ASTM C856-95e1

(Practice)Standard Practice for Petrographic Examination of Hardened Concrete

Standard Practice for Petrographic Examination of Hardened Concrete

SCOPE

1.1 This practice outlines procedures for the petrographic examination of samples of hardened concrete. The samples examined may be taken from concrete constructions, they may be concrete products or portions thereof, or they may be concrete or mortar specimens that have been exposed in natural environments, or to simulated service conditions, or subjected to laboratory tests. The phrase "concrete constructions" is intended to include all sorts of objects, units, or structures that have been built of hydraulic cement concrete. Note-A photographic chart of materials, phenomena, and reaction products discussed in Sections 7 through 12 and Tables 1 through 6 are available as Adjunct C856.

1.2 The petrographic procedures outlined herein are applicable to the examination of samples of all types of hardened hydraulic-cement mixtures, including concrete, mortar, grout, plaster, stucco, terrazzo, and the like. In this practice, the material for examination is designated as "concrete," even though the commentary may be applicable to the other mixtures, unless the reference is specifically to media other than concrete.

1.3 Annex A1 outlines an uranyl acetate method for identifying locations where alkali-silica gel may be present. It is a requirement that the substances in those locations must be identified using any other more definitive techniques, such as petrographic microscopy.

1.4 The purposes of and procedures for petrographic examination of hardened concrete are given in the following sections: Section Qualifications of Petrographers 3 Purposes of Examination 4 Apparatus 5 Selection and Use of Apparatus 6 Samples 7 Examination of Samples 8 Specimen Preparation 9 Visual and Stereomicroscope Examination 10 Polarizing Microscope Examination 11 Metallographic Microscope Examination 12 Report 13

1.5 The values stated in inch-pound units are to be regarded as the standard. The SI units in parentheses are provided for information purposes only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific hazard statement is given in 5.2.10.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: C 856 – 95

Standard Practice for

Petrographic Examination of Hardened Concrete

This standard is issued under the fixed designation C 856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Values for (OH ) within formulas in Table 6 were editorially corrected in September 1999 to (OH) .

6 6

1. Scope

Section

Polarizing Microscope Examination 11

1.1 This practice outlines procedures for the petrographic

Metallographic Microscope Examination 12

examination of samples of hardened concrete. The samples Report 13

examined may be taken from concrete constructions, they may

1.5 The values stated in inch-pound units are to be regarded

be concrete products or portions thereof, or they may be

as the standard. The SI units in parentheses are provided for

concrete or mortar specimens that have been exposed in natural

information purposes only.

environments, or to simulated service conditions, or subjected

1.6 This standard does not purport to address all of the

to laboratory tests. The phrase “concrete constructions” is

safety concerns, if any, associated with its use. It is the

intended to include all sorts of objects, units, or structures that

responsibility of the user of this standard to establish appro-

have been built of hydraulic cement concrete.

priate safety and health practices and determine the applica-

NOTE 1—A photographic chart of materials, phenomena, and reaction

bility of regulatory limitations prior to use. A specific hazard

products discussed in Sections 7-12 and Tables 1-6 are available as

statement is given in 5.2.10.1.

Adjunct C856.

2. Referenced Documents

1.2 The petrographic procedures outlined herein are appli-

cable to the examination of samples of all types of hardened

2.1 ASTM Standards:

hydraulic-cement mixtures, including concrete, mortar, grout,

C 42 Test Method for Obtaining and Testing Drilled Cores

plaster, stucco, terrazzo, and the like. In this practice, the

and Sawed Beams of Concrete

material for examination is designated as “concrete,” even

C 215 Test Method for Fundamental Transverse, Longitu-

though the commentary may be applicable to the other mix-

dinal, and Torsional Frequencies of Concrete Specimens

tures, unless the reference is specifically to media other than

C 227 Test Method for Potential Alkali Reactivity of

concrete.

Cement-Aggregate Combinations (Mortar-Bar Method)

1.3 Annex A1 outlines an uranyl acetate method for identi-

C 294 Descriptive Nomenclature of Constituents of Natural

fying locations where alkali-silica gel may be present. It is a

Mineral Aggregates

requirement that the substances in those locations must be

C 295 Guide for Petrographic Examination of Aggregates

identified using any other more definitive techniques, such as

for Concrete

petrographic microscopy.

