ASTM B36/B36M-95

(Specification)Standard Specification for Brass Plate, Sheet, Strip, And Rolled Bar

Standard Specification for Brass Plate, Sheet, Strip, And Rolled Bar

SCOPE

1.1 This specification establishes the requirements for brass plate, sheet, strip, and rolled bar of the following alloys:

Nominal CompositionCopper Alloy Previously Used Copper, %Zinc, %UNS No.DesignationC210001955C2200029010C22600. . .87.512.5C2300038515C2400048020C2600067030C2680086634C2720096337C28000. . .6040

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combing values from two systems may results in nonconformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

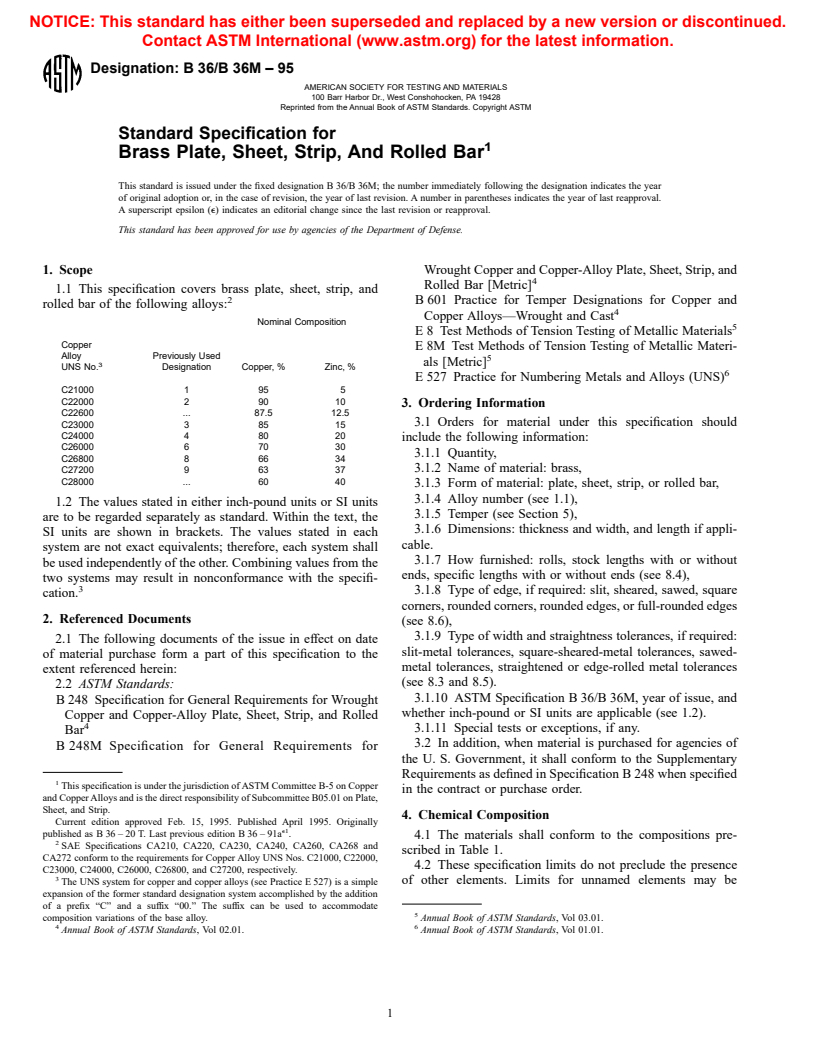

Designation: B 36/B 36M – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Brass Plate, Sheet, Strip, And Rolled Bar

This standard is issued under the fixed designation B 36/B 36M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and

Rolled Bar [Metric]

1.1 This specification covers brass plate, sheet, strip, and

B 601 Practice for Temper Designations for Copper and

rolled bar of the following alloys:

Copper Alloys—Wrought and Cast

Nominal Composition

E 8 Test Methods of Tension Testing of Metallic Materials

Copper

E 8M Test Methods of Tension Testing of Metallic Materi-

Alloy Previously Used

als [Metric]

UNS No. Designation Copper, % Zinc, %

E 527 Practice for Numbering Metals and Alloys (UNS)

C21000 1 95 5

C22000 2 90 10

3. Ordering Information

C22600 . 87.5 12.5

3.1 Orders for material under this specification should

C23000 3 85 15

C24000 4 80 20

include the following information:

C26000 6 70 30

3.1.1 Quantity,

C26800 8 66 34

C27200 9 63 37 3.1.2 Name of material: brass,

C28000 . 60 40

3.1.3 Form of material: plate, sheet, strip, or rolled bar,

3.1.4 Alloy number (see 1.1),

1.2 The values stated in either inch-pound units or SI units

3.1.5 Temper (see Section 5),

are to be regarded separately as standard. Within the text, the

3.1.6 Dimensions: thickness and width, and length if appli-

SI units are shown in brackets. The values stated in each

cable.

