ASTM F918-96

(Specification)Standard Specification for Noncarbonated Mechanically Refrigerated, Beverage Dispenser (Visible Product)

Standard Specification for Noncarbonated Mechanically Refrigerated, Beverage Dispenser (Visible Product)

SCOPE

1.1 This specification covers counter-top model noncarbonated beverage dispensers that are mechanically refrigerated and have rigid, transparent, impact-resistant containers to afford a visual display of the beverage dispensed. The beverage dispensers covered by this specification are intended to circulate, cool, and dispense noncarbonated beverages such as pulpy juices, frozen concentrates, and syrup drinks.

1.2 The following safety hazard caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 918 – 96

Standard Specification for

Noncarbonated Mechanically Refrigerated, Beverage

Dispenser (Visible Product)

This standard is issued under the fixed designation F 918; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope UL Standard No. 471, Commercial Refrigerators and Freez-

ers

1.1 This specification covers counter-top model noncarbon-

UL Standard No. 969, Marking and Labeling Systems

ated beverage dispensers that are mechanically refrigerated and

2.5 ANSI Standard:

have rigid, transparent, impact-resistant containers to afford a

ANSI Z1.4, Sampling Procedures and Tables for Inspection

visual display of the beverage dispensed. The beverage dis-

by Attributes

pensers covered by this specification are intended to circulate,

2.6 Military Standards:

cool, and dispense noncarbonated beverages such as pulpy

MIL-STD-167/1 Mechanical Vibrations of Shipboard

juices, frozen concentrates, and syrup drinks.

Equipment Type I—Environmental and Type II—

1.2 The following safety hazard caveat pertains only to the

Internally Excited

test method portion, Section 11, of this specification: This

MIL-V-173 Varnish, Moisture and Fungus-Resistant

standard does not purport to address all of the safety concerns,

MIL-STD-461 Electromagnetic Interference and Suscepti-

if any, associated with its use. It is the responsibility of the user

bility Requirements For the Control of Electromagnetic

of this standard to establish appropriate safety and health

Interference

practices and determine the applicability of regulatory limita-

MIL-STD-462 Electromagnetic Interference Characteris-

tions prior to use.

tics, Measurement of

2. Referenced Documents MIL-STD-1399/300 Interface Standard for Shipboard Sys-

tems, Section 300A, Electric Power, Alternating Current

2.1 ASTM Standards:

D 3951 Practice for Commercial Packaging

3. Terminology

F 760 Specification for Food Service Equipment Manuals

3.1 Definitions:

F 1166 Practice for Human Engineering Design for Marine

3.1.1 aeration system—a type of circulation system that

Systems, Equipment and Facilities

causes the beverage to cascade across the top and down the

2.2 NSTA Standard:

sides of the bowl interior incorporating air into the beverage.

NSTA Pre-Shipping Test Procedures

3.1.2 beverage dispenser—a beverage dispenser is a com-

2.3 NSF Standards:

mercial appliance designed to deliver a beverage.

NSF Standard No. 18, Manual Food and Beverage Dispens-

6 3.1.3 circulation system—the system which moves the bev-

ing Equipment

erage within the bowl to ensure proper cooling and mixing.

NSF Standard No. 51, Plastic Materials and Components

6 3.1.4 whippers—a mechanical device used to beat air into a

Used in Food Equipment

beverage so as to change its properties from a liquid drink to a

2.4 UL Standards:

frothy drink.

4. Classification

This specification is under the jurisdiction of ASTM Committee F-26 on Food

4.1 General—The beverage dispensers shall be of the fol-

Service Equipment and is the direct responsibility of Subcommittee F26.03 on

lowing types, classes, styles, sizes, and electrical ratings:

Storage and Dispensing Equipment.

4.2 Types:

Current edition approved Oct. 10, 1996. Published February 1997. Originally

published as F 918 – 85. Last previous edition F 918 – 85 (1990).

4.2.1 Type I—Dispenser with circulation system and with

Annual Book of ASTM Standards, Vol 15.09.

Annual Book of ASTM Standards, Vol 15.07.

4 7

Annual Book of ASTM Standards, Vol 01.07. Available from the Underwriters Laboratories Inc., 1655 Scott Blvd., Santa

Available from National Safe Transit Association, 6022 West Touhy Ave., Clara, CA 95050; 333 Pfingsten Road, Northbrook, IL 60062; 1285 Walt Whitman

Chicago, IL 60648. Road, Melville, L.I., NY 11746; or 2602 Tampa East Blvd., Tampa, FL 33619.

