ASTM B90/B90M-98(2005)

(Specification)Standard Specification for Magnesium-Alloy Sheet and Plate

Standard Specification for Magnesium-Alloy Sheet and Plate

SCOPE

1.1 This specification covers magnesium alloys in sheet and plate form designated as shown in .

1.2 The values stated in either inch-pound or SI units are to be regarded separately as standards. The SI units are shown in brackets or in separate tables or columns. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 Unless the order specifies the "M" specification designation, the material shall be furnished to the inch-pound units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 90/B 90M – 98 (Reapproved 2005)

Standard Specification for

Magnesium-Alloy Sheet and Plate

This standard is issued under the fixed designation B 90/B 90M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Determine Conformance with Specification

E35 Test Methods for Chemical Analysis of Magnesium

1.1 This specification covers magnesium alloys in sheet and

and Magnesium Alloys

plate form designated as shown in Table 1.

E55 PracticeforSamplingWroughtNonferrousMetalsand

1.2 The values stated in either inch-pound or SI units are to

Alloys for Determination of Chemical Composition

be regarded separately as standards. The SI units are shown in

2.3 Federal Standards:

brackets or in separate tables or columns. The values stated in

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

each system are not exact equivalents; therefore, each system

Fed. Std. No. 184 Identification Marking of Aluminum,

must be used independent of the other. Combining values from

Magnesium and Titanium

the two systems may result in nonconformance with the

2.4 Military Standards:

specification.

MIL-STD-129 Marking for Shipment and Storage

1.3 Unless the order specifies the “M” specification desig-

MIL-M-3171 Magnesium Alloy, Processes for Pretreat-

nation, the material shall be furnished to the inch-pound units.

ment and Prevention of Corrosion

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety and health practices and determine the applica-

3.1.1 plate—a rolled product rectangular in cross section

bility of regulatory limitations prior to use.

and form, of thickness 0.250 in., or more, [over 6.30 mm],

2. Referenced Documents either sheared or sawed edges.

3.1.2 sheet—a rolled product rectangular in cross section

2.1 The following documents of the issue in effect on date

and form, of thickness of 0.006 through 0.249 in. [over 0.15

of material purchase form a part of this specification to the

through 6.30 mm] with sheared, slit, or sawed edges.

extent referenced herein:

2.2 ASTM Standards:

4. Ordering Information

B 557 Test Methods of Tension Testing Wrought and Cast

4.1 Orders for sheet and plate to this specification shall

Aluminum- and Magnesium-Alloy Products

include the following information:

B 557M TestMethodsofTensionTestingWroughtandCast

4.1.1 Quantity in pieces, lbs, or [kg]

Aluminum- and Magnesium Alloy Products [Metric]

4.1.2 Alloy (Section 5 and Table 1),

B 660 Practices for Packaging/Packing of Aluminum and

4.1.3 Temper (Section 6 and Table 2),

Magnesium Products

4.1.4 Thickness, width, and length,

E29 Practice for Using Significant Digits in Test Data to

4.1.5 Surface treatment (see 8.2),

4.1.6 Whether inspection is required at the manufacturer’s

1 works (see 13.1), and

This specification is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on 4.1.7 Whether certification of the material by the vendor is

Magnesium Alloy Cast and Wrought Products.

required (Section 15).

Current edition approved Feb. 1, 2005. Published February 2005. Originally

approved in 1932. Last previous edition approved in 1998 as B 90/B 90 – 98.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5098.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

B 90/B 90M – 98 (2005)

A

TABLE 1 Chemical Composition Limits

NOTE 1—Analysis shall regularly be made only for the elements specifically mentioned in this table. If, however, the presence of other elements is

suspectedorindicatedinamountsgreaterthanthespecifiedlimits,furtheranalysisshallbemadetodeterminethattheseelementsarenotpresentinexcess

of the specified limits.

NOTE 2—The following applies to all specified limits in this table: For purposes of acceptance and rejection, an observed value or a calculated value

obtained from analysis should be rounded to the nearest unit in the last right-hand place of figures used in expressing the specified limit.

