ASTM D3759/D3759M-96e1

(Test Method)Standard Test Method for Tensile Strength and Elongation of Pressure-Sensitive Tapes

Standard Test Method for Tensile Strength and Elongation of Pressure-Sensitive Tapes

SCOPE

1.1 This test method covers the measurement of tensile strength (breaking strength) and stretch properties (elongation and "F" value) for pressure-sensitive tapes. It includes procedures for machine- direction and cross-direction tests and tests for tapes with low and high stretch and reinforced backings. It also includes a procedure for obtaining stretch force ("F" value) in conjunction with a determination of tensile strength. These procedures employ a constant-rate-of-extension (CRE)-type testing machine. They apply to the principle of stretching the specimen at a fixed strain rate of one inch per inch of specimen length per minute with the exception of the procedure for reinforced tapes.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-A complete metric companion to Test Method D3759 has been developed-D3759M; therefore, no metric equivalents are presented in this test method. Test Method D3759M uses specimen widths of 12 mm and 24 mm rather than 1/2 in. and 1 in. used in Test Method D3759. This difference in test parameters will generally produce lower values for Test Method D3759M.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 3759/D 3759M – 96

Standard Test Method for

Tensile Strength and Elongation of Pressure-Sensitive

Tapes

This standard is issued under the fixed designation D 3759/D 3759M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—D 3759 and D 3759M were combined editorially in December 1997.

1. Scope D 4332 Practice for Conditioning Containers, Packages, or

Packaging Components for Testing

1.1 This test method covers the measurement of tensile

E 122 Practice for Choice of Sample Size to Estimate a

strength (breaking strength) and stretch properties (elongation

Measure of Quality for a Lot or Process

and “F” value) for pressure-sensitive tapes. It includes proce-

dures for machine direction cross-direction tests and tests for

3. Terminology

tapes with low and high stretch and reinforced backings. It also

3.1 Terminology found in Terminology D 996 shall apply.

includes a procedure for obtaining stretch force (“F” value) in

conjunction with a determination of tensile strength. These

4. Significance and Use

procedures employ a constant-rate-of-extension (CRE)-type

4.1 This test method provides information that can be used

testing machine. They apply to the principle of stretching the

in material specifications for product design and quality

specimen at a fixed strain rate of 25 mm per 25 mm [1 in. per

assurance applications. It can be used in comparing different

inch] of specimen length per minute with the exception of the

products.

procedure for reinforced tapes.

4.2 The use of this test method must be related to the

1.2 The values stated in either SI or inch-pound units are to

purpose for which the test is performed. One purpose is for

be regarded separately as standard. The values stated in each

determining the relative strength of the tape in the size in which

system may not be exact equivalents; therefore, each system

it is purchased or used. Another purpose is to identify or

must be used independently, without combining values in any

characterize a particular backing material.

way.

4.2.1 When relative strength is of interest, the test should be

1.3 This standard does not purport to address all of the

performed on the tape as-received, that is, without cutting the

safety concerns, if any, associated with its use. It is the

material to a specimen width less than the as-received width.

responsibility of the user of this standard to establish appro-

4.2.1.1 Usually tapes wider than 48 mm [2 in.] are not tested

priate safety and health practices and determine the applica-

due principally to the limitations of equipment. Tapes as

bility of regulatory limitations prior to use.

narrow as approximately 3 mm [0.125 in.] can be tested.

4.2.1.2 Comparison of materials by different test methods

2. Referenced Documents

should be avoided because the test parameters of specimen

2.1 ASTM Standards:

dimensions and crosshead velocity determine the outcome.

D 996 Terminology of Packaging and Distribution Environ-

2 Changes in the parameter levels will produce different results

ments

for the same material.

D 2904 Practice for Interlaboratory Testing of a Textile Test

Method that Produces Normally Distributed Data

NOTE 1—It is usual to find the tensile strength increasing significantly

D 2906 Practice for Statements on Precision and Bias for with increasing crosshead velocity and, therefore, strain rate.

