ASTM B403-20

(Specification)Standard Specification for Magnesium-Alloy Investment Castings

Standard Specification for Magnesium-Alloy Investment Castings

ABSTRACT

This specification covers magnesium-alloy investment castings designated as AM100A, AZ81A, AZ91C, AZ91E, AZ92A, EQ21A, EZ33A, K1A, QE22A, ZE41A, and ZK61A. Sufficient stock shall be allowed for shrinkage and, where required, for finishing; but castings of excessive weight shall not be furnished. The castings shall conform to the chemical composition requirements prescribed for magnesium, aluminum, manganese, zinc, zirconium, rare earth elements, copper, nickel, silicon, iron, and other impurities, as determined by chemical analysis, and shall meet the specified requirements for the tensile properties such as tensile strength, yield strength, and elongation. Requirements for heat treatment and tensile test are detailed. The castings shall be of uniform quality and condition, free from cracks and other injurious defects, shall be cleaned before inspection by blasting or other approved process, and shall not be repaired by welding, impregnation, peening, or other method unless it is required.

SCOPE

1.1 This specification covers magnesium-alloy investment castings designated as shown in Table 1.

1.2 Alloy designations are in accordance with Practice E527; temper designations are in accordance with Practice B296.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B403 −20

Standard Specification for

1

Magnesium-Alloy Investment Castings

This standard is issued under the fixed designation B403; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B951 PracticeforCodificationofUnalloyedMagnesiumand

Magnesium-Alloys, Cast and Wrought

1.1 This specification covers magnesium-alloy investment

B953 Practice for Sampling Magnesium and Magnesium

castings designated as shown in Table 1.

Alloys for Spectrochemical Analysis

1.2 Alloy designations are in accordance with Practice

B954 Test Method for Analysis of Magnesium and Magne-

E527; temper designations are in accordance with Practice

sium Alloys by Atomic Emission Spectrometry

B296.

D3951 Practice for Commercial Packaging

E29 Practice for Using Significant Digits in Test Data to

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical Determine Conformance with Specifications

E94 Guide for Radiographic Examination Using Industrial

conversions to SI units that are provided for information only

and are not considered standard. Radiographic Film

E155 Reference Radiographs for Inspection of Aluminum

1.4 This international standard was developed in accor-

and Magnesium Castings

dance with internationally recognized principles on standard-

E165 Practice for Liquid Penetrant Testing for General

ization established in the Decision on Principles for the

Industry

Development of International Standards, Guides and Recom-

E527 Practice for Numbering Metals and Alloys in the

mendations issued by the World Trade Organization Technical

Unified Numbering System (UNS)

Barriers to Trade (TBT) Committee.

3

2.3 Federal Standards:

Fed. Std. No. 123 Marking for Shipping (Civil Agencies)

2. Referenced Documents

3

2.4 Military Standards:

2.1 The following documents of the issue in effect on the

MIL-STD-129 Marking for Shipment and Storage (Military

date of order acceptance form a part of this specification to the

Agencies)

extent referenced herein:

2

3. Ordering Information

2.2 ASTM Standards:

B296 Practice for Temper Designations of Magnesium 3.1 Orders for castings under this specification shall include

Alloys, Cast and Wrought

the following information:

B557 Test Methods for Tension Testing Wrought and Cast 3.1.1 Quantity of each casting,

