ASTM E3205-20

(Test Method)Standard Test Method for Small Punch Testing of Metallic Materials

Standard Test Method for Small Punch Testing of Metallic Materials

SIGNIFICANCE AND USE

4.1 The safety margins provided in the design for a component or structure can be reduced throughout its service life by aging. Aging is the process by which the physical and mechanical characteristics of component or structure materials change with time or use; this process may proceed by a single aging mechanism or a combination of several aging mechanisms.

4.2 The term “safety margin” is used in a broad sense, meaning the safety state (that is, integrity and functional capability) of components in excess of their normal operational requirements (1).3

4.3 The determination of mechanical properties such as yield strength, tensile strength, and ductile-to-brittle transition temperature of structural components is, hence, desirable for optimization of operating procedures and inspection intervals, as well as repair strategies and residual lifetime assessment. Current standardized mechanical tests require relatively large volumes of test material that cannot be extracted from in-service equipment without post-sampling removal repair (2).

4.4 The need to obtain estimates of the mechanical properties of components without post-sampling removal repair has led to the development of small punch (SP) test techniques based on penetration/bulge tests of miniaturized test specimens (often disk-shaped, or square) (3, 4, 5). It can be considered as a quasi-nondestructive technique because of the very limited amount of material to be sampled. It is an efficient and cost-effective technique and has the potential to provide estimates of the material properties of the specific component, identifying the present state of damage and focusing on the most critical (most stressed, most damaged) locations in the component. Examples of empirical correlations that have been established between small punch test results and mechanical properties for specific classes of materials are provided in Appendix X1.

4.5 This test method can be also used for identifying the most suitable ma...

SCOPE

1.1 This test method covers procedures for conducting the small punch deformation test for metallic materials. The results can be used to derive estimates of yield and tensile strength up to 450 °C, and estimates of the ductile-to-brittle transition temperature from the results of small punch bulge tests in the temperature range from -193 °C to 350 °C for iron based materials or 0.4 Tm for other metallic materials, where Tm is their melting temperature in K.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3205 − 20

Standard Test Method for

1

Small Punch Testing of Metallic Materials

This standard is issued under the fixed designation E3205; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers procedures for conducting the

E220Test Method for Calibration of Thermocouples By

smallpunchdeformationtestformetallicmaterials.Theresults

Comparison Techniques

can be used to derive estimates of yield and tensile strength up

to 450 °C, and estimates of the ductile-to-brittle transition

3. Terminology

temperature from the results of small punch bulge tests in the

temperature range from -193 °C to 350 °C for iron based 3.1 Definitions:

materials or 0.4 T for other metallic materials, where T is

3.1.1 force, F [F], n—force applied to the test specimen by

m m

their melting temperature in K.

the punch.

3.1.1.1 Discussion—This includes the weights of the equip-

1.2 The values stated in SI units are to be regarded as

ment acting on the punch.

standard. No other units of measurement are included in this

standard. 3.1.2 force-punch displacement (F-v) curve, n—relationship

between force and punch displacement, which is continuously

1.3 This standard does not purport to address all of the

recorded during the small punch (SP) bulge test.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1.3 force-specimen deflection (F-u) curve, n—relationship

priate safety, health, and environmental practices and deter-

between force and deflection, which is continuously recorded

mine the applicability of regulatory limitations prior to use. during the SP bulge test.

1.4 This international standard was developed in accor-

3.1.4 punch displacement, v [L], n—displacement of the

dance with internationally recognized principles on standard-

center of the top of the punch in contact with the specimen.

ization established in the Decision on Principles for the

3.1.4.1 Discussion—Determination of the punch displace-

Development of International Standards, Guides and Recom-

ment from the measurement of machine crosshead displace-

mendations issued by the World Trade Organization Technical

ment requires correcting for machine compliance.

Barriers to Trade (TBT) Committee.

3.1.4.2 Discussion—In this test method, specimen

deflection, u, is used as the reference displacement signal.

2. Referenced Documents

However, if specimen deflection is unavailable or not

2

2.1 ASTM Standards:

measured, punch displacement, v, may be used instead.

