ASTM D7797-23

(Test Method)Standard Test Method for Determination of the Fatty Acid Methyl Esters Content of Aviation Turbine Fuel Using Flow Analysis by Fourier Transform Infrared Spectroscopy-Rapid Screening Method

Standard Test Method for Determination of the Fatty Acid Methyl Esters Content of Aviation Turbine Fuel Using Flow Analysis by Fourier Transform Infrared Spectroscopy-Rapid Screening Method

SIGNIFICANCE AND USE

5.1 The present and growing international governmental requirements to add fatty acid methyl esters (FAME) to diesel fuel has had the unintended side-effect of leading to potential FAME contamination of jet turbine fuel in multifuel transport facilities such as cargo tankers and pipelines, and industry wide concerns.

5.2 Analytical methods have been developed with the capability of measuring down to

SCOPE

1.1 This test method specifies a rapid screening method using flow analysis by Fourier transform infrared (FA-FTIR) spectroscopy with partial least squares (PLS-1) processing for the determination of the fatty acid methyl ester (FAME) content of aviation turbine fuel (AVTUR), in the range of 10 mg/kg to 150 mg/kg.

Note 1: Specifications falling within the scope of this test method are: Specification D1655 and Defence Standard 91-91.

Note 2: This test method detects all FAME components, with peak IR absorbance at approximately 1749 cm-1 and C8 to C22 molecules, as specified in standards such as Specification D6751 and EN 14214. The accuracy of the method is based on the molecular weight of C16 to C18 FAME species; the presence of other FAME species with different molecular weights could affect the accuracy.

Note 3: Additives such as antistatic agents, antioxidants and corrosion inhibitors are measured with the FAME by the FTIR spectrometer. However the effects of these additives are removed by the flow analysis processing.

Note 4: FAME concentrations from 150 mg/kg to 500 mg/kg, and below 10 mg/kg can be measured but the precision could be affected.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Frequently Asked Questions

ASTM D7797-23 is a standard published by ASTM International. Its full title is "Standard Test Method for Determination of the Fatty Acid Methyl Esters Content of Aviation Turbine Fuel Using Flow Analysis by Fourier Transform Infrared Spectroscopy-Rapid Screening Method". This standard covers: SIGNIFICANCE AND USE 5.1 The present and growing international governmental requirements to add fatty acid methyl esters (FAME) to diesel fuel has had the unintended side-effect of leading to potential FAME contamination of jet turbine fuel in multifuel transport facilities such as cargo tankers and pipelines, and industry wide concerns. 5.2 Analytical methods have been developed with the capability of measuring down to SCOPE 1.1 This test method specifies a rapid screening method using flow analysis by Fourier transform infrared (FA-FTIR) spectroscopy with partial least squares (PLS-1) processing for the determination of the fatty acid methyl ester (FAME) content of aviation turbine fuel (AVTUR), in the range of 10 mg/kg to 150 mg/kg. Note 1: Specifications falling within the scope of this test method are: Specification D1655 and Defence Standard 91-91. Note 2: This test method detects all FAME components, with peak IR absorbance at approximately 1749 cm-1 and C8 to C22 molecules, as specified in standards such as Specification D6751 and EN 14214. The accuracy of the method is based on the molecular weight of C16 to C18 FAME species; the presence of other FAME species with different molecular weights could affect the accuracy. Note 3: Additives such as antistatic agents, antioxidants and corrosion inhibitors are measured with the FAME by the FTIR spectrometer. However the effects of these additives are removed by the flow analysis processing. Note 4: FAME concentrations from 150 mg/kg to 500 mg/kg, and below 10 mg/kg can be measured but the precision could be affected. 1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 5.1 The present and growing international governmental requirements to add fatty acid methyl esters (FAME) to diesel fuel has had the unintended side-effect of leading to potential FAME contamination of jet turbine fuel in multifuel transport facilities such as cargo tankers and pipelines, and industry wide concerns. 5.2 Analytical methods have been developed with the capability of measuring down to SCOPE 1.1 This test method specifies a rapid screening method using flow analysis by Fourier transform infrared (FA-FTIR) spectroscopy with partial least squares (PLS-1) processing for the determination of the fatty acid methyl ester (FAME) content of aviation turbine fuel (AVTUR), in the range of 10 mg/kg to 150 mg/kg. Note 1: Specifications falling within the scope of this test method are: Specification D1655 and Defence Standard 91-91. Note 2: This test method detects all FAME components, with peak IR absorbance at approximately 1749 cm-1 and C8 to C22 molecules, as specified in standards such as Specification D6751 and EN 14214. The accuracy of the method is based on the molecular weight of C16 to C18 FAME species; the presence of other FAME species with different molecular weights could affect the accuracy. Note 3: Additives such as antistatic agents, antioxidants and corrosion inhibitors are measured with the FAME by the FTIR spectrometer. However the effects of these additives are removed by the flow analysis processing. Note 4: FAME concentrations from 150 mg/kg to 500 mg/kg, and below 10 mg/kg can be measured but the precision could be affected. 1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D7797-23 is classified under the following ICS (International Classification for Standards) categories: 75.160.20 - Liquid fuels. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D7797-23 has the following relationships with other standards: It is inter standard links to ASTM D1655-24, ASTM D6300-24, ASTM D4175-23a, ASTM D6300-23a, ASTM D1655-23a, ASTM D4175-23e1, ASTM D6300-19a, ASTM D6751-18, ASTM D1655-18, ASTM D1655-17a, ASTM D1655-16c, ASTM D1655-16b, ASTM D1655-16, ASTM D6300-16, ASTM D6751-15c. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ASTM D7797-23 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7797 − 23

