ASTM F584-06e1

(Practice)Standard Practice for Visual Inspection of Semiconductor Lead-Bonding Wire (Withdrawn 2015)

Standard Practice for Visual Inspection of Semiconductor Lead-Bonding Wire (Withdrawn 2015)

SIGNIFICANCE AND USE

Spooled wire viewed under bright direct lighting or in deep shadow generally exhibits a flawless appearance. Proper arrangement of the viewing angle and illumination, however, permits accurate observation of wire-surface condition. This practice specifies the conditions under which reliable and reproducible surface finish inspection may be achieved. Such inspection is appropriate for evaluating surface quality with respect to the requirements in Specifications F 72 and F 487.

Surface smoothness and degree of cleanliness may affect the performance of wire. This practice may be used to determine whether or not spooled wire meets performance-based surface finish criteria agreed upon between a manufacturer or supplier and a wire purchaser.

The magnification recommended may not be sufficient to permit detection of all defects on the wire surface affecting wire performance; however, it is sufficient to permit an inspector to determine the overall state of the wire finish and the manner in which the wire lies on the spool.

SCOPE

1.1 This practice covers conditions for nondestructive visual inspection of the surface finish of spooled aluminum and gold wire used for making internal semiconductor device connections and hybrid microelectronic connections.

1.2 This practice specifies the recommended lighting, magnification, and specimen positioning for inspecting spooled wire under an optical microscope.

1.3 Photographs ( ) are included in as guides to aid the inspector in identifying particular surface conditions. These photographs are not intended as standards for specifying wire surface quality.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the aplicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice covers conditions for nondestructive visual inspection of the surface finish of spooled aluminum and gold wire used for making internal semiconductor device connections and hybrid microelectronic connections.

Formerly under the jurisdiction of Committee F01 on Electronics, this practice was withdrawn in January 2015 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F584 − 06

StandardPractice for

1

Visual Inspection of Semiconductor Lead-Bonding Wire

ThisstandardisissuedunderthefixeddesignationF584;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Adjunct references were corrected editorially in April 2006.