Textiles

4.2.2 When identity or material characterization is of inter-

D 3715 Practice for Quality Assurance of Pressure-

est, the test should be performed on a specimen cut from within

Sensitive Tapes

the sample material boundaries using a sharp razor cutter, such

as that defined in Section 5.

NOTE 2—Some of the traditional tools for specimen preparation must

This test method is under the jurisdiction of ASTM Committee D-10 on

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and be avoided when the backing is comprised of thin plastic sheeting. These

Labels.

include chopping dies and sample cutters operating on a shearing

Current edition approved March 10, 1996. Published May 1996. Originally

published as D 3759 – 83. Last previous edition D 3759 – 88 (1993)e .

Annual Book of ASTM Standards, Vol 15.09.

3 4

Annual Book of ASTM Standards, Vol 07.01. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3759/D 3759M

principle. The reason for this restraint is that edges sufficiently ragged and

damaged resulting from chopping or shearing cause tearing to occur

before the true tensile strength level is reached. Tapes with fibrous

backings may be cut to satisfactory specimens with these tools.

4.2.3 Stretch characteristics can be related to the tape’s

intended use or for identifying or characterizing a material.

NOTE 3—Elongation measurements become difficult to perform on

stretchy materials (greater than 25 % ultimate elongation) when the ratio

of specimen length to width is small (approaching 2). The results show

high variability and do not allow for practical use of this information

except when one wishes to demonstrate large differences between a

material.

5. Apparatus

5.1 Tension Tester—A constant-rate-of-extension (CRE)

type with load cell capacity such that the maximum expected

specimen strength does not exceed 90 % of its normal limit.

5.1.1 Test Information should be displayed in at least an

alphanumeric digital display or a load-elongation curve plotted

by a pen or stylus responding to load and with a chart driven

synchronously with the crosshead.

5.1.2 Load-Elongation Curve, plotted by a pen or stylus

responding to load and with a servo-chart drive or x-y recorder

driven by an extensometer.

