ASTM E1747-95(2005)

(Guide)Standard Guide for Purity of Carbon Dioxide Used in Supercritical Fluid Applications

Standard Guide for Purity of Carbon Dioxide Used in Supercritical Fluid Applications

ABSTRACT

This guide defines purity standards for carbon dioxide to ensure the suitability of liquefied carbon dioxide gas for use in supercritical fluid extraction (SFE) and supercritical fluid chromatography (SFC) applications. This guide defines quantitation, labeling, and statistical standards for impurities in carbon dioxide that are necessary for successful SFE or SFC laboratory work, and it suggests methods of analysis for quantifying these impurities. These contaminants are those components that either cause detector signals that interfere with those of the target analytes or physically impede the SFE or SFC experiment. Also, this guide is provided for use by specialty gas suppliers who manufacture carbon dioxide specifically for SFE or SFC applications. SFE or SFC CO2 products offered with a claim of adherence to this guide will meet certain absolute purity and contaminant detectability requirements matched to the needs of current SFE or SFC techniques.

SCOPE

1.1 This guide defines purity standards for carbon dioxide to ensure the suitability of liquefied carbon dioxide gas for use in SFE and SFC applications (see Guide E 1449 for definitions of terms). This guide defines quantitation, labeling, and statistical standards for impurities in carbon dioxide that are necessary for successful SFE or SFC laboratory work, and it suggests methods of analysis for quantifying these impurities.

1.2 This guide is provided for use by specialty gas suppliers who manufacture carbon dioxide specifically for SFE or SFC applications. SFE or SFC CO2 products offered with a claim of adherence to this guide will meet certain absolute purity and contaminant detectability requirements matched to the needs of current SFE or SFC techniques. The use of this guide allows different SFE or SFC CO2 product offerings to be compared on an equal purity basis.

1.3 This guide considers contaminants to be those components that either cause detector signals that interfere with those of the target analytes or physically impede the SFE or SFC experiment.

1.4 &solely-SI-units;

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1747 – 95 (Reapproved 2005)

Standard Guide for

Purity of Carbon Dioxide Used in Supercritical Fluid

Applications

This standard is issued under the fixed designation E1747; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Therapidcommercialdevelopmentofcarbondioxideforuseinsupercriticalfluidextraction(SFE)

and supercritical fluid chromatography (SFC) has hastened the need to establish common purity

standards to be specified by specialty gas suppliers. As a consequence of its isolation from

petrochemical side-streams or as a by-product of fermentation or ammonia synthesis, carbon dioxide

contains a wide range of impurities that can interfere with analytical quantification or instrument

operation.Thisguideisintendedtoserveasaguidetospecialtygassuppliersfortestingthesuitability

of carbon dioxide for use in SFC and SFE applications.

1. Scope priate safety and health practices and determine the applica-

bility of limitations prior to use.

1.1 Thisguidedefinespuritystandardsforcarbondioxideto

ensure the suitability of liquefied carbon dioxide gas for use in

2. Referenced Documents

SFE and SFC applications (see Guide E1449 for definitions of

2.1 ASTM Standards:

terms).This guide defines quantitation, labeling, and statistical

D2504 Test Method for Noncondensable Gases in C and

standards for impurities in carbon dioxide that are necessary

Lighter Hydrocarbon Products by Gas Chromatography

for successful SFE or SFC laboratory work, and it suggests

D2820 Test Method for C Through C Hydrocarbons in the

methods of analysis for quantifying these impurities.

Atmosphere By Gas Chromatography

1.2 Thisguideisprovidedforusebyspecialtygassuppliers

D3670 Guide for Determination of Precision and Bias of

who manufacture carbon dioxide specifically for SFE or SFC

Methods of Committee D22

applications.SFEorSFCCO productsofferedwithaclaimof

D3686 Practice for Sampling Atmospheres to Collect Or-

adherence to this guide will meet certain absolute purity and

ganic Compound Vapors (Activated Charcoal Tube Ad-

contaminantdetectabilityrequirementsmatchedtotheneedsof

sorption Method)

current SFE or SFC techniques. The use of this guide allows

D3687 Practice for Analysis of Organic Compound Vapors

differentSFEorSFCCO productofferingstobecomparedon

Collected by the Activated Charcoal Tube Adsorption

an equal purity basis.

Method

1.3 This guide considers contaminants to be those compo-

D4178 Practice for Calibrating Moisture Analyzers

nentsthateithercausedetectorsignalsthatinterferewiththose

D4532 Test Method for Respirable Dust in Workplace

of the target analytes or physically impede the SFE or SFC

Atmospheres

experiment.

E260 Practice for Packed Column Gas Chromatography

1.4 The values stated in SI units are to be regarded as

E355 Practice for Gas Chromatography Terms and Rela-

standard. No other units of measurement are included in this

tionships

standard.

