ASTM C685/C685M-00a

(Specification)Standard Specification for Concrete Made By Volumetric Batching and Continuous Mixing

Standard Specification for Concrete Made By Volumetric Batching and Continuous Mixing

SCOPE

1.1 This specification covers concrete made from materials continuously batched by volume, mixed in a continuous mixer, and delivered to the purchaser in a freshly mixed and unhardened state. Tests and criteria for batching accuracy and mixing efficiency are specified herein.

1.2 The values stated in either SI units, shown in brackets, or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This specification references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 685/C 685M – 00a

Standard Specification for

Concrete Made by Volumetric Batching and Continuous

Mixing

This standard is issued under the fixed designation C 685/C 685M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C 231 Test Method for Air Content of Freshly Mixed

Concrete by the Pressure Method

1.1 This specification covers concrete made from materials

C 260 Specification for Air-Entraining Admixtures for Con-

continuously batched by volume, mixed in a continuous mixer,

crete

and delivered to the purchaser in a freshly mixed and unhard-

C 330 Specification for Lightweight Aggregates for Struc-

ened state. Tests and criteria for batching accuracy and mixing

tural Concrete

efficiency are specified herein.

C 494 Specification for Chemical Admixtures for Concrete

1.2 The values stated in either SI units, shown in brackets,

C 567 Test Method for Unit Weight of Structural Light-

or inch-pound units are to be regarded separately as standard.

weight Concrete

The values stated in each system may not be exact equivalents;

C 595 Specifications for Blended Hydraulic Cements

therefore, each system shall be used independently of the other.

C 618 Specification for Coal Fly Ash and Raw or Calcined

Combining values from the two systems may result in noncon-

Natural Pozzolan for Use as a Mineral Admixture in

formance with the standard.

Portland Cement Concrete

1.3 This specification references notes and footnotes which

C 989 Specification for Ground Granulated Blast-Furnace

provide explanatory material. These notes and footnotes (ex-

Slag for Use in Concrete and Mortars

cluding those in tables and figures) shall not be considered as

C 1017/C 1017M Specification for Chemical Admixtures

requirements of this specification.

for Use in Producing Flowing Concrete

2. Referenced Documents C 1064 Test Method for Temperature of Freshly Mixed

Portland Cement Concrete

2.1 ASTM Standards:

C 1077 Practice for Laboratories Testing Concrete and Con-

C 31/C 31M Practice for Making and Curing Concrete Test

crete Aggregates for Use in Construction and Criteria for

Specimens in the Field

Laboratory Evaluation

C 33 Specification for Concrete Aggregates

C 1157 Performance Specification for Blended Hydraulic

C 39 Test Method for Compressive Strength of Cylindrical

Cement

Concrete Specimens

D 512 Test Methods for Chloride Ion in Water

C 109/C 109M Test Method for Compressive Strength of

D 516 Test Method for Sulfate Ion in Water

Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube

2.2 ACI Documents:

Specimens)

CP-1 Technician Workbook for ACI Certification of Con-

C 138 Test Method for Unit Weight, Yield, and Air Content

crete Field Testing Technician-Grade I

(Gravimetric) of Concrete

211.1 Standard Practice for Selecting Proportions for Nor-

C 143/C 143M Test Method for Slump of Hydraulic Ce-

mal, Heavyweight, and Mass Concrete

ment Concrete

211.2 Standard Practice for Selecting Proportions for Struc-

C 150 Specification for Portland Cement

tural Lightweight Concrete

C 173 Test Method for Air Content of Freshly Mixed

214 Recommended Practice for Evaluation of Strength Test

Concrete by the Volumetric Method

Results of Concrete

C 191 Test Method for Time of Setting of Hydraulic Ce-

301 Standard Specifications for Structural Concrete

ment by Vicat Needle

305R Hot Weather Concreting

306R Cold Weather Concreting

This specification is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

C09.40 on Ready-Mixed Concrete.