4

1. Scope 2.3 ASTM Adjunct:

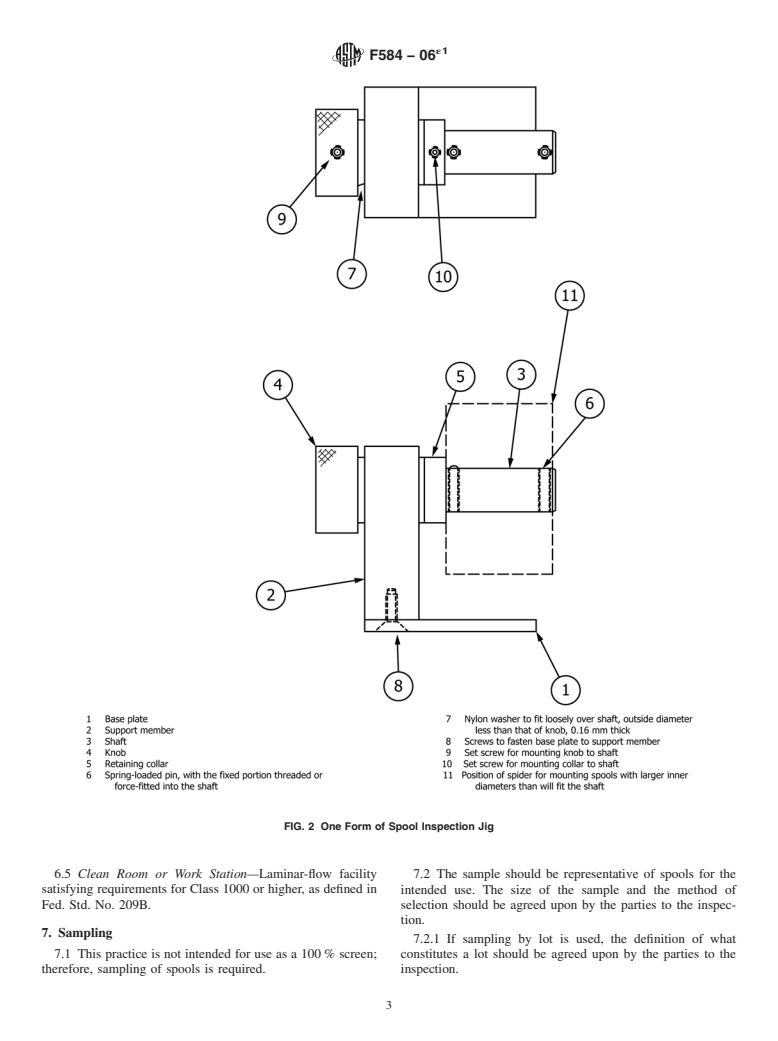

ADJF0584Spoolinspectionjig(4drawingsanddescription)

1.1 Thispracticecoversconditionsfornondestructivevisual

inspection of the surface finish of spooled aluminum and gold

3. Terminology

wire used for making internal semiconductor device connec-

3.1 Definitions of Terms Specific to This Standard:

tions and hybrid microelectronic connections.

3.1.1 chatter marks—for the purposes of this practice—

1.2 This practice specifies the recommended lighting,

repetitive closely spaced wire surface blemishes.

magnification,andspecimenpositioningforinspectingspooled

3.1.2 dark area—for the purposes of this practice—wire

wire under an optical microscope.

surface shadowed from direct light-source illumination.

1.3 Photographs (Figs. X1.1-X1.5 ) are included in Appen-

3.1.3 fingerprint—for the purposes of this practice—

dix X1 as guides to aid the inspector in identifying particular

residual surface contamination deposited during handling.

surface conditions. These photographs are not intended as

standards for specifying wire surface quality.

4. Summary of Practice

1.4 The values stated in SI units are to be regarded as the

4.1 The wire spool to be inspected is first mounted on a

standard. The values given in parentheses are for information

holding fixture that permits rotation of the spool about its axis.

only.

The spool fixture is then placed on the stage of a binocular

1.5 This standard does not purport to address all of the

microscope.Thewiresurfaceisilluminatedwithlightincident

safety concerns, if any, associated with its use. It is the atagrazingangle;themicroscopeandfixturearepositionedso

responsibility of the user of this standard to establish appro-

that the microscope field shows the partially shadowed wire

priate safety and health practices and determine the aplicabil- wrap just adjacent to the brilliantly lit surface at the top of the

ity of regulatory limitations prior to use. spool.

4.2 Inspection is accomplished by slowly rotating the spool

2. Referenced Documents

aboutitsaxisandmovingthefixtureoverthemicroscopestage

2

2.1 ASTM Standards:

until the operator has viewed the entire exposed wire surface

F72Specification for Gold Wire for Semiconductor Lead

area under partially shadowed illumination.

Bonding

4.3 The defects to be identified, the manner in which their

F487SpecificationforFineAluminum–1%SiliconWirefor

presence is reported, and the manner in which the wire surface

Semiconductor Lead-Bonding

3

quality is to be characterized should be agreed upon by the

2.2 Federal Standard:

parties to the inspection.

Fed. Std. No. 209B Clean Room and Work Station

Requirements, Controlled Environment

NOTE 1—Viewing a wire spool in the partial shadow of glancing

illumination is particularly revealing of surface flaws and soil. The

viewing arrangement amounts to dark-field illumination with imperfec-

1

This practice is under the jurisdiction of ASTM Committee F01 on Electron-

tions appearing as bright glints on the wire surface.

icsand is the direct responsibility of Subcommittee F01.07 on Wire Bonding, Flip

Chip, and Tape Automated Bonding.

5. Significance and Use

Current edition approved Jan. 1, 2006. Published February 2006. Originally

approvedin1978.Lastpreviouseditionapprovedin2005asF584–87(2005).DOI:

5.1 Spooled wire viewed under bright direct lighting or in

10.1520/F0584-06E01.

deep shadow generally exhibits a flawless appearance. Proper

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

arrangement of the viewing angle and illumination, however,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

4

3

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 Detailed working drawings of the apparatus are available from: ASTM

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. International Headquarters. Order Adjunct ADJF0584.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F584 − 06

permits accurate observation of wire-surface condition. This 6.2 Eyepieces, wide-field, with 10× magnification for a

practice specifies the conditions under which reliable and binocular microscope.

reproduci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.