ASTM F792-01e2

(Practice)Standard Practice for Evaluating the Imaging Performance of Security X-Ray Systems

Standard Practice for Evaluating the Imaging Performance of Security X-Ray Systems

SIGNIFICANCE AND USE

This practice applies to and establishes a method to measure the imaging performance of X-ray systems used for the screening for prohibited items such as weapons, explosives and explosive devices in baggage, packages, cargo or mail.

This practice is intended for use by manufacturers to assess performance and by evaluators of security and contraband screening X-ray systems to verify performance.

This practice is intended to establish whether an X-ray system meets the manufacturer’specification or if the system’performance has deteriorated over time.

This practice may be used for manufacturing control, specification acceptance, service evaluation or regulatory statutes.

This practice is intended for use at both the point of manufacture and where the system is operated. The latter includes locations such as security checkpoints of transportation terminals, nuclear power stations, correctional institutions, corporate mailrooms, government offices and other security areas.

The most significant attributes of this practice are the design of a standard Test Object and standard methods for determining the performance levels of the system.

In screening objects with X-ray systems video images are the primary inputs provided to operators. The better the quality of these images, the better the potential performance of the operator.

SCOPE

1.1 This practice applies to all X-ray based screening systems, with tunnel apertures up to 1 m wide 1 m high, whether it is a conventional X-ray system or an explosives detection system (EDS) that provides a projection or projection/scatter image for an operator to interpret.

1.2 This practice applies to X-ray systems used for the screening for prohibited items such as weapons, explosives, and explosive devices in baggage, packages, cargo, or mail.

1.3 This practice establishes quantitative and qualitative methods for evaluating the systems. This practice does not establish minimum performance requirements for any particular application.

1.4 The values as stated in SI units are to be regarded as the standard.

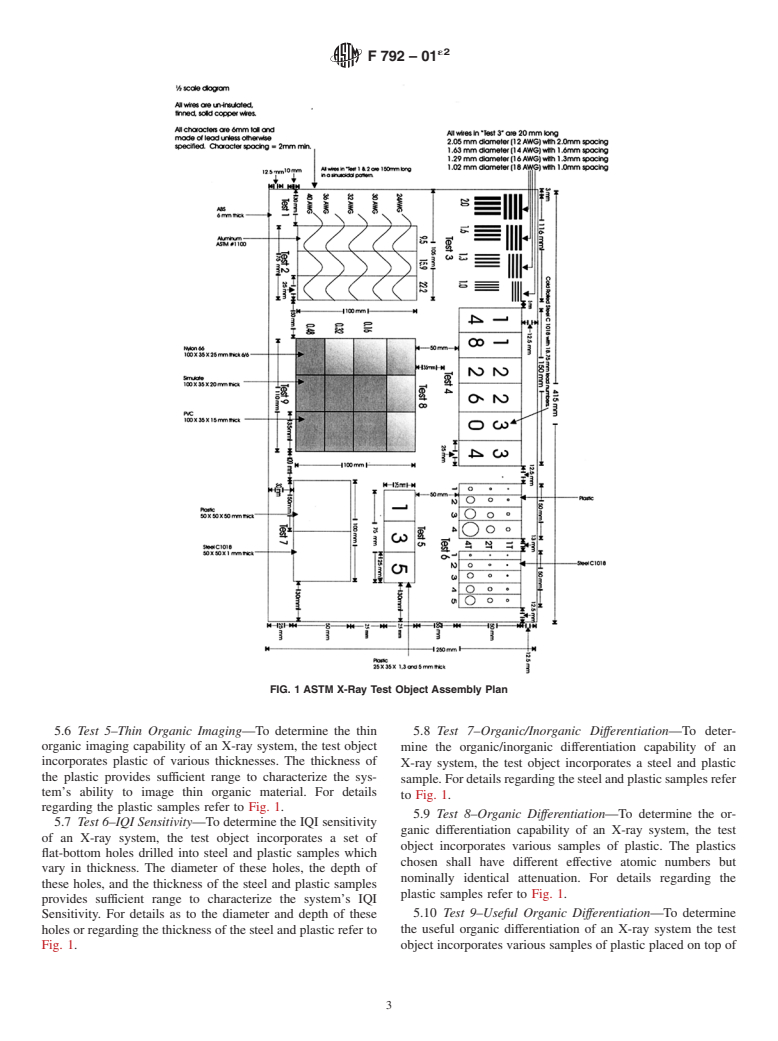

1.5 This practice relies upon the use of a standard test object (ASTM X-ray Test Object) to determine the applicable performance levels of the systems. The specific test object is subsequently described and referred to in this document as the "Test Object."

