ASTM D473-07(2012)

(Test Method)Standard Test Method for Sediment in Crude Oils and Fuel Oils by the Extraction Method

Standard Test Method for Sediment in Crude Oils and Fuel Oils by the Extraction Method

SIGNIFICANCE AND USE

4.1 A knowledge of the sediment content of crude oils and fuel oils is important both to the operation of refining and the buying or selling of these commodities.

SCOPE

1.1 This test method covers the determination of sediment in crude oils and fuel oils by extraction with toluene. The precision applies to a range of sediment levels from 0.01 to 0.40 % mass, although higher levels may be determined.Note 1—Precision on recycled oils and crankcase oils is unknown and additional testing is required to determine that precision.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 5.1.1.6 and 6.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D473 − 07(Reapproved 2012)

Manual of Petroleum Measurement Standards (MPMS), Chapter 10.1

Designation: 53/82

Standard Test Method for

Sediment in Crude Oils and Fuel Oils by the Extraction

Method

This standard is issued under the fixed designation D473; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E29Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.1 This test method covers the determination of sediment

2.2 API Standards:

in crude oils and fuel oils by extraction with toluene. The

precision applies to a range of sediment levels from 0.01 to Chapter 8.1Manual Sampling of Petroleum and Petroleum

Products (ASTM Practice D4057)

0.40% mass, although higher levels may be determined.

Chapter 8.2Automatic Sampling of Petroleum and Petro-

NOTE 1—Precision on recycled oils and crankcase oils is unknown and

leum Products (ASTM Practice D4177)

additional testing is required to determine that precision.

Chapter 8.3Mixing and Handling of Liquid Samples of

1.2 The values stated in SI units are to be regarded as

Petroleum and Petroleum Products (ASTM Practice

standard. No other units of measurement are included in this

D5854)

standard.

2.3 ISO Standard:

1.3 This standard does not purport to address all of the

5272 Toluene for industrial use—Specifications

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Summary of Test Method

priate safety and health practices and determine the applica-

3.1 Extract test portion of a representative oil sample,

bility of regulatory limitations prior to use. For specific

contained in a refractory thimble, with hot toluene until the

warning statements, see 5.1.1.6 and 6.1.

residue reaches constant mass.The mass of residue, calculated

2. Referenced Documents

as a percentage, is reported as sediment by extraction.

2.1 ASTM Standards:

4. Significance and Use

D4057Practice for Manual Sampling of Petroleum and

Petroleum Products (API MPMS Chapter 8.1)

4.1 A knowledge of the sediment content of crude oils and

D4177Practice for Automatic Sampling of Petroleum and

fuel oils is important both to the operation of refining and the

Petroleum Products (API MPMS Chapter 8.2)

buying or selling of these commodities.

D5854Practice for Mixing and Handling of Liquid Samples

of Petroleum and Petroleum Products (API MPMS Chap-

5. Apparatus

ter 8.3)

5.1 Usuallaboratoryapparatusandglassware,togetherwith

the following are required for this test method.

