ASTM D6112-10

(Test Method)Standard Test Methods for Compressive and Flexural Creep and Creep-Rupture of Plastic Lumber and Shapes

Standard Test Methods for Compressive and Flexural Creep and Creep-Rupture of Plastic Lumber and Shapes

SIGNIFICANCE AND USE

Data from creep and creep-rupture tests are necessary to predict the creep modulus and strength of materials under long-term loads and to predict dimensional changes that have the potential to occur as a result of such loads.

Data from these test methods can be used to characterize plastic lumber: for comparison purposes, for the design of fabricated parts, to determine long-term performance under constant load, and under certain conditions, for specification purposes.

For many products, it is possible that there will be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that product specification before using this test method. Table 1 in Classification D4000 lists the ASTM materials standards that currently exist.

SCOPE

1.1 These test methods cover the determination of the creep and creep-rupture properties of plastic lumber and shapes, when loaded in compression or flexure under specified environmental conditions. Test specimens in the “as-manufactured” form are employed. As such, these are test methods for evaluating the properties of plastic lumber or shapes as a product and not material property test methods.

1.2 Plastic lumber and plastic shapes are currently made predominantly with recycled plastics. However, this test method would also be applicable to similar manufactured plastic products made from virgin resins where the product is non-homogenous in the cross-section.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6112 − 10

StandardTest Methods for

Compressive and Flexural Creep and Creep-Rupture of

1

Plastic Lumber and Shapes

This standard is issued under the fixed designation D6112; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5033GuideforDevelopmentofASTMStandardsRelating

to Recycling and Use of Recycled Plastics (Withdrawn

1.1 These test methods cover the determination of the creep

3

2007)

and creep-rupture properties of plastic lumber and shapes,

D5947Test Methods for Physical Dimensions of Solid

when loaded in compression or flexure under specified envi-

Plastics Specimens

ronmentalconditions.Testspecimensinthe“as-manufactured”

E4Practices for Force Verification of Testing Machines

form are employed. As such, these are test methods for

evaluating the properties of plastic lumber or shapes as a

3. Terminology

product and not material property test methods.

3.1 Definitions:

1.2 Plastic lumber and plastic shapes are currently made

3.1.1 compression—in a compressive creep test, the de-

predominantly with recycled plastics. However, this test

creaseinlengthproducedinthegaugelengthorthetotallength

method would also be applicable to similar manufactured

of a test specimen.

plastic products made from virgin resins where the product is

3.1.2 creep modulus—the ratio of initial applied stress to

non-homogenous in the cross-section.

creep strain.

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.3 creep strain—the total strain, at any given time,

as standard. The values given in parentheses are for informa-

produced by the applied stress during a creep test.

tion only.

3.1.3.1 Discussion—The term creep, as used in this test

1.4 This standard does not purport to address all of the

method,reflectscurrentplasticsengineeringusage.Inscientific

safety concerns, if any, associated with its use. It is the

practice, creep is often defined to be the nonelastic portion of

responsibility of the user of this standard to establish appro-

strain. However, this definition is not applicable to existing

priate safety and health practices and determine the applica-

engineering formulas. Plastics have a wide spectrum of retar-

bility of regulatory limitations prior to use.

dation times, and elastic portions of strain cannot be separated

NOTE 1—There is no known ISO equivalent to this standard.

in practice from nonelastic. Therefore, wherever “strain” is

mentioned in these test methods, it refers to the sum of elastic

2. Referenced Documents

strain plus the additional strain with time.

