ASTM D4495-12

(Test Method)Standard Test Method for Impact Resistance of Poly(Vinyl Chloride) (PVC) Rigid Profiles by Means of a Falling Weight

Standard Test Method for Impact Resistance of Poly(Vinyl Chloride) (PVC) Rigid Profiles by Means of a Falling Weight

SIGNIFICANCE AND USE

The impact strength of PVC profiles relates to suitability for service and to quality of processing. Impact tests are used for quality-control purposes and as an indication that products can withstand handling during assembling, installation, or in service.

Results obtained by use of this test method are able to be used in two ways:

As the basis for establishing impact-test requirements in product standards, and

To measure the effect of changes in materials or processing.

SCOPE

1.1 This test method covers the determination of the energy required to crack or break rigid poly(vinyl chloride) (PVC) profile under specified conditions of impact by means of a falling weight.

1.2 This test method is used either by itself or in conjunction with other methods for measuring PVC product toughness.

1.3 Because of the wide variety of profile sizes and shapes and the wide variety of manufacturing procedures and field abuse, this test method does not correlate universally with all types of abuse. Therefore, correlations must be established as needed.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this standard.

1.5 The values stated in inch-pound units are to be regarded as the standard.

Note 1—There is no known ISO equivalent to this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4495 −12 AnAmerican National Standard

Standard Test Method for

Impact Resistance of Poly(Vinyl Chloride) (PVC) Rigid

1

Profiles by Means of a Falling Weight

This standard is issued under the fixed designation D4495; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This test method covers the determination of the energy 3.1 Definitions—Definitions are in accordance with Termi-

required to crack or break rigid poly(vinyl chloride) (PVC) nology D883, unless otherwise indicated.

profile under specified conditions of impact by means of a

3.2 Definitions of Terms Specific to This Standard:

falling weight.

3.2.1 failure—thepresenceofabrittlefailurereadilyvisible

1.2 Thistestmethodisusedeitherbyitselforinconjunction by the naked eye, including a sharp crack, split, or shatter in

with other methods for measuring PVC product toughness. any part of the profile as a result of the impact of the falling

weight. Failure does not include ductile tears (where the

1.3 Because of the wide variety of profile sizes and shapes

surfaces at the tip of the crack have a greater than 0° angle), or

and the wide variety of manufacturing procedures and field

ductile breaks (hinged breaks where the cracked part remains

abuse, this test method does not correlate universally with all

joined to the unbroken part throughout the length of the

types of abuse. Therefore, correlations must be established as

cracked part or section), (Fig. 1).

needed.

3.2.2 mean failure height—the height from which the

1.4 The text of this standard references notes and footnotes

falling weight will cause 50 % of the specimens to fail.

which provide explanatory material. These notes and footnotes

3.2.3 mean failure energy—energy required to produce

(excluding those in tables and figures) shall not be considered

50 % failures. The product of the weight and mean failure

as requirements of this standard.

height.

1.5 The values stated in inch-pound units are to be regarded

3.2.4 outlier—an observation that appears to deviate mark-

as the standard.

edly from other members of the sample in which it occurs.

NOTE 1—There is no known ISO equivalent to this standard.

4. Summary of Test Method

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 The profile is cut into lengths of at least 6 in. The test

responsibility of the user of this standard to establish appro-

method establishes the height from which a standard falling

priate safety and health practices and determine the applica-

weight will cause 50 % of the specimens to fail.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

5.1 TheimpactstrengthofPVCprofilesrelatestosuitability

2

for service and to quality of processing. Impact tests are used

2.1 ASTM Standards:

for quality-control purposes and as an indication that products

D618 Practice for Conditioning Plastics for Testing

can withstand handling during assembling, installation, or in

D883 Terminology Relating to Plastics

service.

E178 Practice for Dealing With Outlying Observations

5.2 Resultsobtainedbyuseofthistestmethodareabletobe

used in two ways:

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics 5.2.1 As the basis for establishing impact-test requirements

and is the direct responsibility of Subcommittee D20.24 on Plastic Building

in product standards, and

Products.

5.2.2 To measure the effect of changes in materials or

Current edition approved May 1, 2012. Published June 2012. Originally

processing.

approved in 1985. Last previous edition approved in 2005 as D4495 – 00(2005).