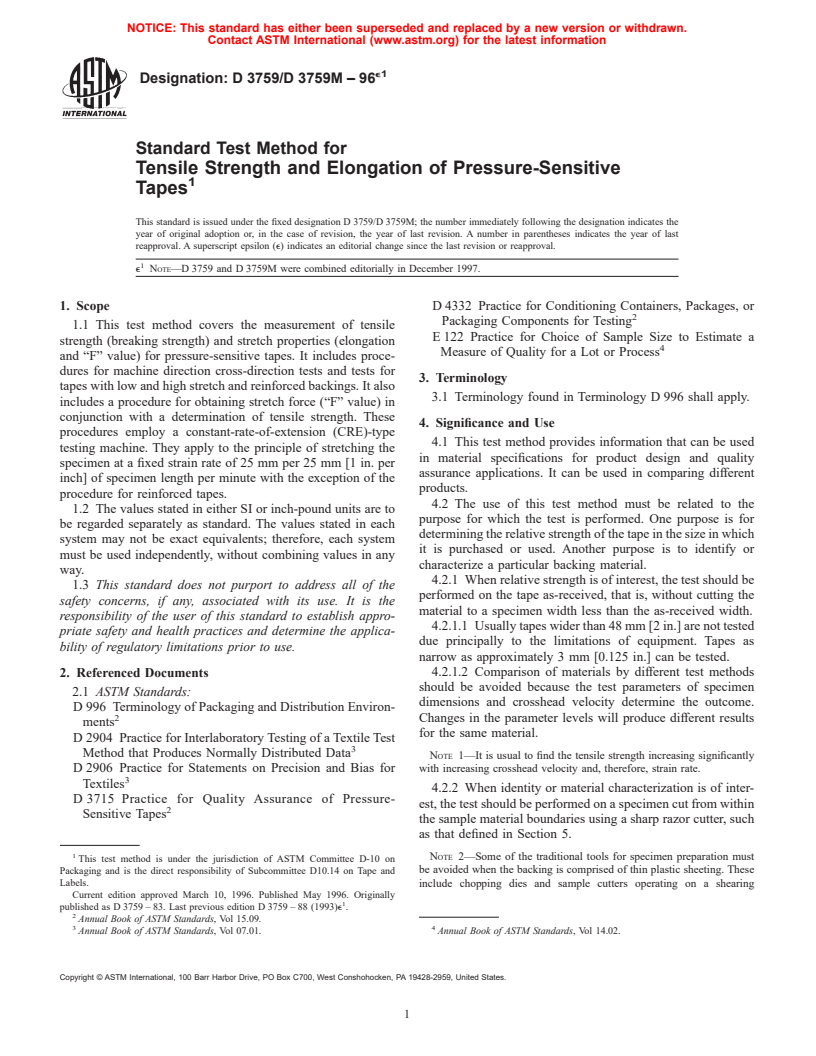

5.1.3 Clamps, preferably the pneumatic action type. FIG. 1 Test Configuration for Reinforced Tapes

5.1.3.1 Clamp faces at least 50 mm [2 in.] wide by 38 mm

[1 ⁄2 in.] deep. Faces shall have a light cross-hatch serration.

5.1.5 Scale, approximately 22 mm [1 in.] in length divided

into 2-mm [0.1-in.] increments attached to each cylinder. The

NOTE 4—Plastic materials are reduced in width and thickness while

zero point or (origin) shall be at the point of tangency of the

being stretched. This causes them to be drawn out of the clamps.

Pneumatic clamps minimize this effect. It can be further reduced by the

tape with the cylinder during the test and the scale shall

appropriate choice of surface of the clamps. The greatest improvement,

increase upward on the lower cylinder and downward on the

both with respect to the above mentioned shrinkage problem and simple

upper cylinder.

slippage, may be found from the use of urethane film which can be

obtained as a pressure-sensitive tape approximately 20 mils thick. This NOTE 5—These scales will be used to observe and measure the tape

material has a very high coefficient of friction, is somewhat malleable, and slippage during the tension test for reinforced tapes.

is easily replaced. Alternative materials are coated abrasive, rubber

5.2 Cutter, holding two single-edged razor blades in paral-

(neoprene or other synthetic type), or other tape.

lel planes, a precise distance apart, to form a cutter of exact

5.1.4 Cylinders, in place of clamps for testing reinforced

specimen width. Appropriate widths shall be available (refer to

tapes. Each of two cylinders shall be 100 mm [4 in.] in

specimen width in Table 1) patterned after the 12 mm [ ⁄2-in.]

diameter by 38 mm [1.5 in.] thick held in the position

cutter in 5.2.1. The differences between cutters of various

ordinarily occupied by the clamps so that the tape, when

applied to the cylinders and extending between them, falls in

the fine of stress otherwise occupied by the specimens when

Available from Chemsultants International, 9349 Hamilton Dr., Mentor, OH

clamps are used. See Fig. 1. 44061-1118.

TABLE 1 Tester Preparation and Specimen Dimensions

A B

Gage Length, Crosshead Velocity, Chart Velocity, Specimen Width, Length,

mm [in.] mm [in.]/min mm [in.]/min mm [in.] mm [in.]

Tapes with ultimate

elongation of:

Up to 200 %:

Machine direction 125 [5] 125 [5] 125 [5] 12–24 [ ⁄2-1] 230 [9]

CDE

1 1

Cross direction 25 [1] 25 [1] 125 [5] 12 [ ⁄4– ⁄2] 125 [5]

200 % and up:

Machine direction 50 [2] 50 [2] 125 [5] 12 [ ⁄2] 150 [6]

Reinforced tapes 250 [10] 125 [5] 125 [5] 12–24 [ ⁄2–1] 710 [28]

A

The chart velocity may be set at other velocities. It should not be slower than the crosshead velocity.

B

The specimen widths shown are for tests in which the specimen is cut from within the sample dimension. See 4.2.1.1.

C

Cross-direction (C.D.) tests are limited to sample rolls of tape at least 2 in. in width.

D

It is unusual to test C.D. tensile strength of tapes having ultimate elongations greater than 150 %. Therefore no reference to this is made in this table. However C.D.

tests could be made under that category on the high-stretch materials.