583/15 (2015)

Standard Test Method for

Determination of the Fatty Acid Methyl Esters Content of

Aviation Turbine Fuel Using Flow Analysis by Fourier

Transform Infrared Spectroscopy—Rapid Screening

1,2

Method

This standard is issued under the fixed designation D7797; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method specifies a rapid screening method

ization established in the Decision on Principles for the

using flow analysis by Fourier transform infrared (FA-FTIR)

Development of International Standards, Guides and Recom-

spectroscopy with partial least squares (PLS-1) processing for

mendations issued by the World Trade Organization Technical

the determination of the fatty acid methyl ester (FAME)

Barriers to Trade (TBT) Committee.

content of aviation turbine fuel (AVTUR), in the range of

10 mg ⁄kg to 150 mg ⁄kg.

2. Referenced Documents

NOTE 1—Specifications falling within the scope of this test method are:

2.1 ASTM Standards:

Specification D1655 and Defence Standard 91-91.

NOTE 2—This test method detects all FAME components, with peak IR

D1298 Test Method for Density, Relative Density, or API

-1

absorbance at approximately 1749 cm and C to C molecules, as

8 22

Gravity of Crude Petroleum and Liquid Petroleum Prod-

specified in standards such as Specification D6751 and EN 14214. The

ucts by Hydrometer Method

accuracy of the method is based on the molecular weight of C to C

16 18

D1655 Specification for Aviation Turbine Fuels

FAME species; the presence of other FAME species with different

molecular weights could affect the accuracy. D4052 Test Method for Density, Relative Density, and API

NOTE 3—Additives such as antistatic agents, antioxidants and corrosion

Gravity of Liquids by Digital Density Meter

inhibitors are measured with the FAME by the FTIR spectrometer.

D4057 Practice for Manual Sampling of Petroleum and

However the effects of these additives are removed by the flow analysis

Petroleum Products

processing.

D4175 Terminology Relating to Petroleum Products, Liquid

NOTE 4—FAME concentrations from 150 mg/kg to 500 mg/kg, and

below 10 mg/kg can be measured but the precision could be affected.

Fuels, and Lubricants

D4177 Practice for Automatic Sampling of Petroleum and

1.2 The values stated in SI units are to be regarded as

Petroleum Products

standard. No other units of measurement are included in this

D6300 Practice for Determination of Precision and Bias

standard.

Data for Use in Test Methods for Petroleum Products,

1.3 This standard does not purport to address all of the

Liquid Fuels, and Lubricants

safety concerns, if any, associated with its use. It is the

D6751 Specification for Biodiesel Fuel Blend Stock (B100)

responsibility of the user of this standard to establish appro-

for Middle Distillate Fuels

priate safety, health, and environmental practices and deter-

E1655 Practices for Infrared Multivariate Quantitative

mine the applicability of regulatory limitations prior to use.

