ASTM D120-02a(2006)

(Specification)Standard Specification for Rubber Insulating Gloves

Standard Specification for Rubber Insulating Gloves

ABSTRACT

This specification covers manufacturing and testing of rubber insulating gloves for protection of workers from electrical shock. Two types of gloves are provided and are designated as Type I, non-resistant to ozone, and Type II, resistant to ozone. Six classes of gloves, differing in electrical characteristics, are provided and are designated as Class 00, Class 0, Class 1, Class 2, Class 3, and Class 4. The following tests shall be performed: ac proof test; ac breakdown test; ac moisture absorption/proof test; dc proof test; dc breakdown test; ozone resistance test; chemical tests; tensile strength; tear resistance test; and puncture resistance test.

SCOPE

1.1 This specification covers manufacturing and testing of rubber insulating gloves for protection of workers from electrical shock.

1.2 Two types of gloves are provided and are designated as Type I, non-resistant to ozone, and Type II, resistant to ozone.

1.3 Six classes of gloves, differing in electrical characteristics, are provided and are designated as Class 00, Class 0, Class 1, Class 2, Class 3, and Class 4.

1.4 The values stated in SI units are to be regarded as the standard. See ASTM SI 10.

The following safety hazards caveat pertains only to the test method portion, Sections 16, 17, 18, and 19, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.For specific precaution statements, see 18.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 120 – 02a (Reapproved 2006)

Standard Specification for

Rubber Insulating Gloves

This standard is issued under the fixed designation D 120; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 1149 Test Method for Rubber Deterioration—Surface

Ozone Cracking in a Chamber

1.1 This specification covers manufacturing and testing of

D 1415 Test Method for Rubber Property—International

rubber insulating gloves for protection of workers from elec-

Hardness

trical shock.

D 2240 Test Method for Rubber Property—Durometer

1.2 Two types of gloves are provided and are designated as

Hardness

Type I, non-resistant to ozone, and Type II, resistant to ozone.

D 2865 Practice for Calibration of Standards and Equip-

1.3 Six classes of gloves, differing in electrical characteris-

ment for Electrical Insulating Materials Testing

tics,areprovidedandaredesignatedasClass00,Class0,Class

F 819 Terminology Relating to Electrical Protective Equip-

1, Class 2, Class 3, and Class 4.

ment for Workers

1.4 The values stated in SI units are to be regarded as the

SI 10 Standard for Use of the International System of Units

standard. See ASTM SI 10.

(SI): The Modern Metric System

1.5 The following safety hazards caveat pertains only to the

test method portion, Sections 16, 17, 18, and 19, of this

3. Terminology

specification: This standard does not purport to address all of

3.1 Definitions:

the safety concerns, if any, associated with its use. It is the

3.1.1 color splash—a splash, smear, or streak of contrasting

responsibility of the user of this standard to establish appro-

color evident on the inside or outside surface of the gloves that

priate safety and health practices and determine the applica-

was deposited during the dipping operation and is vulcanized

bility of regulatory limitations prior to use. For specific

into the glove as part of the homogenous compound.

precaution statements, see 18.2.

3.1.2 glove cuff roll—the roll or reinforced edge of an

2. Referenced Documents insulating glove at the cuff.

2 3.1.3 halogenation treatment—exposure of the entire glove

2.1 ASTM Standards:

surface area to a halogen for the purpose of reducing surface

D 297 Test Methods for Rubber Products—Chemical

friction.

Analysis

3.1.4 ozone—a very active form of oxygen that may be

D 412 Test Methods for Vulcanized Rubber and Thermo-

produced by corona, arcing, or ultraviolet rays.

plastic Elastomers—Tension

3.1.5 user—the employer or entity purchasing the equip-

D 518 Test Method for Rubber Deterioration—Surface

ment to be utilized by workers for their protection; in the

Cracking

absence of such an employer or entity, the individual purchas-

D 573 Test Method for Rubber—Deterioration in an Air

ing and utilizing the protective equipment.