C 342 Test Method for Potential Volume Change of

1.4 The purposes of and procedures for petrographic exami-

Cement-Aggregate Combinations

nation of hardened concrete are given in the following sections:

C 441 Test Method for Effectiveness of Mineral Admixtures

Section

or Ground Blast-Furnace Slag in Preventing Excessive

Expansion of Concrete Due to the Alkali-Silica Reaction

Qualifications of Petrographers 3

C 452 Test Method for Potential Expansion of Portland

Purposes of Examination 4

Apparatus 5

Cement Mortars Exposed to Sulfate

Selection and Use of Apparatus 6

C 457 Practice for Microscopical Determination of Air-Void

Samples 7

Content and Parameters of the Air-Void System in Hard-

Examination of Samples 8

Specimen Preparation 9

ened Concrete

Visual and Stereomicroscope Examination 10

C 496 Test Method for Splitting Tensile Strength of Cylin-

drical Concrete Specimens

C 597 Test Method for Pulse Velocity Through Concrete

This practice is under the jurisdiction of ASTM Committee C09 on Concrete

and Concrete Aggregatesand is the direct responsibility of Subcommittee C09.65on

Petrography.

Current edition approved Dec. 10, 1995. Published March 1996. Originally Annual Book of ASTM Standards, Vol 04.02.

1 3

published as C 856 – 77. Last previous edition C 856 – 83 (1998)e . Annual Book of ASTM Standards, Vol 04.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

C856–95

TABLE 1 Visual Examination of Concrete (1)

Coarse Aggregate + Fine Aggregate + Matrix + Air + Embedded Items

Composition:

A

Maximum dimension, in. or

mm, in the range> d>

Type: Type: color, by comparison with more than 3 % of total, Type, size, location;

National Research kinds of metal; other

Council Rock Color items

Chart (1963)

1 Gravel 1 Natural sand predominantly in spherical

2 Crushed stone 2 Manufactured sand color distribution: voids?

3 Mixed 1 and 2 3 Mixed 1 mottled less than 3 % of total,

4 Other (name) 4 Other (name) 2 even abundant nonspherical

5 Mixed 1 + /or 2 + /or 4 5 Mixed 1 + /or 2 + /or 4 3 gradational changes voids?

If Type 1, 2, or 4, homogeneous If Type 1, 2, or 4, color differences between

or heterogeneous homogeneous or voids and mortar?

heterogeneous

Lithologic types voids empty, filled, lined, or

Coarse aggregate more than 20, partly filled

30, 40, or 50 % of total

Fabric:

Shape distribution distribution shape voids below horizontal

particle shape

Distribution as per- distribution or low-angle

grading

Packing 6 ceptible grading (as perceptible) reinforcement

preferred orientation

Grading (even, uneven, parallelism of long axes of

excess, or deficiency of irregular voids or sheets

size or sizes) of voids: with each other;

Parallelism of flat sides or with flat sides or long

long axes of exposed axes of coarse aggregate

sections, normal to

direction of placement

+ /or parallel to formed and

B

finished surfaces

Condition: clean or corroded?

Does it ring when hit lightly with a hammer or give a dull flat sound? Can you break it with your fingers? Cracks? How distributed? Are cracks associated

Through or around coarse aggregate? With cores or sawed specimens, did the aggregate tear in drilling or sawing? Crack fillings? with embedded

Surface deposits? If air dry, are there unusually wet or dry looking areas? Rims on aggregate? items?

A

A substantial portion of the coarse aggregate has maximum dimensions in the range shown as measured on sawed or broken surfaces.

B

Sections sawed or drilled close to and parallel to formed surfaces appear to show local turbulence as a result of spading or rodding close to the form. Sections sawed

in the plane of bedding (normal to the direction of placement) are likely to have inconspicuous orientation. Sections broken normal to placement in conventionally placed

concrete with normal bond tend to have aggregate knobs abundant on the bottom of the upper piece as cast and sockets abundant on the top of the lower piece as cast.

C 637 Specification for Aggregates for Radiation-Shielding Adjunct C856 A chart of 27 photos

Concrete

3. Qualifications of Petrographers

C 638 Descriptive Nomenclature of Constituents of Aggre-

gates for Radiation-Shielding Concrete 3.1 The examination should be performed by persons quali-

C 803 Test Method for Penetration Resistance of Hardened fied by education and experience to operate the equipment used

Concrete and to record and interpret the results obtained. In some cases,

C 805 Test Method for Rebound Number of Hardened the petrographer will have had experience adequate to provide

Concrete detailed interpretation of the materials’ performance with

C 823 Practice for Examination and Sampling of Hardened respect to engineering and other consequences of the observa-

tions. In others, the interpretation will be made in part by

Concrete in Constructions

C 944 Test Method for Abrasion Resistance of Concrete or engineers, scientists, or others qualified to relate the observa-

tions to the questions to be answered.

