ASTM D244-00

(Test Method)Standard Test Methods for Emulsified Asphalts

Standard Test Methods for Emulsified Asphalts

SCOPE

1.1 These test methods and practices, given under the headings titled Composition, Consistency, Stability, and Examination of Residue, cover the examination of asphalt emulsions composed principally of a semisolid or liquid asphaltic base, water, and an emulsifying agent. The test methods cover the following tests:Test SectionsComposition:Water Content4-10Residue and Oil Distillate by Distillation11-15Residue by Evaporation16-22Particle Charge of Cationic Emulsified Asphalts23-28Consistency:Viscosity (Saybolt Furol)29-33Stability:Demulsibility34-39Settlement40-45Cement Mixing46-52Sieve Test53-58Coating59-62Miscibility with Water63-65Freezing66-68Coating Ability and Water Resistance69-76Storage Stability of Asphalt Emulsion77-83Examination of Residue84-91Identification Test for Rapid Setting Cationic Emulsified Asphalt92-99Identification of Cationic Slow Set Emulsions100-105Field Coating Test on Emulsified Asphalts106-111Emulsified Asphalt/Job Aggregate Coating Test112-117Weight per Gallon of Emulsified Asphalt118-124Residue by Low-Temperature Vacuum Distillation126-131

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

Designation: D 244 – 00 Highway and Transportation Officials Standard

AASHTO No.: T59

Standard Test Methods and Practices for

Emulsified Asphalts

This standard is issued under the fixed designation D244; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods and practices, given under the

headings titled Composition, Consistency, Stability, and Ex- C150 Specification for Portland Cement

amination of Residue, cover the examination of asphalt emul- C778 Specification for Standard Sand

sions composed principally of a semisolid or liquid asphaltic D5 Test Method for Penetration of Bituminous Materials

base, water, and an emulsifying agent. The test methods cover D70 Test Method for Specific Gravity and Density of

the following tests: Semi-Solid Bituminous Materials

D86 Test Method for Distillation of Petroleum Products

Test Sections

Composition:

D88 Test Method for Saybolt Viscosity

Water Content 4-10

D113 Test Method for Ductility of Bituminous Materials

Residue and Oil Distillate by Distillation 11-15

D128 Test Methods for Analysis of Lubricating Grease

Residue by Evaporation 16-22

Particle Charge of Cationic Emulsified Asphalts 23-28

D139 TestMethodforFloatTestforBituminousMaterials

Consistency:

D140 Practice for Sampling Bituminous Materials

Viscosity (Saybolt Furol) 29-33

D977 Specification for Emulsified Asphalt

Stability:

Demulsibility 34-39

D2042 Test Method for Solubility of Asphalt Materials in

Settlement 40-45

Trichloroethylene

Cement Mixing 46-52

Sieve Test 53-58 D2397 Specification for Cationic Emulsified Asphalt

Coating 59-62

D3289 Test Method for Specific Gravity or Density of

Miscibility with Water 63-65

Semi-Solid and Solid Bituminous Materials by Nickel

Freezing 66-68

Coating Ability and Water Resistance 69-76 Crucible

Storage Stability of Asphalt Emulsion 77-83

E1 Specification for ASTM Thermometers

Examination of Residue 84-91

E11 Specification for Wire-Cloth Sieves for Testing Pur-

Identification Test for Rapid Setting Cationic Emulsified 92-99

Asphalt poses

Identification of Cationic Slow Set Emulsions 100-105

E145 Specification for Gravity-Convection and Forced-

Field Coating Test on Emulsified Asphalts 106-111

Ventilation Ovens

Emulsified Asphalt/Job Aggregate Coating Test 112-117

Weight per Gallon of Emulsified Asphalt 118-124

Residue by Low-Temperature Vacuum Distillation 126-131 3. Sample Conditioning for Testing

3.1 All emulsions with viscosity requirements of 50°C

1.2 The values stated in SI units are to be regarded as the

should be heated to 50 6 3°C in the original sample container

standard. The values given in parentheses are for information

in a 71°C water bath or oven. The container should be vented

only.

torelievepressure.Afterthesamplereaches50 63°C,stirthe

1.3 This standard does not purport to address all of the

sample to achieve homogeneity.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

Annual Book of ASTM Standards, Vol 04.01.