Oven

3.1.6 working area—allfingerandthumbcrotches,thepalm

D 624 Test Method for Tear Strength of Conventional

(area between the wrist and the base of the finger and thumb)

Vulcanized Rubber and Thermoplastic Elastomers

and the area of the finger and thumb facing the palm not

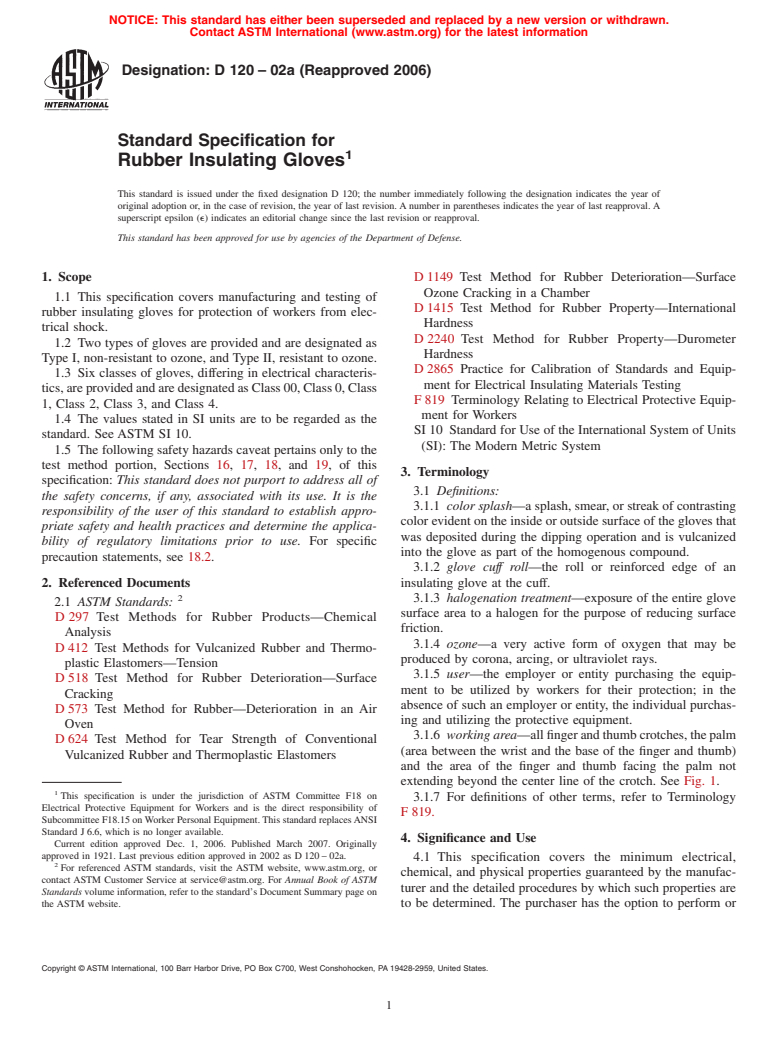

extending beyond the center line of the crotch. See Fig. 1.

This specification is under the jurisdiction of ASTM Committee F18 on

3.1.7 For definitions of other terms, refer to Terminology

Electrical Protective Equipment for Workers and is the direct responsibility of

F 819.

Subcommittee F18.15 onWorker Personal Equipment.This standard replacesANSI

Standard J 6.6, which is no longer available.

4. Significance and Use

Current edition approved Dec. 1, 2006. Published March 2007. Originally

approved in 1921. Last previous edition approved in 2002 as D 120 – 02a.

4.1 This specification covers the minimum electrical,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

chemical, and physical properties guaranteed by the manufac-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

turer and the detailed procedures by which such properties are

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. to be determined. The purchaser has the option to perform or

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 120 – 02a (2006)

FIG. 1 Working Area of a Rubber Insulating Glove

TABLE 1 Proof-Test/Use Voltage Relationship

4.4 It is common practice and the responsibility of the user

Maximum AC of this type of protective equipment to prepare complete

AC Proof-Test DC Proof-Test Maximum DC Use

A

Class of Glove Use Voltage

instructions and regulations to govern the correct and safe use

Voltage, rms, V Voltage, avg, V Voltage avg, V

ac rms, V

of such equipment.

00 2 500 500 10 000 750

0 5 000 1 000 20 000 1 500

5. Classification

1 10 000 7 500 40 000 11 250

5.1 Gloves covered under this specification shall be desig-

2 20 000 17 000 50 000 25 500

3 30 000 26 500 60 000 39 750

nated as Type I or Type II; Class 00, Class 0, Class 1, Class 2,

4 40 000 36 000 70 000 54 000

Class 3, or Class 4.

