ASTM C674-88(2006)

(Test Method)Standard Test Methods for Flexural Properties of Ceramic Whiteware Materials

Standard Test Methods for Flexural Properties of Ceramic Whiteware Materials

SIGNIFICANCE AND USE

These test methods provide a means for determining the modulus of rupture and the modulus of elasticity, which may be required in product specifications.

SCOPE

1.1 These test methods cover determination of the modulus of rupture and the modulus of elasticity of fired ceramic whitewares bodies, formed by any fabrication method, and are applicable to both glazed and unglazed test specimens.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C674 − 88(Reapproved 2006)

Standard Test Methods for

Flexural Properties of Ceramic Whiteware Materials

This standard is issued under the fixed designation C674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope strengths of specimens intermediate of those specified, inter-

polation can be used to obtain the equivalent loading rate.

1.1 These test methods cover determination of the modulus

4.1.2 For the prescribed rectangular specimens the loading

of rupture and the modulus of elasticity of fired ceramic

rate shall be 1000 6 150 lbs (454 6 68 kg)/min.

whitewares bodies, formed by any fabrication method, and are

applicable to both glazed and unglazed test specimens. 4.2 Bearing Edges—For the support of the test specimen,

two steel (or high-strength ceramic) knife edges rounded to a

1.2 The values stated in inch-pound units are to be regarded

radius of 0.125 in. (3.18 mm) shall be provided. The load shall

as the standard. The metric equivalents of inch-pound units

be applied by means of a third steel knife edge rounded to a

may be approximate.

radius of 0.125 in. When testing rectangular specimens, the

1.3 This standard does not purport to address all of the

supporting members for the bearing edges shall be constructed

safety concerns, if any, associated with its use. It is the

to provide a means for alignment of the bearing surfaces with

responsibility of the user of this standard to establish appro-

the surfaces of the test specimen (it being possible that the

priate safety and health practices and determine the applica-

rectangular specimen may be wedge-shaped or twisted). The

bility of regulatory limitations prior to use.