1 3

These test methods are under the jurisdiction of ASTM Committee D04 on Annual Book of ASTM Standards, Vol 04.03.

Road and Paving Materials and are the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 04.04.

D04.42 on Emulsified Asphalt Tests. Annual Book of ASTM Standards, Vol 05.01.

Current edition approved July 10, 2000. Published September 2000. Originally Annual Book of ASTM Standards, Vol 14.03.

published as D244–26T. Last previous edition D244–99. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 244

COMPOSITION

WATER CONTENT The end of the condenser shall be ground to an angle of 30 6

5° from the vertical axis of the condenser.

4. Scope

6.5 Trap—The trap shall be made of annealed glass con-

structed in accordance with Fig. 1(c) and shall be graduated in

4.1 This test method covers the procedure for determining

0.10-mL divisions from 0 to 2 mL, and in 0.20-mL divisions

the water content of an emulsified asphalt by reflux distillation

from2to25mL.

using a water trap.

6.6 Solvent—Xylolorotherpetroleumdistillateconforming

to the following distillation requirements: 98% distills be-

5. Significance and Use

tween 120 and 250°C. This distillation shall be conducted in

5.1 This test method measures the amount of water present

accordance with Test Method D86.

in the emulsified asphalt, as distinguished from either bitumen

or petroleum solvent.

7. Sample

6. Apparatus and Materials

7.1 Obtain a representative sample of the material for test

using standard procedures as specified in Practice D140.

6.1 MetalStill—Themetalstill(Fig.1(a))shallbeavertical

cylindrical vessel, preferably of copper, having a faced flange

NOTE 1—The difficulties in obtaining representative samples for this

at the top to which the head is tightly attached by means of a

determination are unusually great, so that the importance of sampling

clamp. The head shall be made of metal, preferably brass or cannot be too strongly emphasized.

copper,andshallbeprovidedwithatubulation25.4mm(1in.)

8. Procedure

in inside diameter.

6.2 Glass Still—The glass still (Fig. 1(b)) shall be a short- 8.1 When the material to be tested contains less than 25%

neck, round-bottom flask, made of well-annealed glass, and water, place 100 6 0.1 g of sample in the still. When the

having an approximate capacity of 500 mL. material contains more than 25% water, use a 50 6 0.1-g

6.3 Heat Source—The heat source used with the metal still sample. Thoroughly mix the sample to be tested with 200 mL

shall be a ring gas burner of 100-mm (4-in.) inside diameter or of solvent by swirling, taking proper care to avoid any loss of

an electric mantle heater. The heat source for the glass still material.

shall be either an ordinary gas burner or an electric heater. 8.2 Connect the still, trap, and condenser by means of

6.4 Condenser—The condenser shall be a water-cooled tight-fitting corks as shown in Fig. 1(a) or (b). Adjust the end

reflux glass-tube type, having a jacket not less than 400 mm in of the condenser in the trap to a position which will allow the

length, with an inner tube 9.5 to 12.7 mm in outside diameter. end to be submerged to a depth of not more than 1 mm below

