ASTM F1709-97

(Specification)Standard Specification for High Purity Titanium Sputtering Targets for Electronic Thin Film Applications

Standard Specification for High Purity Titanium Sputtering Targets for Electronic Thin Film Applications

SCOPE

1.1 This specification covers pure titanium sputtering targets used as a raw material in fabricating semiconductor electronic devices.

1.2 This standard sets purity grade levels, physical attributes, analytical methods, and packaging.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1709 – 97

Standard Specification for

High Purity Titanium Sputtering Targets for Electronic Thin

Film Applications

This standard is issued under the fixed designation F 1709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

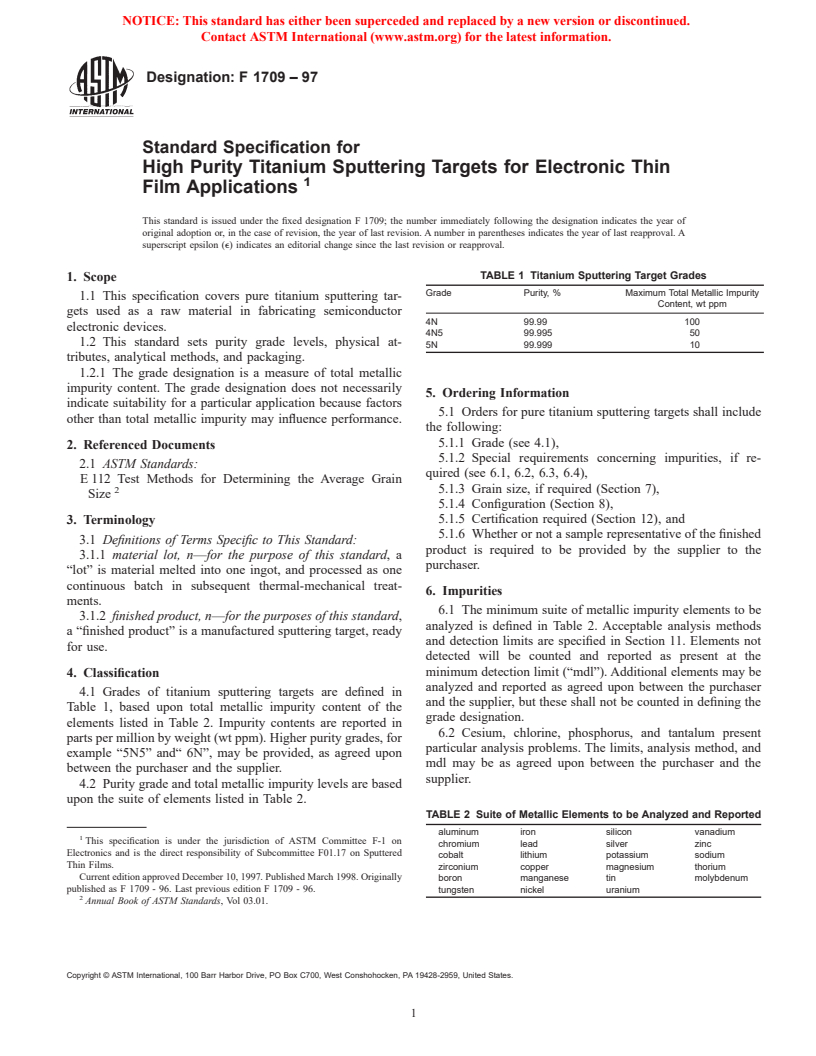

TABLE 1 Titanium Sputtering Target Grades

1. Scope

Grade Purity, % Maximum Total Metallic Impurity

1.1 This specification covers pure titanium sputtering tar-

Content, wt ppm

gets used as a raw material in fabricating semiconductor

4N 99.99 100

electronic devices.

4N5 99.995 50

1.2 This standard sets purity grade levels, physical at-

5N 99.999 10

tributes, analytical methods, and packaging.

