ASTM F2715-19(2024)

(Specification)Standard Specification for Temporary Protective Equipotential Bond Mat To Be Used on De-Energized Equipment

Standard Specification for Temporary Protective Equipotential Bond Mat To Be Used on De-Energized Equipment

SCOPE

1.1 This specification covers the manufacture and testing of the temporary protective equipotential bond mat used on or around de-energized electrical equipment.

1.2 It is common practice for users of protective equipment to prepare complete instructions and regulations to govern in detail the correct use and maintenance of such equipment.

1.3 The use and maintenance of this equipment is beyond the scope of this specification.

1.4 It is recognized that the use of temporary protective equipotential bond mats requires additional equipment for installation and use, typically temporary connecting jumper assemblies.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2715 − 19 (Reapproved 2024)

Standard Specification for

Temporary Protective Equipotential Bond Mat To Be Used

on De-Energized Equipment

This standard is issued under the fixed designation F2715; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Wire for Electrical Purposes

D2261 Test Method for Tearing Strength of Fabrics by the

1.1 This specification covers the manufacture and testing of

Tongue (Single Rip) Procedure (Constant-Rate-of-

the temporary protective equipotential bond mat used on or

Extension Tensile Testing Machine)

around de-energized electrical equipment.

F855 Specifications for Temporary Protective Grounds to Be

1.2 It is common practice for users of protective equipment

Used on De-energized Electric Power Lines and Equip-

to prepare complete instructions and regulations to govern in

ment

detail the correct use and maintenance of such equipment.

F1267 Specification for Metal, Expanded, Steel

1.3 The use and maintenance of this equipment is beyond F2453 Specification for Welded Wire Mesh Fence Fabric

(Metallic-Coated or Polymer Coated) for Meshes of 6 in.

the scope of this specification.

[3871 mm ] or Less, in Panels or Rolls, with Uniform

1.4 It is recognized that the use of temporary protective

Meshes

equipotential bond mats requires additional equipment for

2.2 Other Standards:

installation and use, typically temporary connecting jumper

Fed Std 191/5100 Strength and Elongation, Breaking of

assemblies.

Woven Cloth; Grab Method

1.5 The values stated in SI units are to be regarded as

Fed Std 191/5874 Temperature, Low; Effect on Coated

standard. The values given in parentheses after SI units are

Cloth

provided for information only and are not considered standard.

Fed Std MVSS302 Flammability of Interior Materials

1.6 This standard does not purport to address all of the

A-A-59551 Wire, Electrical, Copper Un-insulated

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

3.1 Definitions:

mine the applicability of regulatory limitations prior to use.

3.1.1 bonding, n—the mechanical interconnection of con-

1.7 This international standard was developed in accor-

ductive parts to maintain a common electrical potential.

dance with internationally recognized principles on standard-

3.1.2 carrier, fabric, n—the main body of the equipotential

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- bond mat on which the flat braid conductor is sewn.

mendations issued by the World Trade Organization Technical

3.1.3 carrier, non-fabric, n—the main body of the equipo-

Barriers to Trade (TBT) Committee.

tential bond mat on which a conductive metal mesh is attached

by means other than sewing.

2. Referenced Documents

3.1.4 equipotential grounding system, n—temporary

2.1 ASTM Standards:

grounding system placed in such locations and arranged in

B33 Specification for Tin-Coated Soft or Annealed Copper

such a manner as to minimize the likelihood of workers being

exposed to hazardous differences in electrical potential.

This specification is under the jurisdiction of ASTM Committee F18 on

4. Significance and Use

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.45 on Mechanical Apparatus.

4.1 Protective equipotential bond mats in this specification

Current edition approved March 1, 2024. Published March 2024. Originally

shall not be considered Temporary Protective Grounds and are

approved in 2008. Last previous edition approved in 2019 as F2715 – 19. DOI:

10.1520/F2715-19R24.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from U.S. Government Publishing Office (GPO), 732 N. Capitol St.,

the ASTM website. NW, Washington, DC 20401, http://www.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2715 − 19 (2024)

TABLE 2 Metallic Mesh Size

not designed nor intended to carry full rated fault current. Refer

to Specifications F855 for specifications for Temporary Pro- Expanded Mesh Style Mesh Rigidity, D N*m (lb*i)

m

⁄4 #9 7738 (5707)

tective Grounds.