E594 Practice for Testing Flame Ionization Detectors Used

1.5 This standard does not purport to address all of the

in Gas or Supercritical Fluid Chromatography

safety concerns, if any, associated with its use. It is the

E697 PracticeforUseofElectron-CaptureDetectorsinGas

responsibility of the user of this standard to establish appro-

Chromatography

This guide is under the jurisdiction of ASTM Committee E13 on Molecular

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Spectroscopy and Separation Science and is the direct responsibility of Subcom-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mittee E13.19 on Separation Science.

Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 1, 2005. Published September 2005. Originally

the ASTM website.

approved in 1995. Last previous edition approved in 2000 as E1747–95(2000).

Withdrawn. The last approved version of this historical standard is referenced

DOI: 10.1520/E1747-95R05.

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1747 – 95 (2005)

E1449 Guide for Supercritical Fluid Chromatography CO , such as small particles and high-boiling solutes, are

Terms and Relationships detrimental to both SFE and SFC applications. Species repre-

E1510 Practice for Installing Fused Silica Open Tubular sentative of this class include nonchromatographicable hydro-

Capillary Columns in Gas Chromatographs carbonsorhalocarbonoils,greases,andinorganicparticles(for

2.2 CGA Publications: example, silica). A maximum concentration of 1 ppm will be

CGA P-1 Safe Handling of Compressed Gases in Contain- considered acceptable.

ers

4. Purity Specifications for SFE or SFC Grade CO

CGA V-7 Standard for Hydrogen Piping Systems at Con-

4.1 This guide proposes the following minimum purity

sumer Locations

specifications for CO for each of the classes of contaminants,

CGA P-9 The Inert Gases: Argon, Nitrogen and Helium 2

based on the demands of currently practiced SFE or SFC

CGAV-7 Standard Method of Determining Cylinder Valve

techniques.

Outlets Connections for Industrial Gas Mixtures

4.1.1 Liquid-Phase Contaminants Specification:

CGA P12 Safe Handling of Cryogenic Liquids

4.1.1.1 SFE grade carbon dioxide is intended to be used as

G6 Carbon Dioxide

anextractionsolventfromwhichasignificantconcentrationof

HB-3 Handbook of Compressed Gases

self-containedcontaminatesispossiblebecauserelativelylarge

3. Classification

(>50g)amountsofcarbondioxidemaybeused.Becauseeach

3.1 This guide covers the following four different classes of impurity cannot be identified, a known amount of internal

compounds: referencecompounds(forexample,HDandHCB)willbeused

3.1.1 Liquid-Phase Contaminants—Thesearematerialsdis- during the analysis to quantify contaminants on a relative

solved in the CO liquid phase that can be volatilized below weight basis. Total contaminant levels will be expressed in ng

300°C and resolved chromatographically using a gas chroma- of contaminant per g of CO and defined as that amount of

tography (CG) column; and detected by either a flame ioniza- impurity that will produce a detector signal at the “typical”

tion (FI) or electron capture (EC) detector (D). Species detection limits for an FID or ECD found in 1.0 g of CO .The

representative of this class include moderate (100 to 600) 1-g amount of carbon dioxide was selected as a convenient

molecular weight hydrocarbons and halocarbons (oils and mass from which the chemist could relate carbon dioxide

lubricants). contamination levels with the amount of carbon dioxide

required for his/her analysis by a simple ratio.

NOTE 1—Liquid-phase contaminant levels are defined in terms of the

4.1.1.2 SFC grade carbon dioxide is intended to be used as

lowestlimitofdetectorresponse(LLDR) forFIDsorECDsonly,because

a mobile phase material transferred directly from a chromato-

they are the primary detectors used with SFE or SFC techniques.

graphic column to a detector (FID or ECD) without pre-

However, the purification procedures used by the gas supplier to remove

FID- and ECD-responsive contaminants are assumed to be effective for concentration (see Practice E355).Accepted internal reference

contaminants responsive to other (for example, NPD, MS, IR, UV, etc.)

compounds (for example, HD and HCB) will be used as

detectors.

surrogate contaminants. Contaminant levels will be expressed

Because a wide variety of contaminants are found in liquid-phase CO

in ng of contaminant per g of CO and will be defined as that

as a consequence of its source, full speculation of every impurity by the

amount which will produce a detector signal 20 times greater

gas supplier is impractical. All liquid-phase contaminants are therefore

than the “typical” detection limit for FID and 25 times greater

quantified relative to two representative internal primary reference stan-

than an ECD at the lowest detectable limit for a single peak.A

dards: hexadecane (HD or C H ) for the FID and hexachlorobenzene

16 34

(HCB or C Cl ) for the ECD. Contaminant limits are defined on a mass

6 6 total of 200 times the lowest detectable limit will be set for all

basis for single peaks and for the sum of all detector responses.

contaminants for a specific detector.