A

Composition %

Al Mn R.E. Zn Zr Ca Cu Fe Ni Si Each Total Mg

AZ31B 2.5-3.5 0.20-1.0 . . . 0.6-1.4 . . . 0.04 0.05 0.005 0.005 0.10 . . . 0.30 Remainder

A

Limits are in weight percent maximum unless shown as a range.

TABLE 2 Tensile Requirements

NOTE—For purposes of determining conformance with this specification, each value for tensile strength and yield strength shall be rounded to the

nearest 0.1 ksi, and each value for elongation shall be rounded to the nearest 0.5 %, both in accordance with the rounding method of PracticeE29.

Yield Strength (0.2% Elongation in 2 in.,

Alloy and Temper Specified Thickness, in. Tensile Strength, min, ksi

Offset), min, ksi or 4 3dia min,%

A

AZ31B-O 0.016–0.500 32.0 . 12

A

0.501–2.000 32.0 . 10

A

2.001–3.000 32.0 . 9

AZ31B-H24 0.016–0.249 39.0 29.0 6

0.250–0.374 38.0 26.0 8

0.375–0.500 37.0 24.0 8

0.501–1.000 36.0 22.0 8

1.001–2.000 34.0 20.0 8

2.001–3.000 34.0 18.0 8

AZ31B-H26 0.250–0.374 39.0 27.0 6

0.375–0.500 38.0 26.0 6

0.501–0.750 37.0 25.0 6

0.751–1.000 37.0 23.0 6

1.001–1.500 35.0 22.0 6

1.501–2.000 35.0 21.0 6

A

Tensile strength shall be 40.0 ksi max.

5. Chemical Composition 6. Tensile Properties

5.1 The sheet and plate shall conform to the chemical 6.1 The sheet and plate shall conform to the tensile require-

requirements in Table 1. ments in Table 2 [Table 3] unless another agreement is made

A

TABLE 3 Tensile Requirements [Metric]

Specified Tensile Yield Strength

Elongation, min%

B

Thickness, mm Strength, MPa (0.2% offset), MPa

Alloy and

Temper

in 5 3dia

C

Over Through Min Max Min in 50 mm

(5.65 V A)

AZ31B-O 0.40 12.50 221 275 . . . 12 . . .

12.50 50.00 221 275 . . . . . . 9

50.00 80.00 221 275 . . . . . . 8

AZ31B-H24 0.40 6.30 269 . . . 200 6 . . .

6.30 10.00 262 . . . 179 8 . . .

10.00 12.50 255 . . . 165 8 . . .

12.50 25.00 248 . . . 152 . . . 7

25.00 50.00 234 . . . 138 . . . 7

50.00 80.00 234 . . . 124 . . . 7

AZ31B-H26 6.30 10.00 269 . . . 186 6 . . .

10.00 12.50 262 . . . 179 6 . . .

12.50 20.00 255 . . . 172 . . . 5

20.00 25.00 255 . . . 159 . . . 5

25.00 40.00 241 . . . 152 . . . 5

40.00 50.00 241 . . . 148 . . . 5

A

The basis for establishment of mechanical property limits as shown inAppendix X1.

B

Todetermineconformancetothisspecificationeachvaluefortensilestrengthshallberoundedtothenearest1MPaandeachvalueforelongationtothenearest0.5%,

both in accordance with the rounding-off method of PracticeE29.

C

Elongation in 50 mm apply for thicknesses up through 12.50 mm and in 53diameter (5.65 V A) for thicknesses over 12.50 mm where A is the cross-sectional area

of the specimen.

B 90/B 90M – 98 (2005)

between seller and purchaser. Properties for sizes and tempers 9. Sampling for Chemical Analysis

notshowninTable2[Table3]shallbeasagreeduponbyseller

9.1 Ingot—At least one sample shall be taken for each

and purchaser.

group of ingots of the same alloy poured from the same source

of molten metal and analyzed to determine conformance to

7. Dimensional Tolerances

Table 1. Ingots not conforming shall be rejected.