A

Except for Class 00 and 0 gloves, the AC maximum use voltage is based

RMS

5.1.1 Type I,non-resistanttoozone,madefromahigh-grade

on the following formula:

cis-1,4-polyisoprene rubber compound of natural or synthetic

Maximum AC use voltage (maximum nominal design voltage) = 0.95 ac proof-test

voltage − 2000 V

origin, properly vulcanized.

This formula takes into account the reduction in the volts per mil capability of the

5.1.2 Type II, ozone-resistant made of any elastomer or

glove with increasing thickness of the rubber.

combination of elastomeric compounds.

5.1.3 The class designation shall be based on the electrical

have performed any of these tests in order to verify the

properties as shown in Table 2 and Table 3.

guarantee. Claims for failure to meet the specification are

6. Ordering Information

subject to verification by the manufacturer.

4.2 Gloves are used for personal protection; therefore, when

6.1 Ordersforglovesunderthisspecificationshouldinclude

authorizing their use, a margin of safety shall be allowed the following information:

between the maximum voltage on which they are used and the

6.1.1 Type,

proof-test voltage at which they are tested. The relationship 6.1.2 Class,

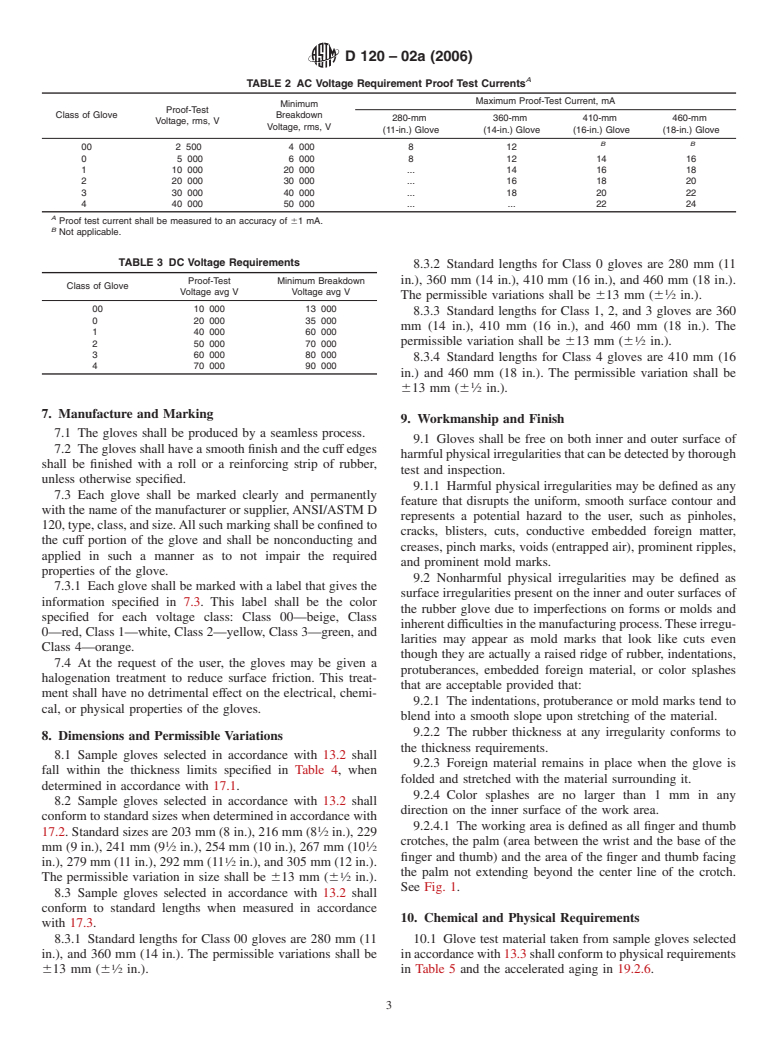

between proof-test voltage and the maximum voltage at which 6.1.3 Length, Fig. 2

the gloves shall be used is shown in Table 1. 6.1.4 Size,

4.3 Work practices vary from user to user and are dependent 6.1.5 Color,

upon many factors. These may include, but are not limited to, 6.1.6 Cuff design, and

operating system voltages, construction design, work proce- 6.1.7 With or without a halogenation treatment.

dure techniques, weather conditions, and so forth. Therefore, 6.2 The listing of types, classes, lengths, sizes, colors, and

except for the restriction set forth in this specification because cuffdesignsisnotintendedtomeanthatallshallnecessarilybe

of design limitations, the use and maintenance of this equip- available from manufacturers; it signifies only that, if made,

ment is beyond the scope of this specification. they shall conform to the details of this specification.

