ASTM G66-99(2018)e1

(Test Method)Standard Test Method for Visual Assessment of Exfoliation Corrosion Susceptibility of 5XXX Series Aluminum Alloys (ASSET Test)

Standard Test Method for Visual Assessment of Exfoliation Corrosion Susceptibility of 5XXX Series Aluminum Alloys (ASSET Test)

SIGNIFICANCE AND USE

5.1 This test method provides a reliable prediction of the exfoliation corrosion behavior of Al-Mg alloys in marine environments.5,6,7 The test is useful for alloy development studies and quality control of mill products such as sheet and plate.

SCOPE

1.1 This test method covers a procedure for continuous immersion exfoliation corrosion testing of 5XXX series aluminum-magnesium alloys containing 2.0 % or more magnesium.

1.2 This test method applies only to wrought products.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: G66 − 99 (Reapproved 2018)

Standard Test Method for

Visual Assessment of Exfoliation Corrosion Susceptibility of

5XXX Series Aluminum Alloys (ASSET Test)

This standard is issued under the fixed designation G66; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Adjunct description in 2.2 and adjunct stock number in Footnote 4 were updated editorially in February 2023.

1. Scope 2.2 ASTM Adjunct:

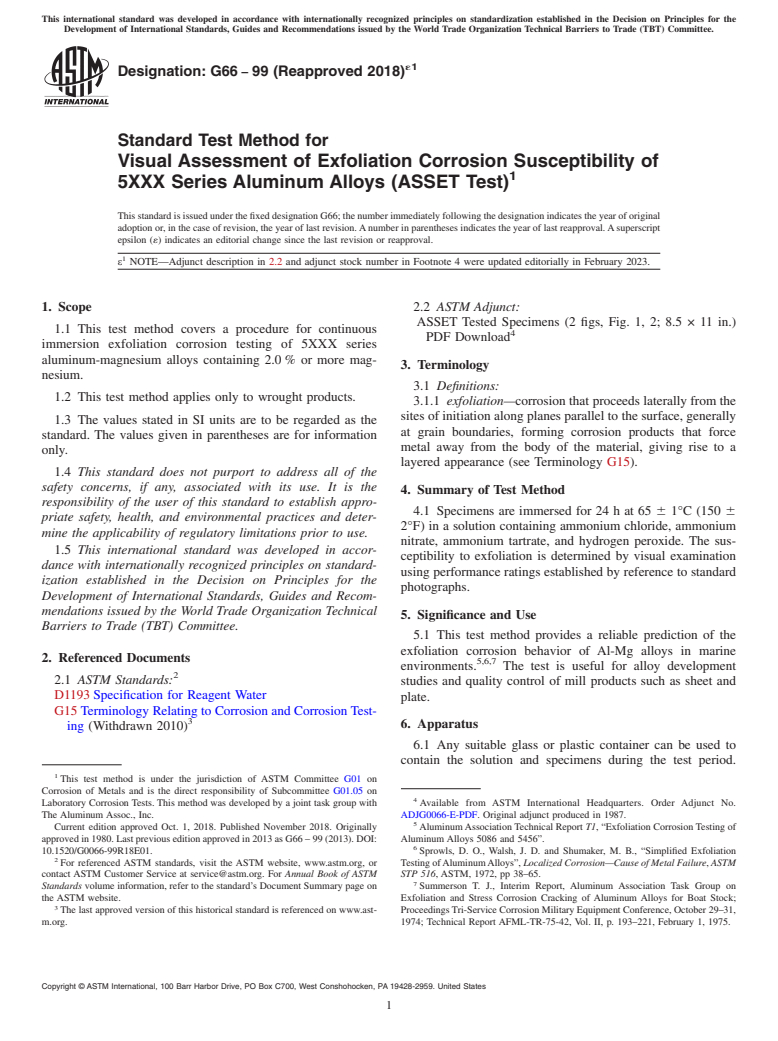

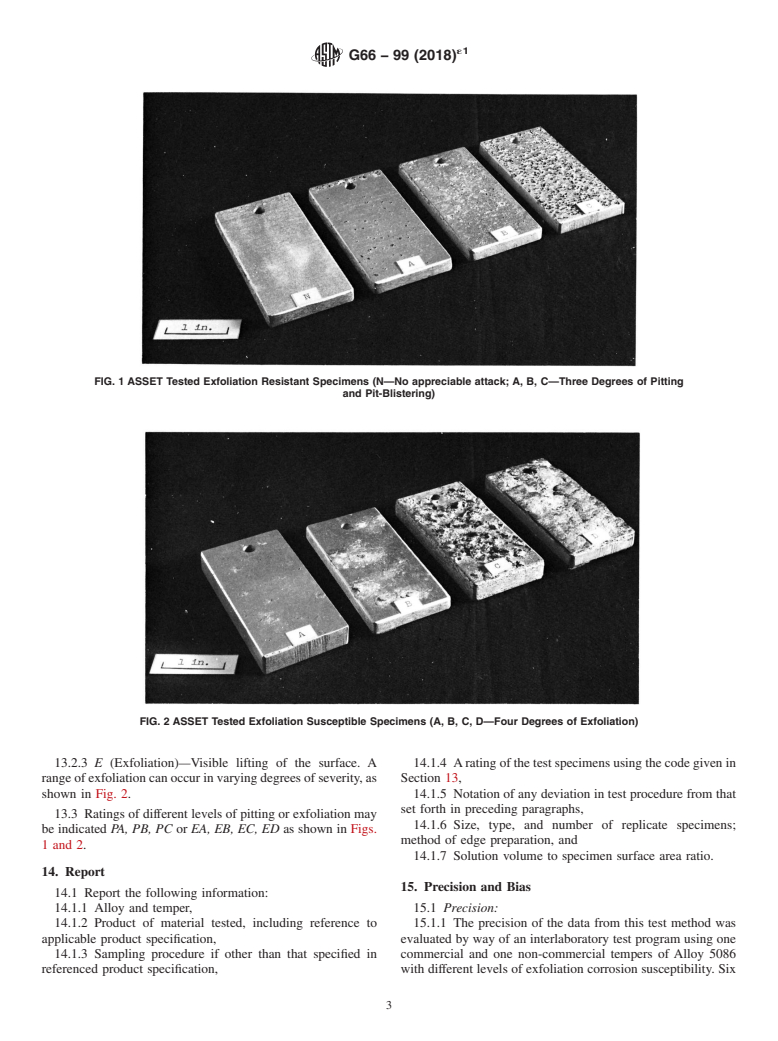

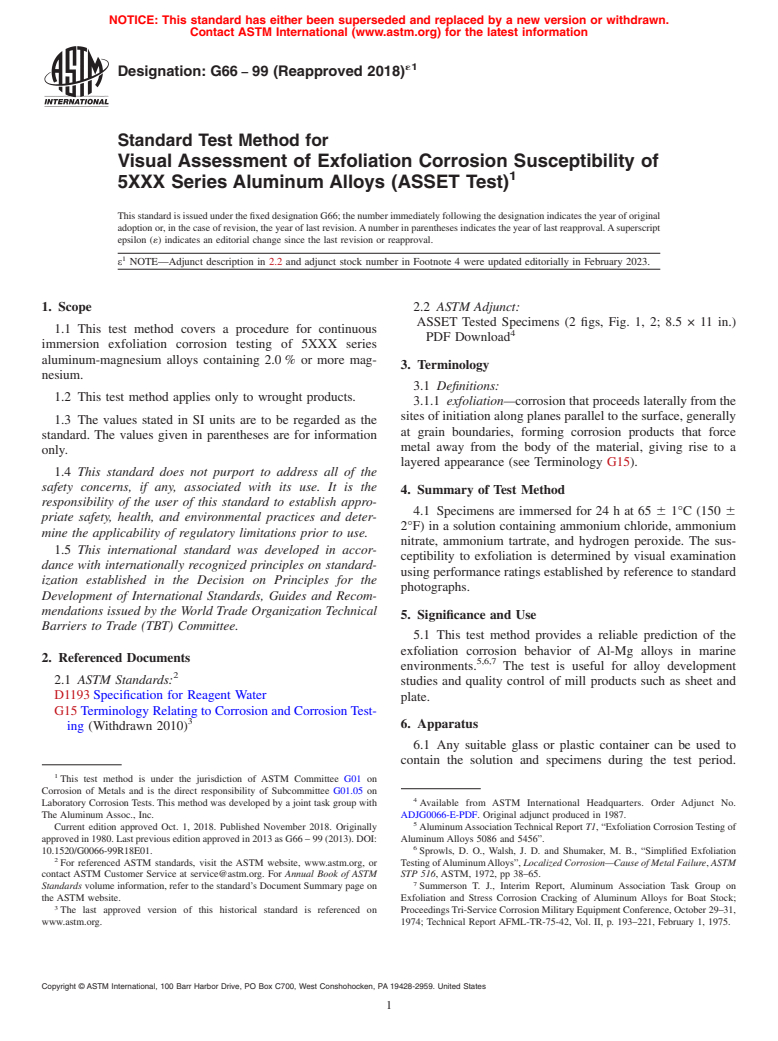

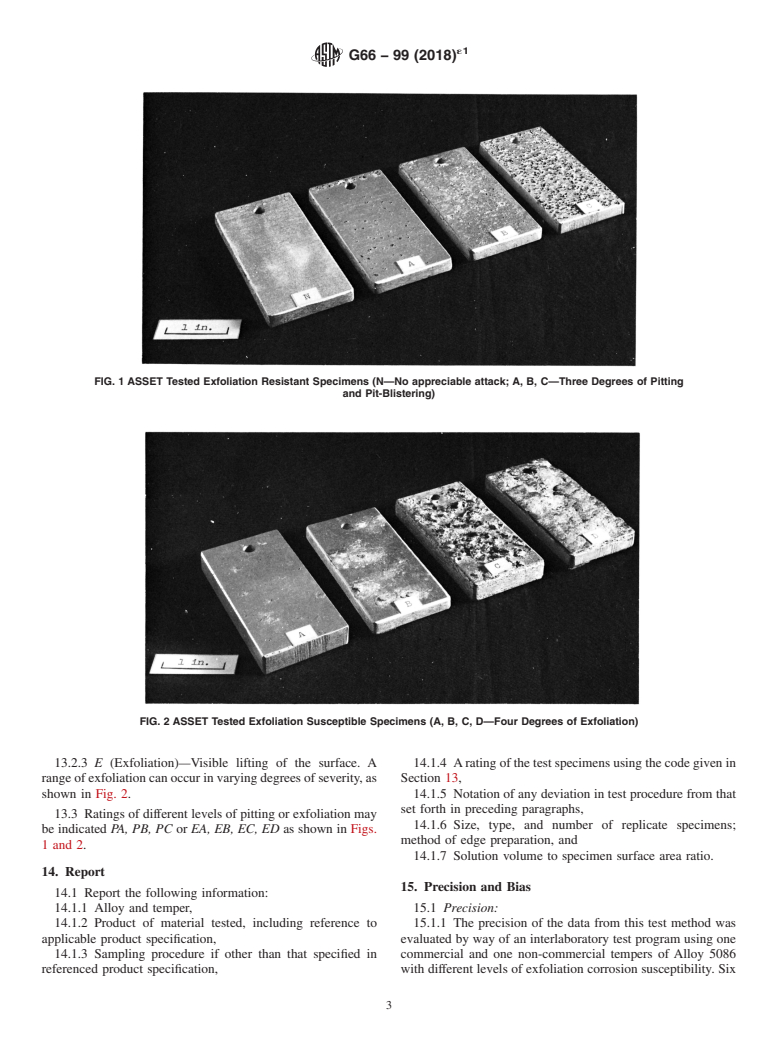

ASSET Tested Specimens (2 figs, Fig. 1, 2; 8.5 × 11 in.)

1.1 This test method covers a procedure for continuous

PDF Download

immersion exfoliation corrosion testing of 5XXX series

aluminum-magnesium alloys containing 2.0 % or more mag-

3. Terminology

nesium.

3.1 Definitions:

1.2 This test method applies only to wrought products.

3.1.1 exfoliation—corrosion that proceeds laterally from the

sites of initiation along planes parallel to the surface, generally

1.3 The values stated in SI units are to be regarded as the

at grain boundaries, forming corrosion products that force

standard. The values given in parentheses are for information

metal away from the body of the material, giving rise to a

only.

layered appearance (see Terminology G15).