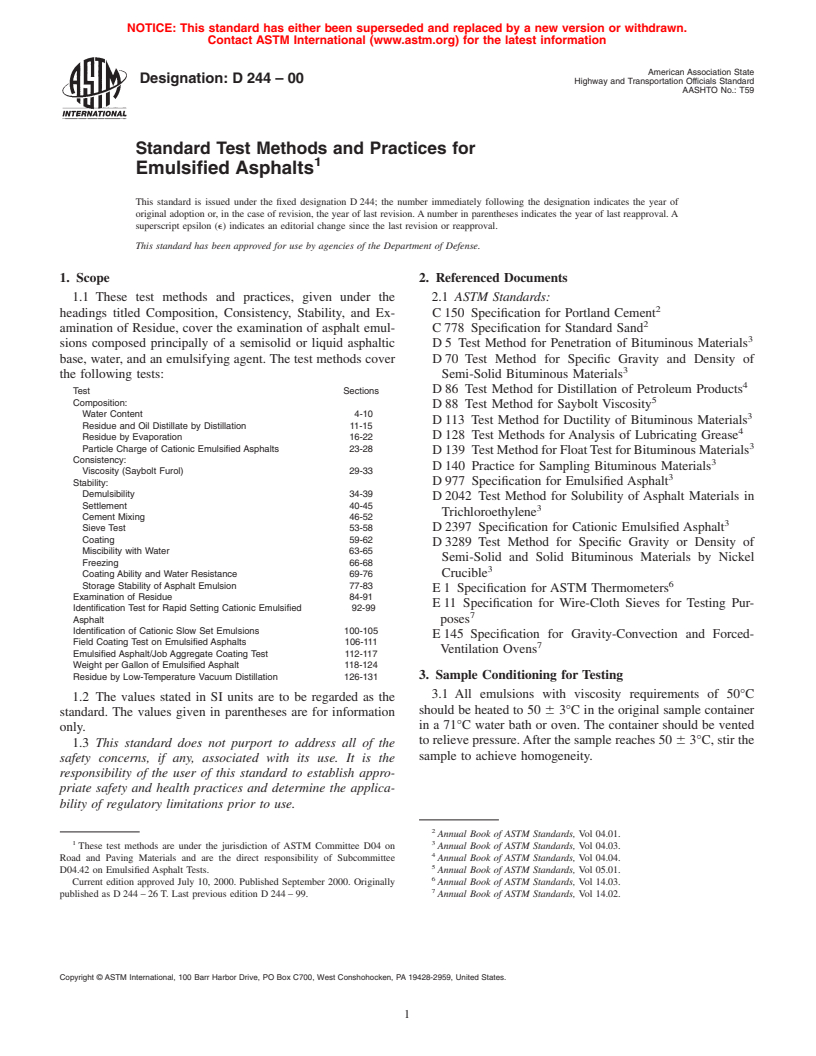

A=45to55mm E=25to38mm

B = 14 to 16 mm F = 186 to 194 mm

C=12to16mm H=18to19mm

D = 235 to 255 mm

FIG. 1 Apparatus for Determining Water Content

D 244

the surface of the liquid in the trap after distillation conditions 13. Apparatus