⁄2 #13 1536 (1133)

Square Welded Wire Mesh Size,

4.2 Non-fabric carrier protective equipotential bond mat

mm (in.)

systems have more stringent electrical current tests to verify

50 × 12 (2 × 0.25) 18297 (13495)

structural and interconnection integrity. Test values in this

25 × 6 (1 × 0.12) 8435 (6221)

specification shall be considered a minimum; end users may

request testing to higher values.

5. Classification

7.2.1 Tensile (Grab)—Fabric carrier material shall be ca-

pable of a tensile (grab) of 1828 N to 2037 N (411 lbf to

5.1 Equipotential bond mats covered under this specifica-

458 lbf) in accordance with Fed Std 191/5100.

tion shall be designated as Type I or Type II; Style 1, Style 2,

7.2.2 Tongue Tear—Fabric carrier material shall be capable

Style 3 or Style 4; Grid Conductor, flexible, 1 to 6, or Grid

of tongue tear of 485 N to 516 N (109 lbf to 116 lbf) in

Conductor, metallic mesh; and Fabric Carrier Material I or II.

accordance with Test Methods D2261.

5.1.1 Type I, capable of being cascaded (joined together).

7.2.3 Cold Flexure—Fabric carrier material shall be capable

5.1.2 Type II, without capability of being cascaded.

of a low cold crack of –40 °C (–40 °F) in accordance with Fed

5.1.3 Style 1, fabric carrier with exposed conductor termi-

Std 191/5874-1978

nation.

5.1.4 Style 2, fabric carrier with jacketed conductor termi-

7.3 Flat braid conductor shall comply with A-A-59551 and

nation.

Specification B33 requirements and have the properties con-

5.1.5 Style 3, non-fabric carrier with exposed conductor

tained in Table 3 or greater.

terminations for the metallic mesh.

7.4 Metallic mesh conductor shall comply with Specifica-

5.1.6 Style 4, non-fabric carrier with jacketed conductor

tions F1267 or F2453. The maximum opening size shall not

terminations for the metallic mesh.

exceed 50 mm by 50 mm (2 in. by 2 in.).

5.1.6.1 Grid Conductor, flexible, 1 to 6, in accordance with

the normal flat width, or equivalent, of the flat braid conductors 7.5 Non-fabric carriers shall have a minimum plate flexural

rigidity of 5 times that of the metallic mesh that they carry.

combination that makes up the grid conductor and perimeter

conductor of the fabric carrier, as shown in Table 1. Mesh rigidity values, D , are given in Table 2. Non-fabric

m

carrier isotropic plate flexural rigidity, D , may be calculated

5.1.6.2 Grid Conductor, metallic mesh. Expanded metal

c

3 2

sheet, or welded wire mesh, which makes up the grid by: D 5Et ⁄12~1 2 v !, where E is Young’s Modulus, t is the

c

effective thickness, and v is Poisson’s ratio.

conductor, as shown in Table 2. Mesh type, size and attachment

to the perimeter conductive provisions shall be such that the

7.6 Carrier Fire Resistance—The flame resistance of the

equipotential bond mat meets all electrical test requirements of

carrier shall be performed in accordance with Fed Std

Section 11.

MVSS302 and shall be self extinguishing.

5.1.7 Fabric Carrier Material I, slip resistant.

5.1.8 Fabric Carrier Material II, without slip resistance.

8. Dimensions and Permissible Variations

8.1 Equipotential bond mat size is the combination of grid

6. Manufacture and Marking

spacing and perimeter dimensional configurations.

6.1 Each equipotential bond mat shall be marked clearly and

8.2 The maximum length and width of grid spacing for

permanently with the name of the manufacturer or supplier,

fabric carrier mats shall be 200 mm by 200 mm (8 in. by 8 in.),

ASTM F2715-YYYY (where YYYY is the year of the

with a permissible variation of 625 mm (61 in.). Mesh sizes

standard), serial number, type, and style.

for non-fabric carrier mats shall be accordance with Table 2.

7. Chemical and Physical Requirements

8.3 Fabric carrier mat thread stitch spacing shall be 6

7.1 Equipotential bond mats samples selected in accordance stitches or more per 25.4 mm (6 stitches or more per 1 in.).

with Section 10 shall conform to the physical and chemical

8.4 A minimum adequate area must be provided for footing

2 2

requirements as specified in this section.

surface of 0.37 m (4 ft ) and a minimum of 0.6 m linear (2 ft)

in any direction, with a permissible variation of 625 mm

7.2 Fabric Carrier Strength:

(61 in.).