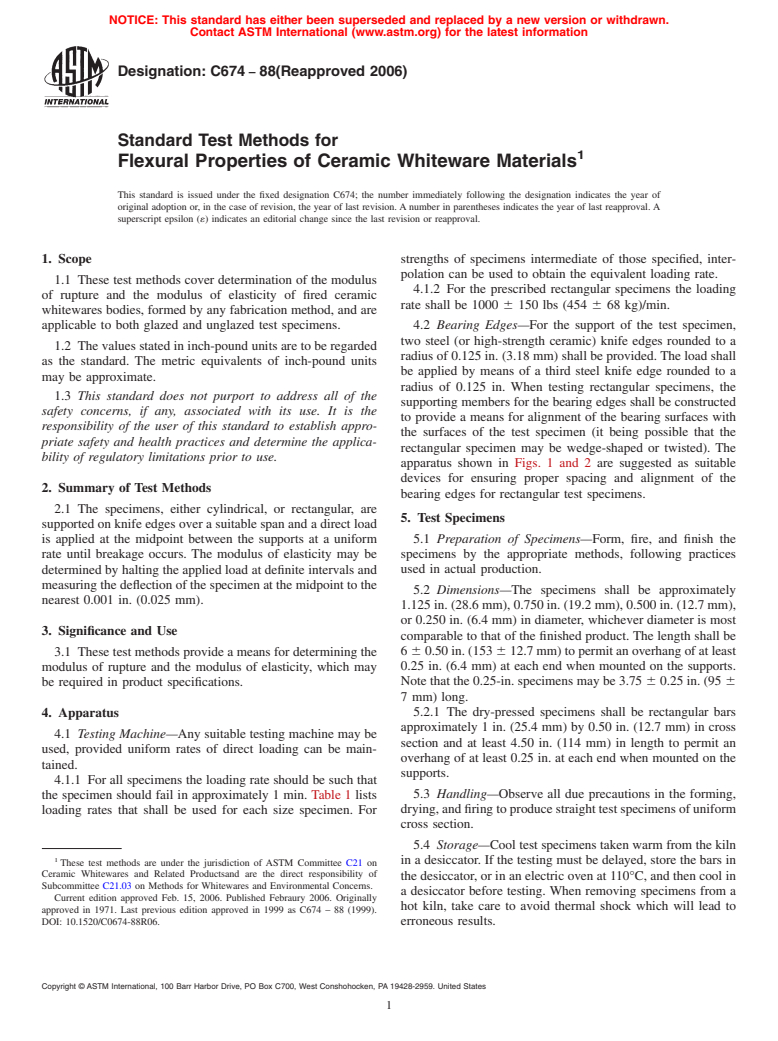

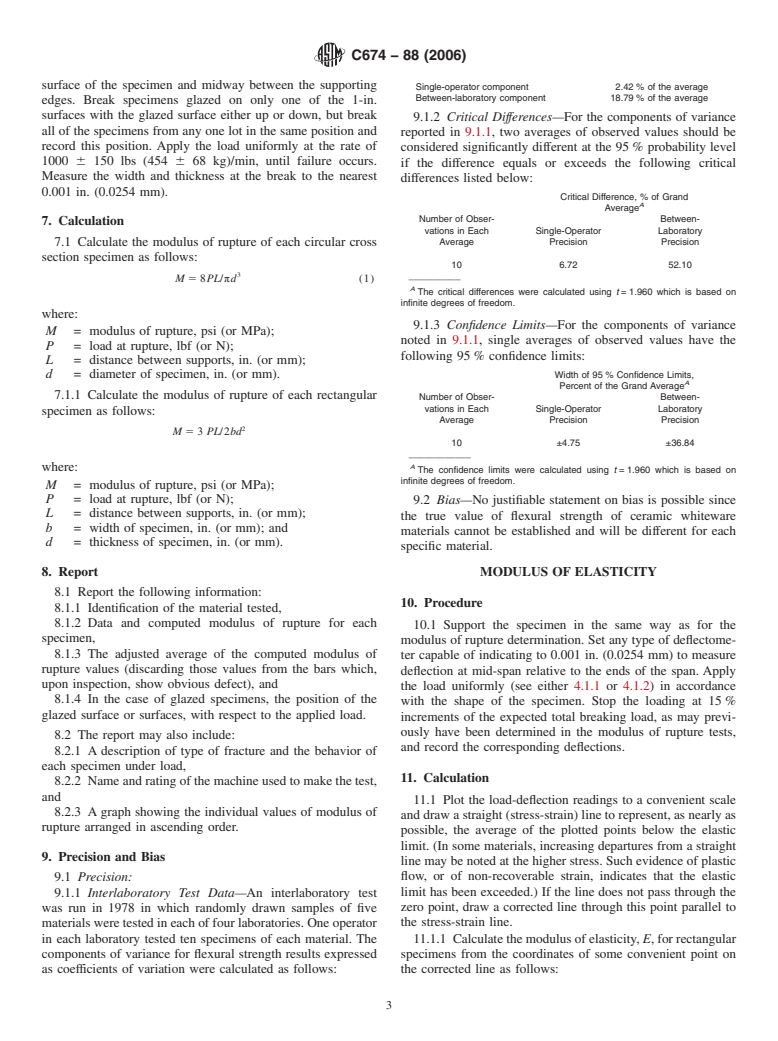

apparatus shown in Figs. 1 and 2 are suggested as suitable

devices for ensuring proper spacing and alignment of the

2. Summary of Test Methods

bearing edges for rectangular test specimens.

2.1 The specimens, either cylindrical, or rectangular, are

5. Test Specimens

supported on knife edges over a suitable span and a direct load

is applied at the midpoint between the supports at a uniform 5.1 Preparation of Specimens—Form, fire, and finish the

specimens by the appropriate methods, following practices

rate until breakage occurs. The modulus of elasticity may be

determined by halting the applied load at definite intervals and used in actual production.

measuring the deflection of the specimen at the midpoint to the

5.2 Dimensions—The specimens shall be approximately

nearest 0.001 in. (0.025 mm).