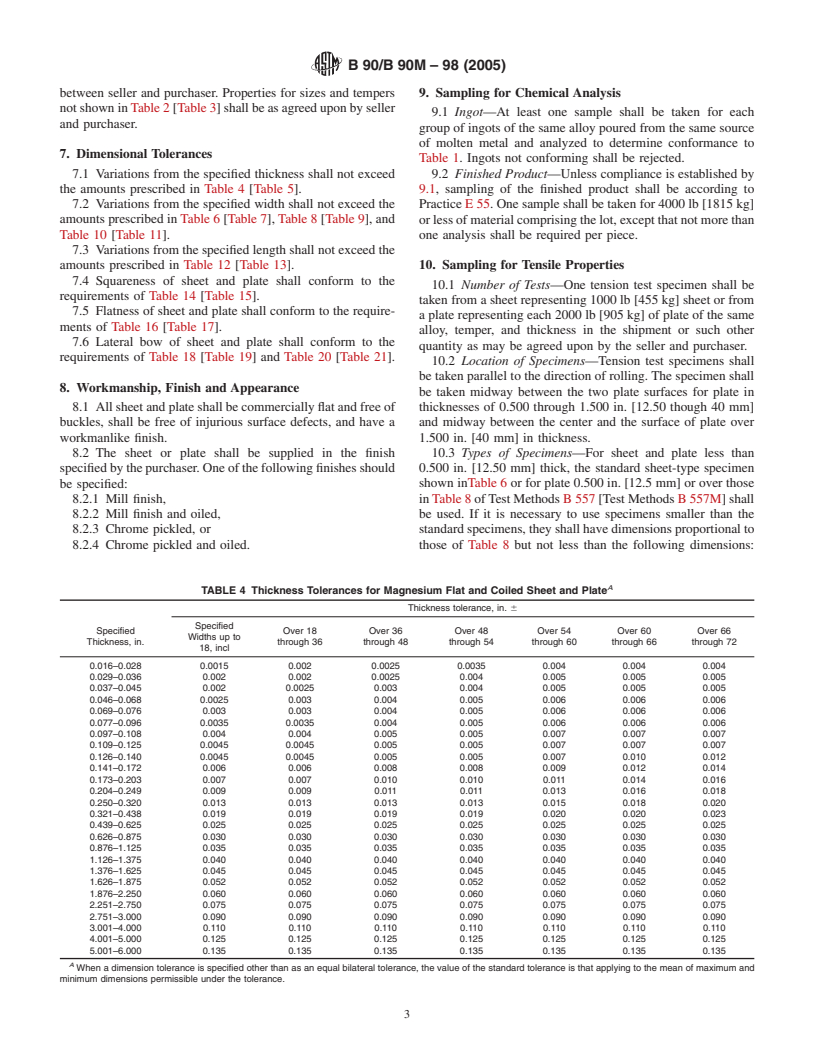

7.1 Variations from the specified thickness shall not exceed 9.2 Finished Product—Unless compliance is established by

the amounts prescribed in Table 4 [Table 5]. 9.1, sampling of the finished product shall be according to

7.2 Variations from the specified width shall not exceed the PracticeE55. One sample shall be taken for 4000 lb [1815 kg]

amounts prescribed inTable 6 [Table 7],Table 8 [Table 9], and orlessofmaterialcomprisingthelot,exceptthatnotmorethan

Table 10 [Table 11]. one analysis shall be required per piece.

7.3 Variations from the specified length shall not exceed the

10. Sampling for Tensile Properties

amounts prescribed in Table 12 [Table 13].

7.4 Squareness of sheet and plate shall conform to the

10.1 Number of Tests—One tension test specimen shall be

requirements of Table 14 [Table 15].

taken from a sheet representing 1000 lb [455 kg] sheet or from

7.5 Flatness of sheet and plate shall conform to the require-

a plate representing each 2000 lb [905 kg] of plate of the same

ments of Table 16 [Table 17].

alloy, temper, and thickness in the shipment or such other

7.6 Lateral bow of sheet and plate shall conform to the

quantity as may be agreed upon by the seller and purchaser.

requirements of Table 18 [Table 19] and Table 20 [Table 21].