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 Specimens are immersed for 24 h at 65 6 1°C (150 6

priate safety, health, and environmental practices and deter-

2°F) in a solution containing ammonium chloride, ammonium

mine the applicability of regulatory limitations prior to use.

nitrate, ammonium tartrate, and hydrogen peroxide. The sus-

1.5 This international standard was developed in accor-

ceptibility to exfoliation is determined by visual examination

dance with internationally recognized principles on standard-

using performance ratings established by reference to standard

ization established in the Decision on Principles for the

photographs.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 This test method provides a reliable prediction of the

exfoliation corrosion behavior of Al-Mg alloys in marine

2. Referenced Documents

5,6,7

environments. The test is useful for alloy development

2.1 ASTM Standards:

studies and quality control of mill products such as sheet and

D1193 Specification for Reagent Water

plate.

G15 Terminology Relating to Corrosion and Corrosion Test-

6. Apparatus

ing (Withdrawn 2010)

6.1 Any suitable glass or plastic container can be used to

contain the solution and specimens during the test period.

This test method is under the jurisdiction of ASTM Committee G01 on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.05 on

Laboratory Corrosion Tests. This method was developed by a joint task group with Available from ASTM International Headquarters. Order Adjunct No.

The Aluminum Assoc., Inc. ADJG0066-E-PDF. Original adjunct produced in 1987.

Current edition approved Oct. 1, 2018. Published November 2018. Originally Aluminum Association Technical Report T1, “Exfoliation Corrosion Testing of

approved in 1980. Last previous edition approved in 2013 as G66 – 99 (2013). DOI: Aluminum Alloys 5086 and 5456”.

10.1520/G0066-99R18E01. Sprowls, D. O., Walsh, J. D. and Shumaker, M. B., “Simplified Exfoliation

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Testing of Aluminum Alloys”, Localized Corrosion—Cause of Metal Failure, ASTM

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM STP 516, ASTM, 1972, pp 38–65.

Standards volume information, refer to the standard’s Document Summary page on Summerson T. J., Interim Report, Aluminum Association Task Group on

the ASTM website. Exfoliation and Stress Corrosion Cracking of Aluminum Alloys for Boat Stock;

The last approved version of this historical standard is referenced on www.ast- Proceedings Tri-Service Corrosion Military Equipment Conference, October 29–31,

m.org. 1974; Technical Report AFML-TR-75-42, Vol. II, p. 193–221, February 1, 1975.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

G66 − 99 (2018)

Depending upon the shape and size of the specimens, rods or 11. Standardization

racks of glass, plastic, or other inert substance shall be used to

11.1 To provide an indication when some inadvertent de-

support the specimens above the bottom of the container. The

viation from the correct test conditions occurs, it is necessary

container should be fitted with a removable cover to reduce

to expose to the test at regular intervals a control specimen of

evaporation.

a material of known susceptibility. This control should exhibit

the same degree of exfoliation each time it is included in the

7. Reagents

test.

7.1 Purity of Reagents—Reagent grade chemicals shall be

11.2 The control may be any material of the Al-Mg series

used in all tests.

that has a well-documented susceptibility to exfoliation

corrosion, preferably one with an intermediate susceptibility.

7.2 Purity of Water—Distilled or deionized water conform-

ing to Specification D1193. Type IV shall be used to prepare

12. Procedure

the test solution except chloride ion sodium limits can be

12.1 Degrease the specimens with a suitable solvent. After

disregarded.

degreasing, prepare specimens as follows: Etch 1 min in 5 %

by weight sodium hydroxide solution at 80°C (176°F), rinse in

8. Test Solution

water, desmut 30 s in concentrated nitric acid at room

8.1 Preparation of Test Solution:

temperature, rinse with distilled or deionized water, air dry.

8.1.1 The test solution shall have the following composi-

NOTE 2—If specimens are not to be immersed in the test solution

tion:

immediately, they should be stored in a desiccator maintained at less than

NH Cl (1.0 M)

1 % relative humidity (use fresh desiccant such as activated alumina or

NH NO (0.25 M) 8

4 3

anhydrous calcium sulfate).