system are not exact equivalents; therefore, each system shall

3.1.7 How furnished: rolls, stock lengths with or without

be used independently of the other. Combining values from the

ends, specific lengths with or without ends (see 8.4),

two systems may result in nonconformance with the specifi-

3.1.8 Type of edge, if required: slit, sheared, sawed, square

cation.

corners, rounded corners, rounded edges, or full-rounded edges

2. Referenced Documents

(see 8.6),

3.1.9 Type of width and straightness tolerances, if required:

2.1 The following documents of the issue in effect on date

slit-metal tolerances, square-sheared-metal tolerances, sawed-

of material purchase form a part of this specification to the

metal tolerances, straightened or edge-rolled metal tolerances

extent referenced herein:

(see 8.3 and 8.5).

2.2 ASTM Standards:

3.1.10 ASTM Specification B 36/B 36M, year of issue, and

B 248 Specification for General Requirements for Wrought

whether inch-pound or SI units are applicable (see 1.2).

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

3.1.11 Special tests or exceptions, if any.

Bar

3.2 In addition, when material is purchased for agencies of

B 248M Specification for General Requirements for

the U. S. Government, it shall conform to the Supplementary

Requirements as defined in Specification B 248 when specified

This specification is under the jurisdiction of ASTM Committee B-5 on Copper

in the contract or purchase order.

and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

Sheet, and Strip.

4. Chemical Composition

Current edition approved Feb. 15, 1995. Published April 1995. Originally

e1

published as B 36 – 20 T. Last previous edition B 36 – 91a .

4.1 The materials shall conform to the compositions pre-

SAE Specifications CA210, CA220, CA230, CA240, CA260, CA268 and

scribed in Table 1.

CA272 conform to the requirements for Copper Alloy UNS Nos. C21000, C22000,

4.2 These specification limits do not preclude the presence

C23000, C24000, C26000, C26800, and C27200, respectively.

The UNS system for copper and copper alloys (see Practice E 527) is a simple of other elements. Limits for unnamed elements may be

expansion of the former standard designation system accomplished by the addition

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate

composition variations of the base alloy. Annual Book of ASTM Standards, Vol 03.01.

4 6

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 01.01.

B 36/B 36M

TABLE 1 Chemical Requirements

Copper Alloy UNS No. Copper, % Lead, max, % Iron, max, % Zinc

C21000 (95 Cu, 5 Zn) 94.0 to 96.0 0.03 0.05 remainder

C22000 (90 Cu, 10 Zn) 89.0 to 91.0 0.05 0.05 remainder

C22600 (87.5 Cu, 12.5 Zn) 86.0 to 89.0 0.05 0.05 remainder

C23000 (85 Cu, 15 Zn) 84.0 to 86.0 0.05 0.05 remainder

C24000 (80 Cu, 20 Zn) 78.5 to 81.5 0.05 0.05 remainder

C26000 (70 Cu, 30 Zn) 68.5 to 71.5 0.07 0.05 remainder

A

C26800 (66 Cu, 34 Zn) 64.0 to 68.5 0.15 0.05 remainder

B

C27200 (63 Cu, 37 Zn) 62.0 to 65.0 0.07 0.07 remainder

C

C28000 (60 Cu, 40 Zn) 59.0 to 63.0 0.30 0.07 remainder

A

Material shall be free from beta constituent when examined at a magnification of 75 diameters.

B

Small amounts of beta constituent, if present, may interfere in some instances with severe forming or drawing; therefore, suitability for forming or drawing should be

established between manufacturer and purchaser.

C

It is anticipated that this material will contain the beta constituent that may interfere with severe forming or drawing operations.

established by agreement between manufacturer or supplier

C24000 99.8

C26000 99.7

and purchaser.

C26800 99.7

4.3 Either copper or zinc may be taken as the difference

C27200 99.7

between the sum of all elements analyzed and 100 %. When all

C28000 99.7

elements in Table 1 are analyzed, their sum shall be as shown

in the table as follows: 5. Temper

Copper Plus Named Ele-

5.1 As Hot-Rolled (M20) Material—The standard temper of

Copper Alloy UNS No. ments, % min

sheet and plate produced by hot rolling is as designated in

C21000 99.8

Table 2.