Analysis

2.2 CEN Standards:

This test method is under the jurisdiction of ASTM International Committee

EN 14214 Specification Automotive Fuels—Fatty Acid

D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct

Methyl Esters (FAME) for Diesel Engines—Requirements

responsibility of ASTM Subcommittee D02.J0.05 on Fuel Cleanliness. The techni-

cally equivalent standard as referenced is under the jurisdiction of the Energy and Test Methods

Institute Subcommittee SC-G-4.

Current edition approved March 1, 2023. Published April 2023. Originally

approved in 2012. Last previous edition approved in 2018 as D7797 – 18. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D7797-23. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method has been developed through the cooperative effort between Standards volume information, refer to the standard’s Document Summary page on

ASTM and the Energy Institute, London. ASTM and IP standards were approved by the ASTM website.

ASTM and EI technical committees as being technically equivalent but that does not Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

imply both standards are identical. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7797 − 23

2.3 Energy Institute Standards: FAME contamination of jet turbine fuel in multifuel transport

IP 583 Test Method for Determination of the Fatty Acid facilities such as cargo tankers and pipelines, and industry wide

Methyl Esters Content of Aviation Turbine Fuel Using concerns.

Flow Analysis by Fourier Transform Infrared

5.2 Analytical methods have been developed with the capa-

Spectroscopy—Rapid Screening Method

bility of measuring down to <5 mg ⁄kg levels of FAME,

2.4 Other Standards:

however these are complex, and require specialized personnel

Defence Standard 91-91 Issue 7 (DERD 2494) Turbine Fuel,

and laboratory facilities. This Rapid Screening method has

Aviation Kerosine Type, Jet A1

been developed for use in the supply chain by non specialized

2.5 ASTM Adjuncts:

personnel to cover the range of 10 mg ⁄kg to 150 mg ⁄kg.

ADJD6300 (D2PP) Determination of Precision and Bias

6. Interferences

Data for Use in Test Methods for Petroleum Products

6.1 Chemical compounds, which can arise during

3. Terminology

production, storage, distribution or sampling, containing car-

3.1 Definitions: bonyl groups, whose spectral absorbances appear in the IR

–1

3.1.1 For definitions of terms used in this test method, refer

spectrum close to 1749 cm , can affect the reading. Plasticiz-

to Terminology D4175. ers: bis (2-ethyl hexyl) adipate; dibutyl-sebacate are known to

3.1.2 FAME, n—Fatty acid methyl esters, also known as

increase measurement readings obtained by this test method.

biodiesel.

NOTE 5—In a limited study, bis (2-ethyl hexyl) adipate at a concentra-

3.1.2.1 Discussion—Used as a component in automotive

tion of 30 mg ⁄kg in aviation fuel gave an increased reading of 15 mg ⁄kg,

diesel fuel and the potential source of contamination in aviation

and dibutyl-sebacate at 50 mg ⁄L gave an increased reading of 20 mg ⁄kg.

turbine fuel due to multi-fuel tankers and pipelines.

7. Apparatus

3.2 Definitions of Terms Specific to This Standard:

7.1 Automatically controlled, closely integrated, instrument

3.2.1 FA-FTIR, n—flow analysis by Fourier Transform Infra

comprising FTIR spectrometer with a 2 mm effective optical

red technique uses a flow-through measurement cell to make a

path length flow-through cell, computer controlled pump,

number of measurements on a stream of test specimen.

sorbent cartridge holder, control and interface electronics, test

3.2.1.1 Discussion—The test specimen is analyzed before

specimen and waste containers, and solenoid valves.

and after passing through a sorbent that is designed to retard

the FAME contamination to be measured. The results are

7.2 The processing computer can be integrated into the

compared to enable the amount of FAME present in the instrument.

aviation fuel to be determined.

7.3 This apparatus and the required sorbent cartridge are

3.2.2 sorbent cartridge, n—a cartridge, through which the

described in more detail in Annex A1.

test specimen flows, containing a specific sorbent

7.4 Density Measuring Device (optional)—According to

3.2.2.1 Discussion—The sorbent cartridge is discarded after

Test Methods D1298, or D4052, or equivalent national

each test.

standards, to determine the density of the aviation fuel test

sample if required.