have been established. When using the metal still, insert a

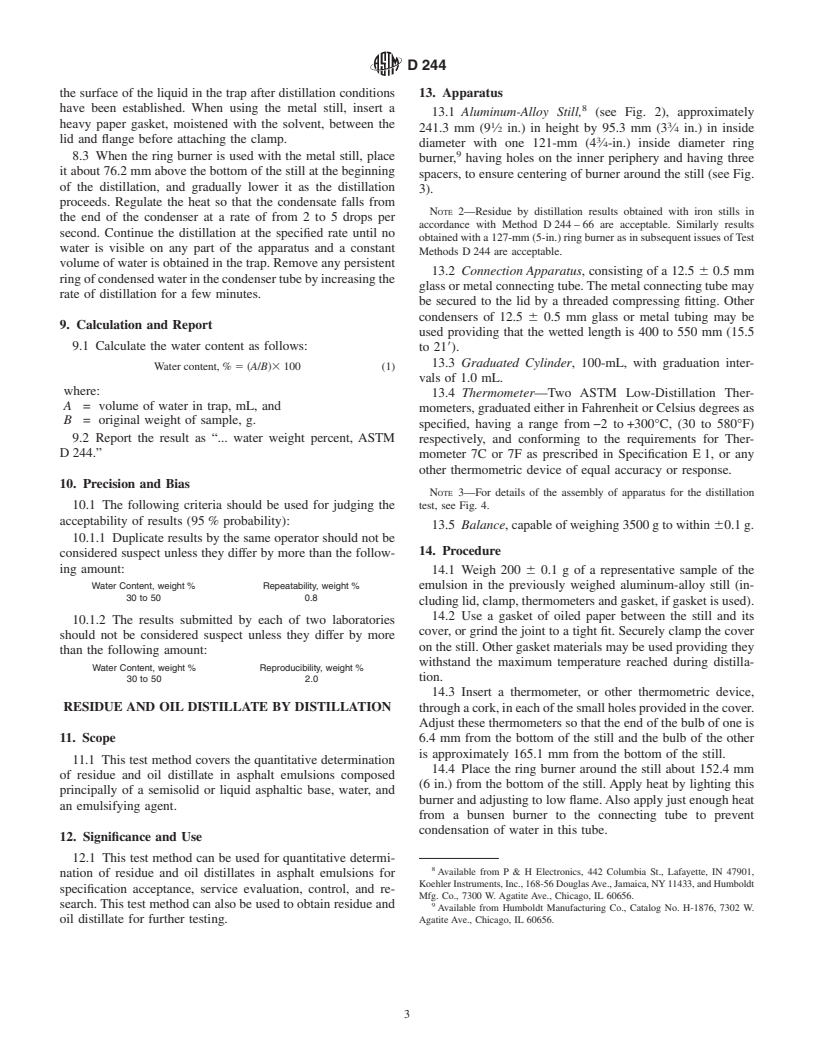

13.1 Aluminum-Alloy Still, (see Fig. 2), approximately

heavy paper gasket, moistened with the solvent, between the

1 3

241.3 mm (9 ⁄2 in.) in height by 95.3 mm (3 ⁄4 in.) in inside

lid and flange before attaching the clamp. 3

diameter with one 121-mm (4 ⁄4-in.) inside diameter ring

8.3 When the ring burner is used with the metal still, place

burner, having holes on the inner periphery and having three

it about 76.2 mm above the bottom of the still at the beginning

spacers, to ensure centering of burner around the still (see Fig.

of the distillation, and gradually lower it as the distillation

3).

proceeds. Regulate the heat so that the condensate falls from

NOTE 2—Residue by distillation results obtained with iron stills in

the end of the condenser at a rate of from 2 to 5 drops per

accordance with Method D244–66 are acceptable. Similarly results

second. Continue the distillation at the specified rate until no

obtainedwitha127-mm(5-in.)ringburnerasinsubsequentissuesofTest

water is visible on any part of the apparatus and a constant

Methods D244 are acceptable.

volumeofwaterisobtainedinthetrap.Removeanypersistent

13.2 Connection Apparatus, consisting of a 12.5 6 0.5 mm

ringofcondensedwaterinthecondensertubebyincreasingthe

glassormetalconnectingtube.Themetalconnectingtubemay

rate of distillation for a few minutes.

be secured to the lid by a threaded compressing fitting. Other

condensers of 12.5 6 0.5 mm glass or metal tubing may be

9. Calculation and Report

used providing that the wetted length is 400 to 550 mm (15.5

9.1 Calculate the water content as follows:

to 218).

13.3 Graduated Cylinder, 100-mL, with graduation inter-

Watercontent,% 5 ~A/B!3100 (1)

vals of 1.0 mL.

where:

13.4 Thermometer—Two ASTM Low-Distillation Ther-

A = volume of water in trap, mL, and

mometers,graduatedeitherinFahrenheitorCelsiusdegreesas

B = original weight of sample, g.

specified, having a range from−2 to+300°C, (30 to 580°F)

9.2 Report the result as “. water weight percent, ASTM

respectively, and conforming to the requirements for Ther-

D244.”

mometer 7C or 7F as prescribed in Specification E1, or any

other thermometric device of equal accuracy or response.

10. Precision and Bias

NOTE 3—For details of the assembly of apparatus for the distillation

test, see Fig. 4.

10.1 The following criteria should be used for judging the

acceptability of results (95% probability):

13.5 Balance,capableofweighing3500gtowithin 60.1g.

10.1.1 Duplicate results by the same operator should not be

14. Procedure

considered suspect unless they differ by more than the follow-

ing amount:

14.1 Weigh 200 6 0.1 g of a representative sample of the

Water Content, weight % Repeatability, weight %

emulsion in the previously weighed aluminum-alloy still (in-

30 to 50 0.8

cludinglid,clamp,thermometersandgasket,ifgasketisused).

14.2 Use a gasket of oiled paper between the still and its

10.1.2 The results submitted by each of two laboratories

cover, or grind the joint to a tight fit. Securely clamp the cover

should not be considered suspect unless they differ by more

onthestill.Othergasketmaterialsmaybeusedprovidingthey

than the following amount:

withstand the maximum temperature reached during distilla-

Water Content, weight % Reproducibility, weight %

tion.

30 to 50 2.0

14.3 Insert a thermometer, or other thermometric device,

RESIDUE AND OIL DISTILLATE BY DISTILLATION throughacork,ineachofthesmallholesprovidedinthecover.