DOI: 10.1520/D4495-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Apparatus

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

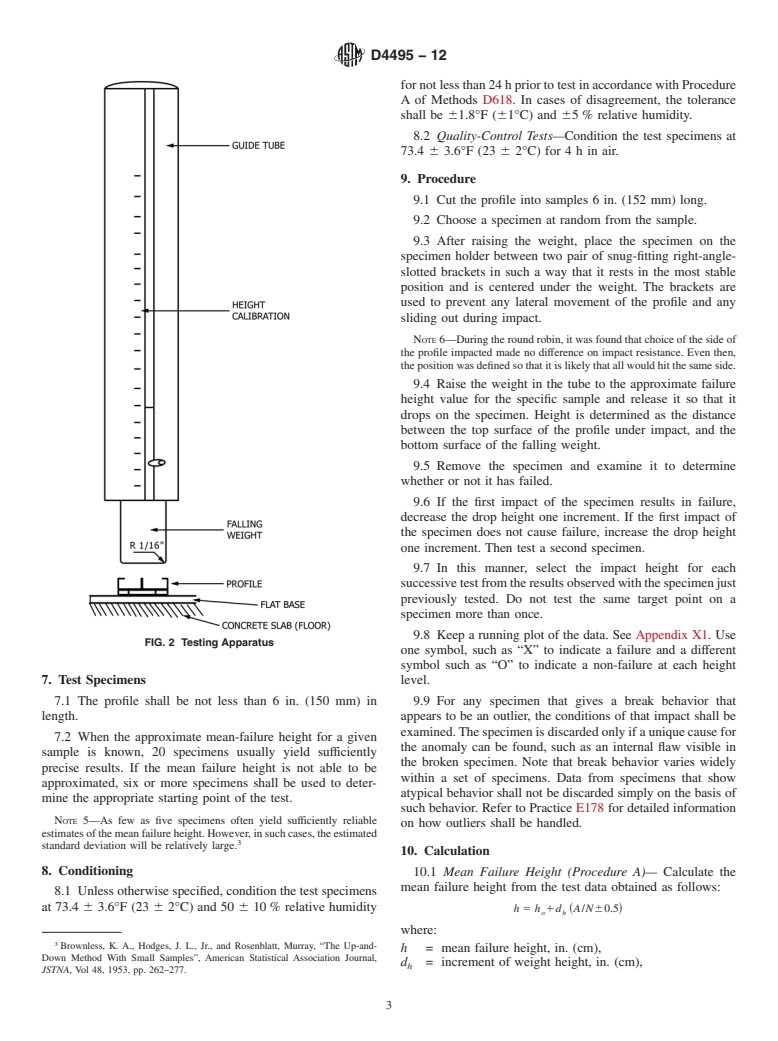

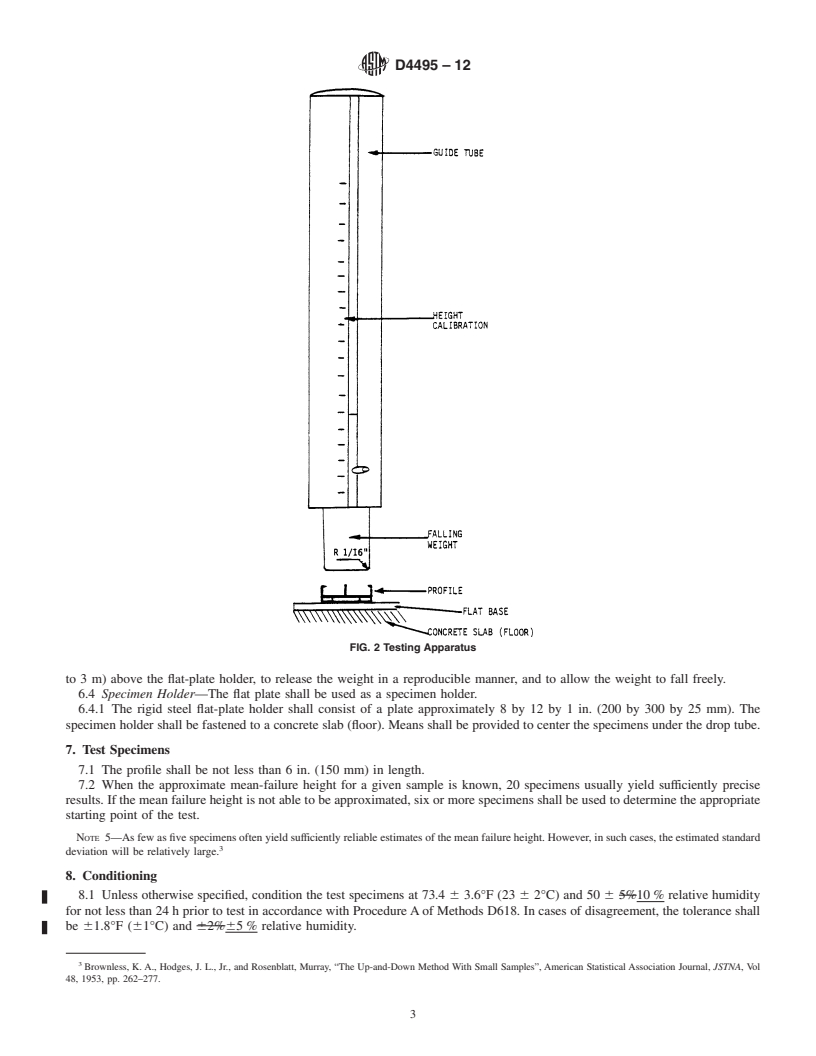

6.1 General—One type of impact tester is illustrated in Fig.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 2.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4495−12

FIG. 1 Types of Breaks

1

for larger sizes of profile, to protect the operator from flying broken

6.2 Falling Weight, shall be cylindrical and 2 ⁄2 in. in

pieces.

diameter, with a flat-bottom surface that strikes the test

NOTE 4—The dropped weight may not fall freely if the clearance

specimen.

between the weight and tube is too larg

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D4495–00 (Reapproved 2005) Designation: D4495 – 12

Standard Test Method for

Impact Resistance of Poly(Vinyl Chloride) (PVC) Rigid

1

Profiles by Means of a Falling Weight

This standard is issued under the fixed designation D4495; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the energy required to crack or break rigid poly(vinyl chloride) (PVC) profile

under specified conditions of impact by means of a falling weight.

1.2 This test method is able to be used either by itself or in conjunction with other methods offor measuring PVC product

toughness.

1.3 Because of the wide variety of profile sizes and shapes and the wide variety of manufacturing procedures and field abuse,

this test method does not correlate universally with all types of abuse. Therefore, correlations must be established as needed.

1.4The1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be considered as requirements of this standard.

1.5 The values stated in inch-pound units are to be regarded as the standard.

NOTE1—There is no equivalent or similar ISO standard. 1—There is no known ISO equivalent to this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

E178 Practice for Dealing With Outlying Observations

3. Terminology