Current edition approved Sept. 10, 2000. Published December 2000. Originally

published as C 685 – 71 T. Last previous edition C 685 – 00. Annual Book of ASTM Standards, Vol 11.01.

2 5

Annual Book of ASTM Standards, Vol 04.02. Available from the American Concrete Institute, 38800 Country Club Drive,

Annual Book of ASTM Standards, Vol 04.01. Farmington Hills, MI 48331.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 685/C 685M

318 Building Code Requirements for Structural Concrete 5.1.3 Water:

and Commentary 5.1.3.1 The mixing water shall be clear and apparently

2.3 Other Documents: clean. If it contains quantities of substances that discolor it or

Bureau of Reclamation Concrete Manual make it smell or taste unusual or objectionable, or cause

AASHTO T 26 Method of Test for Quality of Water to be suspicion, it shall not be used unless service records of

Used in Concrete concrete made with it (or other information) indicate that it is

not injurious to the quality of the concrete. Water of question-

3. Terminology

able quality shall be subject to the acceptance criteria of Table

1.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 manufacturer, n—the contractor, subcontractor, sup- 5.1.3.2 Test results of wash water from mixer washout

operations to be used for mixing concrete shall comply with the

plier, or producer who furnishes the ready-mixed concrete.

3.1.2 purchaser, n—the owner, or representative thereof, physical test limits of Table 1. Wash water shall be tested at a

weekly interval for approximately 4 weeks, and thereafter at a

who buys the ready-mixed concrete.

monthly interval provided no single test exceeds the applicable

4. Basis of Purchase

limit (Note 3). Optional chemical limits in Table 2 shall be

specified by the purchaser when appropriate for the construc-

4.1 The basis of purchase shall be the cubic yard or cubic

tion. The testing frequency for chemical limits shall be as given

metre of plastic and unhardened concrete as it is continuously

above or as specified by the purchaser.

discharged from the batching and mixing apparatus.

NOTE 3—When recycled wash water is used, attention should be given

NOTE 1—It should be understood that the volume of hardened concrete

to effects on the dosage rate and batching sequence of air entraining and

may be, or may appear to be, less than expected due to waste and spillage,

other chemical admixtures and a uniform amount should be used in

over-excavation, spreading forms, some loss of entrained air, or settlement

consecutive batches.

of wet mixtures, none of which are the responsibility of the manufacturer.

5.1.4 Mineral Admixtures—Fly ash and raw or calcined

4.2 The volume of plastic and unhardened concrete shall be

3 3

natural pozzolan shall conform to Specification C 618 as

checked daily on projects requiring more than 50 yd [40 m ]

applicable.

of concrete per day (see 7.4). The amount of various ingredi-

5.1.5 Ground Granulated Blast-Furnace Slag—Ground

ents (cement, fine and coarse aggregate, admixtures, and water)

granulated blast furnace slag shall conform to Specification

shall be checked as required in 7.5.

C 989.

4.3 The manufacturer of the concrete shall conduct calibra-

5.1.6 Air-Entraining Admixtures—Air-entraining admix-

tion and mixer efficiency tests at intervals not exceeding 6

tures shall conform to Specification C 260. (Note 4)

months. Data on such tests using materials proposed for use in

5.1.7 Chemical Admixtures—Chemical admixtures shall

the project shall be furnished the purchaser upon request.

conform to either Specification C 494 or C 1017/C 1017M, as

5. Materials

applicable (Note 4).

5.1 In the absence of designated applicable specifications

NOTE 4—In any given instance, the required dosage of air-entraining,

covering requirements for quality of materials, the following

accelerating, and retarding admixtures may vary. Therefore, a range of

specifications shall govern: dosages should be allowed which will permit obtaining the desired effect.

5.1.1 Cement—Cement shall conform to Specification

6. Ordering Information

C 150, Specification C 595, or Specification C 1157 (Note 2).

6.1 In the absence of designated applicable general specifi-

The purchaser shall specify the type or types required, but if no

type is specified, the requirements of Type I as prescribed in cations, the purchaser shall specify the following:

6.1.1 Designated size or sizes of coarse aggregate,

Specification C 150 shall apply.