E

If the sample provides ample material, C.D. tests should preferably be made in the same way machine-direction (M.D.) tests are. This would occur with web material

or sufficiently wide rolls.

D 3759/D 3759M

widths is in the final width of the bar after removing the 7.4.2 The covering shall be free of wrinkles, leaving the

thickness of one razor blade. gage-length area uncovered and completely cover the rest of

5.2.1 The cutter shall consist of a 12 mm [ ⁄2 in.] thick by the specimen so that the clamps will apply uniform pressure

approximately 200 mm [8-in.] length of aluminum bar stock ⁄2 against the specimen.

in. wide. The edges, for about 125 mm [5 in.] from one end 7.4.3 A special specimen preparation is required for cross-

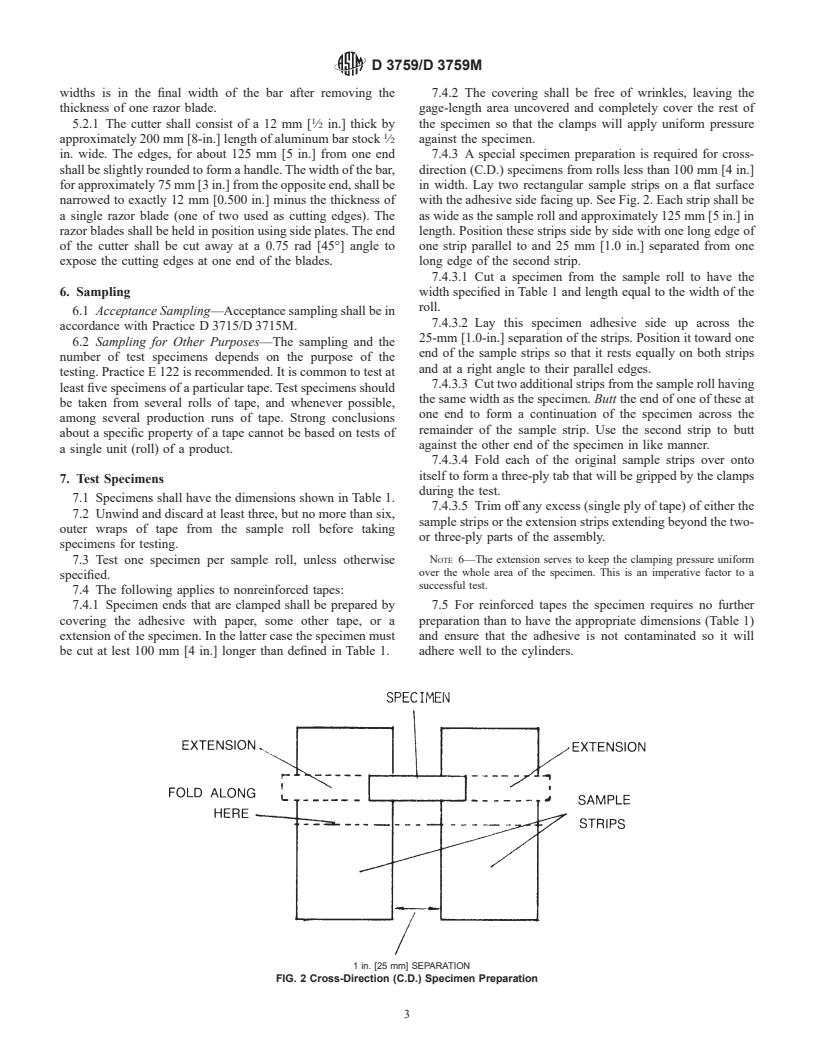

shall be slightly rounded to form a handle. The width of the bar, direction (C.D.) specimens from rolls less than 100 mm [4 in.]

for approximately 75 mm [3 in.] from the opposite end, shall be in width. Lay two rectangular sample strips on a flat surface

narrowed to exactly 12 mm [0.500 in.] minus the thickness of with the adhesive side facing up. See Fig. 2. Each strip shall be

a single razor blade (one of two used as cutting edges). The as wide as the sample roll and approximately 125 mm [5 in.] in

razor blades shall be held in position using side plates. The end length. Position these strips side by side with one long edge of

of the cutter shall be cut away at a 0.75 rad [45°] angle to one strip parallel to and 25 mm [1.0 in.] separated from one

expose the cutting edges at one end of the blades. long edge of the second strip.