E8/E8MTest Methods for Tension Testing of Metallic Ma-

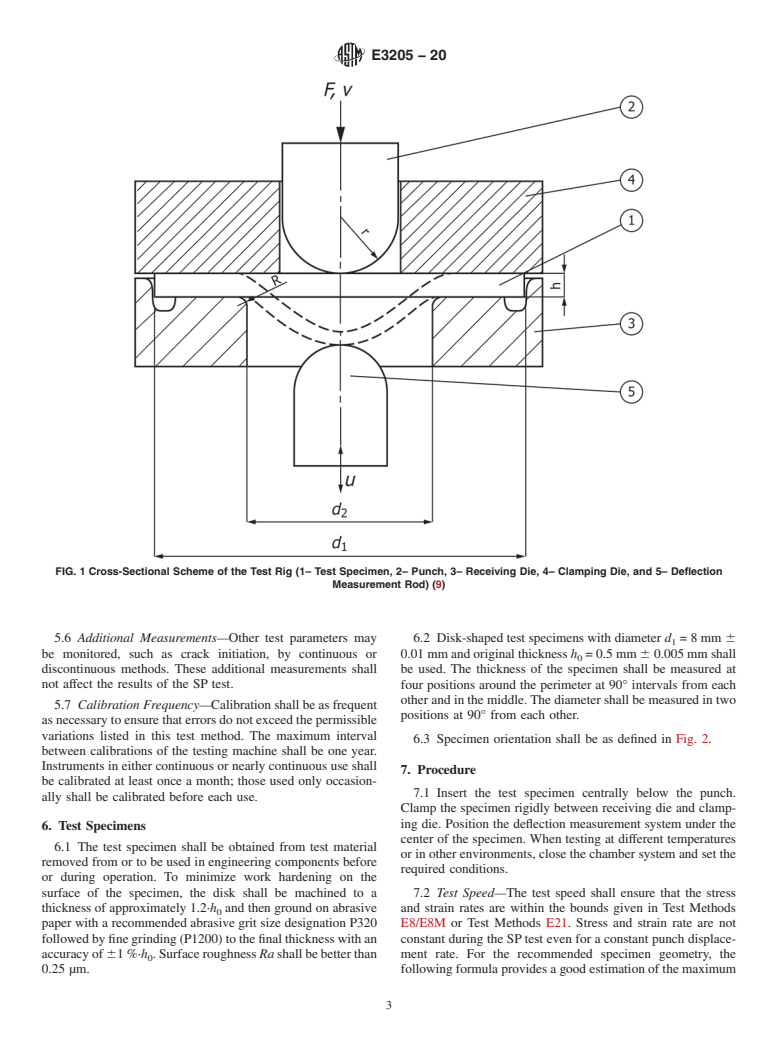

3.1.5 small punch (SP) bulge test, n—mechanical test con-

terials

sisting of loading a small disk-shaped specimen clamped

E21TestMethodsforElevatedTemperatureTensionTestsof

between two dies by means of a hemispherical-shaped punch,

Metallic Materials

deforming it to failure, and analyzing the resulting F-u curve.

E74Practices for Calibration and Verification for Force-

3.1.6 specimen deflection, u [L], n—displacement of a point

Measuring Instruments

at the center of the specimen opposite to the punch during the

E177Practice for Use of the Terms Precision and Bias in

small punch (SP) bulge test.

ASTM Test Methods

4. Significance and Use

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE10onNuclear

4.1 The safety margins provided in the design for a compo-

Technology and Applications and is the direct responsibility of Subcommittee

nent or structure can be reduced throughout its service life by

E10.02 on Behavior and Use of Nuclear Structural Materials.

aging. Aging is the process by which the physical and

Current edition approved July 1, 2020. Published August 2020. DOI: 10.1520/

E3205-20.

mechanical characteristics of component or structure materials

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

change with time or use; this process may proceed by a single

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

aging mechanism or a combination of several aging mecha-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. nisms.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3205 − 20

4.2 Th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.