Mortar Surfaces by the Rotating Cutter Method

C 1012 Test Method for Length Change of Hydraulic- 3.2 This practice may be used by a petrographer employed

directly by those for whom the examination is made. The

Cement Mortars Exposed to a Sulfate Solution

C 1260 Test Method for Potential Alkali Reactivity of employer should tell the petrographer, in as much detail as

necessary, the purposes and objectives of the examination, the

Aggregates (Mortar-Bar Method)

E 3 Methods of Preparation of Metallographic Specimens kind of information needed, and the extent of examination

desired. Pertinent background information, including results of

E 883 Practice for Metallographic Photomicrography

2.2 ASTM Adjuncts: prior testing, should be made available. If the petrographer is

highly experienced, his advice and judgment should be sought

Annual Book of ASTM Standards, Vol 03.01.

Available from ASTM Headquarters, 100 Barr Harbor Drive, West Consho-

hocken, PA 19428. Request Adjunct No. ADJC0856.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

C856–95

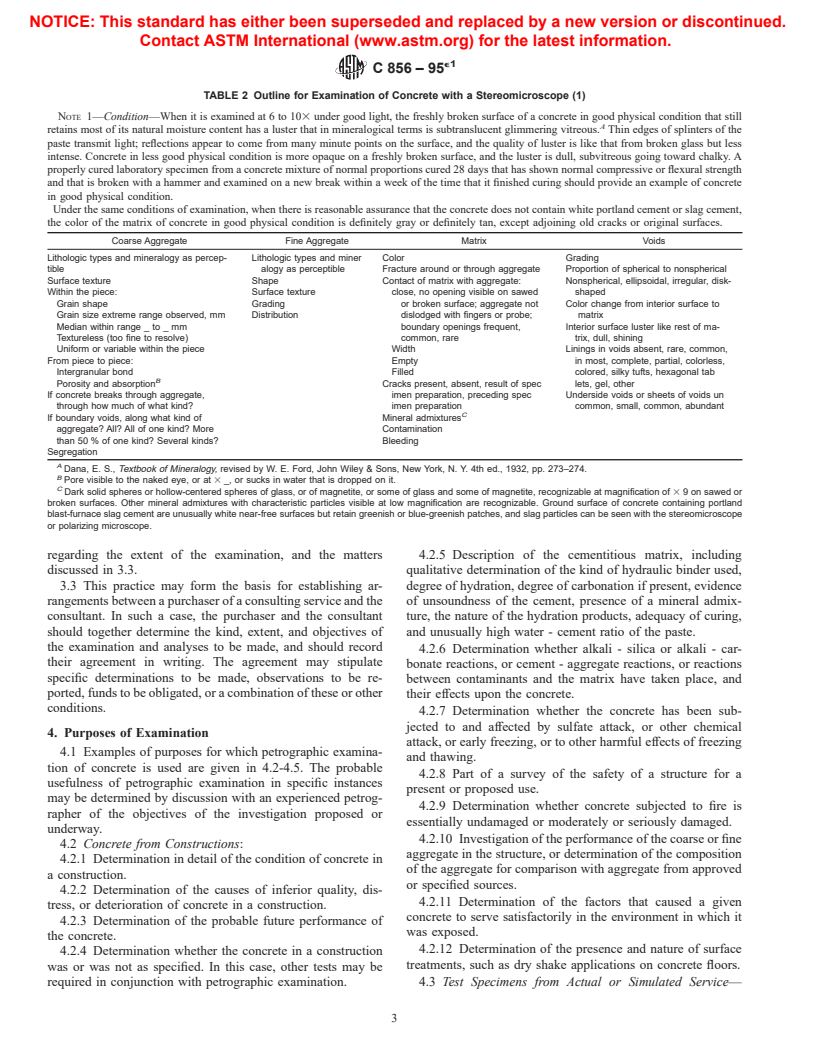

TABLE 2 Outline for Examination of Concrete with a Stereomicroscope (1)

NOTE 1—Condition—When it is examined at 6 to 103 under good light, the freshly broken surface of a concrete in good physical condition that still

A

retains most of its natural moisture content has a luster that in mineralogical terms is subtranslucent glimmering vitreous. Thin edges of splinters of the

paste transmit light; reflections appear to come from many minute points on the surface, and the quality of luster is like that from broken glass but less

intense. Concrete in less good physical condition is more opaque on a freshly broken surface, and the luster is dull, subvitreous going toward chalky. A

properly cured laboratory specimen from a concrete mixture of normal proportions cured 28 days that has shown normal compressive or flexural strength

and that is broken with a hammer and examined on a new break within a week of the time that it finished curing should provide an example of concrete

in good physical condition.

