ASTM E2925-14

(Specification)Standard Specification for Manufactured Polymeric Drainage and Ventilation Materials Used to Provide a Rainscreen Function

Standard Specification for Manufactured Polymeric Drainage and Ventilation Materials Used to Provide a Rainscreen Function

ABSTRACT

This specification covers the requirements and corresponding test methods for manufactured polymeric materials used to provide a rainscreen function, a means for the drainage of liquid moisture and the ventilation of vapor moisture that enters an above-grade exterior wall assembly. Rainscreen materials that conform to this specification are intended to be used behind exterior cladding products and to cover the entire wall area that is designed to provide a rainscreen function to resist water infiltration. Three types of rainscreen materials are addressed: Type A (entangled mesh materials), Type B (formed/textured sheet material), and Type C (formed battens). This specification also covers descriptions of the materials and material composition; material properties and material performance requirements; specimen preparation; reporting requirements; marking and labeling; and packaging and package marking. A table presents the requirements for ventilation/airflow, drainage, thickness, compression, strength, UV exposure, heat aging, mold/fungal growth, and water exposure.

SCOPE

1.1 This specification is applicable to manufactured polymeric materials used to provide a rainscreen function, a means for the drainage of liquid moisture and the ventilation of vapor moisture that enters an above-grade exterior wall assembly. Rainscreen materials that comply with this specification are intended to be used behind exterior cladding products and intended to cover one hundred percent (100 %) of the wall area that is designed to provide a rainscreen function to resist water infiltration.

1.2 This specification addresses the following types of rainscreen materials:

1.2.1 Type A—entangled mesh materials.

1.2.2 Type B—formed/textured sheet material.

1.2.3 Type C—formed battens.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2925 −14

Standard Specification for

Manufactured Polymeric Drainage and Ventilation Materials

Used to Provide a Rainscreen Function

This standard is issued under the fixed designation E2925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5322 Practice for Laboratory Immersion Procedures for

Evaluating the Chemical Resistance of Geosynthetics to

1.1 This specification is applicable to manufactured poly-

Liquids

meric materials used to provide a rainscreen function, a means

D6108 Test Method for Compressive Properties of Plastic

for the drainage of liquid moisture and the ventilation of vapor

Lumber and Shapes

moisture that enters an above-grade exterior wall assembly.

D6364 Test Method for Determining Short-Term Compres-

Rainscreen materials that comply with this specification are

sion Behavior of Geosynthetics

intended to be used behind exterior cladding products and

E84 Test Method for Surface Burning Characteristics of

intendedtocoveronehundredpercent(100 %)ofthewallarea

Building Materials

that is designed to provide a rainscreen function to resist water

E283 Test Method for Determining Rate of Air Leakage

infiltration.

Through Exterior Windows, Curtain Walls, and Doors

1.2 This specification addresses the following types of

Under Specified Pressure Differences Across the Speci-

rainscreen materials:

men

1.2.1 Type A—entangled mesh materials.

E631 Terminology of Building Constructions

1.2.2 Type B—formed/textured sheet material.

E2273 Test Method for Determining the Drainage Efficiency

1.2.3 Type C—formed battens.

of Exterior Insulation and Finish Systems (EIFS) Clad

1.3 The values stated in SI units are to be regarded as Wall Assemblies

E2556/E2556M Specification for Vapor Permeable Flexible

standard. No other units of measurement are included in this

standard. Sheet Water-Resistive Barriers Intended for Mechanical

Attachment

1.4 This standard does not purport to address all of the

G154 Practice for Operating Fluorescent Ultraviolet (UV)

safety concerns, if any, associated with its use. It is the

Lamp Apparatus for Exposure of Nonmetallic Materials

responsibility of the user of this standard to establish appro-

2.2 Other Standard:

priate safety and health practices and determine the applica-

CAN/CGSB 51.33-M89 Vapor Barrier Sheet, Excluding

bility of regulatory limitations prior to use.

Polyethylene, for Use in Building Construction

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions—For definitions of general terms related to

C578 Specification for Rigid, Cellular Polystyrene Thermal

building construction used in this specification, refer to Termi-

Insulation

nology E631.

C1338 Test Method for Determining Fungi Resistance of

3.2 Definitions of Terms Specific to This Standard:

Insulation Materials and Facings

3.2.1 capillary action, v—liquid water movement against

D3045 Practice for Heat Aging of Plastics Without Load

gravity induced by the force of molecular attraction (surface

D5199 Test Method for Measuring the Nominal Thickness

tension) between the water and the material it contacts,

of Geosynthetics

facilitated by a small gap between materials.