TABLE 1 Bond Mat Conductor Size

Grid

Grid, mm (in.) Perimeter, mm (in.) TABLE 3 Flat Braid Minimum Specifications

Conductor

Nominal Nominal

1 1

1 6.3 ( ⁄4) 6.3 ( ⁄4)

Strand No. of No. Wires

Braid Width, Thickness,

1 1

2 6.3 ( ⁄4) 12.6 ( ⁄2)

AWG Strands Per Strand

mm (in.) mm (in.)

1 3

3 6.3 ( ⁄4) 19 ( ⁄4)

1 1 1

4 12.6 ( ⁄2) 12.6 ( ⁄2) 6.35 ( ⁄4) 0.76 (0.03) 36 24 7

1 3 1

5 12.6 ( ⁄2) 19 ( ⁄4) 12.7 ( ⁄2) 0.76 (0.03) 36 48 8

3 3 3

6 19 ( ⁄4) 19 ( ⁄4) 19 ( ⁄4) 1.0 (0.04) 36 48 18

F2715 − 19 (2024)

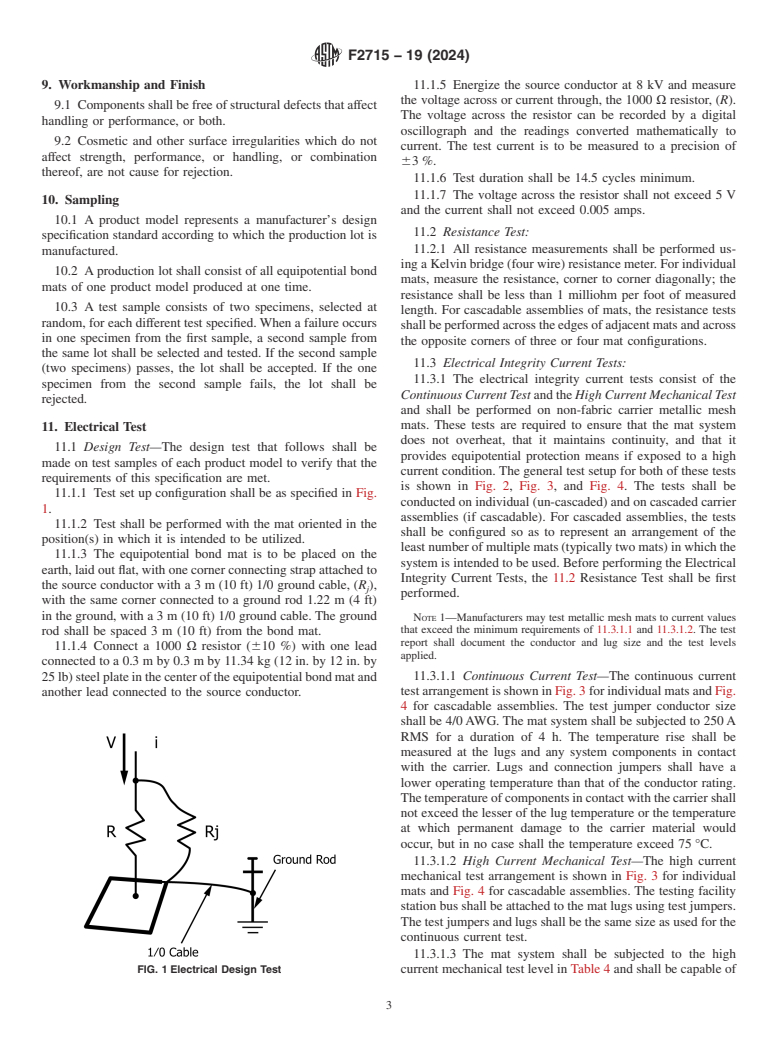

9. Workmanship and Finish 11.1.5 Energize the source conductor at 8 kV and measure

the voltage across or current through, the 1000 Ω resistor, (R).

9.1 Components shall be free of structural defects that affect

The voltage across the resistor can be recorded by a digital

handling or performance, or both.

oscillograph and the readings converted mathematically to

9.2 Cosmetic and other surface irregularities which do not

current. The test current is to be measured to a precision of

affect strength, performance, or handling, or combination

63 %.

thereof, are not cause for rejection.

11.1.6 Test duration shall be 14.5 cycles minimum.

11.1.7 The voltage across the resistor shall not exceed 5 V

10. Sampling

and the current shall not exceed 0.005 amps.

10.1 A product model represents a manufacturer’s design

11.2 Resistance Test:

specification standard according to which the production lot is

11.2.1 All resistance measurements shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.