6.1.2 Slump or slumps desired at the point of delivery (see

NOTE 2—These different cements will produce concretes of different

10.3),

properties and should not be used interchangeably.

6.1.3 When air-entrained concrete is specified, the air con-

5.1.2 Aggregates—Aggregates shall conform to Specifica-

tent of samples taken at the point of discharge from the

tion C 33 or Specification C 330 if lightweight concrete is

transportation unit (see 10.4 and Table 3 for the total air content

specified by the purchaser.

and tolerances) (Note 5),

6.1.4 When structural lightweight concrete is specified, the

density as fresh density, equilibrium density, or oven-dry

Available from Superintendent of Documents, U.S. Government Printing

density (Note 6), and

Office, Washington, DC 20402.

6.1.5 Which of Options A, B, or C shall be used as a basis

Available from the American Association of State Highway and Transportation

for determining the proportions of the concrete to produce the

Officials, 444 N. Capitol St., NW, Suite 225, Washington, DC 20001.

TABLE 1 Acceptance Criteria for Questionable Water Supplies

Limits Test Method

A

Compressive strength, min, % control at 7 days 90 C 109/C 109M

A

Time of set, deviation from control from 1:00 earlier to 1:30 later C 191

A

Comparisons shall be based on fixed proportions and the same volume of test water compared to control mix using city water or distilled water.

