ASTM A995/A995M-98(2003)

(Specification)Standard Specification for Castings, Austenitic-Ferritic (Duplex) Stainless Steel, for Pressure-Containing Parts

Standard Specification for Castings, Austenitic-Ferritic (Duplex) Stainless Steel, for Pressure-Containing Parts

SCOPE

1.1 This specification covers austenitic-ferritic (duplex) stainless steel castings for valves, flanges, fittings, and other pressure-containing parts.

1.2 The duplex stainless steels offer a combination of enhanced mechanical properties and corrosion resistance when properly balanced in composition and properly heat treated. Ferrite levels are not specified, but these grades will develop a range of approximately 30 to 60 % ferrite with the balance austenite. It is the responsibility of the purchaser to determine which grade shall be furnished depending on design and service conditions, mechanical properties, and corrosion-resistant characteristics.

Note 1—Because of the possibility of precipitation of embrittling phases, the grades included in this specification are not recommended for service at temperatures above 600°F [315°C].

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 995/A 995M – 98 (Reapproved 2003)

Standard Specification for

Castings, Austenitic-Ferritic (Duplex) Stainless Steel, for

Pressure-Containing Parts

This standard is issued under the fixed designationA 995/A 995M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

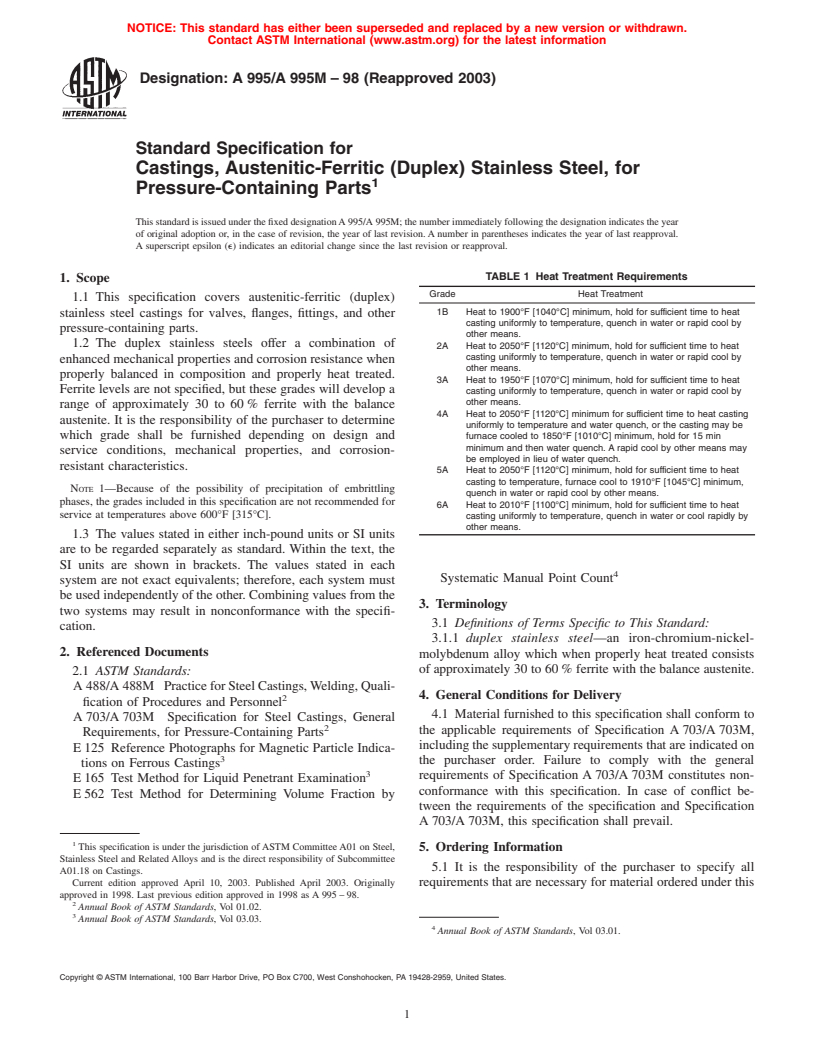

TABLE 1 Heat Treatment Requirements

1. Scope

Grade Heat Treatment

1.1 This specification covers austenitic-ferritic (duplex)

1B Heat to 1900°F [1040°C] minimum, hold for sufficient time to heat

stainless steel castings for valves, flanges, fittings, and other

casting uniformly to temperature, quench in water or rapid cool by

pressure-containing parts.

other means.

1.2 The duplex stainless steels offer a combination of

2A Heat to 2050°F [1120°C] minimum, hold for sufficient time to heat

casting uniformly to temperature, quench in water or rapid cool by

enhanced mechanical properties and corrosion resistance when

other means.

properly balanced in composition and properly heat treated.