C22000 99.8

C22600 99.8

C23000 99.8

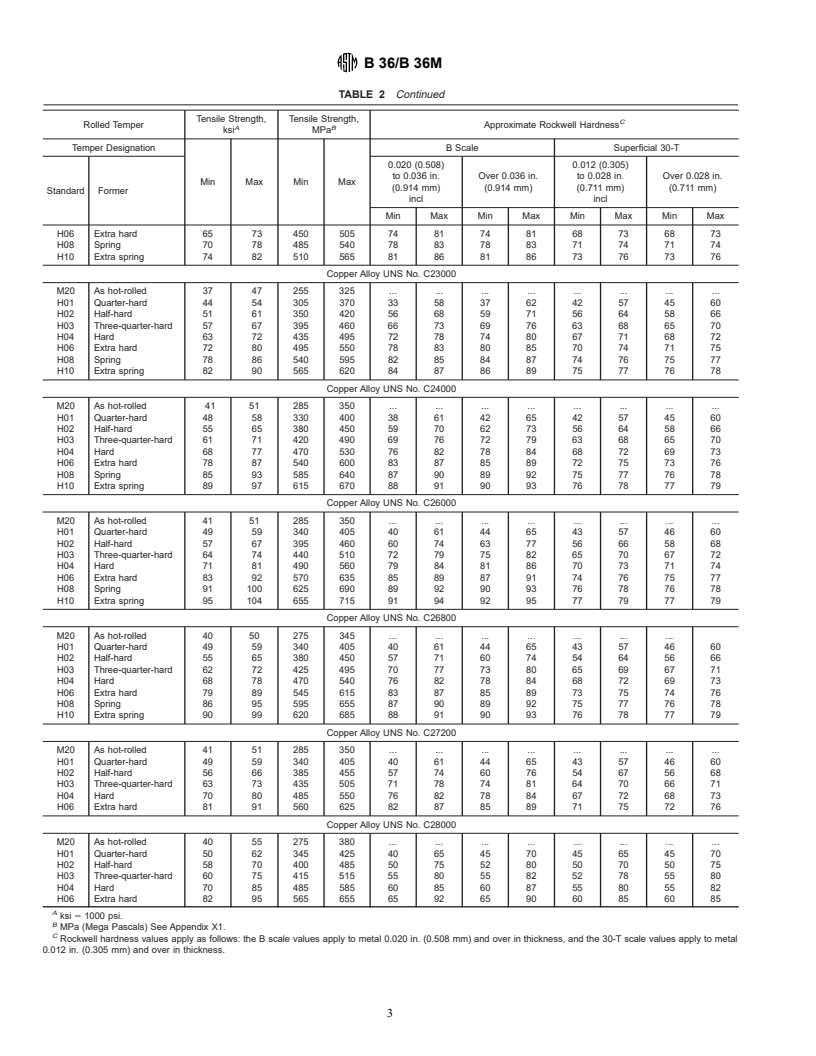

TABLE 2 Tensile Strength Requirements and Approximate Rockwell Hardness Values for Rolled Tempers

NOTE 1—Plate is generally available in only the as hot-rolled (M20) temper. Required properties for other tempers shall be agreed upon between the

manufacturer and the purchaser at the time of placing the order.

Tensile Strength, Tensile Strength,

C

Rolled Temper Approximate Rockwell Hardness

A B

ksi MPa

Temper Designation B Scale Superficial 30-T

0.020 (0.508) 0.012 (0.305)

to 0.036 in. Over 0.036 in. to 0.028 in. Over 0.028 in.

Min Max Min Max

(0.914 mm) (0.914 mm) (0.711 mm) (0.711 mm)

Standard Former

incl incl

Min Max Min Max Min Max Min Max

Copper Alloy UNS No. C21000

M20 As hot-rolled 32 42 220 290 . . . . . . . .

H01 Quarter hard 37 47 255 325 20 48 24 52 34 51 37 54

H02 Half-hard 42 52 290 355 40 56 44 60 46 57 48 59

H03 Three-quarter-hard 46 56 315 385 50 61 53 64 52 60 54 62

H04 Hard 50 59 345 405 57 64 60 67 57 62 59 64

H06 Extra hard 56 64 385 440 64 70 66 72 62 66 63 67

H08 Spring 60 68 415 470 68 73 70 75 64 68 65 69

H10 Extra spring 61 69 420 475 69 74 71 76 65 69 66 70

Copper Alloy UNS No. C22000

M20 As hot-rolled 33 43 230 295 . . . . . . . .