Adjustthesethermometerssothattheendofthebulbofoneis

11. Scope 6.4 mm from the bottom of the still and the bulb of the other

is approximately 165.1 mm from the bottom of the still.

11.1 This test method covers the quantitative determination

14.4 Place the ring burner around the still about 152.4 mm

of residue and oil distillate in asphalt emulsions composed

(6 in.) from the bottom of the still.Apply heat by lighting this

principally of a semisolid or liquid asphaltic base, water, and

burnerandadjustingtolowflame.Alsoapplyjustenoughheat

an emulsifying agent.

from a bunsen burner to the connecting tube to prevent

condensation of water in this tube.

12. Significance and Use

12.1 This test method can be used for quantitative determi-

Available from P & H Electronics, 442 Columbia St., Lafayette, IN 47901,

nation of residue and oil distillates in asphalt emulsions for

KoehlerInstruments,Inc.,168-56DouglasAve.,Jamaica,NY11433,andHumboldt

specification acceptance, service evaluation, control, and re-

Mfg. Co., 7300 W. Agatite Ave., Chicago, IL 60656.

search.Thistestmethodcanalsobeusedtoobtainresidueand 9

Available from Humboldt Manufacturing Co., Catalog No. H-1876, 7302 W.

oil distillate for further testing. Agatite Ave., Chicago, IL 60656.

D 244

NOTE 4—The location of the burner at the start of the test is flexible. It

may be raised to decrease chance of foam-over or lowered to middle of

still for emulsion containing no solvent.Asudden change in temperature

reading of upper thermometer indicates foam on bulb. Remove heat until

foaming ceases.

14.6 Immediately at the expiration of the heating period,

again weigh the still and accessories as described in 14.1.

Calculate and report the percentage residue by distillation.

Record the volume of oil distillate to the nearest ⁄2mL.

Calculateandreporttheoildistillateasavolumepercentageon

the total emulsion. Save this oil distillate if identification is

desired.

NOTE 5—The aluminum-alloy still at room temperature (9.1) weighs

1.5 g more than at 260°C. Correct for this error by adding 1.5 g to gross

weight obtained in 14.6 prior to calculating the percentage of residue by

distillation.

14.7 Remove the cover from the still, stir, and immediately

poursuitableportionsoftheresidueintoan8-oztinorsuitable

molds and containers for making the required tests. Handle or

condition molds and containers for desired examination of the

residueasdescribedinSections86-91,andproceedasrequired

by the appropriate ASTM test method from the points that

follow the pouring stage. If there is foreign matter in the

residue, the material shall be poured through a 300-µm sieve

prior to pouring into the test molds and containers.

15. Precision and Bias

15.1 The following criteria should be used for judging the

acceptability of results (95% probability):

15.1.1 Duplicate results by the same operator should not be

considered suspect unless they differ by more than the follow-

ing amount:

Metric Equivalents

Residue by Distillation, Repeatability,

weight % weight %

in. mm

50 to 70 1.0

⁄8 3.2

⁄16 4.8

15.1.2 The results submitted by each of two laboratories

⁄8 9.5

should not be considered suspect unless they differ by more

⁄2 12.7

than the following amount:

⁄16 14.3

⁄8 15.9

Residue by Distillation, Reproducibility,

⁄4 19.1

weight % weight %

1 25.4

50 to 70 2.0

1 ⁄8 41.3

1 ⁄4 44.5

15.2 The precision for penetration of residue from distilla-

2 ⁄4 57.2

tion by this method is the same as that shown in Section 79.

2 ⁄2 63.5

4 101.6

5 ⁄8 130.2

RESIDUE BY EVAPORATION

6 ⁄4 158.8

7 ⁄4 184.2

9 ⁄2 241.3

16. Scope

16.1 This test method covers procedures for a relatively

NOTE 1—The still cover may be machined from Rolled Aluminum

rapid determination of the percentage of emulsion residue.

Plate Alloy 3003-H14.

FIG. 2 Aluminum-Alloy Still

17. Significance and Use

14.5 Move the ring burner approximately level with the 17.1 The test may be used to indicate compositional char-

bottom when the temperature can be read on the lower acteristics of emulsified asphalt. Evaporation residue may also

thermometer, approxima

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.