3.1.2 Moisture—Although water is sparingly (<0.1 % 4.1.1.3 When specifying a FID response for SFE, the

maximumamountofanyonecontaminant(thatis,onepeakin

weight) soluble in liquid-phase CO , more than 10 ppm of

moisture may result in physical interference resulting from ice the chromatogram) will be 1 ng/g of liquid-phase CO . This is

equivalent to 1 ppb on a mass basis, or 1 ppb w/w. The

formation during SFC or SFE applications. A maximum limit

of 1 ppm of water in the carbon dioxide will be considered maximum amount of all FID-responsive contaminants (that is,

the sum of all peaks in the chromatogram) will be 10 ng/g of

acceptable.

liquid-phase CO or 10 ppb w/w. Contaminant concentrations

3.1.3 Gas-Phase Contaminants—Gaseous, noncondensible

are expressed in terms of the equivalent response for hexade-

moleculesreleaseduponvaporizationofliquidCO mayactas

cane, the internal standard, regardless of the actual identity of

interferencesduringSFCapplications;thisislessofaproblem

the contaminant.

inSFEapplications.Speciesrepresentativeofthisclassinclude

4.1.1.4 When specifying an FID response for SFC, the

oxygen and light hydrocarbons, such as methane, ethane, and

generally accepted LLDR for a FID is 0.25 6 0.1 ng for a

propane.Acombinedmaximumconcentrationinthegasphase

singlecomponentwithasignal-to-noiseratioof3:1.Therefore,

of 10 ppm will be considered acceptable.

“20” 30.25 ng=5 ng to the detector (one peak), and

3.1.4 Nonvolatile—Materials that leave a nonvolatile (boil-

“200” 30.25 ng=50 ng total detector response. If all 5 ng of

ing point >250°C) residue following the vaporization of liquid

the contaminant comes from1gof liquid-phase carbon

dioxide,thesinglecomponentimpuritylevelwouldbe50ppb.

Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

This assumes that1gof carbon dioxide arrives at the detector

Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

Poole, C. F., and Poole, S. K., Chromatography Today , Elsevier, 1991, p. 86. at one time, and the density of the CO is 1 g/mL. Under

E1747 – 95 (2005)

typical SFC conditions of ;400 atm and 75°C, less than 0.1 g 4.1.5 Nonvolatile Contaminants Specification—The maxi-

of CO actually reaches the FID when using a 0.25 mm inside mum amount of nonvolatile residue acceptable is 1 mg/g of

diameter column with a 15-s wide peak. Therefore, the CO or 1 ppm (w/w).

contamination level acceptable for SFC applications would be 4.1.6 Specification Summary—Proposed minimum specifi-