6 8

Available from National Sanitation Foundation, NSF Building, Ann Arbor, MI Available from American National Standards Institute, 11 W. 42nd St., 13th

48105. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 918

overhead spray type aeration system (for syrup drinks and 7.1.1.3 Style C units shall be equipped with three bowls or

other nonfoaming beverages). compartments, each with at least one dispensing valve and

4.2.2 Type II—Dispenser with circulation system but with- each with a circulation system.

out aeration system (for pulpy fruit juices and other beverages

7.1.2 The dispenser shall be designed to comply with the

not suitable for aeration).

requirements of UL Standard 471 and NSF Standard 18. (Note

4.3 Classes:

1).

4.3.1 Class A—Without whippers.

7.2 Base Assembly—The base assembly shall be designed

4.3.2 Class B—With whippers.

and constructed to house the refrigeration system and to

4.4 Styles:

support the container bowl(s), dispensing valve(s), and drip

4.4.1 Style A—Single Bowl.

tray(s). The base assembly shall be equipped with panels to

4.4.1.1 Size 1—Capacity up to and including 5 gal.

provide access to the components therein.

4.4.1.2 Size 2—Capacity of more than 5 up to and including

7.3 Refrigeration System—The refrigeration system shall

8 gal.

have sufficient capacity to meet the performance requirements

4.4.1.3 Size 3—Capacity of more than 8 up to and including

defined in Section 8. The refrigeration system on each dis-

12 gal.

penser shall be properly dehydrated and charged prior to

4.4.1.4 Size 4—Capacity of more than 12 gal.

shipment.

4.4.2 Style B—Twin bowl or twin compartment.

7.4 Circulation System—Each bowl or compartment shall

4.4.2.1 Size 1—Capacity up to 5 gal per bowl or compart-

be equipped with either a spray and circulation system (Type

ment.

I), or a circulation system only (Type II). The circulation

4.4.2.2 Size 2—Capacity of more than 5 gal per bowl or

systems shall impart a sufficient motion to the stored beverage

compartment.

to prevent settlement of beverage constituents, and to assist in

4.4.3 Style C—Triple bowl or triple compartment.

maintaining a required uniform beverage temperature through-

4.4.3.1 Size 1—Capacity up to 5 gal per bowl or compart-

out the bowl and particularly at the inlet to the dispensing port.

ment.

7.5 Bowls—Bowls and covers shall be fabricated of a rigid,

4.5 Electrical Rating—Nominal 115 v, single-phase, 60 Hz.

impact-resistant, transparent material. The bowls shall have

5. Ordering Information sufficient net volume, exclusive of space occupied by the

cooling dome or plate and mixing system components, to meet

5.1 Procurement documents should specify the following

the capacity requirements applicable to the size specified.

information:

Bowls shall be furnished and installed with parts required to

5.1.1 Title, number, and date of this Specification.

provide leak-tight containers. Bowls shall not crack or break

5.1.2 Type, class, style, and size of dispenser (see Section

when tested as specified in 11.7.2

4).

7.6 Dispensing Valves—The bowl on Style A units and each

5.1.3 Special requirements should be included.

bowl or compartment on Style B and Style C units shall be

6. Materials and Manufacture

equipped with at least one self-closing dispensing valve.

6.1 Materials—Materials used in the dispenser shall be as

Valves shall be designed to permit thorough cleaning of all

specified herein, and the dispenser shall be fabricated of

fluid passages and parts exposed to the beverage.

materials acceptable under NSF Standards 18 and 51.

7.7 Drip Tray—Each dispenser shall be equipped with a

drip tray having a readily removable perforated, slotted, or wire

NOTE 1—Evidence of compliance with NSF 18, NSF 51, and UL 471

cover. The drip tray may have provisions for draining the

is as follows: (a) NSF—Listing of the dispenser in the current edition of

the NSF “Listing of Food Service Equipment” and display of the NSF seal

splash and drippings into a drain.

on the finished dispenser. (b) UL—Acceptable evidence of meeting the

7.8 Temperature Control—Each dispenser shall be equipped

requirements of UL 471 shall be the UL label, or listing mark, indicating

with a temperature control to control automatically the refrig-

that the dispenser has been tested and conforms to the requirements of UL

eration system to maintain the beverage within the temperature

471.

range specified in Section 8.