(NH ) C H O (0.01 M)

4 2 4 4 6

H O (0.09 M)

12.2 Use fresh solution at the start of each test.

2 2

8.1.2 Dissolve 53.5 g ammonium chloride (NH Cl), 20.0 g

12.3 Immerse the specimens vertically with the top edge of

ammonium nitrate (NH NO ), 1.8 g ammonium tartrate

4 3 the specimens at least 25 mm (1 in.) below the surface of the

((NH ) C H O ), and 10 mL of 30 % stock solution hydrogen

solution and the bottom edge at least 25 mm above the bottom

4 2 4 4 6

peroxide (H O ) in a small amount of water. After dissolving,

2 2 of the container.

mix the components together thoroughly and adjust the final

12.4 Immerse the specimens in the test solution continu-

dilution to 1 L.

ously for 24 h.

NOTE 1—If a stock solution of the above chemicals is to be stored, the

12.5 Rinse the specimens gently in running tap water

hydrogen peroxide should not be added until the solution is heated for the

immediately after remov

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: G66 − 99 (Reapproved 2018)

Standard Test Method for

Visual Assessment of Exfoliation Corrosion Susceptibility of

5XXX Series Aluminum Alloys (ASSET Test)

This standard is issued under the fixed designation G66; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Adjunct description in 2.2 and adjunct stock number in Footnote 4 were updated editorially in February 2023.

1. Scope 2.2 ASTM Adjunct:

ASSET Tested Specimens (2 figs, Fig. 1, 2; 8.5 × 11 in.)

1.1 This test method covers a procedure for continuous

PDF Download

immersion exfoliation corrosion testing of 5XXX series

aluminum-magnesium alloys containing 2.0 % or more mag-

3. Terminology

nesium.

3.1 Definitions:

1.2 This test method applies only to wrought products.

3.1.1 exfoliation—corrosion that proceeds laterally from the

sites of initiation along planes parallel to the surface, generally

1.3 The values stated in SI units are to be regarded as the

at grain boundaries, forming corrosion products that force

standard. The values given in parentheses are for information

metal away from the body of the material, giving rise to a

only.

layered appearance (see Terminology G15).

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 Specimens are immersed for 24 h at 65 6 1°C (150 6

priate safety, health, and environmental practices and deter-

2°F) in a solution containing ammonium chloride, ammonium

mine the applicability of regulatory limitations prior to use.

nitrate, ammonium tartrate, and hydrogen peroxide. The sus-

1.5 This international standard was developed in accor-

ceptibility to exfoliation is determined by visual examination

dance with internationally recognized principles on standard-

using performance ratings established by reference to standard

ization established in the Decision on Principles for the

photographs.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 This test method provides a reliable prediction of the

exfoliation corrosion behavior of Al-Mg alloys in marine

2. Referenced Documents

5,6,7

environments. The test is useful for alloy development

2.1 ASTM Standards:

studies and quality control of mill products such as sheet and

D1193 Specification for Reagent Water

plate.

G15 Terminology Relating to Corrosion and Corrosion Test-

6. Apparatus

ing (Withdrawn 2010)

6.1 Any suitable glass or plastic container can be used to

contain the solution and specimens during the test period.

This test method is under the jurisdiction of ASTM Committee G01 on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.05 on

Laboratory Corrosion Tests. This method was developed by a joint task group with Available from ASTM International Headquarters. Order Adjunct No.

The Aluminum Assoc., Inc. ADJG0066-E-PDF. Original adjunct produced in 1987.

Current edition approved Oct. 1, 2018. Published November 2018. Originally Aluminum Association Technical Report T1, “Exfoliation Corrosion Testing of

approved in 1980. Last previous edition approved in 2013 as G66 – 99 (2013). DOI: Aluminum Alloys 5086 and 5456”.

10.1520/G0066-99R18E01. Sprowls, D. O., Walsh, J. D. and Shumaker, M. B., “Simplified Exfoliation

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Testing of Aluminum Alloys”, Localized Corrosion—Cause of Metal Failure, ASTM

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM STP 516, ASTM, 1972, pp 38–65.

