ASTM E1783-96(2005)

(Specification)Standard Specification for Preformed Architectural Strip Seals for Buildings and Parking Structures

Standard Specification for Preformed Architectural Strip Seals for Buildings and Parking Structures

ABSTRACT

This specification covers the physical requirements and movement capabilities of preformed architectural strip seals for use in sealing expansion joints in buildings and parking structures. However, this specification does not provide information on the durability of the architectural strip seals under actual service conditions, loading capability of the system, and the effects of a load on the functional parameters. Material covered by this specification consists of architectural strip seals extruded as a membrane or tubular, with frames, with flanges mechanically or chemically secured, used in interior or exterior application, and used in any construction of the building. The architectural strip seal shall be manufactured from a fully cured elastomeric alloy as a preformed extrusion free of defects such as holes and air bubbles, and with dimensions conforming to the requirements specified. Tests for tensile strength, elongation at break, hardness, ozone resistance, compression set, heat aging, tear resistance, brittleness temperature, and water absorption shall be performed and shall conform to the requirements specified.

SCOPE

1.1 This specification covers the physical requirements for the fully cured elastomeric alloy and the movement capabilities of preformed architectural compression seals used for sealing expansion joints in buildings and parking structures. The preformed architectural strip seal is an elastomeric extrusion. This extrusion is either a membrane or tubular having an internal baffle system produced continuously and longitudinally throughout the material. These extrusions are secured in or over a joint by locking rails or an end dam nosing material. The architectural strip seal is compressed and expanded by this mechanical or chemical attachment. Note 1Movement capability is defined in Test Method E 1399.

1.2 This specification covers all colors of architectural strip seals. Note 2The products described in this specification are manufactured from thermoplastic elastomers defined as "fully cured elastomeric alloys" in Test Method D 5048.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E1783 – 96 (Reapproved 2005)

Standard Specification for

Preformed Architectural Strip Seals for Buildings and

Parking Structures

This standard is issued under the fixed designation E1783; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D471 Test Method for Rubber Property—Effect of Liquids

D518 Test Method for Rubber Deterioration—Surface

1.1 This specification covers the physical requirements for

Cracking

thefullycuredelastomericalloyandthemovementcapabilities

D573 Test Method for Rubber—Deterioration in an Air

of preformed architectural compression seals used for sealing

Oven

expansion joints in buildings and parking structures. The

D624 Test Method for Tear Strength of Conventional Vul-

preformed architectural strip seal is an elastomeric extrusion.

canized Rubber and Thermoplastic Elastomers

This extrusion is either a membrane or tubular having an

D746 Test Method for Brittleness Temperature of Plastics

internal baffle system produced continuously and longitudi-

and Elastomers by Impact

nally throughout the material. These extrusions are secured in

D792 Test Methods for Density and Specific Gravity (Rela-

or over a joint by locking rails or an end dam nosing material.

tive Density) of Plastics by Displacement

The architectural strip seal is compressed and expanded by this

D865 TestMethodforRubber—DeteriorationbyHeatingin

mechanical or chemical attachment.

Air (Test Tube Enclosure)

NOTE 1—Movement capability is defined in Test Method E1399.

D1052 Test Method for Measuring Rubber Deterioration—

1.2 This specification covers all colors of architectural strip Cut Growth Using Ross Flexing Apparatus

seals. D1149 Test Methods for Rubber Deterioration—Cracking

in an Ozone Controlled Environment

NOTE 2—The products described in this specification are manufactured

D2000 Classification System for Rubber Products in Auto-

from thermoplastic elastomers defined as “fully cured elastomeric alloys”

motive Applications

in Test Method D5048.

D2240 Test Method for Rubber Property—Durometer

1.3 The values stated in SI units are to be regarded as the

Hardness

standard. The values given in parentheses are for information

D3183 Practice for Rubber—Preparation of Pieces for Test

only.

Purposes from Products

1.4 This standard does not purport to address all of the

D5048 Test Method for Measuring the Comparative Burn-

safety concerns, if any, associated with its use. It is the

ing Characteristics and Resistance to Burn-Through of

responsibility of the user of this standard to establish appro-

Solid Plastics Using a 125-mm Flame

priate safety and health practices and determine the applica-

E577 Guide for Dimensional Coordination of Rectilinear

bility of regulatory limitations prior to use.

Building Parts and Systems

E631 Terminology of Building Constructions

2. Referenced Documents

E1399 Test Method for Cyclic Movement and Measuring

2.1 ASTM Standards:

the Minimum and Maximum Joint Widths ofArchitectural

D395 Test Methods for Rubber Property—Compression Set

Joint Systems

D412 Test Methods for Vulcanized Rubber and Thermo-

plastic Elastomers—Tension

3. Terminology

3.1 Definitions: Terms defined in Terminology E631 will

prevail for terms not defined in this document.

