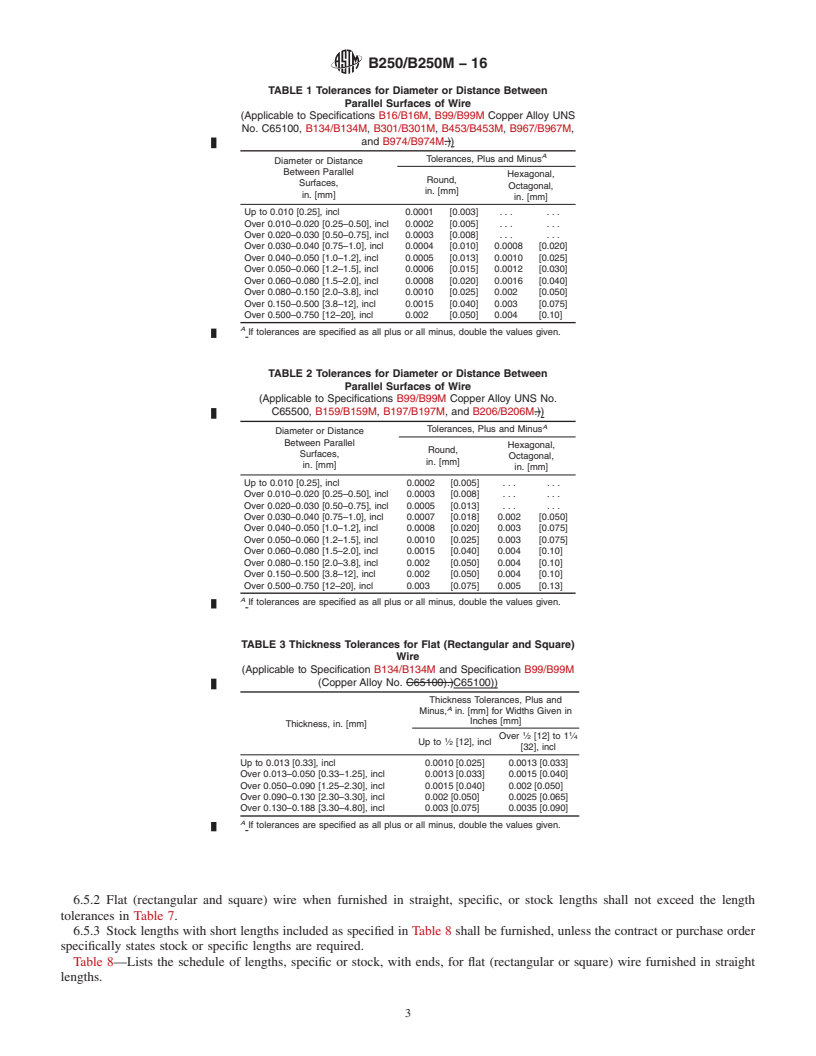

NOTE 2—Blank spaces in the tolerance tables indicate either that the

E255Practice for Sampling Copper and Copper Alloys for

product is not generally available or that no tolerances have

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B250/B250M − 13 B250/B250M − 16

Standard Specification for

1

General Requirements for Wrought Copper Alloy Wire

This standard is issued under the fixed designation B250/B250M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification establishes requirements common to wrought copper and copper alloy wire and shall apply to

Specifications B16/B16M, B99/B99M, B134/B134M, B159/B159M, B197/B197M, B206/B206M, B272, B301/B301M, B453/

B453M, B967/B967M, and B974/B974M to the extent referenced therein.

1.2 The chemical composition, physical and mechanical properties, and all other requirements not included in this specification

shall be prescribed in the product specification.

1.3 Units—Values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 The following safety hazard caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B16/B16M Specification for Free-Cutting Brass Rod, Bar and Shapes for Use in Screw Machines

B99/B99M Specification for Copper-Silicon Alloy Wire for General Applications

B134/B134M Specification for Brass Wire

B159/B159M Specification for Phosphor Bronze Wire

B193 Test Method for Resistivity of Electrical Conductor Materials

B194 Specification for Copper-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar

B197/B197M Specification for Copper-Beryllium Alloy Wire

B206/B206M Specification for Copper-Nickel-Zinc (Nickel Silver) Wire and Copper-Nickel Alloy Wire

B272 Specification for Copper Flat Products with Finished (Rolled or Drawn) Edges (Flat Wire and Strip)

B301/B301M Specification for Free-Cutting Copper Rod, Bar, Wire, and Shapes

B453/B453M Specification for Copper-Zinc-Lead Alloy (Leaded-Brass) Rod, Bar, and Shapes

B846 Terminology for Copper and Copper Alloys

B900 Practice for Packaging of Copper and Copper Alloy Mill Products for U.S. Government Agencies

B967/B967M Specification for Copper-Zinc-Tin-Bismuth Alloy Rod, Bar and Wire

B974/B974M Specification for Free-Cutting Bismuth Brass Rod, Bar and Wire

E3 Guide for Preparation of Metallographic Specimens

E8/E8M Test Methods for Tension Testing of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3

E54 Test Methods for Chemical Analysis of Special Brasses and Bronzes (Withdrawn 2002)

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.02 on Rod, Bar,

Wire, Shapes and Forgings.

Current edition approved April 1, 2013Oct. 1, 2016. Published April 2013October 2016. Originally approved in 1951. Last previous edition approved in 20122013 as

B250 – 12.B250/B250M–13. DOI: 10.1520/B0250_B0250M-13. 10.1520/B0250_B0250M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B250/B250M − 16

3

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods) (Withdrawn 2010)

3

E75 Test Methods for Chemical Analysis of Copper-Nickel and Copper-Nickel-Zinc Alloys (Wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.