1.2.1 The grade designation is a measure of total metallic

impurity content. The grade designation does not necessarily

5. Ordering Information

indicate suitability for a particular application because factors

5.1 Orders for pure titanium sputtering targets shall include

other than total metallic impurity may influence performance.

the following:

5.1.1 Grade (see 4.1),

2. Referenced Documents

5.1.2 Special requirements concerning impurities, if re-

2.1 ASTM Standards:

quired (see 6.1, 6.2, 6.3, 6.4),

E 112 Test Methods for Determining the Average Grain

5.1.3 Grain size, if required (Section 7),

Size

5.1.4 Configuration (Section 8),

5.1.5 Certification required (Section 12), and

3. Terminology

5.1.6 Whether or not a sample representative of the finished

3.1 Definitions of Terms Specific to This Standard:

product is required to be provided by the supplier to the

3.1.1 material lot, n—for the purpose of this standard,a

purchaser.

“lot” is material melted into one ingot, and processed as one

continuous batch in subsequent thermal-mechanical treat-

6. Impurities

ments.

6.1 The minimum suite of metallic impurity elements to be

3.1.2 finished product, n—for the purposes of this standard,

analyzed is defined in Table 2. Acceptable analysis methods

a “finished product” is a manufactured sputtering target, ready

and detection limits are specified in Section 11. Elements not

for use.

detected will be counted and reported as present at the

minimum detection limit (“mdl”). Additional elements may be

4. Classification

analyzed and reported as agreed upon between the purchaser

4.1 Grades of titanium sputtering targets are defined in

and the supplier, but these shall not be counted in defining the

Table 1, based upon total metallic impurity content of the

grade designation.

elements listed in Table 2. Impurity contents are reported in

6.2 Cesium, chlorine, phosphorus, and tantalum present

parts per million by weight (wt ppm). Higher purity grades, for

particular analysis problems. The limits, analysis method, and

example “5N5” and“ 6N”, may be provided, as agreed upon

mdl may be as agreed upon between the purchaser and the

between the purchaser and the supplier.

supplier.

4.2 Purity grade and total metallic impurity levels are based

upon the suite of elements listed in Table 2.

TABLE 2 Suite of Metallic Elements to be Analyzed and Reported

aluminum iron silicon vanadium

This specification is under the jurisdiction of ASTM Committee F-1 on

chromium lead silver zinc

Electronics and is the direct responsibility of Subcommittee F01.17 on Sputtered

cobalt lithium potassium sodium

Thin Films.

zirconium copper magnesium thorium

Current edition approved December 10, 1997. Published March 1998. Originally boron manganese tin molybdenum

published as F 1709 - 96. Last previous edition F 1709 - 96. tungsten nickel uranium

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1709 – 97

6.3 Nonmetallic elements which shall be analyzed and grade designation (4.1), other metallic impurity limits (6.1, 6.2,

reported are carbon, hydrogen, nitrogen, oxygen, and sulfur. 6.4), and the agreed upon limits for nonmetallic content (6.3).

Maximum limits for nonmetallic impurities shall be as agreed

11. Analytical Methods

upon between the purchaser and the supplier.

11.1 Analysis for impurities listed in Section 6 and Table 2

6.4 Acceptable limits and analytical techniques for particu-

shall be performed as follows:

lar elements in critical applications may be agreed upon

11.1.1 Trace Metallic Impurities—By glow discharge mass

between the purchaser and the supplier.

spectrometer (GDMS) with a nominal mdl # 0.05 weight ppm.

7. Grain Size NOTE 1—The mdl for some metallic species by GDMS is >0.05 weight

ppm, as limited by interferences.

7.1 The average and the maximum grain size shall be as

11.1.2 Carbon, Oxygen, Sulfur—By fusion and gas

agreed upon between the purchaser and the supplier.

extraction/infrared spectroscopy with an mdl of #10 weight

7.2 Average grain size shall be measured and reported in

ppm.

accordance with Test Methods E 112, or other equivalent

11.1.3 Nitrogen—By fusion and gas extraction with an mdl

method.

of #10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.