Standards volume information, refer to the standard’s Document Summary page on Summerson T. J., Interim Report, Aluminum Association Task Group on

the ASTM website. Exfoliation and Stress Corrosion Cracking of Aluminum Alloys for Boat Stock;

The last approved version of this historical standard is referenced on Proceedings Tri-Service Corrosion Military Equipment Conference, October 29–31,

www.astm.org. 1974; Technical Report AFML-TR-75-42, Vol. II, p. 193–221, February 1, 1975.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

G66 − 99 (2018)

Depending upon the shape and size of the specimens, rods or 11. Standardization

racks of glass, plastic, or other inert substance shall be used to

11.1 To provide an indication when some inadvertent de-

support the specimens above the bottom of the container. The

viation from the correct test conditions occurs, it is necessary

container should be fitted with a removable cover to reduce

to expose to the test at regular intervals a control specimen of

evaporation.

a material of known susceptibility. This control should exhibit

the same degree of exfoliation each time it is included in the

7. Reagents

test.

7.1 Purity of Reagents—Reagent grade chemicals shall be

11.2 The control may be any material of the Al-Mg series

used in all tests.

that has a well-documented susceptibility to exfoliation

corrosion, preferably one with an intermediate susceptibility.

7.2 Purity of Water—Distilled or deionized water conform-

ing to Specification D1193. Type IV shall be used to prepare

12. Procedure

the test solution except chloride ion sodium limits can be

12.1 Degrease the specimens with a suitable solvent. After

disregarded.

degreasing, prepare specimens as follows: Etch 1 min in 5 %

by weight sodium hydroxide solution at 80°C (176°F), rinse in

8. Test Solution

water, desmut 30 s in concentrated nitric acid at room

8.1 Preparation of Test Solution:

temperature, rinse with distilled or deionized water, air dry.

8.1.1 The test solution shall have the following composi-

NOTE 2—If specimens are not to be immersed in the test solution

tion:

immediately, they should be stored in a desiccator maintained at less than

NH Cl (1.0 M)

1 % relative humidity (use fresh desiccant such as activated alumina or

NH NO (0.25 M) 8

4 3

anhydrous calcium sulfate).

(NH ) C H O (0.01 M)

4 2 4 4 6

H O (0.09 M) 12.2 Use fresh solution at the start of each test.

2 2

8.1.2 Dissolve 53.5 g ammonium chloride (NH Cl), 20.0 g

4 12.3 Immerse the specimens vertically with the top edge of

ammonium nitrate (NH NO ), 1.8 g ammonium tartrate

the specimens at least 25 mm (1 in.) below the surface of the

4 3

((NH ) C H O ), and 10 mL of 30 % stock solution hydrogen

4 2 4 4 6 solution and the bottom edge at least 25 mm above the bottom

peroxide (H O ) in a small amount of water. After dissolving,

of the container.

2 2

mix the components together thoroughly and adjust the final

12.4 Immerse the specimens in the test solution continu-

dilution to 1 L.

ously for 24 h.

NOTE 1—If a stock solution of the above chemicals is to be stored, the

12.5 Rinse the specimens gently in running tap water

hydrogen peroxide should not be added until the solution is heated for the

immediately after removal from the solution, then soak in

test.

concentrated nitric acid at room tempera

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: G66 − 99 (Reapproved 2018) G66 − 99 (Reapproved 2018)

Standard Test Method for

Visual Assessment of Exfoliation Corrosion Susceptibility of

5XXX Series Aluminum Alloys (ASSET Test)

This standard is issued under the fixed designation G66; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Adjunct description in 2.2 and adjunct stock number in Footnote 4 were updated editorially in February 2023.

1. Scope

1.1 This test method covers a procedure for continuous immersion exfoliation corrosion testing of 5XXX series aluminum-

magnesium alloys containing 2.0 % or more magnesium.

1.2 This test method applies only to wrought products.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1193 Specification for Reagent Water

G15 Terminology Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

2.2 ASTM Adjuncts:Adjunct:

ASSET Tested Specimens (Glossy Prints)(2 figs, Fig. 1, 2; 8.5 × 11 in.) PDF Download

3. Terminology

3.1 Definitions:

3.1.1 exfoliation—corrosion that proceeds laterally from the sites of initiation along planes parallel to the surface, generally at

grain boundaries, forming corrosion products that force metal away from the body of the material, giving rise to a layered

appearance (see Terminology G15).

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory

Corrosion Tests. This method was developed by a joint task group with The Aluminum Assoc., Inc.