Aluminum- and Magnesium-Alloy Products

3.1.2 Alloy (see Section 6 and Table 1),

B660 Practices for Packaging/Packing of Aluminum and

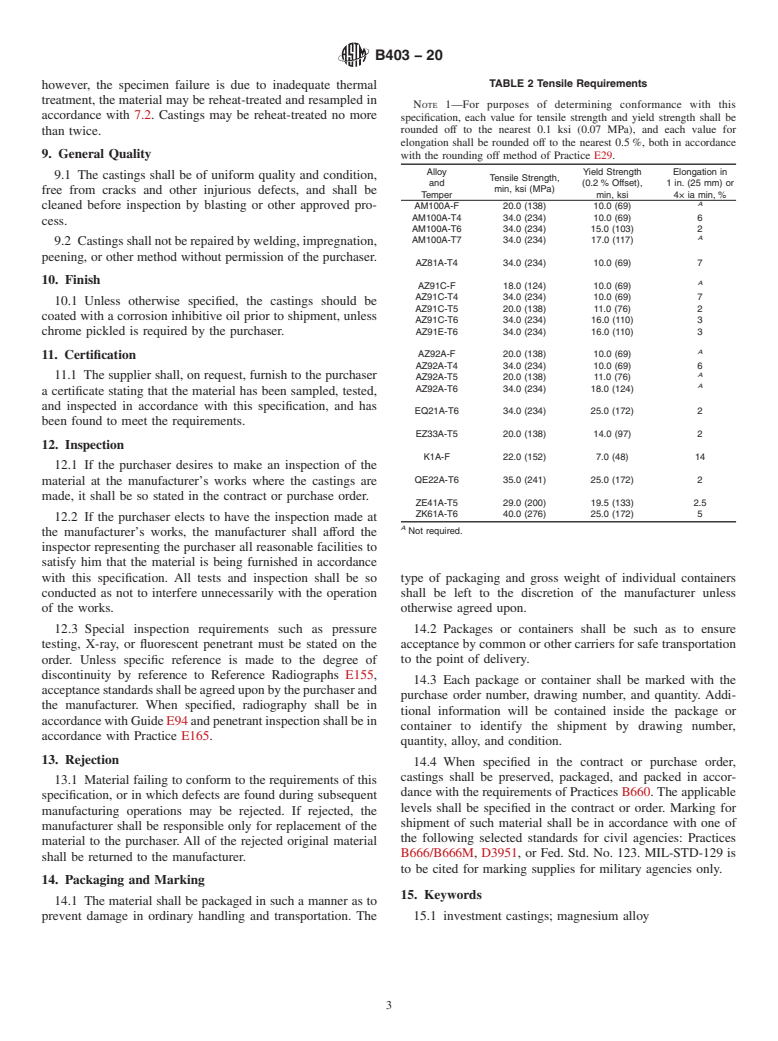

3.1.3 Temper (see 5.1 and Table 2),

Magnesium Products

3.1.4 Casting drawing giving all necessary dimensions and

B661 Practice for Heat Treatment of Magnesium Alloys

showing amount of finish left for machining,

B666/B666M Practice for Identification Marking of Alumi-

3.1.5 Surface treatment (see 10.1),

num and Magnesium Products

3.1.6 Whether certification is required (see 11.1),

3.1.7 Whether inspection is required at the manufacturer’s

works (see 12.1), and

1

This specification is under the jurisdiction of ASTM Committee B07 on Light

3.1.8 Special inspection requirements (see 12.3).

Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on

Magnesium Alloy Cast and Wrought Products.

4. Materials and Manufacture

Current edition approved Nov. 1, 2020. Published December 2020. Originally

4.1 The responsibility for furnishing castings that can be

approved in 1963. Last previous edition approved in 2012 as B403 – 12. DOI:

10.1520/B0403-20.

laid out and machined to the finished dimensions within the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B403−20

A

TABLE 1 Chemical Composition Limits

NOTE1—Analysisshallregularlybemadefortheelementsspecificallymentionedinthistable.If,however,thepresenceofotherelementsissuspected

or indicated in amounts greater than the specified limits, further analysis

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B403 − 12 B403 − 20

Standard Specification for

1

Magnesium-Alloy Investment Castings

This standard is issued under the fixed designation B403; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers magnesium-alloy investment castings designated as shown in Table 1.

1.2 Alloy designations are in accordance with Practice E527; temper designations are in accordance with Practice B296.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are for information

only. mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of order acceptance form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B296 Practice for Temper Designations of Magnesium Alloys, Cast and Wrought

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B660 Practices for Packaging/Packing of Aluminum and Magnesium Products

B661 Practice for Heat Treatment of Magnesium Alloys

B666/B666M Practice for Identification Marking of Aluminum and Magnesium Products

B951 Practice for Codification of Unalloyed Magnesium and Magnesium-Alloys, Cast and Wrought

B953 Practice for Sampling Magnesium and Magnesium Alloys for Spectrochemical Analysis

B954 Test Method for Analysis of Magnesium and Magnesium Alloys by Atomic Emission Spectrometry

D3951 Practice for Commercial Packaging

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E88 Practice for Sampling Nonferrous Metals and Alloys in Cast Form for Determination of Chemical Composition

E94 Guide for Radiographic Examination Using Industrial Radiographic Film

E155 Reference Radiographs for Inspection of Aluminum and Magnesium Castings

1

This specification is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on Magnesium

Alloy Cast and Wrought Products.