Under the same conditions of examination, when there is reasonable assurance that the concrete does not contain white portland cement or slag cement,

the color of the matrix of concrete in good physical condition is definitely gray or definitely tan, except adjoining old cracks or original surfaces.

Coarse Aggregate Fine Aggregate Matrix Voids

Lithologic types and mineralogy as percep- Lithologic types and miner Color Grading

tible alogy as perceptible Fracture around or through aggregate Proportion of spherical to nonspherical

Surface texture Shape Contact of matrix with aggregate: Nonspherical, ellipsoidal, irregular, disk-

Within the piece: Surface texture close, no opening visible on sawed shaped

Grain shape Grading or broken surface; aggregate not Color change from interior surface to

Grain size extreme range observed, mm Distribution dislodged with fingers or probe; matrix

Median within range _ to _ mm boundary openings frequent, Interior surface luster like rest of ma-

Textureless (too fine to resolve) common, rare trix, dull, shining

Uniform or variable within the piece Width Linings in voids absent, rare, common,

From piece to piece: Empty in most, complete, partial, colorless,

Intergranular bond Filled colored, silky tufts, hexagonal tab

B

Porosity and absorption Cracks present, absent, result of spec lets, gel, other

If concrete breaks through aggregate, imen preparation, preceding spec Underside voids or sheets of voids un

through how much of what kind? imen preparation common, small, common, abundant

C

If boundary voids, along what kind of Mineral admixtures

aggregate? All? All of one kind? More Contamination

than 50 % of one kind? Several kinds? Bleeding

Segregation

A

Dana, E. S., Textbook of Mineralogy, revised by W. E. Ford, John Wiley & Sons, New York, N. Y. 4th ed., 1932, pp. 273–274.

B

Pore visible to the naked eye, or at 3 _, or sucks in water that is dropped on it.

C

Dark solid spheres or hollow-centered spheres of glass, or of magnetite, or some of glass and some of magnetite, recognizable at magnification of 3 9 on sawed or

broken surfaces. Other mineral admixtures with characteristic particles visible at low magnification are recognizable. Ground surface of concrete containing portland

blast-furnace slag cement are unusually white near-free surfaces but retain greenish or blue-greenish patches, and slag particles can be seen with the stereomicroscope

or polarizing microscope.

regarding the extent of the examination, and the matters 4.2.5 Description of the cementitious matrix, including

discussed in 3.3. qualitative determination of the kind of hydraulic binder used,

3.3 This practice may form the basis for establishing ar- degree of hydration, degree of carbonation if present, evidence

rangements between a purchaser of a consulting service and the of unsoundness of the cement, presence of a mineral admix-

consultant. In such a case, the purchaser and the consultant ture, the nature of the hydration products, adequacy of curing,

should together determine the kind, extent, and objectives of and unusually high water - cement ratio of the paste.

the examination and analyses to be made, and should record

4.2.6 Determination whether alkali - silica or alkali - car-

their agreement in writing. The agreement may stipulate

bonate reactions, or cement - aggregate reactions, or reactions

specific determinations to be made, observations to be re-

between contaminants and the matrix have taken place, and

ported, funds to be obligated, or a combination of these or other

their effects upon the concrete.

conditions.

4.2.7 Determination whether the concrete has been sub-

jected to and affected by sulfate attack, or other chemical

4. Purposes of Examination

attack, or early freezing, or to other harmful effects of freezing

4.1 Examples of purposes for which petrographic examina-

and thawing.

tion of concrete is used are given in 4.2-4.5. The probable

4.2.8 Part of a survey of the safety of a structure for a

usefulness of petrographic examination in specific instances

present or proposed use.

may be determined by discussion with an experienced petrog-

4.2.9 Determination whether concrete subjected to fire is

rapher of the objectives of the investigation proposed or

essentially undamaged or moder

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.