ASTM E1221-96

(Test Method)Standard Test Method for Determining Plane-Strain Crack-Arrest Fracture Toughness, KIa, of Ferritic Steels

Standard Test Method for Determining Plane-Strain Crack-Arrest Fracture Toughness, K<sub>Ia</sub>, of Ferritic Steels

SCOPE

1.1 This test method employs a side-grooved, crack-line-wedge-loaded specimen to obtain a rapid run-arrest segment of flat-tensile separation with a nearly straight crack front. This test method provides a static analysis determination of the stress intensity factor at a short time after crack arrest. The estimate is denoted K a. When certain size requirements are met, the test result provides an estimate, termed KIa, of the plane-strain crack-arrest toughness of the material.

1.2 The specimen size requirements, discussed later, provide for in-plane dimensions large enough to allow the specimen to be modeled by linear elastic analysis. For conditions of plane-strain, a minimum specimen thickness is also required. Both requirements depend upon the crack arrest toughness and the yield strength of the material. A range of specimen sizes may therefore be needed, as specified in this test method.

1.3 If the specimen does not exhibit rapid crack propagation and arrest, Ka cannot be determined.

1.4 Values stated in inch-pound units are to be regarded as the standards. SI units are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1221 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determining Plane-Strain Crack-Arrest Fracture Toughness,

K , of Ferritic Steels

Ia

This standard is issued under the fixed designation E 1221; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1304 Test Method for Plane-Strain (Chevron Notch)

Fracture Toughness of Metallic Materials

1.1 This test method employs a side-grooved, crack-line-

wedge-loaded specimen to obtain a rapid run-arrest segment of

3. Terminology

flat-tensile separation with a nearly straight crack front. This

3.1 Definitions:

test method provides a static analysis determination of the

3.1.1 Definitions in Terminology E 616 are applicable to

stress intensity factor at a short time after crack arrest. The

this test method.

estimate is denoted K . When certain size requirements are

a

3.2 Definitions of Terms Specific to This Standard:

met, the test result provides an estimate, termed K ,ofthe

Ia

3.2.1 conditional value of the plane-strain crack-arrest

plane-strain crack-arrest toughness of the material.

−3/2

fracture toughness, K (FL )—the conditional value of K

Qa Ia

1.2 The specimen size requirements, discussed later, pro-

calculated from the test results and subject to the validity

vide for in-plane dimensions large enough to allow the speci-

criteria specified in this test method.

men to be modeled by linear elastic analysis. For conditions of

3.2.1.1 Discussion—In this test method, side-grooved

plane-strain, a minimum specimen thickness is also required.

specimens are used. The calculation of K is based upon

Qa

Both requirements depend upon the crack arrest toughness and

measurements of both the arrested crack length and of the

the yield strength of the material. A range of specimen sizes

crack-mouth opening displacement prior to initiation of a

may therefore be needed, as specified in this test method.

fast-running crack and shortly after crack arrest.

1.3 If the specimen does not exhibit rapid crack propagation

−3/2

3.2.2 crack-arrest fracture toughness, K (FL )—the

a

and arrest, K cannot be determined.

a

value of the stress intensity factor shortly after crack arrest.

1.4 Values stated in inch-pound units are to be regarded as

3.2.2.1 Discussion—The in-plane specimen dimensions

the standards. SI units are provided for information only.

must be large enough for adequate enclosure of the crack-tip

1.5 This standard does not purport to address all of the

plastic zone by a linear-elastic stress field.

safety concerns, if any, associated with its use. It is the

3.2.3 plane-strain crack-arrest fracture toughness, K

Ia

responsibility of the user of this standard to establish appro-

−3/2

(FL )—the value of crack-arrest fracture toughness, K , for

a

priate safety and health practices and determine the applica-

a crack that arrests under conditions of crack-front plane-strain.

bility of regulatory limitations prior to use.

3.2.3.1 Discussion—The requirements for attaining condi-

2. Referenced Documents tions of crack-front plane-strain are specified in the procedures

of this test method.

2.1 ASTM Standards:

−3/2

3.2.4 stress intensity factor at crack initiation, K (FL )—

o

E 8 Test Methods for Tension Testing of Metallic Materials

the value of K at the onset of rapid fracturing.