3.2.2 exterior cladding, n—weather-exposed materials of a

This specification is under the jurisdiction of ASTM Committee E06 on

wall assembly including but not limited to siding, stucco,

Performance of Buildings and is the direct responsibility of Subcommittee E06.55

on Performance of Building Enclosures.

masonry veneer, but excluding fenestration (doors and win-

Current edition approved June 1, 2014. Published June 2014. DOI: 10.1520/

dows).

E2925–14

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Canadian General Standards Board, Place du Portage III, 6B1,

Standards volume information, refer to the standard’s Document Summary page on 11 Laurier Street, Gatineau, Quebec K1A 1G6 Canada, http://www.tpsgc-

the ASTM website. pwgsc.gc.ca/ongc-cgsb.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2925−14

3.2.3 mortar screen, n—layer of material designed to pre- 6.6.1 The test specimens shall be heat aged in accordance

vent mortar from entering the drainage space. with Practice D3045 at a temperature of (77 6 3)°C for 90

days.

3.2.4 polymeric, n—materials composed primarily of poly-

6.6.2 After the heat aging test has been completed, the

mers.

thickness test (6.3) and the compression test (6.4) shall be

3.2.5 polymeric rainscreen material, n—material intended

repeated.

to be installed behind exterior cladding products which creates

6.7 Mold and Fungi Resistance:

a drainage and ventilation space for liquid and vapor moisture

6.7.1 The specimens shall be tested in accordance with Test

that enters an above-grade exterior wall assembly reducing

Method C1338 for 28 days exposure.

water transfer to the water resistive barrier (WRB).

6.8 Water Exposure:

3.2.6 rainscreen space, n—separationbehindthecladdingin

6.8.1 The specimens with dimensions (250 6 2) mm by

the wall assembly intended to inhibit capillary action and

(250 6 2) mm shall be immersed in water in accordance with

moisture bridging as well as to promote ventilation and the

Practice D5322 using tap water at (50 6 2)°C for 168 h.

drainage of moisture.

6.8.2 After the water exposure test has been completed and

3.2.7 water-resistive barrier (WRB), n—material that is

within one hour of removal from the water, the compression

intended to resist liquid water that has penetrated the cladding

test (6.4) shall be repeated.

system.

6.9 Flame Spread Test (Optional):

4. Classification

6.9.1 When desired, the material shall be tested in accor-

dance with Test Method E84 for flame spread.

4.1 Type A—entangled mesh materials.

6.10 Freeze-Thaw (Optional):

4.2 Type B—formed/textured sheet material.

6.10.1 The freeze-thaw exposure shall be conducted in

4.3 Type C—formed battens.

accordance with the aging procedure of Section 8.3.2.1 of

CAN/CGSB 51.33-M89.

5. Materials and Manufacture

6.10.2 After the freeze thaw exposure test has been com-

5.1 Description of the material composition and structure

pleted and within one hour of the completion of the test, the

shall be made available upon request.

compression test (6.4) shall be repeated.

5.1.1 Descriptions of the materials shall include roll or

package weight and dimensions.