7. Physical Requirements

7.9 Switches—Style A dispensers shall be equipped with at

least one on-off switch to control the power supply to the

7.1 Design:

dispenser. Style B and Style C units shall be equipped with an

7.1.1 The beverage dispenser shall consist essentially of a

independent on-off switch for the mixing system in each bowl

base which contains a complete refrigeration system and

or compartment, plus an additional main power supply or

supports a rigid, transparent, impact resistant, bowl-type bev-

compressor motor switch.

erage container(s) with cover(s). Each dispenser shall be

7.10 Miscellaneous—The dispenser base shall be provided

equipped with an electrically powered beverage circulation

with protectors to prevent damage to the surface on which it

system, a dispensing valve, and the controls and appurtenances

rests. The dispenser shall be easily assembled on location

specified as follows:

without tools and be ready for operation when connected to the

7.1.1.1 Style A units shall be equipped with one bowl and

electrical supply.

one or more dispensing valves.

7.1.1.2 Style B units shall be equipped with two bowls or 7.11 Electrical Requirements—The dispensers shall be de-

compartments, each with at least one dispensing valve and signed for operation on a nominal 115 V 6 10 %, single-phase,

each with a circulation system. 60 Hz current. Each dispenser shall be equipped with a flexible

F 918

power supply cord with suitable plug. and cracks. Castings and molded parts, if used, shall be free of

7.12 Standard Product—The dispenser delivered under this sand, fins, pits, blowholes, and sprues. External surfaces shall

specification shall be the manufacturer’s standard product. meet the UL Sharp Edge Test.

Parts and assemblies for each dispenser model furnished by a

NOTE 2—Although paragraph 10.2 requires subjective judgments, its

particular manufacturer under this specification shall be inter-

inclusion is considered important as a guide in evaluating and manufac-

changeable.

turing equipment.

10.2.1 Metal Fabrication—Metal used in the fabrication of

8. Performance Requirements

the dispensers shall be free from visually apparent defects.

8.1 Performance Design Requirements—Each dispenser

Forming and shearing shall not cause damage to the metal, and

shall refrigerate the beverage and maintain the stored beverage

the metal shall be free from trimming marks.

in a constant state of motion or circulation to prevent settle-

10.2.2 Welding—The surfaces of parts to be welded shall be

ment of beverage constituents.

free from rust, scale, paint, grease, and other foreign matter.

8.1.1 Operational Requirement—The refrigeration system

Welds shall be smooth and free from cracks, burn holes,

shall be capable of automatically maintaining the beverage

undercuts, or incomplete fusion. All scale and flux shall be

within the limits of 33 to 40°F inclusive when the dispenser is

removed from the finish weld area.

filled to the manufacturer’s rate capacity, and is operating in an

10.2.3 Fastening Devices—Holes punched or drilled shall

ambient temperature of 90 6 2°F.