4. Summary of Test Method

8. Reagents and Materials

4.1 A test specimen of aviation turbine (AVTUR) fuel is

automatically analyzed, by an FTIR spectrometer, in a 2 mm

8.1 Cleaning Solvent, heptane, reagent grade.

effective path length flow-through cell, before and after flow-

8.2 Verification Fluids:

ing through a cartridge containing a sorbent designed to have

8.2.1 100 mg ⁄kg, containing 100 mg ⁄kg 6 10 mg ⁄kg of

a relatively long residence time for FAME. The spectroscopic

FAME, with a certified value and uncertainty.

absorbance differences of the IR spectra, between the

8.2.2 30 mg ⁄kg, containing 30 mg ⁄kg 6 5 mg ⁄kg of FAME,

measurements, are processed in conjunction with a PLS-1

with a certified value and uncertainty.

model to determine the presence and amplitude of the carbonyl

-1

peak of FAME at approximately 1749 cm . Test time is 8.3 Calibration Fluids:

typically 20 min. The flow analysis by FTIR enables the FAME 8.3.1 Set of Five Fluids, containing amounts of FAME with

IR peak to be resolved from the bulk IR properties of the fuel. certified values and uncertainty.

8.4 Lint-free Cloth, for cleaning and drying the sample input

5. Significance and Use

tube.

5.1 The present and growing international governmental

9. Sampling

requirements to add fatty acid methyl esters (FAME) to diesel

fuel has had the unintended side-effect of leading to potential

9.1 Unless otherwise specified, take a sample of at least

60 mL in accordance with Practices D4057 or D4177 or in

Available from the Energy Institute, 61 New Cavendish St., London, WIG 7AR,

U.K., http://www.energyinst.org.uk. The following reagents and materials were used to develop the precision

Available from Procurement Executive DF5 (air), Ministry of Defence, statements: Seta Verification and Calibration fluids for Seta FIJI, Stanhope-Seta,

www.dstan.mod.uk. Chertsey, Surrey, KT16 8AP, UK. This is not an endorsement or certification by

ADJD6300 is no longer available from ASTM International Headquarters. ASTM.

D7797 − 23

accordance with the requirements of national standards or 11.1.2 Verify the correct operation of the instrument using

regulations for the sampling of petroleum products, or both. the verification fluid (8.2.1), in accordance with the manufac-

turer’s instructions, at least every six months. More frequent

9.2 Use new, opaque glass or epoxy lined metal containers

performance checks shall be carried out according to local

with inert closures.

quality control requirements.

9.2.1 Used sample containers are permitted provided it can

11.1.3 Verify the correct operation of the instrument using

be confirmed they have not been used for unknown fluids or for

both verification fluids (8.2.1 and 8.2.2) in accordance with the

fluids containing >5 % FAME.

manufacturer’s instructions at least every 12 months or imme-

NOTE 6—New sample containers are strongly recommended due to

diately after any maintenance on the measurement system.

concerns over the difficulty in removing all traces of FAME retained from

11.1.4 If the result is not within R/√2 plus the uncertainty of

previous samples.

the verification fluid’s certified value or within the tolerances

9.2.2 Rinse all sample containers with heptane (8.1) or

supplied with the verification fluid, recheck the validity date of

another suitable solvent and drain. Then rinse with the product

the verification fluid and run a flushing sequence (10.2) and

to be sample

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7797 − 18 D7797 − 23

583/15 (2015)

Standard Test Method for

Determination of the Fatty Acid Methyl Esters Content of

Aviation Turbine Fuel Using Flow Analysis by Fourier

Transform Infrared Spectroscopy—Rapid Screening

1,2

Method

This standard is issued under the fixed designation D7797; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method specifies a rapid screening method using flow analysis by Fourier transform infrared (FA-FTIR) spectroscopy

with partial least squares (PLS-1) processing for the determination of the fatty acid methyl ester (FAME) content of aviation turbine

fuel (AVTUR), in the range of 10 mg ⁄kg to 150 mg ⁄kg.

NOTE 1—Specifications falling within the scope of this test method are: Specification D1655 and Defence Standard 91-91.