This test method is under the jurisdiction of ASTM Committee D02 on

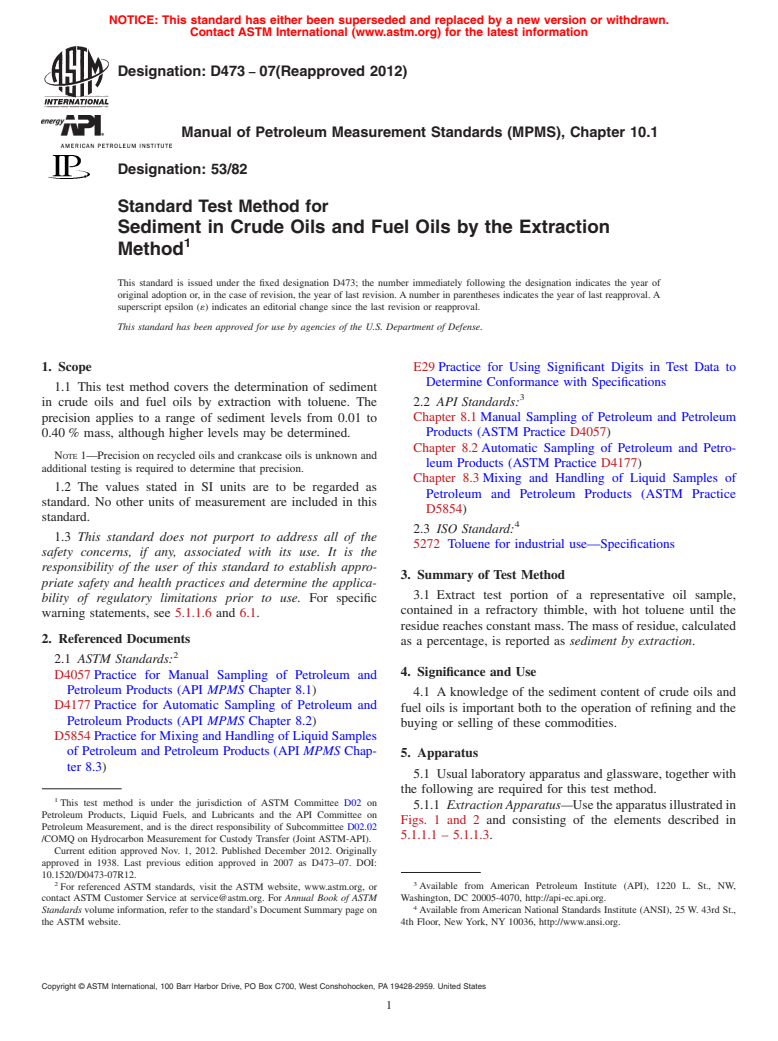

5.1.1 Extraction Apparatus—Usetheapparatusillustratedin

Petroleum Products, Liquid Fuels, and Lubricants and the API Committee on

Figs. 1 and 2 and consisting of the elements described in

Petroleum Measurement, and is the direct responsibility of Subcommittee D02.02

5.1.1.1 – 5.1.1.3.

/COMQ on Hydrocarbon Measurement for Custody Transfer (Joint ASTM-API).

Current edition approved Nov. 1, 2012. Published December 2012. Originally

approved in 1938. Last previous edition approved in 2007 as D473–07. DOI:

10.1520/D0473-07R12.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Petroleum Institute (API), 1220 L. St., NW,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Washington, DC 20005-4070, http://api-ec.api.org.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D473 − 07 (2012)

NOTE 1—Apparatus B shows the water cup in position.

FIG. 1 Extraction Apparatus for Determination of Sediment

5.1.1.1 Extraction Flask—Use a wide-neck (Erlenmeyer) basket so that it hangs approximately midway between the

flask of 1-L capacity, with a minimum external neck diameter surface of the extracting solvent and the bottom of the

of 50 mm, for the procedure.

condenser coil.

5.1.1.2 Condenser—Acondenser in the form of a metal coil

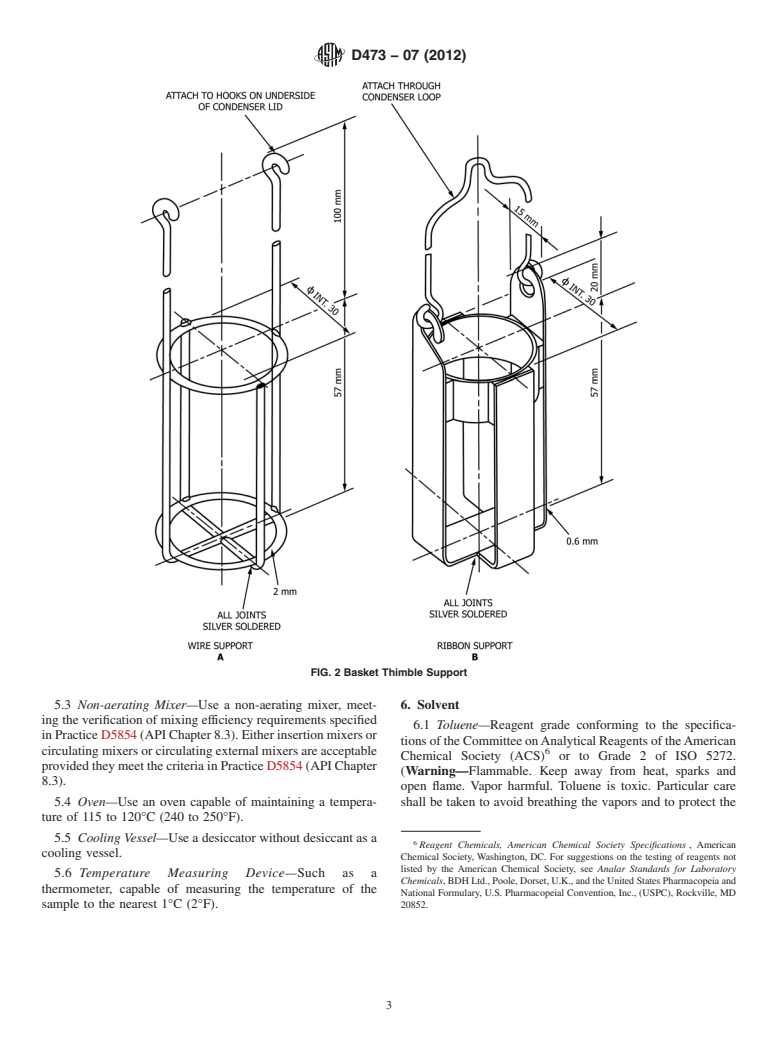

5.1.1.4 Thimble Basket—The thimble basket shall be

approximately 25 mm in diameter and 50 mm in length

corrosion-resistant and shall be made of platinum, stainless

attached to, and with the ends projecting through, a lid of

steel, nickel-chromium alloy, or similar material. Fig. 2 shows

sufficient diameter to cover the neck of the flask as shown in

the design and dimensions of two typical baskets that have

Fig. 1. The coil shall be made from stainless steel, tin,

been used successfully in the industry.