Current edition approved Nov. 1, 2012Nov. 1, 2020. Published November 2012December 2020. Originally approved in 1963. Last previous edition approved in 20072012

as B403 – 07.B403 – 12. DOI: 10.1520/B0403-12.10.1520/B0403-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B403 − 20

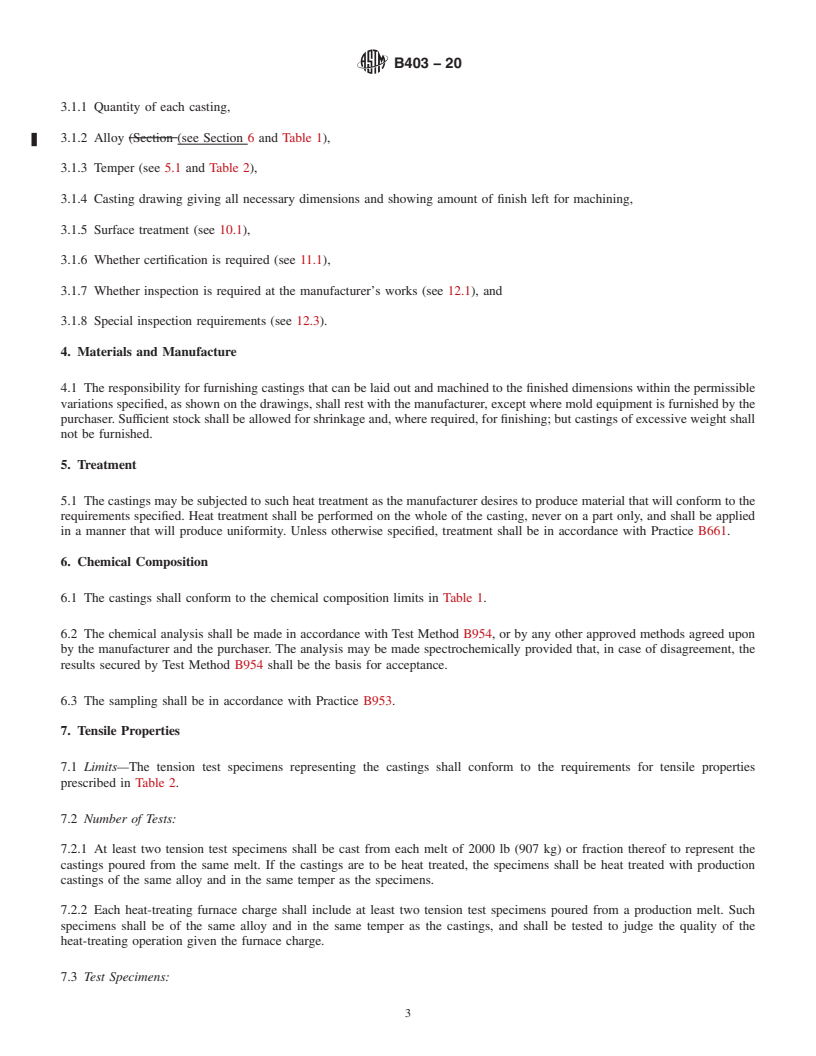

A

TABLE 1 Chemical Composition Limits

NOTE 1—Analysis shall regularly be made for the elements specifically mentioned in this table. If, however, the presence of other elements is suspected

or indicated in amounts greater than the specified limits, further analysis shall be made to determine that these elements are not present in excess of the

specified limits.

NOTE 2—The following applied to all specified limits in this table: For purposes of acceptance and rejection, an observed value or a calculated value

obtained from analysis should be rounded off to the nearest unit in the last right-hand place of figures used in expressing the specified limit.

B

Alloy Number Composition, percent

Others

C

Total

Each

Other

Magne- Alu- Manga- Rare

Impurities

ASTM UNS Iron Zinc Zirconium Thorium Copper Nickel Silicon

sium minum nese Earths

... 9.3–10.7 0.30 0.10–0.35AM100Aremain-... M10100... ...0.100.010.30

der

AZ81A M11810 . remainder 7.0–8.1 0.13–0.35 0.40–1.0 . . . 0.10 0.01 0.30 0.30 .

AZ91C M11914 . remainder 8.1–9.3 0.13–0.35 0.40–1.0 .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.