2

2.1 ASTM Standards:

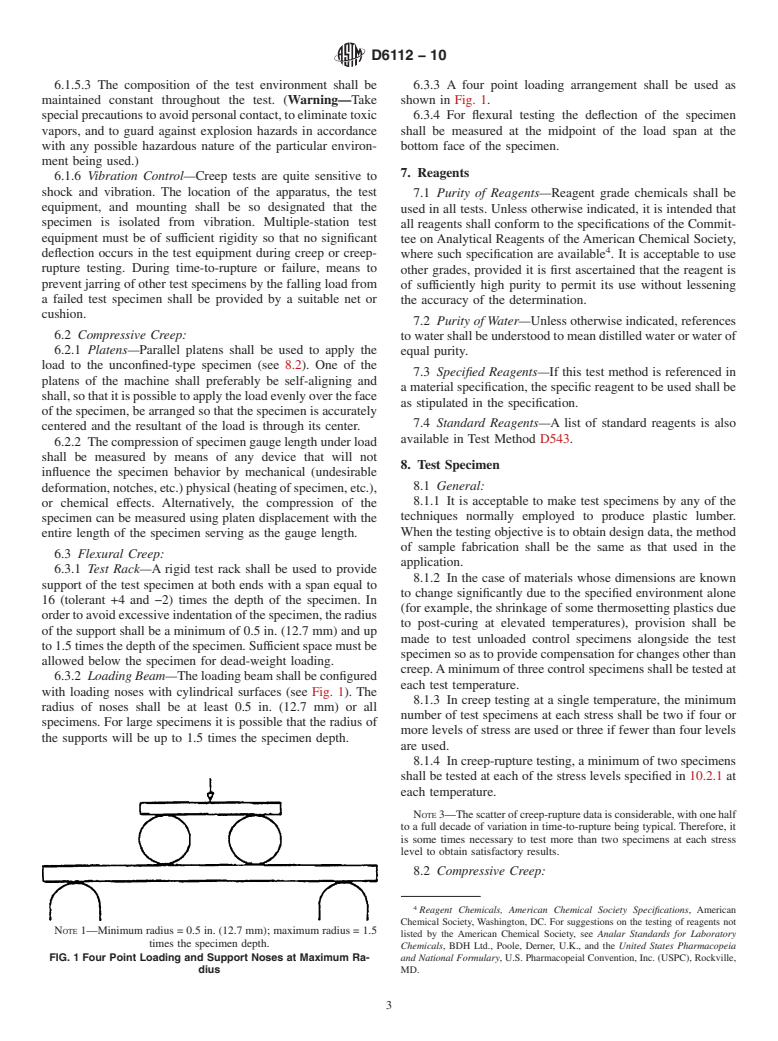

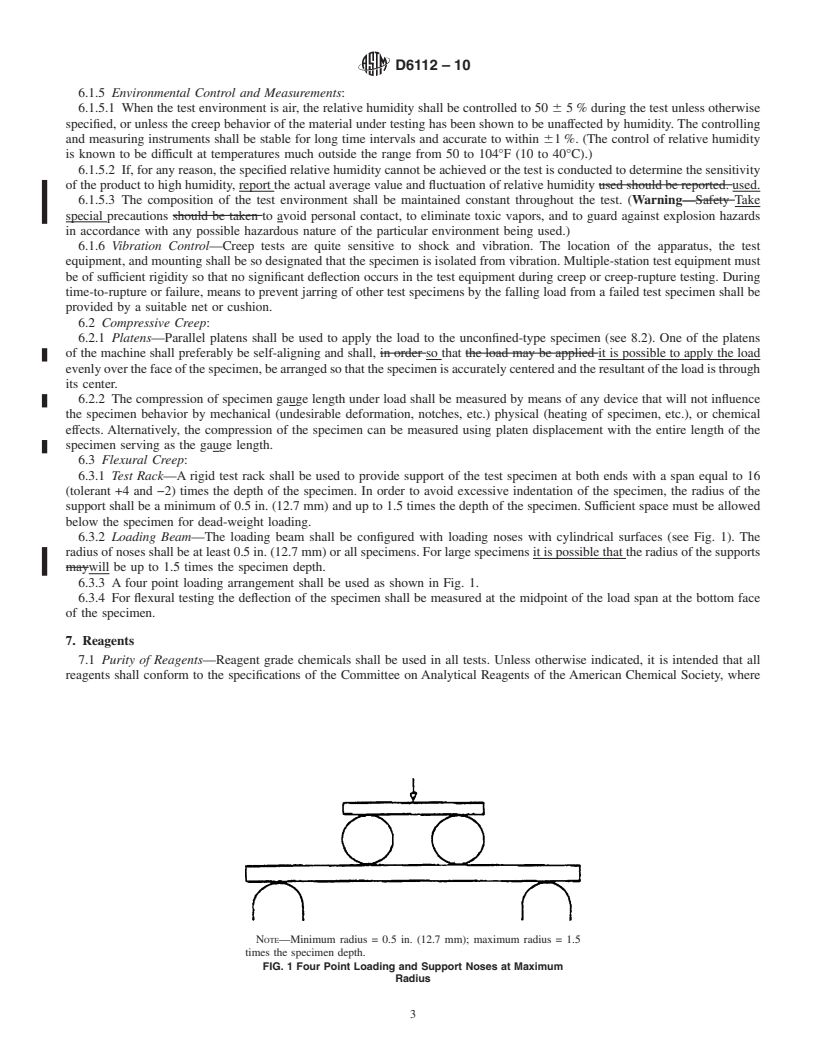

3.1.4 deflection—in a flexural creep test, the change in

D543Practices for Evaluating the Resistance of Plastics to

mid-span position of a test specimen.