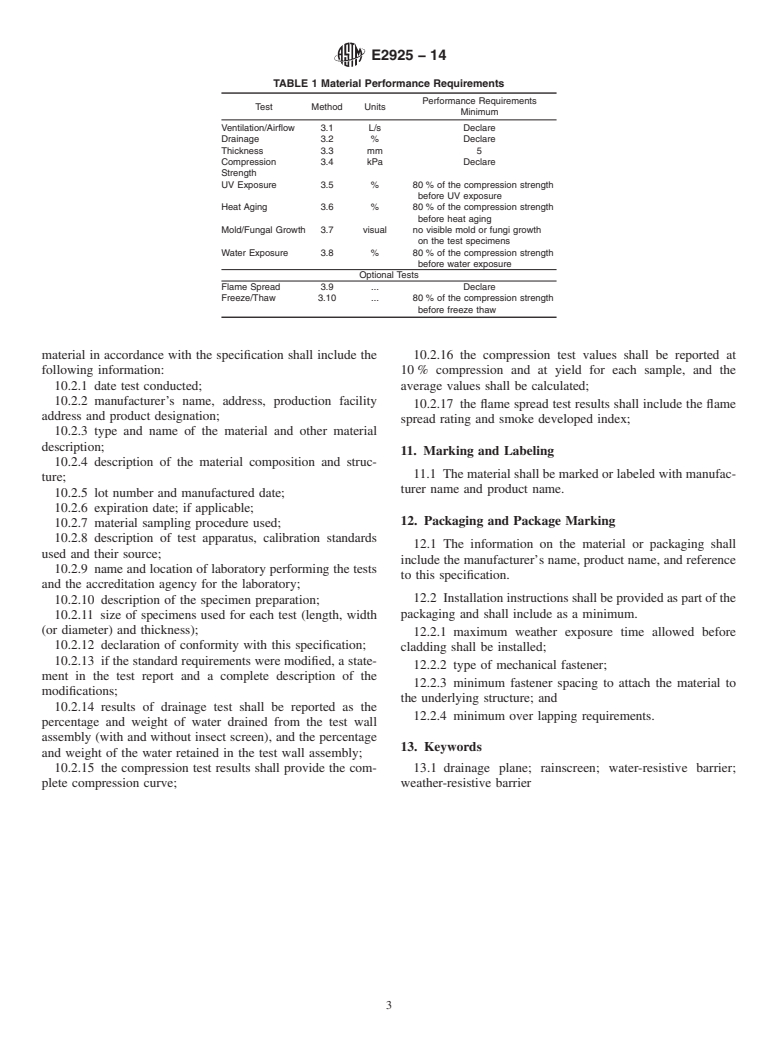

7. Material Performance Requirements

5.1.2 Descriptions of the material composition shall include

7.1 All materials shall provide the minimum performance

linear density (basis weight).

requirements listed in Table 1.

5.1.3 All materials claiming compliance with this specifica-

tion shall be described in such statements as described in all

8. Sampling

applicable test reports.

8.1 The material to be tested for conformance to this

specification shall be taken directly from a randomly selected

6. Material Properties

roll or package which is representative of the commercial

6.1 Ventilation/Airflow Test:

product.

6.1.1 The airflow rate shall be measured in accordance with

9. Specimen Preparation

Annex A1.

6.2 Drainage Test: 9.1 The specimens from roll materials shall be cut from the

6.2.1 The drainage test shall be conducted in accordance interior of the sample roll so that no specimen edge is nearer

with Annex A2. than 75 mm to the original roll edge.

6.3 Thickness Test: 9.2 Unlessotherwisestatedinthetestmethod,allspecimens

6.3.1 The thickness shall be measured in accordance with shall be conditioned for a minimum period of 40 h at (23 6

Test Method D5199 at 0.20 kPa. 2)°C and (50 6 10) % relative humidity (RH).

6.4 Compression Test: 9.3 The specimen size shall be determined by the test

6.4.1 The compressive strength for Type A and B shall be method.

determined in accordance with Test Method D6364 at 10 %

9.4 If not otherwise specified in the referenced test method,

compression and at full yield (if yield occurs).

a minimum of five specimens shall be tested and each

6.4.2 The compressive strength for Type C shall be deter-

specimen shall meet the minimum performance requirements.

mined in accordance with Test Method D6108.

10. Reporting Requirements

6.5 UV Exposure Test:

6.5.1 The test specimens shall be exposed in accordance 10.1 Report required and declared test data in the form of a

with Practice G154 following Cycle 1 for 336 h. table(s) with property, result and pass/fail status including

6.5.2 After the UV exposure test has been completed, the results for all properties tested.

compression test (6.4) shall be repeated.

10.2 In addition to the information specified in the indi-

6.6 Heat Aging: vidual test methods, all reports describing the testing of the

E2925−14

TABLE 1 Material Performance Requirements

Performance Requirements

Test Method Units

Minimum

Ventilation/Airflow 3.1 L/s Declare

Drainage 3.2 % Declare

Thickness 3.3 mm 5

Compression 3.4 kPa Declare

Strength

UV Exposure 3.5 % 80 % of the compression strength

before UV exposure

Heat Aging 3.6 % 80 % of the compression strength

before heat aging

Mold/Fungal Growth 3.7 visual no visible mold or fungi growth

on the test specimens

Water Exposure 3.8 % 80 % of the compression strength

before water exposure

Optional Tests

Flame Spread 3.9 . Declare

Freeze/Thaw 3.10 . 80 % of the compression strength

before freeze thaw

material in accordance with the specification shall include the 10.2.16 the compression test values shall be reported at

following information: 10 % compression and at yield for each sample, and the

10.2.1 date test conducted; average values shall be calculated;

10.2.2 manufacturer’s name, address, production facility

10.2.17 the flame spread test results shall include the flame

address and product designation;

spread rating and smoke developed index;

10.2.3 type and name of the material and other material

description;

11. Marking and Labeling

10.2.4 description of the material composition and struc-

11.1 The material shall be marked or labeled with manufac-

ture;

turer name and product name.