1.125 in. (28.6 mm), 0.750 in. (19.2 mm), 0.500 in. (12.7 mm),

or 0.250 in. (6.4 mm) in diameter, whichever diameter is most

3. Significance and Use

comparable to that of the finished product. The length shall be

6 6 0.50 in. (153 6 12.7 mm) to permit an overhang of at least

3.1 These test methods provide a means for determining the

modulus of rupture and the modulus of elasticity, which may 0.25 in. (6.4 mm) at each end when mounted on the supports.

Note that the 0.25-in. specimens may be 3.75 6 0.25 in. (95 6

be required in product specifications.

7 mm) long.

5.2.1 The dry-pressed specimens shall be rectangular bars

4. Apparatus

approximately 1 in. (25.4 mm) by 0.50 in. (12.7 mm) in cross

4.1 Testing Machine—Any suitable testing machine may be

section and at least 4.50 in. (114 mm) in length to permit an

used, provided uniform rates of direct loading can be main-

overhang of at least 0.25 in. at each end when mounted on the

tained.

supports.

4.1.1 For all specimens the loading rate should be such that

5.3 Handling—Observe all due precautions in the forming,

the specimen should fail in approximately 1 min. Table 1 lists

drying, and firing to produce straight test specimens of uniform

loading rates that shall be used for each size specimen. For

cross section.

5.4 Storage—Cool test specimens taken warm from the kiln

in a desiccator. If the testing must be delayed, store the bars in

These test methods are under the jurisdiction of ASTM Committee C21 on

Ceramic Whitewares and Related Productsand are the direct responsibility of

the desiccator, or in an electric oven at 110°C, and then cool in

Subcommittee C21.03 on Methods for Whitewares and Environmental Concerns.

a desiccator before testing. When removing specimens from a

Current edition approved Feb. 15, 2006. Published Febraury 2006. Originally

hot kiln, take care to avoid thermal shock which will lead to

approved in 1971. Last previous edition approved in 1999 as C674 – 88 (1999).

DOI: 10.1520/C0674-88R06. erroneous results.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C674 − 88 (2006)

TABLE 1 Loading Rates for Specimens

Nominal MOR, ksi (MPa)

Span, in. (mm) 10 (69) 30 (207) 50 (345)

Specimen Size, in. (mm)

Loading Rate, lb/min (kg/s)

1.125 (28.6) diameter 5 (127) 1100 (8.32) 3400 (25.70) 5600 (42.34)

0.750 (19.2) “ 5 (127) 300 (2.27) 1000 (7.56) 1700 (12.85)

0.500 (12.7) “ 5 (127) 100 (0.76) 300 (2.27) 500 (3.76)

0.250 (6.4) “ 3 (76) 20 (0.15) 60 (0.45) 100 (0.76)

1 by 0.50 (25.4 by 12.7) 4 (102) 400 (3.02) 1250 (9.45) 2100 (15.88)

FIG. 1 Suggested Bearing Edge and Specimen Support

FIG. 2 Alternative Suggested Bearing Edge and Specimen Support

MODULUS OF RUPTURE (62 %) between the supporting edges. Apply the load uni-

formly at the appropriate rate for the specimen size (see 4.1.1)

6. Procedure

until failure occurs. Measure the diameter at four approxi-

mately equidistant points at the break and take the average to

6.1 Test at least ten dry specimens at room temperature.

the nearest 0.001 in. (0.0254 mm) for calculation purposes.

NOTE 1—The modulus of elasticity may be determined as described in

Break the 0.25-in. diameter rods between 3-in. (76-mm)

Sections 10-11 on the same type specimens used for the modulus of

rupture test. centers and note this in the report.

6.2.1 Place the rectangular test specimen on the bearing

6.2 Place the cylindrical specimen on the bearing edges,

spaced 5 in. (127 mm) 6 2 % between centers, with the edges, spaced 4.0 in. (102 mm) between centers, with the

specimen overhanging at each end by at least 0.25 in. (6.4

specimen overhanging each end by at least 0.25 in. (6.4 mm).

Apply the load at a right angle to the specimen and midway mm). Apply the load at a right angle to the 1-in. (25.4-mm)

C674 − 88 (2006)

surface of the specimen and midway between the supporting

Single-operator component 2.42 % of the average

Between-laboratory component 18.79 % of the average

edges. Break specimens glazed on only one of the 1-in.

surfaces with the glazed surface either up or do

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.