E 23 Test Methods for Notched Bar Impact Testing of

3.2.4.1 Discussion—In this test method, only a nominal

Metallic Materials

estimate of the initial driving force is needed. For this reason,

E 208 Test Method for Conducting Drop-Weight Test to

K is calculated on the basis of the original (machined) crack

o

Determine Nil-Ductility Transition Temperature of Ferritic

2 (or notch) length and the crack-mouth opening displacement at

Steels

the initiation of a fast-running crack.

E 399 Test Method for Plane-Strain Fracture Toughness of

Metallic Materials

4. Summary of Test Method

E 616 Terminology Relating to Fracture Testing

4.1 This test method estimates the value of the stress

intensity factor, K, at which a fast running crack will arrest.

This test method is under the jurisdiction of ASTM Committee E-8 on Fracture

This test method is made by forcing a wedge into a split-pin,

Testing and is the direct responsibility of Subcommittee E08.07 on Linear-Elastic

which applies an opening force across the crack starter notch in

Fracture.

Current edition approved June 10, 1996. Published August 1996. Originally a modified compact specimen, causing a run-arrest segment of

published as E 1221 – 88. Last previous edition E 1221 – 88.

crack extension. The rapid run-arrest event suggests need for a

Annual Book of ASTM Standards, Vol 03.01.

E 1221

dynamic analysis of test results. However, experimental obser- the run-arrest event, the loading system must have a low

vations (1, 2) indicate that, for this test method, an adjusted compliance compared with the test specimen. For this reason a

static analysis of test results provides a useful estimate of the wedge and split-pin assembly is used to apply a load on the

value of the stress intensity factor at the time of crack arrest. crack line. This loading arrangement does not permit easy

4.2 Calculation of a nominal stress intensity at initiation, K , measurement of opening loads. Consequently, opening dis-

o

is based on measurements of the machined notch length and the placement measurements in conjunction with crack size and

crack-mouth opening displacement at initiation. The value of compliance calibrations are used for calculating K and K .

o a

K is based on measurements of the arrested crack length and 6.2 Loading Arrangement:

a

the crack-mouth opening displacements prior to initiation and 6.2.1 A typical loading arrangement is shown in Fig. 1. The

shortly after crack arrest. specimen is placed on a support block whose thickness should

be adequate to allow completion of the test without interfer-

5. Significance and Use

ence between the wedge and the lower crosshead of the testing

machine. The support block should contain a hole that is

5.1 In structures containing gradients in either toughness or

stress, a crack may initiate in a region of either low toughness aligned with the specimen hole, and whose diameter should be

between 1.05 and 1.15 times the diameter of the hole in the

or high stress, or both, and arrest in another region of either

higher toughness or lower stress, or both. The value of the specimen. The load that forces the wedge into the split-pin is

transmitted through a load cell.

stress intensity factor during the short time interval in which a

fast-running crack arrests is a measure of the ability of the 6.2.1.1 The surfaces of the wedge, split-pin, support block,

and specimen hole should be lubricated. Lubricant in the form

material to arrest such a crack. Values of the stress intensity

of thin (0.005 in. or 0.13 mm) strips of TFE-fluorocarbon is

factor of this kind, which are determined using dynamic

methods of analysis, provide a value for the crack-arrest preferred. Molybdenum disulfide (both dry and in a grease

vehicle) and high-temperature lubricants can also be used.

fracture toughness which will be termed K in this discussion.

A

Static methods of analysis, which are much less complex, can 6.2.1.2 A low-taper-angle wedge and split-pin arrangement

is used. If grease or dry lubricants are used, a matte finish (grit

often be used to determine K at a short time (1 to 2 ms) after

crack arrest. The estimate of the crack-arrest fracture toughness blasted) on the sliding surfaces may be helpful in avoiding

galling. The split-pin must be long enough to contact the full

obtained in this fashion is termed K . When macroscopic

a

dynamic effects are relatively small, the difference between K

A

and K is also small (1-4). For cracks propagating under

a

conditions of crack-front plane-strain, in situations where the

dynamic effects are also known to be small, K determinations

Ia

using laboratory-sized specimens have been used successfully

to estimate whether, and at what point, a crack will arrest in a

structure (5, 6). Depending upon component design, loading

compliance, and the crack jump length, a dynamic analysis of

a fast-running crack propagation event may be necessary in

order to predict whether crack arrest will occur and the arrest

position. In such cases, values of K determined by this test

Ia

method can be used to identify those values of K below which

the crack speed is zero. More details on the use of dynamic

analyses can be found in Ref (4).

