ASTM D3014-04a

(Test Method)Standard Test Method for Flame Height, Time of Burning, and Loss of Mass of Rigid Thermoset Cellular Plastics in a Vertical Position

Standard Test Method for Flame Height, Time of Burning, and Loss of Mass of Rigid Thermoset Cellular Plastics in a Vertical Position

SIGNIFICANCE AND USE

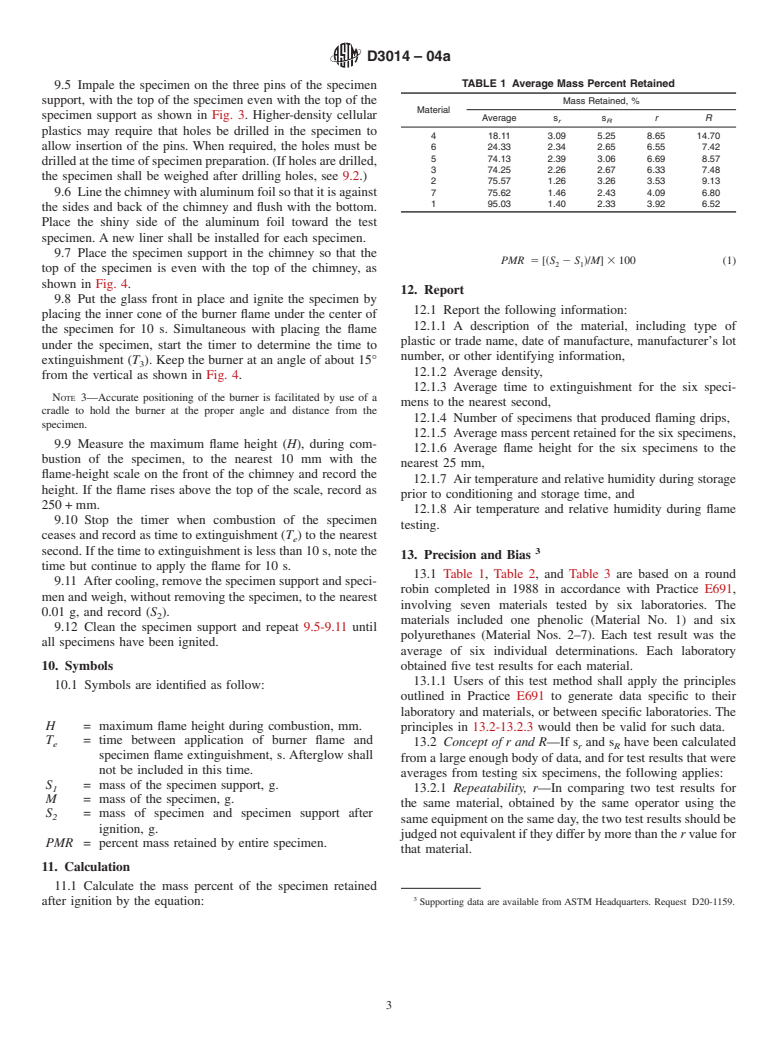

Tests made on rigid cellular materials in accordance with the conditions described by this test method can be of considerable value in comparing their burning characteristics. The height and duration of flame and the mass percent retained by the specimen are recorded.

This test method has been applied to flexible cellular materials and other plastics, but no detailed studies have been conducted to determine its general applicability to these materials.

In this procedure, the specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it may not be possible by or from this test to predict changes in the fire-test-response characteristics measured. The results are therefore valid only for the fire-test-exposure conditions described in this procedure.

SCOPE

1.1 This is a fire-test-response standard. This test method covers a small-scale laboratory screening procedure for comparing relative extent and time of burning and loss of mass of rigid thermoset cellular plastics. This test method is to be used solely to establish relative burning characteristics and shall not be considered or used as a fire-hazard classification.

1.1.1 This test method should not be used for materials that drip or melt under the test conditions.

1.2 During the course of combustion, gases or vapors, or both, are evolved which are hazardous to personnel. Adequate precautions should be taken to protect the operator.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific precautionary statement is given in 1.2.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of materials, products, or assemblies under actual fire conditions.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3014–04a

Standard Test Method for

Flame Height, Time of Burning, and Loss of Mass of Rigid

1

Thermoset Cellular Plastics in a Vertical Position

This standard is issued under the fixed designation D3014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D5025 Specification for Laboratory Burner Used for Small-

Scale Burning Tests on Plastic Materials

1.1 This is a fire-test-response standard. This test method

E176 Terminology of Fire Standards

covers a small-scale laboratory screening procedure for com-

E691 Practice for Conducting an Interlaboratory Study to

paring relative extent and time of burning and loss of mass of

Determine the Precision of a Test Method

rigid thermoset cellular plastics. This test method is to be used

solely to establish relative burning characteristics and shall not

3. Terminology

be considered or used as a fire-hazard classification.

3.1 Definitions—For terms relating to plastics, the defini-

1.1.1 This test method should not be used for materials that

tions in this test method are in accordance with Terminology

drip or melt under the test conditions.

D883. For terms relating to fire, the definitions in this test

1.2 During the course of combustion, gases or vapors, or

method are in accordance with Terminology E176.

both,areevolvedwhicharepotentiallyhazardoustopersonnel.

Adequate precautions should be taken to protect the operator.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

4.1 The specimen is mounted in a vertical chimney with a

safety concerns, if any, associated with its use. It is the

glass front and ignited with a bunsen burner for 10 s. The

responsibility of the user of this standard to establish appro-

height and duration of flame and the mass percent retained by

priate safety and health practices and determine the applica-

the specimen are recorded.

bility of regulatory limitations prior to use. A specific precau-

tionary statement is given in 1.2.

5. Significance and Use

1.4 This standard is used to measure and describe the

5.1 Tests made on rigid cellular materials in accordance

response of materials, products, or assemblies to heat and

with the conditions described by this test method can be of

flame under controlled conditions, but does not by itself

considerable value in comparing their burning characteristics.

incorporate all factors required for fire hazard or fire risk

The height and duration of flame and the mass percent retained

assessment of materials, products, or assemblies under actual

by the specimen are recorded.

fire conditions.

5.2 This test method has been applied to flexible cellular

NOTE 1—There is no similar or equivalent ISO standard.

materials and other plastics, but no detailed studies have been

conducted to determine its general applicability to these

2. Referenced Documents

materials.

2

2.1 ASTM Standards:

5.3 In this procedure, the specimens are subjected to one or

D883 Terminology Relating to Plastics

more specific sets of laboratory test conditions. If different test

D1622 Test Method forApparent Density of Rigid Cellular

conditions are substituted or the end-use conditions are

Plastics

changed, it may not be possible by or from this test to predict

changes in the fire-test-response characteristics measured. The

results are therefore valid only for the fire-test-exposure

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

conditions described in this procedure.

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties

(Section D20.30.03).

6. Apparatus

Current edition approved July 1, 2004. Published July 2004. Originally approved

6.1 Test Chimney, conforming to the dimensions in Fig. 1,

in 1973. Last previous edition approved in 2004 as D3014 - 04. DOI: 10.1520/

D3014-04A.

Fig. 2, and Fig. 3. The body of the chimney may be either

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

galvanized or stainless steel. In it is fastened an insert made of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

0.025-mm aluminum foil. The insert is held in place by a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. stainless steel channel that carries three pins to support the

*A Summary of Changes section appears at the end of this standard.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 -

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.