10.2 Location of Specimens—Tension test specimens shall

be taken parallel to the direction of rolling. The specimen shall

8. Workmanship, Finish and Appearance

be taken midway between the two plate surfaces for plate in

8.1 Allsheetandplateshallbecommerciallyflatandfreeof thicknesses of 0.500 through 1.500 in. [12.50 though 40 mm]

buckles, shall be free of injurious surface defects, and have a and midway between the center and the surface of plate over

workmanlike finish. 1.500 in. [40 mm] in thickness.

8.2 The sheet or plate shall be supplied in the finish 10.3 Types of Specimens—For sheet and plate less than

specifiedbythepurchaser.Oneofthefollowingfinishesshould 0.500 in. [12.50 mm] thick, the standard sheet-type specimen

be specified: shown inTable 6 or for plate 0.500 in. [12.5 mm] or over those

8.2.1 Mill finish, inTable8ofTestMethodsB 557[TestMethodsB 557M]shall

8.2.2 Mill finish and oiled, be used. If it is necessary to use specimens smaller than the

standardspecimens,theyshallhavedimensionsproportionalto

8.2.3 Chrome pickled, or

8.2.4 Chrome pickled and oiled. those of Table 8 but not less than the following dimensions:

A

TABLE 4 Thickness Tolerances for Magnesium Flat and Coiled Sheet and Plate

Thickness tolerance, in. 6

Specified

Specified Over 18 Over 36 Over 48 Over 54 Over 60 Over 66

Widths up to

Thickness, in. through 36 through 48 through 54 through 60 through 66 through 72

18, incl

0.016–0.028 0.0015 0.002 0.0025 0.0035 0.004 0.004 0.004

0.029–0.036 0.002 0.002 0.0025 0.004 0.005 0.005 0.005

0.037–0.045 0.002 0.0025 0.003 0.004 0.005 0.005 0.005

0.046–0.068 0.0025 0.003 0.004 0.005 0.006 0.006 0.006

0.069–0.076 0.003 0.003 0.004 0.005 0.006 0.006 0.006

0.077–0.096 0.0035 0.0035 0.004 0.005 0.006 0.006 0.006

0.097–0.108 0.004 0.004 0.005 0.005 0.007 0.007 0.007

0.109–0.125 0.0045 0.0045 0.005 0.005 0.007 0.007 0.007

0.126–0.140 0.0045 0.0045 0.005 0.005 0.007 0.010 0.012

0.141–0.172 0.006 0.006 0.008 0.008 0.009 0.012 0.014

0.173–0.203 0.007 0.007 0.010 0.010 0.011 0.014 0.016

0.204–0.249 0.009 0.009 0.011 0.011 0.013 0.016 0.018

0.250–0.320 0.013 0.013 0.013 0.013 0.015 0.018 0.020

0.321–0.438 0.019 0.019 0.019 0.019 0.020 0.020 0.023

0.439–0.625 0.025 0.025 0.025 0.025 0.025 0.025 0.025

0.626–0.875 0.030 0.030 0.030 0.030 0.030 0.030 0.030

0.876–1.125 0.035 0.035 0.035 0.035 0.035 0.035 0.035

1.126–1.375 0.040 0.040 0.040 0.040 0.040 0.040 0.040

1.376–1.625 0.045 0.045 0.045 0.045 0.045 0.045 0.045

1.626–1.875 0.052 0.052 0.052 0.052 0.052 0.052 0.052

1.876–2.250 0.060 0.060 0.060 0.060 0.060 0.060 0.060

2.251–2.750 0.075 0.075 0.075 0.075 0.075 0.075 0.075

2.751–3.000 0.090 0.090 0.090 0.090 0.090 0.090 0.090

3.001–4.000 0.110 0.110 0.110 0.110 0.110 0.110 0.110

4.001–5.000 0.125 0.125 0.125 0.125 0.125 0.125 0.125

5.001–6.000 0.135 0.135 0.135 0.135 0.135 0.135 0.135

A

When a dimension tolerance is specified other than as an equal bilateral tolerance, the value of the standard tolerance is that applying to the mean of maximum and

minimum dimensions permissible under the tolerance.