This specification is under the jurisdiction of ASTM Committee E06 on

3.1.1 architectural strip seal—a preformed membrane or

Performance of Buildings and is the direct responsibility of Subcommittee E06.21

tubular extrusion, manufactured from a fully cured elastomeric

on Serviceability.

Current edition approved May 1, 2005. Published May 2005. Originally

alloy, having flanges or other means of mechanically or

approved in 1996. Last previous edition approved in 2000 as E1783 – 96 (2000).

chemically securing it.

DOI: 10.1520/E1783-96R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1783 – 96 (2005)

NOTE 3—Joint is defined in Guide E577.

8.4.2 Prepare the test specimens for determining tensile

strength and elongation using Die C (Test Methods D412)or

4. Materials and Manufacture

Die D when the flat sections of a seal are too small for Die C.

4.1 The architectural strip seal shall be a preformed extru-

However, the requirements of Table 2 shall apply regardless of

sion manufactured from a fully cured elastomeric alloy. This

the die used.

alloy shall be classified under Classification D2000.

8.4.3 The grain or flow pattern for all specimens prepared

fortensilestrengthandelongationtesting(TestMethodsD412)

5. Physical Requirements

shall be parallel to the length of the die.

5.1 The fully cured elastomeric alloy supplied in plaque 8.4.4 Prepare the test specimens for ozone resistance in

form shall conform to the material requirements prescribed in accordance with Procedure A of Test Method D518, and wipe

Table 1. them with toluene before testing to remove surface contami-

5.2 The finished architectural joint seal shall conform to the nation.

material requirements prescribed in Table 2. 8.4.5 The grain or flow pattern for all specimens prepared

5.3 The movement capabilities shall be established using

for tear resistance testing (Test Method D624) shall be perpen-

Test Method E1399. dicular to the length of the die.

6. Dimensions, Mass, and Permissible Variations

9. Significance and Use

6.1 The size, shape, internal structure, and tolerances shall

9.1 Architectural strip seals included in this specification

be as agreed upon by the purchaser and the producer or

shall be those:

supplier.

9.1.1 Extruded as a membrane;

9.1.2 Extruded as tubular;

7. Workmanship, Color, and Appearance

9.1.3 With frames;

7.1 The architectural strip seal shall be free of defects in 9.1.4 With flanges mechanically secured;

workmanship. Defects in the extrusion consist of the follow-

9.1.5 With flanges chemically secured;

ing: 9.1.6 Used in interior or exterior applications; and

7.1.1 Holes;

9.1.7 Used in any construction of the building.

7.1.2 Air bubbles; and 9.2 This specification will give users, producers, building

7.1.3 Parts not conforming to 6.1.

officials, code authorities, and others a basis for verifying

7.2 The cross section of the seal shall be as agreed upon by material and performance characteristics of representative

the purchaser and the producer or supplier.

specimens under common test conditions. This specification

7.3 The color of the seal shall be as agreed upon by the will produce data on the following:

purchaser and the producer or supplier.

9.2.1 The physical properties of the fully cured elastomeric

alloy; and

8. Specimen Preparation

9.2.2 The movement capability in relation to the nominal

8.1 Maintain laboratory at a temperature of 23 6 2°C (73 6 joint width as defined under Test Method E1399.

9.3 This specification compares similar architectural strip

4°F).

8.2 Maintain laboratory at a relative humidity of 5065%. seals but is not intended to reflect the system’s application.

“Similar” refers to the same type of architectural strip seal

8.3 Test Plaque Specimens:

8.3.1 Use equipment per Annex A1. within the same subsection under 9.1.

9.4 This specification does not provide information on the

8.3.2 Produce 20 quality assurance test plaques in accor-

dance with Annex A2. following:

8.4 Strip Seal Specimens: 9.4.1 Durability of the architectural strip seal under actual

8.4.1 Cut all test specimens from the architectural strip seal service conditions, including the effects of cycled temperature

sample. Except as otherwise specified in the applicable speci- on the strip seal;

fications or test methods given in Table 2, prepare the test 9.4.2 Loading capability of the system and the effects of a

specimens in accordance with the requirements of Practice load on the functional parameters established by this specifi-

D3183. cation;

TABLE 1 Requirements for Fully Cured Elastomeric Alloy Injection Molded Plaques

Requirement

Property Test Method

Type I Type II Type III Type IV Type V Type VI

Tensile strength, min, MPa (psi) 13.8 (2000) 9.7 (1400) 7.2 (1050) 6.0 (870) 5.8 (850) 5.8 (850) D412