7.4.3.1 Cut a specimen from the sample roll to have the

6. Sampling

width specified in Table 1 and length equal to the width of the

roll.

6.1 Acceptance Sampling—Acceptance sampling shall be in

7.4.3.2 Lay this specimen adhesive side up across the

accordance with Practice D 3715/D 3715M.

25-mm [1.0-in.] separation of the strips. Position it toward one

6.2 Sampling for Other Purposes—The sampling and the

end of the sample strips so that it rests equally on both strips

number of test specimens depends on the purpose of the

and at a right angle to their parallel edges.

testing. Practice E 122 is recommended. It is common to test at

7.4.3.3 Cut two additional strips from the sample roll having

least five specimens of a particular tape. Test specimens should

the same width as the specimen. Butt the end of one of these at

be taken from several rolls of tape, and whenever possible,

one end to form a continuation of the specimen across the

among several production runs of tape. Strong conclusions

remainder of the sample strip. Use the second strip to butt

about a specific property of a tape cannot be based on tests of

against the other end of the specimen in like manner.

a single unit (roll) of a product.

7.4.3.4 Fold each of the original sample strips over onto

itself to form a three-ply tab that will be gripped by the clamps

7. Test Specimens

during the test.

7.1 Specimens shall have the dimensions shown in Table 1.

7.4.3.5 Trim off any excess (single ply of tape) of either the

7.2 Unwind and discard at least three, but no more than six,

sample strips or the extension strips extending beyond the two-

outer wraps of tape from the sample roll before taking

or three-ply parts of the assembly.

specimens for testing.

7.3 Test one specimen per sample roll, unless otherwise NOTE 6—The extension serves to keep the clamping pressure uniform

over the whole area of the specimen. This is an imperative factor to a

specified.

successful test.

7.4 The following applies to nonreinforced tapes:

7.4.1 Specimen ends that are clamped shall be prepared by 7.5 For reinforced tapes the specimen requires no further

covering the adhesive with paper, some other tape, or a preparation than to have the appropriate dimensions (Table 1)

extension of the specimen. In the latter case the specimen must and ensure that the adhesive is not contaminated so it will

be cut at lest 100 mm [4 in.] longer than defined in Table 1. adhere well to the cylinders.

1 in. [25 mm] SEPARATION

FIG. 2 Cross-Direction (C.D.) Specimen Preparation

D 3759/D 3759M

8. Preparation of Apparatus 11. Calculation

11.1 Tensile Strength:

8.1 Table 1 shows the tension tester settings for use with the

11.1.1 When the recorded load-elongation curve results

specified test categories.

from the testing, calculate tensile strength as follows:

8.2 For testing reinforced tapes, set the cylinders 150 mm [6

11.1.1.1 Find the farthest advance of the plotting pen or

in.] apart so that at the start of a test 25 mm [10 in.] of tape will

stylus from the origin in the direction representing increasing

extend between and without contact with the cylinders.

force. Record this advance as a percent of the chart scale.

NOTE 7—The upper cylinder should be counterbalanced in order that

11.1.1.2 Multiply the full-scale load range used during the

the line of tape contact on the cylinders intersects an imaginary line

test by the percent found in 11.1.1.1.

running between the points of cylinder attachment to the tester and no side

forces are exerted during the test. See Fig. 1.

NOTE 8—For this calculation express the percent fraction, that is, use

0.87 for 87 %.

9. Conditioning

11.1.1.3 Convert the value found in 11.1.1.2 to pounds-force

9.1 Condition rolls of tape in the standard conditioning

per the desired basis of dimension for the final step. For lbf/in.

atmosphere as described in Practice D 4332 for no less than 24

of width, divid

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.