-1

NOTE 2—This test method detects all FAME components, with peak IR absorbance at approximately 1749 cm and C to C molecules, as specified

8 22

in standards such as Specification D6751 and EN 14214. The accuracy of the method is based on the molecular weight of C to C FAME species; the

16 18

presence of other FAME species with different molecular weights could affect the accuracy.

NOTE 3—Additives such as antistatic agents, antioxidants and corrosion inhibitors are measured with the FAME by the FTIR spectrometer. However the

effects of these additives are removed by the flow analysis processing.

NOTE 4—FAME concentrations from 150 mg/kg to 500 mg/kg, and below 10 mg/kg can be measured but the precision could be affected.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

This test method is under the jurisdiction of ASTM International Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility

of ASTM Subcommittee D02.J0.05 on Fuel Cleanliness. The technically equivalent standard as referenced is under the jurisdiction of the Energy Institute Subcommittee

SC-G-4.

Current edition approved Dec. 1, 2018March 1, 2023. Published January 2019April 2023. Originally approved in 2012. Last previous edition approved in 20172018 as

D7797 – 17.D7797 – 18. DOI: 10.1520/D7797-18.10.1520/D7797-23.

This standard test method has been developed through the cooperative effort between ASTM International and the Energy Institute, London. The IP and ASTM logos

imply that the ASTM ASTM and IP standards are technically equivalent, but their use were approved by ASTM and EI technical committees as being technically equivalent

but that does not imply that both standards are editorially identical.identical.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7797 − 23

2. Referenced Documents

2.1 ASTM Standards:

D1298 Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by

Hydrometer Method

D1655 Specification for Aviation Turbine Fuels

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products, Liquid Fuels, and

Lubricants

D6751 Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels

E1655 Practices for Infrared Multivariate Quantitative Analysis

2.2 CEN Standards:

EN 14214 Specification Automotive Fuels—Fatty Acid Methyl Esters (FAME) for Diesel Engines—Requirements and Test

Methods

2.3 Energy Institute Standards:

IP 583 Test Method for Determination of the Fatty Acid Methyl Esters Content of Aviation Turbine Fuel Using Flow Analysis

by Fourier Transform Infrared Spectroscopy—Rapid Screening Method

2.4 Other Standards:

Defence Standard 91-91 Issue 7 (DERD 2494) Turbine Fuel, Aviation Kerosine Type, Jet A1

2.5 ASTM Adjuncts:

ADJD6300 (D2PP) Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology D4175.

3.1.2 FAME, n—Fatty acid methyl esters, also known as biodiesel.

3.1.2.1 Discussion—

Used as a component in automotive diesel fuel and the potential source of contamination in aviation turbine fuel due to multi-fuel

tankers and pipelines.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 FA-FTIR, n—flow analysis by Fourier Transform Infra red technique uses a flow-through measurement cell to make a

number of measurements on a stream of test specimen.

3.2.1.1 Discussion—

The test specimen is analyzed before and after passing through a sorbent that is designed to retard the FAME contamination to be

measured. The results are compared to enable the amount of FAME present in the aviation fuel to be determined.

3.2.2 sorbent cartridge, n—a cartridge, through which the test specimen flows, containing a specific sorbent

3.2.2.1 Discussion—

The sorbent cartridge is discarded after each test.

4. Summary of Test Method

4.1 A test specimen of aviation turbine (AVTUR) fuel is automatically analyzed, by an FTIR spectrometer, in a 2 mm effective

path length flow-through cell, before and after flowing through a cartridge containing a sorbent designed to have a relatively long

residence time for FAME. The spectroscopic absorbance differences of the IR spectra, between the measurements, are processed

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from the Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

Available from Procurement Executive DF5 (air), Ministry of Defence, www.dstan.mod.uk.

ADJD6300 is no longer available from ASTM International Headquarters.

D7797 − 23

in conjunction with a PLS-1 model to determine the presence and amplitude of the carbonyl peak of FAME at approximately 1749

-1

cm . Test time is typically 20 min. The flow analysis by FTIR enables the FAME IR peak to be resolved from the bulk IR

properties of the fuel.