tin-plated copper, or tin-plated brass tubing having an outside

5.1.1.5 Water Cup—Use a water cup when testing a sample

diameter of 5 to 8 mm and a wall thickness of 1.5 mm. If

determined to have a water content greater than 10% volume

constructed of tin-plated copper or brass, the tin coating shall

(see Fig. 1, Apparatus B). The cup shall be made of glass,

have a minimum thickness of 0.075 mm. The exposed surface

conicalinshape,approximately20mmindiameterand25mm

of the coil for cooling purposes is about 115 cm .

deep,andhaveacapacityofapproximately3mL.Aglasshook

NOTE 2—The use of a water flowmeter/controller unit that monitors

fusedontherimatonesideissoshapedthatwhenhungonthe

water flow to the condenser that shuts off the heat source when the flow

condenser the cup hangs with its rim reasonably level. In this

rate drops below a pre-set limit has been found suitable to prevent

procedure, suspend the thimble basket as shown in Fig. 1,

vaporized toluene from igniting. The use of such a device is recom-

Apparatus A by means of the corrosion-resistant wire looped

mended.

overthebottomofthecondensercoilandattachedtothebasket

5.1.1.3 Extraction Thimble —The extraction thimble shall

supports, or as in Fig. 1,Apparatus B, where the wire supports

beofarefractoryporousmaterial,poresize20.0to30.0µm(as

ofthebasketareattachedtohookssolderedtotheundersideof

certifiedbythemanufacturer),25mmindiameterby70mmin

the condenser lid.

height, weighing not less than 15 g and not more than 17 g.

5.1.1.6 Source of Heat—Use a source of heat, preferably a

Suspend the thimble from the condenser coil by means of a

hot plate operated under a ventilated hood, suitable for vapor-

izing toluene (Warning—Flammable.)

The sole source of supply of the extraction thimble, AN 485, 25 × 70-mm,

coarse porosity, drawing number QA005163, known to the committee at this time

5.2 Analytical Balance—Use an analytical balance, with an

is Saint-Gobain/Norton Industrial Ceramics Corporation of Worcester, MA. If you

accuracy of 0.1 mg. Verify the balance, at least annually,

are aware of alternative suppliers, please provide this information to ASTM

against weights traceable to a national standards body such as

International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend. the National Institute of Standards and Technology (NIST).

D473 − 07 (2012)

FIG. 2 Basket Thimble Support

5.3 Non-aerating Mixer—Use a non-aerating mixer, meet- 6. Solvent

ingtheverificationofmixingefficiencyrequirementsspecified

6.1 Toluene—Reagent grade conforming to the specifica-

inPracticeD5854(APIChapter8.3).Eitherinsertionmixersor

tionsoftheCommitteeonAnalyticalReagentsoftheAmerican

circulatingmixersorcirculatingexternalmixersareacceptable 6

Chemical Society (ACS) or to Grade 2 of ISO 5272.

providedtheymeetthecriteriainPracticeD5854(APIChapter

(Warning—Flammable. Keep away from heat, sparks and

8.3).

open flame. Vapor harmful. Toluene is toxic. Particular care

5.4 Oven—Use an oven capable of maintaining a tempera- shall be taken to avoid breathing the vapors and to protect the

ture of 115 to 120°C (240 to 250°F).

5.5 Cooling Vessel—Useadesiccatorwithoutdesiccantasa

Reagent Chemicals, American Chemical Society Specifications , American

cooling vessel.

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

5.6 Temperature Measuring Device—Such as a

Chemicals,BDHLtd.,Poole,Dorset,U.K.,andtheUnitedStatesPharmacopeiaand

thermometer, capable of measuring the temperature of the

National Formulary, U.S. Pharmacopeial Convention, Inc., (USPC), Rockville, MD

sample to the nearest 1°C (2°F). 20852.

D473 − 07 (2012)

TABLE 1 Typical Characteristics for ACS Reagent Grade Toluene

After several determinations (the accumulated sediment may

Assay 99.5+ % be sufficient to interfere with further determinations), follow

Color (APHA) 10

the procedure described in 8.3 to remove the combustible

A

Boiling range (initial to dry point) 2.0°C

portion of the accumulated sediment.Avoid excessive reuse of

Residue after evaporation 0.001 %

Substances darkened by H SO passes test thimbles, as over time the pores become clogged with inor-

2 4

Sulfur compounds (as S) 0.003 %

ganic material resulting in falsely high results. When in doubt

Water (H O) (by Karl Fischer titration) 0.03 %

regarding a higher than normal result, discard the thim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.