D 120 – 02a (2006)

A

TABLE 2 AC Voltage Requirement Proof Test Currents

Maximum Proof-Test Current, mA

Minimum

Proof-Test

Class of Glove Breakdown

280-mm 360-mm 410-mm 460-mm

Voltage, rms, V

Voltage, rms, V

(11-in.) Glove (14-in.) Glove (16-in.) Glove (18-in.) Glove

BB

00 2 500 4 000 8 12

0 5 000 6 000 8 12 14 16

1 10 000 20 000 . 14 16 18

2 20 000 30 000 . 16 18 20

3 30 000 40 000 . 18 20 22

4 40 000 50 000 . . 22 24

A

Proof test current shall be measured to an accuracy of 61 mA.

B

Not applicable.

TABLE 3 DC Voltage Requirements

8.3.2 Standard lengths for Class 0 gloves are 280 mm (11

Proof-Test Minimum Breakdown in.), 360 mm (14 in.), 410 mm (16 in.), and 460 mm (18 in.).

Class of Glove

Voltage avg V Voltage avg V 1

The permissible variations shall be 613 mm (6 ⁄2 in.).

00 10 000 13 000

8.3.3 Standard lengths for Class 1, 2, and 3 gloves are 360

0 20 000 35 000

mm (14 in.), 410 mm (16 in.), and 460 mm (18 in.). The

1 40 000 60 000

permissible variation shall be 613 mm (6 ⁄2 in.).

2 50 000 70 000

3 60 000 80 000

8.3.4 Standard lengths for Class 4 gloves are 410 mm (16

4 70 000 90 000

in.) and 460 mm (18 in.). The permissible variation shall be

613 mm (6 ⁄2 in.).

7. Manufacture and Marking

9. Workmanship and Finish

7.1 The gloves shall be produced by a seamless process.

9.1 Gloves shall be free on both inner and outer surface of

7.2 The gloves shall have a smooth finish and the cuff edges

harmfulphysicalirregularitiesthatcanbedetectedbythorough

shall be finished with a roll or a reinforcing strip of rubber,

test and inspection.

unless otherwise specified.

9.1.1 Harmful physical irregularities may be defined as any

7.3 Each glove shall be marked clearly and permanently

feature that disrupts the uniform, smooth surface contour and

with the name of the manufacturer or supplier,ANSI/ASTM D

represents a potential hazard to the user, such as pinholes,

120, type, class, and size.All such marking shall be confined to

cracks, blisters, cuts, conductive embedded foreign matter,

the cuff portion of the glove and shall be nonconducting and

creases, pinch marks, voids (entrapped air), prominent ripples,

applied in such a manner as to not impair the required

and prominent mold marks.

properties of the glove.

9.2 Nonharmful physical irregularities may be defined as

7.3.1 Each glove shall be marked with a label that gives the

surface irregularities present on the inner and outer surfaces of

information specified in 7.3. This label shall be the color

the rubber glove due to imperfections on forms or molds and

specified for each voltage class: Class 00—beige, Class

inherentdifficultiesinthemanufacturingprocess.Theseirregu-

0—red, Class 1—white, Class 2—yellow, Class 3—green, and

larities may appear as mold marks that look like cuts even

Class 4—orange.

though they are actually a raised ridge of rubber, indentations,

7.4 At the request of the user, the gloves may be given a

protuberances, embedded foreign material, or color splashes

halogenation treatment to reduce surface friction. This treat-

that are acceptable provided that:

ment shall have no detrimental effect on the electrical, chemi-

9.2.1 The indentations, protuberance or mold marks tend to

cal, or physical properties of the gloves.

blend into a smooth slope upon stretching of the material.

9.2.2 The rubber thickness at any irregularity conforms to

8. Dimensions and Permissible Variations

the thickness requirements.