Elongation at break, min,% 500 460 380 350 340 340 D412

Hardness, Type A durometer, points (5 s delay) 87 6380 6373 6370 6367 6364 6 3 D2240

Relative density @ 23°C (73°F) 0.95 6 0.02 0.96 6 0.02 0.97 6 0.02 0.97 6 0.02 0.97 6 0.02 0.97 6 0.02 D792

100 % Modulus, min, MPa (psi) 6.1 (890) 3.8 (550) 2.8 (400) 2.2 (320) 1.9 (280) 1.9 (280) D412

Mass gain, max %, (24 h at 121°C (23°F) ASTM 60 75 80 90 95 95 D471

No. 3 Oil)

E1783 – 96 (2005)

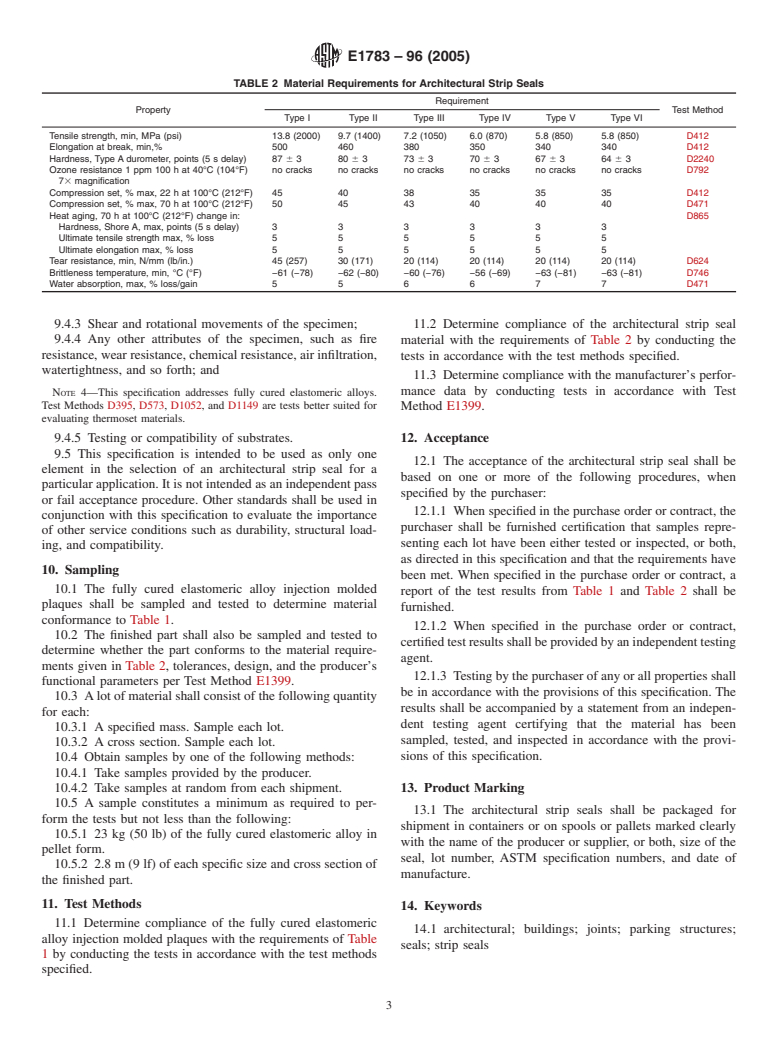

TABLE 2 Material Requirements for Architectural Strip Seals

Requirement

Property Test Method

Type I Type II Type III Type IV Type V Type VI

Tensile strength, min, MPa (psi) 13.8 (2000) 9.7 (1400) 7.2 (1050) 6.0 (870) 5.8 (850) 5.8 (850) D412

Elongation at break, min,% 500 460 380 350 340 340 D412

Hardness, Type A durometer, points (5 s delay) 87 6380 6373 6370 6367 6364 6 3 D2240

Ozone resistance 1 ppm 100 h at 40°C (104°F) no cracks no cracks no cracks no cracks no cracks no cracks D792

73 magnification

Compression set, % max, 22 h at 100°C (212°F) 45 40 38 35 35 35 D412

Compression set, % max, 70 h at 100°C (212°F) 50 45 43 40 40 40 D471

Heat aging, 70 h at 100°C (212°F) change in: D865

Hardness, Shore A, max, points (5 s delay) 333333

Ultimate tensile strength max, % loss 555555

Ultimate elongation max, % loss 555555

Tear resistance, min, N/mm (lb/in.) 45 (257) 30 (171) 20 (114) 20 (114) 20 (114) 20 (114) D624

Brittleness temperature, min, °C (°F) −61 (−78) −62 (−80) −60 (−76) −56 (−69) −63 (−81) −63 (−81) D746

Wate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.