Chemical Reagents

3.1.5 deformation—a change in shape, size or position of a

D883Terminology Relating to Plastics

test specimen as a result of compression, deflection, or exten-

D2990Test Methods forTensile, Compressive, and Flexural

sion:

Creep and Creep-Rupture of Plastics

D4000Classification System for Specifying Plastic Materi- 3.1.6 plastic lumber, n—a manufactured product composed

ofmorethan50weightpercentresin,andinwhichtheproduct

als

generally is rectangular in cross-section and typically supplied

in board and dimensional lumber sizes, may be filled or

1

These test methods are under the jurisdiction of ASTM Committee D20 on

unfilled, and may be composed of single or multiple resin

PlasticsandarethedirectresponsibilityofSubcommitteeD20.20onPlasticLumber

(Section D20.20.01).

blends.

Current edition approved Sept. 1, 2010. Published September 2010. Originally

3.1.7 plastic shape, n—a manufactured product composed

approved in 1997. Last previous edition approved in 1997 as D6112-97(2005).

DOI: 10.1520/D6112-10.

ofmorethan50weightpercentresin,andinwhichtheproduct

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6112 − 10

generally is not rectangular in cross-section, may be filled or shock loading, caused by a specimen failure, is not transferred

unfilled, and may be composed of single or multiple resin to other specimens undergoing testing. The accuracy of the

blends. loading system shall be verified at least on

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6112–97(Reapproved2005) Designation: D6112 – 10

Standard Test Methods for

Compressive and Flexural Creep and Creep-Rupture of

1

Plastic Lumber and Shapes

This standard is issued under the fixed designation D6112; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the determination of the creep and creep-rupture properties of plastic lumber and shapes, when

loaded in compression or flexure under specified environmental conditions. Test specimens in the “as-manufactured” form are

employed.As such, these are test methods for evaluating the properties of plastic lumber or shapes as a product and not material

property test methods.

1.2 Plasticlumberandplasticshapesarecurrentlymadepredominantlywithrecycledplastics.However,thistestmethodwould

also be applicable to similar manufactured plastic products made from virgin resins where the product is non-homogenous in the

cross-section.

1.3 The values stated in inch–-pound units are to be regarded as standard. The values given in parentheses are for information

only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE1—There is no similar or equivalent ISO standard. 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D543 Practices for Evaluating the Resistance of Plastics to Chemical Reagents

D883 Terminology Relating to Plastics

D2990 Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics

D4000 Classification System for Specifying Plastic Materials

D5033 Guide for Development of ASTM Standards Relating to Recycling and Use of Recycled Plastics

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

E4 Practices for Force Verification of Testing Machines

3. Terminology

3.1 Definitions:

3.1.1 compression—in a compressive creep test,thedecreaseinlengthproducedinthegaugelengthorthetotallengthofatest

specimen.

3.1.2 creep modulus—the ratio of initial applied stress to creep strain.

3.1.3 creep strain—the total strain, at any given time, produced by the applied stress during a creep test.

3.1.3.1 Discussion—The term creep, as used in this test method, reflects current plastics engineering usage. In scientific

practice, creep is often defined to be the nonelastic portion of strain. However, this definition is not applicable to existing

engineering formulas. Plastics have a wide spectrum of retardation times, and elastic portions of strain cannot be separated in

practice from nonelastic.Therefore, wherever “strain” is mentioned in these test methods, it refers to the sum of elastic strain plus

the additional strain with time.

3.1.4 deflection—in a flexural creep test, the change in mid-span position of a test specimen.

3.1.5 deformation—a change in shape, size or position of a test specimen as a result of compression, deflection, or extension:

1

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD20onPlasticsandarethedirectresponsibilityofSubcommitteeD20.20onPlasticProductsLumber

(Section D20.20.01).

Current edition approved Nov.Sept. 1, 2005.2010. Published January 2006.September 2010. Originally approved in 1997. Last previous edition approved in 1997 as

D6112-97(2005). DOI: 10.1520/D6112-97R05.10.1520/D6112-10.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6112 – 10

3.1.6 plastic lumber, n—a manufactured product composed of more than 50 weight percent resin, and in which the product

generally is rectangular in cross-section and typically supplied in board and dimensional lumber sizes, may be filled or unfilled,

and may be composed of single or multiple resin blends.

3.1.7 plastic shape, n—a manufactured product composed of more than 50 weight percent resin, and in which the produc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.