3.1 Definitions—Definitions are in accordance with Terminology D883, unless otherwise indicated.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 failure— the presence of a brittle failure readily visible by the naked eye, including a sharp crack, split, or shatter in any

part of the profile as a result of the impact of the falling weight. Failure does not include ductile tears (where the surfaces at the

tip of the crack have a greater than 0° angle), or ductile breaks (hinged breaks where the cracked part remains joined to the

unbroken part throughout the length of the cracked part or section), (Fig. 1).

3.2.2 mean failure height—the height from which the falling weight will cause 50 % of the specimens to fail.

3.2.3 mean failure energy—energy required to produce 50 % failures. The product of the weight and mean failure height.

3.2.4 outlier—an observation that appears to deviate markedly from other members of the sample in which it occurs.

4. Summary of Test Method

4.1 The profile is cut into lengths of at least 6 in. The test method establishes the height from which a standard falling weight

will cause 50 % of the specimens to fail.

5. Significance and Use

5.1 The impact strength of PVC profiles relates to suitability for service and to quality of processing. Impact tests are used for

quality-control purposes and as an indication that products can withstand handling during assembling, installation, or in service.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.24 on Plastic Building Products.

Current edition approved MarchMay 1, 2005.2012. Published March 2005.June 2012. Originally approved in 1985. Last previous edition approved in 20002005 as

D4495 – 00(2005). DOI: 10.1520/D4495-00R05.10.1520/D4495-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4495 – 12

FIG. 1 Types of Breaks

5.2 Results obtained by use of this test method canare able to be used in two ways:

5.2.1 As the basis for establishing impact-test requirements in product

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.