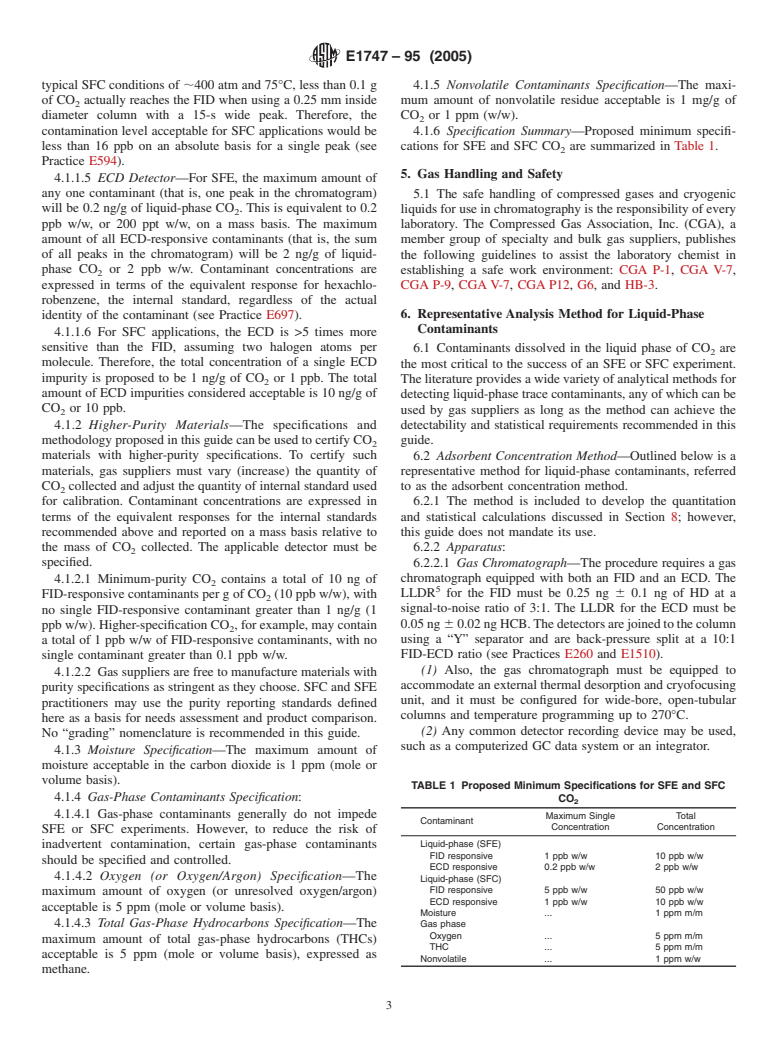

less than 16 ppb on an absolute basis for a single peak (see cations for SFE and SFC CO are summarized in Table 1.

Practice E594).

5. Gas Handling and Safety

4.1.1.5 ECD Detector—For SFE, the maximum amount of

any one contaminant (that is, one peak in the chromatogram) 5.1 The safe handling of compressed gases and cryogenic

will be 0.2 ng/g of liquid-phase CO . This is equivalent to 0.2

liquidsforuseinchromatographyistheresponsibilityofevery

ppb w/w, or 200 ppt w/w, on a mass basis. The maximum laboratory. The Compressed Gas Association, Inc. (CGA), a

amount of all ECD-responsive contaminants (that is, the sum member group of specialty and bulk gas suppliers, publishes

of all peaks in the chromatogram) will be 2 ng/g of liquid-

the following guidelines to assist the laboratory chemist in

phase CO or 2 ppb w/w. Contaminant concentrations are establishing a safe work environment: CGA P-1, CGA V-7,

expressed in terms of the equivalent response for hexachlo-

CGA P-9, CGAV-7, CGAP12, G6, and HB-3.

robenzene, the internal standard, regardless of the actual

6. Representative Analysis Method for Liquid-Phase

identity of the contaminant (see Practice E697).

Contaminants

4.1.1.6 For SFC applications, the ECD is >5 times more

sensitive than the FID, assuming two halogen atoms per

6.1 Contaminants dissolved in the liquid phase of CO are

molecule. Therefore, the total concentration of a single ECD

the most critical to the success of an SFE or SFC experiment.

impurity is proposed to be 1 ng/g of CO or 1 ppb. The total

Theliteratureprovidesawidevarietyofanalyticalmethodsfor

amount of ECD impurities considered acceptable is 10 ng/g of

detectingliquid-phasetracecontaminants,anyofwhichcanbe

CO or 10 ppb.

used by gas suppliers as long as the method can achieve the

4.1.2 Higher-Purity Materials—The specifications and detectability and statistical requirements recommended in this

methodologyproposedinthisguidecanbeusedtocertifyCO guide.

materials with higher-purity specifications. To certify such 6.2 Adsorbent Concentration Method—Outlined below is a

materials, gas suppliers must vary (increase) the quantity of representative method for liquid-phase contaminants, referred

CO collected and adjust the quantity of internal standard used

to as the adsorbent concentration method.

for calibration. Contaminant concentrations are expressed in 6.2.1 The method is included to develop the quantitation

terms of the equivalent responses for the internal standards

and statistical calculations discussed in Section 8; however,

recommended above and reported on a mass basis relative to this guide does not mandate its use.

the mass of CO collected. The applicable detector must be 6.2.2 Apparatus:

specified. 6.2.2.1 Gas Chromatograph—The procedure requires a gas

chromatograph equipped with both an FID and an ECD. The

4.1.2.1 Minimum-purity CO contains a total of 10 ng of

LLDR for the FID must be 0.25 ng 6 0.1 ng of HD at a

FID-responsivecontaminantspergofCO (10ppbw/w),with

signal-to-noise ratio of 3:1. The LLDR for the ECD must be

no single FID-responsive contaminant greater than 1 ng/g (1

0.05ng 60.02ngHCB.Thedetectorsarejoinedtothecolumn

ppbw/w).Higher-specificationCO ,forexample,maycontain

using a “Y” separator and are back-pressure split at a 10:1

a total of 1 ppb w/w of FID-responsive contaminants, with no

FID-ECD ratio (see Practices E260 and E1510).

single contaminant greater than 0.1 ppb w/w.

(1) Also, the gas chromatograph must be equipped to

4.1.2.2 Gassuppliersarefreetomanufacturematerialswith

accommodateanexternalthermaldesorptionandcryofocusing

purity specifications as stringent as they choose. SFC and SFE

unit, and it must be configured for wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.