10.2.5 lot number and manufactured date;

10.2.6 expiration date; if applicable;

12. Packaging and Package Marking

10.2.7 material sampling procedure used;

10.2.8 description of test apparatus, calibration standards

12.1 The information on the material or packaging shall

used and their source;

include the manufacturer’s name, product name, and reference

10.2.9 name and location of laboratory performing the tests

to this specification.

and the accreditation agency for the laboratory;

12.2 Installation instructions shall be provided as part of the

10.2.10 description of the specimen preparation;

packaging and shall include as a minimum.

10.2.11 size of specimens used for each test (length, width

(or diameter) and thickness);

12.2.1 maximum weather exposure time allowed before

10.2.12 declaration of conformity with this specification;

cladding shall be installed;

10.2.13 if the standard requirements were modified, a state-

12.2.2 type of mechanical fastener;

ment in the test report and a complete description of the

12.2.3 minimum fastener spacing to attach the material to

modifications;

the underlying structure; and

10.2.14 results of drainage test shall be reported as the

12.2.4 minimum over lapping requirements.

percentage and weight of water drained from the test wall

assembly (with and without insect screen), and the percentage

13. Keywords

and weight of the water retained in the test wall assembly;

10.2.15 the compression test results shall provide the com- 13.1 drainage plane; rainscreen; water-resistive barrier;

plete compression curve; weather-resistive barrier

E2925−14

ANNEXES

(Mandatory Information)

A1. DRAINAGE AND VENTILATION/AIRFLOW TEST

A1.1 Objective rainscreen material manufacturer’s instructions. The instruc-

tions shall include the perimeter conditions (that is, flashing/

A1.1.1 The objective of this test is to measure the assem-

assembly details at the top and bottom of the wall assembly).

bly’s ability to allow for ventilation from the bottom of the

The sides of the test apparatus shall be completely sealed to

specimen up and behind the cladding. Due to the design of the

restrict air from being able to exit out the sides during the

test apparatus, a separate specimen; other than that which is

ventilation testing.

tested for drainage, shall be permitted to be tested.The air flow

testing procedure is designed to determine the amount of

A1.2.3 If required by the rainscreen material manufacturer,

airflow under a range of relatively low air pressure differences

a mortar screen shall be installed where the rainscreen material

in a wall cavity created by the rainscreen material, over the

is used behind adhered masonry or cement plaster (stucco)

height of a wall, which are understood to be in the range of 1

cladding systems.

to 10 Pa under most natural exposure conditions.

A1.2.4 Where the rainscreen material can be installed with

an insect screen at the top and/or bottom, the test apparatus

A1.2 Test Apparatus

shall be tested with and without the insect screen(s).

A1.2.1 Construct one 1200 mm by 2400 mm test wall

A1.2.5 Install a 1200 mm by 2400 mm by 50 mm thick

assemblycomprisedof50mmby100mm(nominal)perimeter

(nominal) extruded polystyrene (XPS) foam insulation board

framingand50mmby100mm(nominal)framingverticallyat

complying with Specification C578 to the exterior side of the

400 mm on center. Install a wood panel of 11 mm oriented

rainscreen material to simulate a cladding system. Install the

strand board (OSB) to the framing and fasten with 10d

board in place using fasteners that go through the XPS and into

fasteners at 200 mm on center. Install a water resistive barrier

the framing spaced (400 6 25) mm on center both vertically

(WRB) complying with Specification E2556/E2556M on the

and horizontally. Seal the fastener holes in the XPS with

OSB in a seamless, continuous manner.

sealantthatiscompatiblewiththeXPStopreventwaterandair

NOTE A1.1—If the rainscreen material used in the test also qualifies as

leakage. Seal the top and sides of the specimen to restrict air

a WRB, a separate WRB between the rainscreen material and the OSB is

from being able to exit during the testing.

not required.

A1.2.2 Install the rainscreen material being tested over (on A1.2.6 Construct a manifold at the top of the specimen (see

theexteriorsideof)theWRBinaccordancewiththepolymer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.