ASTM D5194-13

(Test Method)Standard Test Method for Trace Chloride in Liquid Aromatic Hydrocarbons

Standard Test Method for Trace Chloride in Liquid Aromatic Hydrocarbons

SIGNIFICANCE AND USE

4.1 Organic and inorganic chlorine compounds can have a deleterious effect on equipment and reactions in processes involving aromatic hydrocarbons.

4.2 Maximum chloride levels are often specified for process streams and for aromatic hydrocarbon products.

SCOPE

1.1 This test method covers the determination of total chloride (organic and inorganic) in liquid aromatic hydrocarbons and cyclohexane.

1.2 The test method is applicable to samples with chloride concentrations of 1 to 25 mg/kg.

1.3 Bromides and iodides, if present, will be calculated as chlorides.

1.4 Materials, such as styrene, that are polymerized by sodium biphenyl reagent cannot be analyzed by this test method.

1.5 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5194 − 13

Standard Test Method for

1

Trace Chloride in Liquid Aromatic Hydrocarbons

This standard is issued under the fixed designation D5194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D3437 Practice for Sampling and Handling Liquid Cyclic

Products

1.1 This test method covers the determination of total

D3505 Test Method for Density or Relative Density of Pure

chloride (organic and inorganic) in liquid aromatic hydrocar-

Liquid Chemicals

bons and cyclohexane.

D4052 Test Method for Density, Relative Density, and API

1.2 The test method is applicable to samples with chloride

Gravity of Liquids by Digital Density Meter

concentrations of 1 to 25 mg/kg.

D6809 Guide for Quality Control and Quality Assurance

Procedures for Aromatic Hydrocarbons and Related Ma-

1.3 Bromides and iodides, if present, will be calculated as

chlorides. terials

E29 Practice for Using Significant Digits in Test Data to

1.4 Materials, such as styrene, that are polymerized by

Determine Conformance with Specifications

sodium biphenyl reagent cannot be analyzed by this test

3

2.2 Other Documents:

method.

OSHA Regulations, 29 CFR paragraphs 1910.1000 and

1.5 In determining the conformance of the test results using

1910.1200

this method to applicable specifications, results shall be

rounded off in accordance with the rounding-off method of

3. Summary of Test Method

Practice E29.

3.1 A known amount of hydrocarbon sample is transferred

1.6 The values stated in SI units are to be regarded as

into a separatory funnel containing toluene. Sodium biphenyl

standard. No other units of measurement are included in this

reagent is added to convert organic halogens into inorganic

standard.

halides. The excess reagent is decomposed with water and the

1.7 This standard does not purport to address all of the

phases are separated. The aqueous phase is acidified, washed,

safety concerns, if any, associated with its use. It is the

and concentrated. Acetone is added and the solution is titrated

responsibility of the user of this standard to establish appro-

with silver nitrate solution.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For a specific

4. Significance and Use

hazard statement, see Section 7.

4.1 Organic and inorganic chlorine compounds can have a

2. Referenced Documents

deleterious effect on equipment and reactions in processes

2

involving aromatic hydrocarbons.

2.1 ASTM Standards:

D891 TestMethodsforSpecificGravity,Apparent,ofLiquid

4.2 Maximum chloride levels are often specified for process

Industrial Chemicals

streams and for aromatic hydrocarbon products.

D1193 Specification for Reagent Water

D1555M TestMethodforCalculationofVolumeandWeight

5. Apparatus

of Industrial Aromatic Hydrocarbons and Cyclohexane

5.1 Titrator, potentiometric, recording, + 2000 mV range, 1

[Metric]

mV resolution with dispenser having a volume readout of 0.00

to 9.99 mL or 0.00 to 99.99 mL and 0.01 % resolution.

1

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

5.2 Electrode, glass, reference.

Subcommittee D16.04 on Instrumental Analysis.