B 90/B 90M – 98 (2005)

A

TABLE 5 Thickness Tolerances for Magnesium Flat and Coiled Sheet and Plate [Metric]

Thickness tolerance, mm6

Specified Thickness,

Specified Over Over Over Over Over Over

mm

Widths up 450 900 1200 1350 1500 1650

Over Through

to 450, Through Through Through Through Through Through

incl. 900 1200 1350 1500 1650 1850

0.40–0.70 0.04 0.05 0.06 0.09 0.10 0.10 0.10

0.70–0.90 0.05 0.05 0.06 0.10 0.12 0.12 0.12

0.90–1.15 0.05 0.06 0.07 0.10 0.12 0.12 0.12

1.15–1.70 0.06 0.07 0.10 0.12 0.15 0.15 0.15

1.70–1.90 0.07 0.07 0.10 0.12 0.15 0.15 0.15

1.90–2.40 0.09 0.09 0.10 0.12 0.15 0.15 0.15

2.40–2.76 0.10 0.10 0.12 0.12 0.18 0.18 0.18

2.76–3.17 0.11 0.11 0.12 0.12 0.18 0.18 0.18

3.17–3.55 0.11 0.11 0.12 0.12 0.18 0.25 0.30

3.55–4.35 0.15 0.15 0.20 0.20 0.22 0.30 0.35

4.35–5.15 0.18 0.18 0.25 0.25 0.27 0.35 0.40

5.15–6.30 0.23 0.23 0.28 0.27 0.33 0.40 0.45

6.30–8.00 0.33 0.33 0.33 0.33 0.38 0.45 0.50

8.00–11.10 0.48 0.48 0.48 0.48 0.50 0.50 0.58

11.10–15.75 0.63 0.63 0.63 0.63 0.63 0.63 0.63

15.75–22.20 0.75 0.75 0.75 0.75 0.75 0.75 0.75

22.20–28.50 0.89 0.88 0.88 0.88 0.88 0.88 0.88

28.50–34.90 1.00 1.00 1.00 1.00 1.00 1.00 1.00

34.90–41.25 1.14 1.14 1.14 1.14 1.14 1.14 1.14

41.25–47.60 1.32 1.32 1.32 1.32 1.32 1.32 1.32

47.60–57.15 1.52 1.52 1.52 1.52 1.52 1.52 1.52

57.15–69.85 1.90 1.90 1.90 1.90 1.90 1.90 1.90

69.85–76.20 2.28 2.25 2.25 2.25 2.25 2.25 2.25

76.20–100.00 2.79 2.75 2.75 2.75 2.75 2.75 2.75

100.00–125.00 3.15 3.15 3.15 3.15 3.15 3.15 3.15

125.00–150.00 3.40 3.40 3.40 3.40 3.40 3.40 3.40

A

When a dimension tolerance is specified other than as an equal bilateral tolerance, the value of the standard tolerance is that applying to the mean of maximum and

minimum dimensions permissible under the tolerance.

A

TABLE 6 Width Tolerances—Magnesium Flat Sheet TABLE 8 Width and Length Tolerances—Magnesium Sawed

Flat Plate

Width tolerances, in. 6

A

Specified Specified Over 4 Over 18 Over 36 Over 54

Tolerances, in. 6 specified width or length, in.

Specified

Thickness, in. Widths up through through through through

Up Over 10 Over 48

Thickness, in. Over 84

through 4 18 36 54 72

through 10 through 48 through 84

0.016–0.064 1/32 1/16 3/32 1/8 5/32

0.250–6.000 3/32 3/16 1/4 5/16

0.065–0.102 1/16 1/16 3/32 1/8 5/32

A

Maximum width=72 in.

0.103–0.249 1/8 3/32 1/8 3/16 3/16

A

0.016–0.099 sheared to above tolerances.

TABLE 9 Width and Length Tolerances, Magnesium Sawed Flat

0.100–0.249 sawed or sheared to above tolerances.

Plate [Metric]

A

A

Tolerances, mm 6 specified width or length

TABLE 7 Width Tolerances,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.