Current edition approved Oct. 1, 2018. Published November 2018. Originally approved in 1980. Last previous edition approved in 2013 as G66 – 99 (2013). DOI:

10.1520/G0066-99R18.10.1520/G0066-99R18E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from ASTM International Headquarters. Order Adjunct No. ADJG0066ADJG0066-E-PDF. Original adjunct produced in 1987.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

G66 − 99 (2018)

4. Summary of Test Method

4.1 Specimens are immersed for 24 h at 65 6 1°C (150 6 2°F) in a solution containing ammonium chloride, ammonium nitrate,

ammonium tartrate, and hydrogen peroxide. The susceptibility to exfoliation is determined by visual examination using

performance ratings established by reference to standard photographs.

5. Significance and Use

5.1 This test method provides a reliable prediction of the exfoliation corrosion behavior of Al-Mg alloys in marine

5,6,7

environments. The test is useful for alloy development studies and quality control of mill products such as sheet and plate.

6. Apparatus

6.1 Any suitable glass or plastic container can be used to contain the solution and specimens during the test period. Depending

upon the shape and size of the specimens, rods or racks of glass, plastic, or other inert substance shall be used to support the

specimens above the bottom of the container. The container should be fitted with a removable cover to reduce evaporation.

7. Reagents

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests.

7.2 Purity of Water—Distilled or deionized water conforming to Specification D1193. Type IV shall be used to prepare the test

solution except chloride ion sodium limits can be disregarded.

8. Test Solution

8.1 Preparation of Test Solution:

8.1.1 The test solution shall have the following composition:

NH Cl (1.0 M)

NH NO (0.25 M)

4 3

(NH ) C H O (0.01 M)

4 2 4 4 6

H O (0.09 M)

2 2

8.1.2 Dissolve 53.5 g ammonium chloride (NH Cl), 20.0 g ammonium nitrate (NH NO ), 1.8 g ammonium tartrate

4 4 3

((NH ) C H O ), and 10 mL of 30 % stock solution hydrogen peroxide (H O ) in a small amount of water. After dissolving, mix

4 2 4 4 6 2 2

the components together thoroughly and adjust the final dilution to 1 L.

NOTE 1—If a stock solution of the above chemicals is to be stored, the hydrogen peroxide should not be added until the solution is heated for the test.

8.2 The solution will have a typical pH of 5.2 to 5.4.

8.3 The solution shall be used in sufficient quantity to provide a volume-to-exposed specimen surface area ratio of at least 100

2 2

L/m (65 mL/in. ).

8.4 The temperature of the solution shall be maintained at 65 6 1°C (150 6 2°F).

9. Sampling

9.1 The procedure for sampling mill products is covered in product specifications, or otherwise, and is considered outside the

scope of this standard.

Aluminum Association Technical Report T1, “Exfoliation Corrosion Testing of Aluminum Alloys 5086 and 5456”.

Sprowls, D. O., Walsh, J. D. and Shumaker, M. B., “Simplified Exfoliation Testing of Aluminum Alloys”, Localized Corrosion—Cause of Metal Failure,ASTM STP 516,

ASTM, 1972, pp 38–65.

Summerson T. J., Interim Report, Aluminum Association Task Group on Exfoliation and Stress Corrosion Cracking of Aluminum Alloys for Boat Stock; Proceedings

Tri-Service Corrosion Military Equipment Conference, October 29–31, 1974; Technical Report AFML-TR-75-42, Vol. II, p. 193–221, February 1, 1975.

´1

G66 − 99 (2018)

10. Test Specimen

10.1 While this test method can be used with any form of specimen or part that can be immersed in the test solution, it is preferred

that specimens be at least 40 by 100 mm (1.5 by 4.0 in.) with the metal working direction in the 40-mm (1.5-in.) dimension.

10.2 The specimens should be sawed or machined to minimize introducing residual stresses in edges during preparation of the

specimens (sheared edges are allowed only if the edges are sufficiently dressed or filed down a distance equal to the thickness of

the specimen in order to remove metal deformed by shearing).

11. Standardization

11.1 To provide an indication when some inadvertent deviation from the correct test conditions occurs, it is necessary to expose

to the test at regular intervals a control specimen of a material of known susceptibility. This control should exhibit the same degree

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.