H01 Quarter-hard 40 50 275 345 27 52 31 56 34 51 37 54

H02 Half-hard 47 57 325 395 50 63 53 66 50 59 52 61

H03 Three-quarter-hard 52 62 355 425 59 68 62 71 55 62 58 64

H04 Hard 57 66 395 455 65 72 68 75 60 65 62 67

H06 Extra hard 64 72 440 495 72 77 74 79 64 68 66 69

H08 Spring 69 77 475 530 76 79 78 81 67 69 68 70

H10 Extra spring 72 80 495 550 78 81 80 83 68 70 69 71

Copper Alloy UNS No. C22600

H01 Quarter-hard 42 52 290 355 29 58 29 58 39 58 39 58

H02 Half-hard 48 58 330 400 52 68 52 68 54 64 54 64

H03 Three-quarter-hard 53 63 365 435 61 73 61 73 59 68 59 68

H04 Hard 58 67 400 460 67 77 67 77 64 70 64 70

B 36/B 36M

TABLE 2 Continued

Tensile Strength, Tensile Strength,

C

Rolled Temper Approximate Rockwell Hardness

A B

ksi MPa

Temper Designation B Scale Superficial 30-T

0.020 (0.508) 0.012 (0.305)

to 0.036 in. Over 0.036 in. to 0.028 in. Over 0.028 in.

Min Max Min Max

(0.914 mm) (0.914 mm) (0.711 mm) (0.711 mm)

Standard Former

incl incl

Min Max Min Max Min Max Min Max

H06 Extra hard 65 73 450 505 74 81 74 81 68 73 68 73

H08 Spring 70 78 485 540 78 83 78 83 71 74 71 74

H10 Extra spring 74 82 510 565 81 86 81 86 73 76 73 76

Copper Alloy UNS No. C23000

M20 As hot-rolled 37 47 255 325 . . . . . . . .

H01 Quarter-hard 44 54 305 370 33 58 37 62 42 57 45 60

H02 Half-hard 51 61 350 420 56 68 59 71 56 64 58 66

H03 Three-quarter-hard 57 67 395 460 66 73 69 76 63 68 65 70

H04 Hard 63 72 435 495 72 78 74 80 67 71 68 72

H06 Extra hard 72 80 495 550 78 83 80 85 70 74 71 75

H08 Spring 78 86 540 595 82 85 84 87 74 76 75 77

H10 Extra spring 82 90 565 620 84 87 86 89 75 77 76 78

Copper Alloy UNS No. C24000

M20 As hot-rolled 41 51 285 350 . . . . . . . .

H01 Quarter-hard 48 58 330 400 38 61 42 65 42 57 45 60

H02 Half-hard 55 65 380 450 59 70 62 73 56 64 58 66

H03 Three-quarter-hard 61 71 420 490 69 76 72 79 63 68 65 70

H04 Hard 68 77 470 530 76 82 78 84 68 72 69 73

H06 Extra hard 78 87 540 600 83 87 85 89 72 75 73 76

H08 Spring 85 93 585 640 87 90 89 92 75 77 76 78

H10 Extra spring 89 97 615 670 88 91 90 93 76 78 77 79

Copper Alloy UNS No. C26000

M20 As hot-rolled 41 51 285 350 . . . . . . . .

H01 Quarter-hard 49 59 340 405 40 61 44 65 43 57 46 60

H02 Half-hard 57 67 395 460 60 74 63 77 56 66 58 68

H03 Three-quarter-hard 64 74 440 510 72 79 75 82 65 70 67 72

H04 Hard 71 81 490 560 79 84 81 86 70 73 71 74

H06 Extra hard 83 92 570 635 85 89 87 91 74 76 75 77

H08 Spring 91 100 625 690 89 92 90 93 76 78 76 78

H10 Extra spring 95 104 655 715 91 94 92 95 77 79 77 79

Copper Alloy UNS No. C26800

M20 As hot-rolled 40 50 275 345 . . . . . . .

H01 Quarter-hard 49 59 340 405 40 61 44 65 43 57 46 60

H02 Half-hard 55 65 380 450 57 71 60 74 54 64 56 66

H03 Three-quarter-hard 62 72 425 495 70 77 73 80 65 69 67 71

H04 Hard 68 78 470 540 76 82 78 84 68 72 69 73

H06 Extra hard 79 89 545 615 83 87 85 89 73 75 74 76

H08 Spring 86 95 595 655 87 90 89 92 75 77 76 78

H10 Extra spring 90 99 620 685 88 91 90 93 76 78 77 79

Copper Alloy UNS No. C27200

M20 As hot-rolled 41 51 285 350 . . . . . . . .

H01 Quarter-hard 49 59 340 405 40 61 44 65 43 57 46 60

H02 Half-hard 56 66 385 455 57 74 60 76 54 67 56 68

H03 Three-quarter-hard 63 73 435 505 71 78 74 81 64 70 66 71

H04 Hard 70 80 485 550 76 82 78 84 67 72 68 73

H06 Extra hard 81 91 560 625 82 87 85 89 71 75 72 76

Copper Alloy UNS No. C28000

M20 As hot-rolled 40 55 275 380 . . . . . . . .

H01 Quarter-hard 50 62 345 425 40 65

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.