5.3 Electrode, silver, billet type.

Current edition approved July 1, 2013. Published July 2013. Originally approved

in 1991. Last previous edition approved in 2011 as D5194 – 11a. DOI: 10.1520/

D5194-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

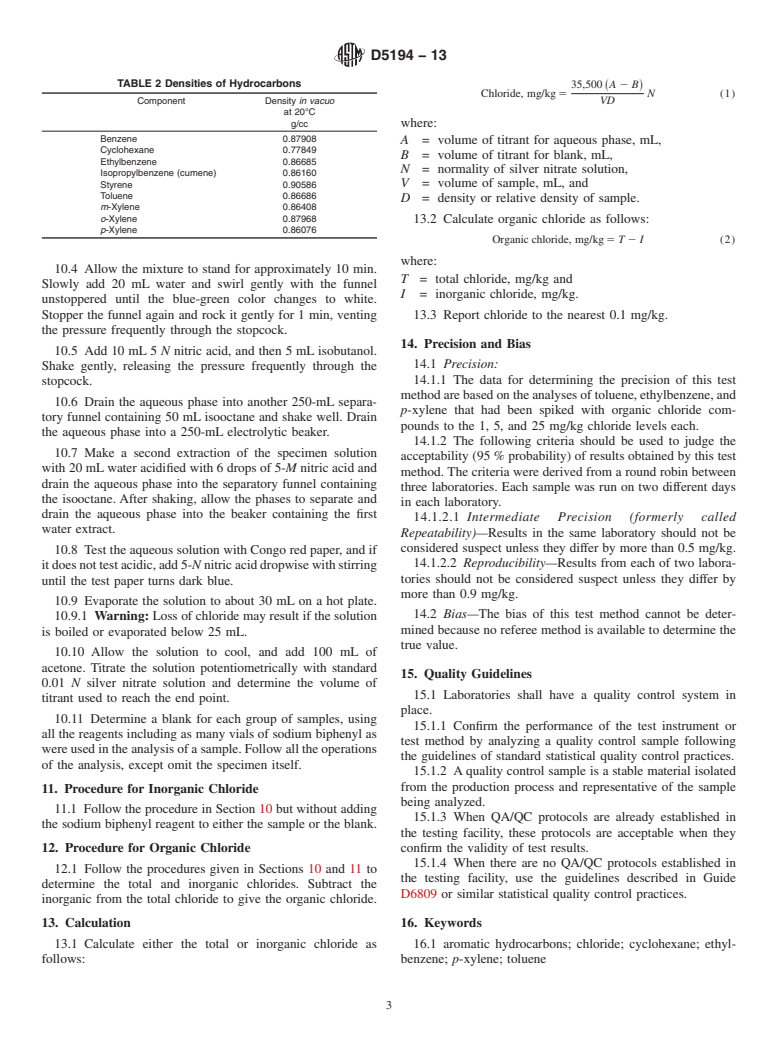

D5194 − 13

6. Reagents and Materials 7. Hazards

7.1 A material, such as styrene, which is polymerized by

6.1 Purity of Reagents—Reagent grade chemicals shall be

sodium biphenyl can cause a violent reaction and should never

used in all tests. Unless otherwise indicated, it is intended that

be used as the sample.

all reagents conform to the specifications of the Committee on

Analytical Reagents of theAmerican Chemical Society, where

7.2 Consult current OSHAregulations and suppliers’ Mate-

4

such specifications are availabl

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5194 − 11a D5194 − 13

Standard Test Method for

1

Trace Chloride in Liquid Aromatic Hydrocarbons

This standard is issued under the fixed designation D5194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of total chloride (organic and inorganic) in liquid aromatic hydrocarbons and

cyclohexane.

1.2 The test method is applicable to samples with chloride concentrations of 1 to 25 mg/kg.

1.3 Bromides and iodides, if present, will be calculated as chlorides.

1.4 Materials, such as styrene, that are polymerized by sodium biphenyl reagent cannot be analyzed by this test method.

1.5 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded

off in accordance with the rounding-off method of Practice E29.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For a specific hazard statement, see Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D891 Test Methods for Specific Gravity, Apparent, of Liquid Industrial Chemicals

D1193 Specification for Reagent Water

D1555M Test Method for Calculation of Volume and Weight of Industrial Aromatic Hydrocarbons and Cyclohexane [Metric]

D3437 Practice for Sampling and Handling Liquid Cyclic Products

D3505 Test Method for Density or Relative Density of Pure Liquid Chemicals

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D6809 Guide for Quality Control and Quality Assurance Procedures for Aromatic Hydrocarbons and Related Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3