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Examples are Title 21 Code of Federal Regulations, Section 1020.40 in the United States and Health Safety Regulation No. 1333 in the United Kingdom.

1.7 Film Safety—If film safety, defined as 2.58x10-7 C/kg (1 mR) per screening, is of importance, refer to Test Method F 1039.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´2

Designation:F792–01

Standard Practice for

Evaluating the Imaging Performance of Security X-Ray

1

Systems

This standard is issued under the fixed designation F 792; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Note from Table 1 was deleted editorially in February 2002.

2

´ NOTE—An adjunct reference was added editorially in June 2002.

1. Scope 2. Referenced Documents

2

1.1 This practice applies to all X-ray based screening 2.1 ASTM Standards:

systems, with tunnel apertures up to 1 m wide 3 1 m high, B 258 Specification for Standard Nominal Diameters and

whether it is a conventional X-ray system or an explosives Cross-SectionalAreasofAWGSizesofSolidRoundWires

detection system (EDS) that provides a projection or Used as Electrical Conductors

projection/scatter image for an operator to interpret. E 1025 Practice for Design, Manufacture, and Material

1.2 This practice applies to X-ray systems used for the Grouping Classification of Hole-Type Image Quality Indi-

screening for prohibited items such as weapons, explosives, cators (IQI) Used for Radiology

and explosive devices in baggage, packages, cargo, or mail. E 1316 Terminology for Nondestructive Examinations

1.3 This practice establishes quantitative and qualitative E 1647 Practice for Determining Contrast Sensitivity in

methods for evaluating the systems. This practice does not Radioscopy

establish minimum performance requirements for any particu- F 1039 Test Method for Measurement of Low Level X

lar application. Radiation Used in X-ray Security Screening Systems

1.4 The values as stated in SI units are to be regarded as the 2.2 ASTM Adjuncts:

3

standard. 30 Autocad Drawings

1.5 Thispracticereliesupontheuseofastandardtestobject 2.3 Other Documents:

(ASTM X-ray Test Object) to determine the applicable perfor- Part 21 Code of Federal Regulations, Section

4

mance levels of the systems. The specific test object is 1020.40, Cabinet X-ray Systems (United States)

subsequently described and referred to in this document as the Health & Safety Regulation 1333 (United Kingdom)

“Test Object.”

3. Terminology

1.6 This standard does not purport to address all of the

3.1 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1.1 contrast sensitivity—a measure of the minimum

change in an object that produces a perceptible brightness

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Examples are Title change in the radiological image on a monitor.

3.1.2 effective atomic number (Z eff)—the effective atomic

21 Code of Federal Regulations, Section 1020.40 in the United

States and Health & Safety Regulation No. 1333 in the United number of a chemical compound or mixture of compounds is

the atomic number of a single hypothetical element which

Kingdom.

-7

1.7 Film Safety—If film safety, defined as <2.58310 C/kg would exhibit essentially identical X-ray attenuation character-

istics.

(<1 mR) per screening, is of importance, refer to Test Method

F 1039.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This practice is under the jurisdiction of ASTM Committee F12 on Security Standards volume information, refer to the standard’s Document Summary page on

Systems and Equipment and is the direct responsibility of Subcommittee F12.60 on the ASTM website.

3

Controlled Access Security, Search and Screening Equipment. Available from ASTM Headquarters. Request adjunct no. ADFF0792.

4

Current edition approved May 24, 2002. Published November 2001. Originally Available from the United States Government Printing Office, 732 North

´1

published as F 792 – 82. Last previous edition F 792 – 88(93) . Capitol St. NW, Washington, DC 20401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´2

F792–01

3.1.3 explosive—a material that can be detonated, that is, 4.3 This practice is intended to establish whether an X-ray

undergo a chemical reaction, expand suddenly, and create a system meets the manufacturer’s specification or if the sys-

shock wave. tem’s performance has deteriorated over time.

4.4 This practice may be used for manufacturing control,

3.1.4 explosive device—a device containing explosives, a

detonator, a timer/switch and an energy source. specification acceptance, service evaluati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.