5. Significance and Use

5.1 The present and growing international governmental requirements to add fatty acid methyl esters (FAME) to diesel fuel has

had the unintended side-effect of leading to potential FAME contamination of jet turbine fuel in multifuel transport facilities such

as cargo tankers and pipelines, and industry wide concerns.

5.2 Analytical methods have been developed with the capability of measuring down to <5 mg ⁄kg levels of FAME, however these

are complex, and require specialized personnel and laboratory facilities. This Rapid Screening method has been developed for use

in the supply chain by non specialized personnel to cover the range of 10 mg ⁄kg to 150 mg ⁄kg.

6. Interferences

6.1 Chemical compounds, which can arise during production, storage, distribution or sampling, containing carbonyl groups, whose

–1

spectral absorbances appear in the IR spectrum close to 1749 cm , can affect the reading. Plasticizers: bis (2-ethyl hexyl) adipate;

dibutyl-sebacate are known to increase measurement readings obtained by this test method.

NOTE 5—In a limited study, bis (2-ethyl hexyl) adipate at a concentration of 30 mg ⁄kg in aviation fuel gave an increased reading of 15 mg ⁄kg, and

dibutyl-sebacate at 50 mg ⁄L gave an increased reading of 20 mg ⁄kg.

7. Apparatus

7.1 Automatically controlled, closely integrated, instrument comprising FTIR spectrometer with a 2 mm effective optical path

length flow-through cell, computer controlled pump, sorbent cartridge holder, control and interface electronics, test specimen and

waste containers, and solenoid valves.

7.2 The processing computer can be integrated into the instrument.

7.3 This apparatus and the required sorbent cartridge are described in more detail in Annex A1.

7.4 Density Measuring Device (optional)—According to Test Methods D1298, or D4052, or equivalent national standards, to

determine the density of the aviation fuel test sample if required.

8. Reagents and Materials

8.1 Cleaning Solvent, heptane, reagent grade.

8.2 Verification Fluids:

8.2.1 100 mg ⁄kg, containing 100 mg ⁄kg 6 10 mg ⁄kg of FAME, with a certified value and uncertainty.

8.2.2 30 mg ⁄kg, containing 30 mg ⁄kg 6 5 mg ⁄kg of FAME, with a certified value and uncertainty.

8.3 Calibration Fluids:

8.3.1 Set of Five Fluids, containing amounts of FAME with certified values and uncertainty.

8.4 Lint-free Cloth, for cleaning and drying the sample input tube.

The following reagents and materials were used to develop the precision statements: Seta Verification and Calibration fluids for Seta FIJI, Stanhope-Seta, Chertsey, Surrey,

KT16 8AP, UK. This is not an endorsement or certification by ASTM.

D7797 − 23

9. Sampling

9.1 Unless otherwise specified, take a sample of at least 60 mL in accordance with Practices D4057 or D4177 or in accordance

with the requirements of national standards or regulations for the sampling of petroleum products, or both.

9.2 Use new, opaque glass or epoxy lined metal containers with inert closures.

9.2.1 Used sample containers are permitted provided it can be confirmed they have not been used for unknown fluids or for fluids

containing >5 % FAME.

NOTE 6—New sample containers are strongly recommended due to concerns over the difficulty in removing all traces of FAME retained from previous

samples.

9.2.2 Rinse all sample containers with heptane (8.1) or another suitable solvent and drain. Then rinse with the product to be

sampled at least three times. Each rinse shall use product with a volume of 10 % to 20 % of the container volume. Each rinse shall

include closing and shaking the container for a minimum of 5 s and then draining the product.

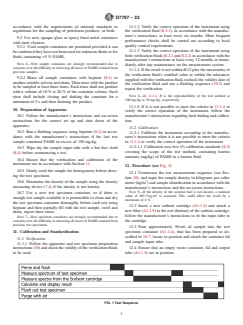

10. Preparation of Apparatus

10.1 Follow the manufacturer’s instructions and on-screen instructions for the correct set up and shut down of the apparatus.

10.2 Run a flushing sequence using heptane (8.1) in accordance with the manufacturer’s instructions if the last test sample

contained FAME in excess of 150 mg ⁄kg.

10.3 Wipe dry the sample input tube with a lint free cloth (8.4) before commencing a test.

10.4 Ensure that the verification and calibratio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...