be free of burrs. Threaded fasteners shall not be broken,

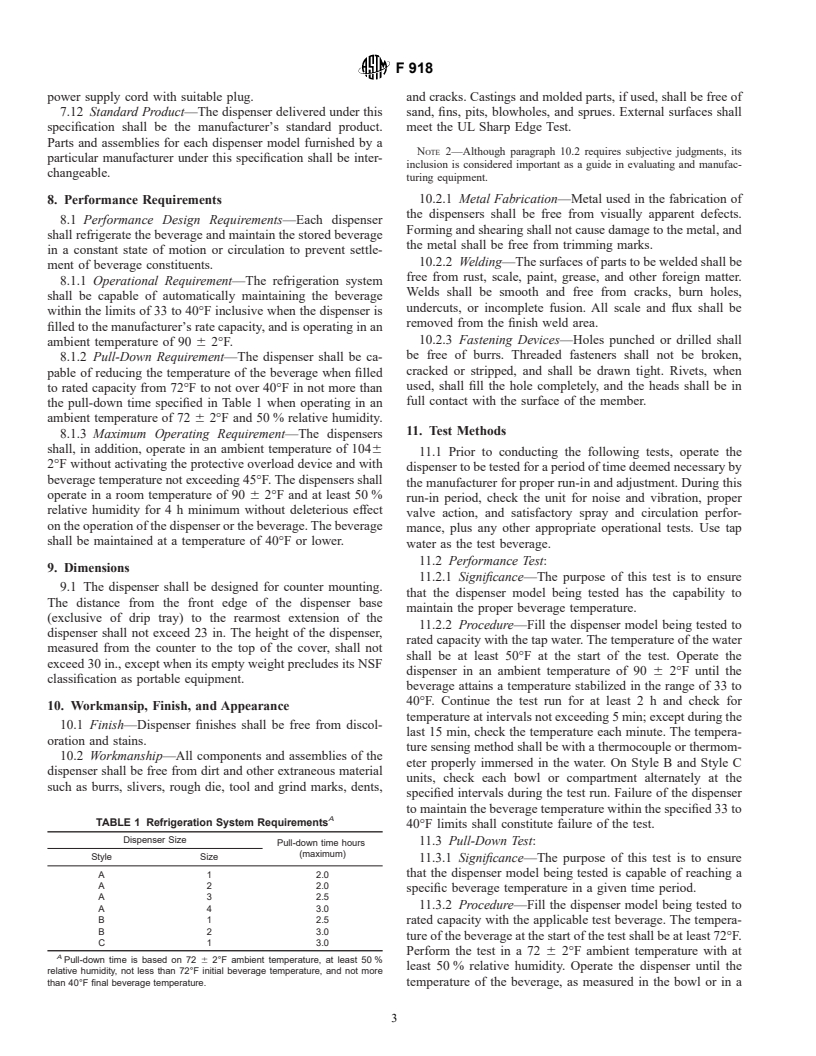

8.1.2 Pull-Down Requirement—The dispenser shall be ca-

cracked or stripped, and shall be drawn tight. Rivets, when

pable of reducing the temperature of the beverage when filled

used, shall fill the hole completely, and the heads shall be in

to rated capacity from 72°F to not over 40°F in not more than

full contact with the surface of the member.

the pull-down time specified in Table 1 when operating in an

ambient temperature of 72 6 2°F and 50 % relative humidity.

11. Test Methods

8.1.3 Maximum Operating Requirement—The dispensers

shall, in addition, operate in an ambient temperature of 1046

11.1 Prior to conducting the following tests, operate the

2°F without activating the protective overload device and with

dispenser to be tested for a period of time deemed necessary by

beverage temperature not exceeding 45°F. The dispensers shall

the manufacturer for proper run-in and adjustment. During this

operate in a room temperature of 90 6 2°F and at least 50 %

run-in period, check the unit for noise and vibration, proper

relative humidity for 4 h minimum without deleterious effect

valve action, and satisfactory spray and circulation perfor-

on the operation of the dispenser or the beverage. The beverage

mance, plus any other appropriate operational tests. Use tap

shall be maintained at a temperature of 40°F or lower.

water as the test beverage.

11.2 Performance Test:

9. Dimensions

11.2.1 Significance—The purpose of this test is to ensure

9.1 The dispenser shall be designed for counter mounting.

that the dispenser model being tested has the capability to

The distance from the front edge of the dispenser base

maintain the proper beverage temperature.

(exclusive of drip tray) to the rearmost extension of the

11.2.2 Procedure—Fill the dispenser model being tested to

dispenser shall not exceed 23 in. The height of the dispenser,

rated capacity with the tap water. The temperature of the water

measured from the counter to the top of the cover, shall not

shall be at least 50°F at the start of the test. Operate the

exceed 30 in., except when its empty weight precludes its NSF

dispenser in an ambient temperature of 90 6 2°F until the

classification as portable equipment.

beverage attains a temperature stabilized in the range of 33 to

40°F. Continue the test run for at least 2 h and check for

10. Workmansip, Finish, and Appearance

temperature at intervals not exceeding 5 min; except during the

10.1 Finish—Dispenser finishes shall be free from discol-

last 15 min, check the temperature each minute. The tempera-

oration and stains.

ture sensing method shall be with a thermocouple or thermom-

10.2 Workmanship—All components and assemblies of the

eter properly immersed in the water. On Style B and Style C

dispenser shall be free from dirt and other extraneous material

units, check each bowl or compartment alternately at the

such as burrs, slivers, rough die, tool and grind marks, dents,

specified inte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.