3A Heat to 1950°F [1070°C] minimum, hold for sufficient time to heat

Ferrite levels are not specified, but these grades will develop a

casting uniformly to temperature, quench in water or rapid cool by

other means.

range of approximately 30 to 60 % ferrite with the balance

4A Heat to 2050°F [1120°C] minimum for sufficient time to heat casting

austenite. It is the responsibility of the purchaser to determine

uniformly to temperature and water quench, or the casting may be

which grade shall be furnished depending on design and furnace cooled to 1850°F [1010°C] minimum, hold for 15 min

minimum and then water quench. A rapid cool by other means may

service conditions, mechanical properties, and corrosion-

be employed in lieu of water quench.

resistant characteristics.

5A Heat to 2050°F [1120°C] minimum, hold for sufficient time to heat

casting to temperature, furnace cool to 1910°F [1045°C] minimum,

NOTE 1—Because of the possibility of precipitation of embrittling

quench in water or rapid cool by other means.

phases, the grades included in this specification are not recommended for

6A Heat to 2010°F [1100°C] minimum, hold for sufficient time to heat

service at temperatures above 600°F [315°C].

casting uniformly to temperature, quench in water or cool rapidly by

other means.

1.3 The values stated in either inch-pound units or SI units

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

Systematic Manual Point Count

system are not exact equivalents; therefore, each system must

be used independently of the other. Combining values from the

3. Terminology

two systems may result in nonconformance with the specifi-

3.1 Definitions of Terms Specific to This Standard:

cation.

3.1.1 duplex stainless steel—an iron-chromium-nickel-

2. Referenced Documents

molybdenum alloy which when properly heat treated consists

of approximately 30 to 60 % ferrite with the balance austenite.

2.1 ASTM Standards:

A 488/A 488M PracticeforSteelCastings,Welding,Quali-

4. General Conditions for Delivery

fication of Procedures and Personnel

4.1 Material furnished to this specification shall conform to

A 703/A 703M Specification for Steel Castings, General

the applicable requirements of Specification A 703/A 703M,

Requirements, for Pressure-Containing Parts

including the supplementary requirements that are indicated on

E 125 Reference Photographs for Magnetic Particle Indica-

the purchaser order. Failure to comply with the general

tions on Ferrous Castings

requirements of Specification A 703/A 703M constitutes non-

E 165 Test Method for Liquid Penetrant Examination

conformance with this specification. In case of conflict be-

E 562 Test Method for Determining Volume Fraction by

tween the requirements of the specification and Specification

A 703/A 703M, this specification shall prevail.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

5. Ordering Information

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

5.1 It is the responsibility of the purchaser to specify all

A01.18 on Castings.

Current edition approved April 10, 2003. Published April 2003. Originally requirements that are necessary for material ordered under this

approved in 1998. Last previous edition approved in 1998 as A 995 – 98.

Annual Book of ASTM Standards, Vol 01.02.

Annual Book of ASTM Standards, Vol 03.03.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 995/A 995M – 98 (2003)

TABLE 2 Chemical Requirements

A A

Grade 1B 2A 3A 4A 5A 6A

Type 25Cr-5Ni-M0-Cu-N 24Cr-10Ni-Mo-N 25Cr-5Ni-Mo-N 22Cr-5Ni-Mo-N 25Cr-7Ni-Mo-N 25Cr-7Ni-Mo-N

UNS J93372 J93345 J93371 J92205 J93404 J93380

ACI CD4MCuN CE8MN CD6MN CD3MN CE3MN CD3MWCuN

Composition:

Carbon, max 0.040 0.080 0.060 0.030 0.030 0.030

Manganese, max 1.00 1.00 1.00 1.50 1.50 1.00

Silicon, max 1.00 1.50 1.00 1.00 1.00 1.00

Phosphorus, max 0.040 0.040 0.040 0.040 0.040 0.030

Sulfur, max 0.040 0.040 0.040 0.020 0.040 0.025

Chromium 24.5-26.5 22.5-25.5 24.0-27.0 21.0-23.5 24.0-26.0 24.0-26.0

Nickel 4.7-6.0 8.0-11.0 4.0-6.0 4.5-6.5 6.0-8.0 6.5-8.5

Molybdenum 1.70-2.30 3.0-4.5 1.75-2.50 2.5-3.5 4.0-5.0 3.0-4.0

Copper 2.7-3.3 . . . . . . 1.00, max . . . 0.50-1.00

Tungsten . . . . . . . . . . . . . . . 0.50-1.00

Nitrogen 0.10-0.25 0.10-0.30 0.15-0.25 0.10-0.30 0.10-0.30 0.20-0.30

A

%Cr+3.3% Mo+16% N$ 40.

TABLE 3 Tensile Requirements

Grade 1B 2A 3A 4A 5A 6A

Type 25Cr-5Ni-Mo-Cu-N 24Cr-10Ni-Mo-N 25Cr-5Ni-Mo-N 22Cr-5Ni-Mo-N 25Cr-7Ni-Mo-N 25Cr-7Ni-Mo-N

Tensile strength, ksi [MPa], min 100 [690] 95 [655] 95 [655] 90 [620] 100 [690] 100 [690]

Yield strength

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.