5.2 This test method can serve at least the following

additional purposes:

5.2.1 In materials research and development, to establish in

quantitative terms significant to service performance, the

effects of metallurgical variables (such as composition or heat

treatment) or fabrication operations (such as welding or form-

ing) on the ability of a new or existing material to arrest

running cracks.

5.2.2 In design, to assist in selection of materials for, and

determine locations and sizes of, stiffeners and arrestor plates.

6. Apparatus

6.1 The procedure involves testing of modified compact

specimens that have been notched by machining. To minimize

the introduction of additional energy into the specimen during

FIG. 1 Schematic Pictorial and Sectional Views Showing the

The boldface numbers in parentheses refer to the list of references at the end of Standard Arrangement of the Wedge and Split-Pin Assembly, the

this test method. Test Specimen, and the Support Block

E 1221

specimen thickness, and the radius must be large enough to

avoid plastic indentations of the test specimen. In all cases it is

recommended that the diameter of the split-pin should be 0.005

in. (0.13 mm) less than the diameter of the specimen hole. The

wedge must be long enough to develop the maximum expected

opening displacement. Any air or oil hardening tool steel is

suitable for making the wedge and split-pins. A hardness in the

range from R 45 to R 55 has been used successfully. With the

C C

recommended wedge angle and proper lubrication, a loading

1 1

machine producing ⁄5 to ⁄10 the expected maximum opening

load is adequate. The dimensions of a wedge and split-pin

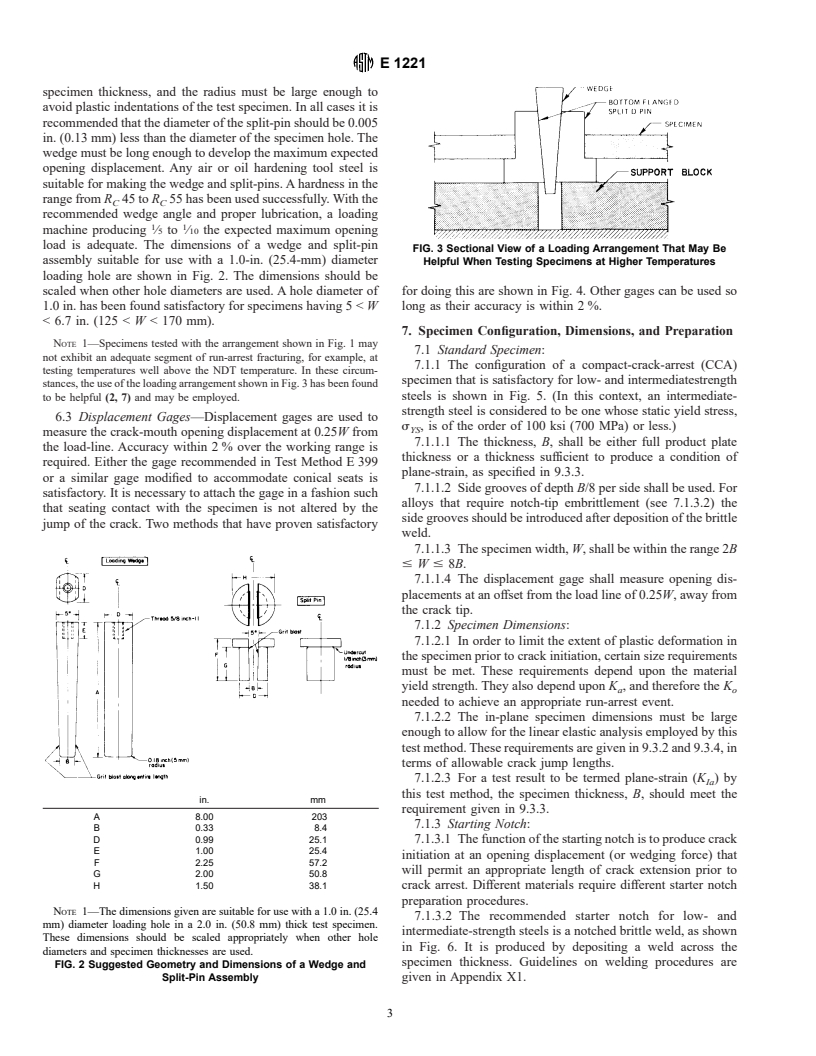

FIG. 3 Sectional View of a Loading Arrangement That May Be

assembly suitable for use with a 1.0-in. (25.4-mm) diameter Helpful When Testing Specimens at Higher Temperatures

loading hole are shown in Fig. 2. The dimensions should be

for doing this are shown in Fig. 4. Other gages can be used so

scaled when other hole diameters are used. A hole diameter of

1.0 in. has been found satisfactory for specimens having 5 < W long as their accuracy is within 2 %.