C 685/C 685M

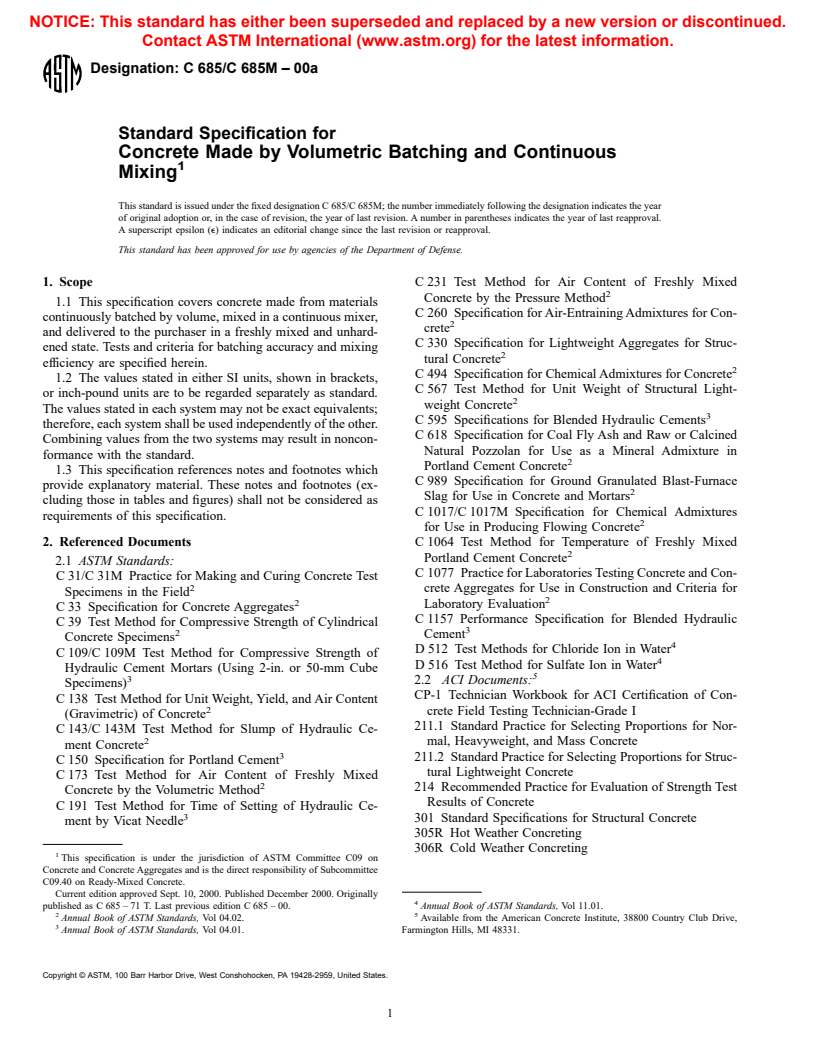

TABLE 2 Optional Chemical Limits for Wash Water

A

Limits Test Method

Chemical requirements, maximum concentration in mixing water,

B

ppm

Chloride as C1, ppm: D 512

C

Prestressed concrete or in bridge decks 500

C

Other reinforced concrete in moist environments or containing 1000

aluminum embedments or dissimilar metals or with stay-in-place

galvanized metal forms

Sulfate as SO , ppm 3000 D 516

Alkalies as (Na O + 0.658 K O), ppm 600

2 2

Total solids, ppm 50 000 AASHTO T26

A

Other test methods that have been demonstrated to yield comparable results are permitted to be used.

B

Wash water reused as mixing water in concrete is allowed to exceed the listed concentrations if it can be shown that the concentration calculated in the total mixing

water, including mixing water on the aggregates and other sources does not exceed the stated limits.

C

For conditions allowing use of CaCl accelerator as an admixture, the chloride limitation is permitted to be waived by the purchaser.

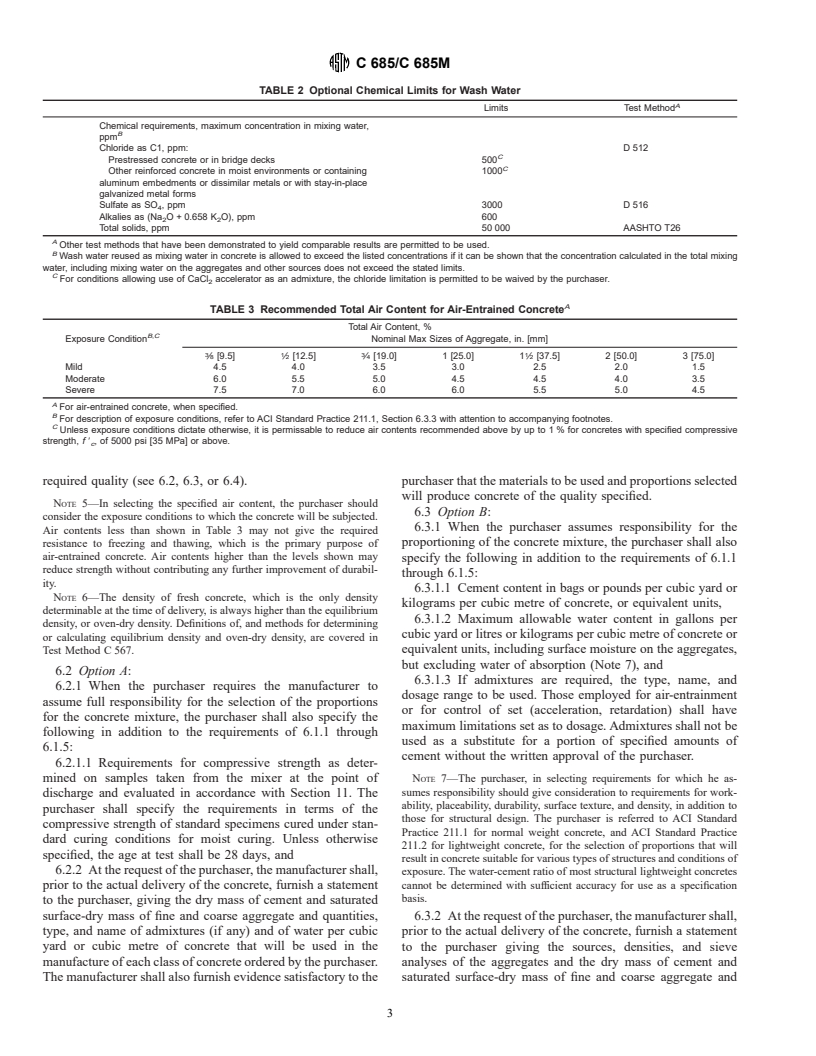

A

TABLE 3 Recommended Total Air Content for Air-Entrained Concrete

Total Air Content, %

B,C

Exposure Condition Nominal Max Sizes of Aggregate, in. [mm]