8.1 Sample gloves selected in accordance with 13.2 shall

9.2.3 Foreign material remains in place when the glove is

fall within the thickness limits specified in Table 4, when

folded and stretched with the material surrounding it.

determined in accordance with 17.1.

9.2.4 Color splashes are no larger than 1 mm in any

8.2 Sample gloves selected in accordance with 13.2 shall

direction on the inner surface of the work area.

conform to standard sizes when determined in accordance with

9.2.4.1 The working area is defined as all finger and thumb

17.2. Standard sizes are 203 mm (8 in.), 216 mm (8 ⁄2 in.), 229

crotches, the palm (area between the wrist and the base of the

1 1

mm (9 in.), 241 mm (9 ⁄2 in.), 254 mm (10 in.), 267 mm (10 ⁄2

finger and thumb) and the area of the finger and thumb facing

in.), 279 mm (11 in.), 292 mm (11 ⁄2 in.), and 305 mm (12 in.).

the palm not extending beyond the center line of the crotch.

The permissible variation in size shall be 613 mm (6 ⁄2 in.).

See Fig. 1.

8.3 Sample gloves selected in accordance with 13.2 shall

conform to standard lengths when measured in accordance

10. Chemical and Physical Requirements

with 17.3.

8.3.1 Standard lengths for Class 00 gloves are 280 mm (11 10.1 Glove test material taken from sample gloves selected

in.), and 360 mm (14 in.). The permissible variations shall be inaccordancewith13.3shallconformtophysicalrequirements

613 mm (6 ⁄2 in.). in Table 5 and the accelerated aging in 19.2.6.

D 120 – 02a (2006)

FIG. 2 Length and Contour Measurements on Contour Cuff Gloves

TABLE 4 Thickness Measurements

proof-test voltage (average value) specified in Table 2 or Table

Minimum Thickness 3.TheprooftestshallbeperformedinaccordancewithSection

Maximum Thickness

Class of

18. The test voltage shall be applied continuously for 3 min.

In Crotch Other Than Crotch

Glove

11.1.1 When the ac proof test is used, the 60-Hz proof-test

mm in. mm in. mm in.

current shall not exceed the values specified in Table 2 at any

00 0.20 0.008 0.25 0.010 0.75 0.030

time during the test period. (Note 1 and Note 2).

0 0.46 0.018 0.51 0.020 1.02 0.040

1 0.63 0.025 0.76 0.030 1.52 0.060

11.2 Sample gloves selected in accordance with 13.2 shall

2 1.02 0.040 1.27 0.050 2.29 0.090

not break down at voltages below those specified in Table 2 or

3 1.52 0.060 1.90 0.075 2.92 0.115

4 2.03 0.080 2.54 0.100 3.56 0.140 Table 3 when tested in accordance with Section 18.

11.2.1 Gloves that have been subjected to a minimum

breakdownvoltagetestshallnotbeusedforelectricprotection.

TABLE 5 Physical Requirements

Proof test current shall be measured to an accuracy of 61 mA.

Property Type I Type II

11.3 Sample gloves selected in accordance with 13.2 shall

Tensile strength, min, Die C, MPa (psi) 17.2 (2500) 10.3 (1500) be subjected to a 60-Hz ac moisture absorption/proof test in

Tensile stress at 200 %, max, MPa (psi) 2.1 (300) 2.1 (300)

accordance with Section 18.

Ultimate elongation, min, % 600 500

11.3.1 The 60-Hz ac proof test current shall not exceed the

Tension set, max at 400, % 25 25

Tear resistance, min, kN/m (lbf/in.) 21 (120) 14 (80)

values specified in Table 2 by more than 2 mA.

Puncture resistance, min, kN/m (lbf/in.) 18 (100) 18 (100)

Hardness, max, shore A 47 47

NOTE 1—If the ac proof test is made at any frequency other than 60 Hz,

the permissible proof-test current shall be computed from the direct ratio

of the frequencies.

NOTE 2—A proof-test current is an indication of the validity of the

10.2 Intheeventofadispute,theidentificationoftherubber

glove make-up, the dielectric constant of the type of material used, the

polymer in Type I gloves shall be performed in accordance thickness, and the total contact area under test.

with 19.1.

12. Guarantee

10.3 Type II glove test material taken from sample gloves

selected in accordance with 13.3 shall show no visible effec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.