2.2 Other Documents:

OSHA Regulations, 29 CFR paragraphs 1910.1000 and 1910.1200

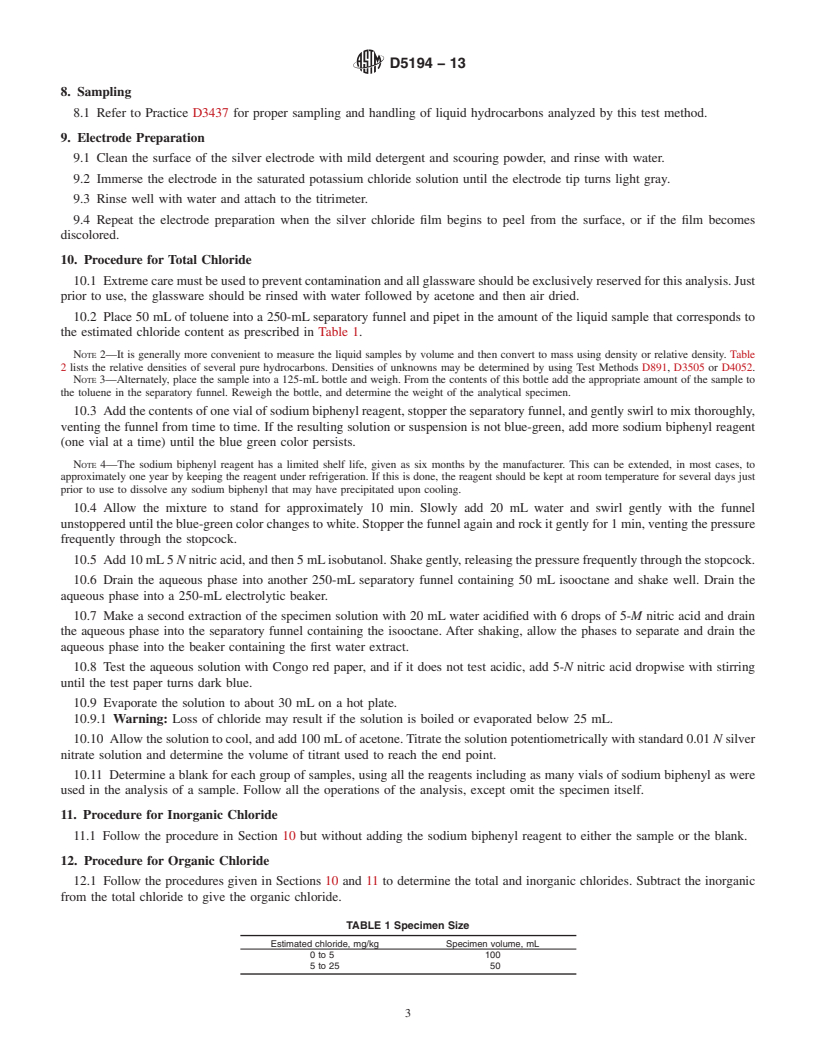

3. Summary of Test Method

3.1 A known amount of hydrocarbon sample is transferred into a separatory funnel containing toluene. Sodium biphenyl reagent

is added to convert organic halogens into inorganic halides. The excess reagent is decomposed with water and the phases are

separated. The aqueous phase is acidified, washed, and concentrated. Acetone is added and the solution is titrated with silver nitrate

solution.

4. Significance and Use

4.1 Organic and inorganic chlorine compounds can have a deleterious effect on equipment and reactions in processes involving

aromatic hydrocarbons.

1

This test method is under the jurisdiction of ASTM Committee D16 on Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of Subcommittee

D16.04 on Instrumental Analysis.

Current edition approved June 1, 2011July 1, 2013. Published July 2011July 2013. Originally approved in 1991. Last previous edition approved in 2011 as

D5194 – 11.D5194 – 11a. DOI: 10.1520/D5194-11A.10.1520/D5194-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5194 − 13

4.2 Maximum chloride levels are often specified for process streams and for aromatic hydrocarbon products.

5. Apparatus

5.1 Titrator, potentiometric, recording, + 2000 mV range, 1 mV resolution with dispenser having a volume readout of 0.00 to

9.99 mL or 0.00 to 99.99 mL and 0.01 % resolution.

5.2 Electrode, glass, reference.

5.3 Electrode, silver, billet type.

6. Reagents and Materials

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.