3 1 3 1

⁄8 [9.5] ⁄2 [12.5] ⁄4 [19.0] 1 [25.0] 1 ⁄2 [37.5] 2 [50.0] 3 [75.0]

Mild 4.5 4.0 3.5 3.0 2.5 2.0 1.5

Moderate 6.0 5.5 5.0 4.5 4.5 4.0 3.5

Severe 7.5 7.0 6.0 6.0 5.5 5.0 4.5

A

For air-entrained concrete, when specified.

B

For description of exposure conditions, refer to ACI Standard Practice 211.1, Section 6.3.3 with attention to accompanying footnotes.

C

Unless exposure conditions dictate otherwise, it is permissable to reduce air contents recommended above by up to 1 % for concretes with specified compressive

strength, f 8 , of 5000 psi [35 MPa] or above.

c

required quality (see 6.2, 6.3, or 6.4). purchaser that the materials to be used and proportions selected

will produce concrete of the quality specified.

NOTE 5—In selecting the specified air content, the purchaser should

6.3 Option B:

consider the exposure conditions to which the concrete will be subjected.

6.3.1 When the purchaser assumes responsibility for the

Air contents less than shown in Table 3 may not give the required

proportioning of the concrete mixture, the purchaser shall also

resistance to freezing and thawing, which is the primary purpose of

air-entrained concrete. Air contents higher than the levels shown may

specify the following in addition to the requirements of 6.1.1

reduce strength without contributing any further improvement of durabil-

through 6.1.5:

ity.

6.3.1.1 Cement content in bags or pounds per cubic yard or

NOTE 6—The density of fresh concrete, which is the only density

kilograms per cubic metre of concrete, or equivalent units,

determinable at the time of delivery, is always higher than the equilibrium

6.3.1.2 Maximum allowable water content in gallons per

density, or oven-dry density. Definitions of, and methods for determining

cubic yard or litres or kilograms per cubic metre of concrete or

or calculating equilibrium density and oven-dry density, are covered in

equivalent units, including surface moisture on the aggregates,

Test Method C 567.

but excluding water of absorption (Note 7), and

6.2 Option A:

6.3.1.3 If admixtures are required, the type, name, and

6.2.1 When the purchaser requires the manufacturer to

dosage range to be used. Those employed for air-entrainment

assume full responsibility for the selection of the proportions

or for control of set (acceleration, retardation) shall have

for the concrete mixture, the purchaser shall also specify the

maximum limitations set as to dosage. Admixtures shall not be

following in addition to the requirements of 6.1.1 through

used as a substitute for a portion of specified amounts of

6.1.5:

cement without the written approval of the purchaser.

6.2.1.1 Requirements for compressive strength as deter-

mined on samples taken from the mixer at the point of NOTE 7—The purchaser, in selecting requirements for which he as-

sumes responsibility should give consideration to requirements for work-

discharge and evaluated in accordance with Section 11. The

ability, placeability, durability, surface texture, and density, in addition to

purchaser shall specify the requirements in terms of the

those for structural design. The purchaser is referred to ACI Standard

compressive strength of standard specimens cured under stan-

Practice 211.1 for normal weight concrete, and ACI Standard Practice

dard curing conditions for moist curing. Unless otherwise

211.2 for lightweight concrete, for the selection of proportions that will

specified, the age at test shall be 28 days, and

result in concrete suitable for various types of structures and conditions of

6.2.2 At the request of the purchaser, the manufacturer shall,

exposure. The water-cement ratio of most structural lightweight concretes

prior to the actual delivery of the concrete, furnish a statement cannot be deter

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.