< 6.7 in. (125 < W < 170 mm).

7. Specimen Configuration, Dimensions, and Preparation

NOTE 1—Specimens tested with the arrangement shown in Fig. 1 may

7.1 Standard Specimen:

not exhibit an adequate segment of run-arrest fracturing, for example, at

7.1.1 The configuration of a compact-crack-arrest (CCA)

testing temperatures well above the NDT temperature. In these circum-

specimen that is satisfactory for low- and intermediatestrength

stances, the use of the loading arrangement shown in Fig. 3 has been found

steels is shown in Fig. 5. (In this context, an intermediate-

to be helpful (2, 7) and may be employed.

strength steel is considered to be one whose static yield stress,

6.3 Displacement Gages—Displacement gages are used to

s , is of the order of 100 ksi (700 MPa) or less.)

YS

measure the crack-mouth opening displacement at 0.25W from

7.1.1.1 The thickness, B, shall be either full product plate

the load-line. Accuracy within 2 % over the working range is

thickness or a thickness sufficient to produce a condition of

required. Either the gage recommended in Test Method E 399

plane-strain, as specified in 9.3.3.

or a similar gage modified to accommodate conical seats is

7.1.1.2 Side grooves of depth B/8 per side shall be used. For

satisfactory. It is necessary to attach the gage in a fashion such

alloys that require notch-tip embrittlement (see 7.1.3.2) the

that seating contact with the specimen is not altered by the

side grooves should be introduced after deposition of the brittle

jump of the crack. Two methods that have proven satisfactory

weld.

7.1.1.3 The specimen width, W, shall be within the range 2B

# W # 8B.

7.1.1.4 The displacement gage shall measure opening dis-

placements at an offset from the load line of 0.25W, away from

the crack tip.

7.1.2 Specimen Dimensions:

7.1.2.1 In order to limit the extent of plastic deformation in

the specimen prior to crack initiation, certain size requirements

must be met. These requirements depend upon the material

yield strength. They also depend upon K , and therefore the K

a o

needed to achieve an appropriate run-arrest event.

7.1.2.2 The in-plane specimen dimensions must be large

enough to allow for the linear elastic analysis employed by this

test method. These requirements are given in 9.3.2 and 9.3.4, in

terms of allowable crack jump lengths.

7.1.2.3 For a test result to be termed plane-strain (K )by

Ia

this test method, the specimen thickness, B, should meet the

in. mm

requirement given in 9.3.3.

A 8.00 203

7.1.3 Starting Notch:

B 0.33 8.4

D 0.99 25.1 7.1.3.1 The function of the starting notch is to produce crack

E 1.00 25.4

initiation at an opening displacement (or wedging force) that

F 2.25 57.2

will permit an appropriate length of crack extension prior to

G 2.00 50.8

H 1.50 38.1

crack arrest. Different materials require different starter notch

preparation procedures.

NOTE 1—The dimensions given are suitable for use with a 1.0 in. (25.4

7.1.3.2 The recommended starter notch for low- and

mm) diameter loading hole in a 2.0 in. (50.8 mm) thick test specimen.

intermediate-strength steels is a notched brittle weld, as shown

These dimensions should be scaled appropriately when other hole

in Fig. 6. It is produced by depositing a weld across the

diameters and specimen thicknesses are used.

specimen thickness. Guidelines on welding procedures are

FIG. 2 Suggested Geometry and Dimensions of a Wedge and

Split-Pin Assembly given in Appendix X1.

E 1221

NOTE 1— Dimension A should be 0.002–0.010 in. (0.05–0.25 mm) less than the thickness of the clip gage arm.

NOTE 2—The knife edge can be attached to the specimen with mechanical fasteners or adhesives.

NOTE 3—The cli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.