ASTM E478-89a(1996)

(Test Method)Standard Test Methods for Chemical Analysis of Copper Alloys

Standard Test Methods for Chemical Analysis of Copper Alloys

SCOPE

1.1 These test methods cover the chemical analysis of copper alloys having chemical compositions within the following limits: Element Concentration, % Aluminum 12.0 max Antimony 1.0 max Arsenic 1.0 max Cadmium 1.5 max Cobalt 1.0 max Copper 40.0 min Iron 6.0 max Lead 27.0 max Manganese 6.0 max Nickel 50.0 max Phosphorus 1.0 max Silicon 5.0 max Sulfur 0.1 max Tin 20.0 max Zinc 50.0 max

1.2 The test methods appear in the following order: Sections Aluminum by the Carbamate Extraction-(Ethyl- enedinitrilo) Tetraacetate Titrimetric Test Method 70 to 77 Copper by the Combined Electrodeposition Gravimetric and Oxalyldihydrazide Photometric Test Method [50 %, minimum] 9 to 18 Iron by the 1,10-Phenanthroline Photometric Test Method [0.003 to 1.25 %] 18 to 27 Lead by the Atomic Absorption Test Method 89 to 99 Lead by the (Ethylenedinitrilo)tetraacetic Acid (EDTA) Titrimetric Test Method [2.0 to 30.0 %] 28 to 35 Nickel by the Dimethylglyoxime Extraction Photometric Test Method [0.03 to 5.0 %] 36 to 45 Nickel by the Dimethylglyoxime Gravimetric Test Method [4 to 50 %] 54 to 61 Silver in Silver-Bearing Copper by the Atomic Absorp- tion Test Method 100 to 111 Tin by the Iodatimetric Titration Test Method [0.5 to 20 %] 62 to 69 Zinc by Atomic Spectrometry 62 to 69 Zinc by the (Ethylenedinitrilo)tetraacetic Acid (EDTA) Titrimetric Test Method [2 to 40 %] 46 to 53

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 5, Note 4, and Section 106.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 478 – 89a (Reapproved 1996)

Standard Test Methods for

Chemical Analysis of Copper Alloys

This standard is issued under the fixed designation E 478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Zinc by the (Ethylenedinitrilo)tetraacetic Acid

(EDTA) Titrimetric Test Method [2 to 40 %] 46-53

1.1 These test methods cover the chemical analysis of

1.3 This standard does not purport to address all of the

copper alloys having chemical compositions within the follow-

safety concerns, if any, associated with its use. It is the

ing limits:

responsibility of the user of this standard to establish appro-

Element Concentration, %

priate safety and health practices and determine the applica-

Aluminum 12.0 max

bility of regulatory limitations prior to use. Specific hazard

Antimony 1.0 max

statements are given in Section 5, Note 4, and Section 106.

Arsenic 1.0 max

Cadmium 1.5 max

Cobalt 1.0 max

2. Referenced Documents

Copper 40.0 min

2.1 ASTM Standards:

Iron 6.0 max

Lead 27.0 max

E 29 Practice for Using Significant Digits in Test Data to

Manganese 6.0 max 3

Determine Conformance with Specifications

Nickel 50.0 max

E 50 Practices for Apparatus, Reagents, and Safety Precau-

Phosphorus 1.0 max

Silicon 5.0 max

tions for Chemical Analysis of Metals

Sulfur 0.1 max

E 60 Practice for Photometric and Spectrophotometric

Tin 20.0 max

Methods for Chemical Analysis of Metals

Zinc 50.0 max

E 173 Practice for Conducting Interlaboratory Studies of

1.2 The test methods appear in the following order:

Methods for Chemical Analysis of Metals

Sections

E 255 Practice for Sampling Copper and Copper Alloys for

Aluminum by the Carbamate Extraction-(Ethyl-

Determination of Chemical Composition

enedinitrilo) Tetraacetate Titrimetric Test

Method 70-77

E 1024 Guide for Chemical Analysis of Metals and Metal

Copper by the Combined Electrodeposition

Bearing Ores by Flame Atomic Absorption Spectropho-

Gravimetric and Oxalyldihydrazide Photomet-

tometry

ric Test Method [50 %, minimum] 9-17

Iron by the 1,10-Phenanthroline Photometric

Test Method [0.003 to 1.25 %] 18-27

3. Significance and Use

Lead by the Atomic Absorption Test Method 89-99

3.1 These test methods for the chemical analysis of metals

Lead by the (Ethylenedinitrilo)tetraacetic Acid

(EDTA) Titrimetric Test Method [2.0 to

and alloys are primarily intended as referee methods to test

30.0 %] 28-35

such materials for compliance with compositional specifica-

Nickel by the Dimethylglyoxime Extraction Pho-

tometric Test Method [0.03 to 5.0 %] 36-45 tions. It is assumed that all who use these methods will be

Nickel by the Dimethylglyoxime Gravimetric

trained analysts capable of performing common laboratory

Test Method [4 to 50 %] 54-61

procedures skillfully and safely. It is expected that work will be

Silver in Silver-Bearing Copper by the Atomic

Absorption Test Method 100-111 performed in a properly equipped laboratory.

Tin by the Iodatimetric Titration Test Method

[0.5 to 20 %] 62-69

4. Apparatus, Reagents, and Photometric Practice

Tin by the Phenylfluorone Photometric Test

Method %] 112-122 4.1 Apparatus and reagents required for each determination

Zinc by Atomic Spectrometry 78-88

are listed in separate sections preceding the procedure. The

apparatus, standard solutions, and certain other reagents used

in more than one procedure are referred to by number and shall

conform to the requirements prescribed in Practices E 50,

These test methods are under the jurisdiction of ASTM Committee E-1 on

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct

responsibility of Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, their Alloys and

Related Metals.

Current edition approved Oct. 27, 1989. Published January 1990. Originally Annual Book of ASTM Standards, Vol 14.02.

published as E 478 – 73. Last previous edition E 478 – 89. Annual Book of ASTM Standards, Vol 03.05.

2 5

The actual limits of application of each test method are presented in 1.2. Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 478 – 89a (1996)

except that photometers shall conform to the requirements 13.3 Lead Nitrate Solution (10 g/L)—Dissolve 10.0 g of

prescribed in Practice E 60. lead nitrate (Pb(NO ) ) in water and dilute to 1 L.

3 2

4.2 Photometric practice prescribed in these test methods

shall conform to Practice E 60. 14. Procedure

14.1 Transfer a 2.000-g sample, weighed to the nearest 0.1

5. Safety Precautions

mg, to a 250-mL poly(tetrafluoroethylene) or polypropylene

5.1 For precautions to be observed in the use of certain

beaker, add 2 mL of HF, and 30 mL of HNO (1 + 1). Cover

reagents in these test methods, refer to Practices E 50.

with a cover glass and allow to stand for a few minutes until the

reaction has nearly ceased. Warm but do not heat over 80°C.

6. Sampling

When dissolution is complete, add 25 mL of 3 % H O and 3

2 2

6.1 For procedures for sampling the material, refer to

mL of Pb(NO ) solution. Rinse the cover glass and dilute to

3 2

Practice E 255. However, this method does not supersede any

approximately 150 mL with NH Cl solution.

sampling requirements specified in a specific ASTM material

14.2 With the electrolyzing current off, position the anode

specification.

and the accurately weighed cathode in the solution so that the

gauze is completely immersed. Cover the beaker with a split

7. Rounding Calculated Values

plastic cover.

7.1 Calculated values shall be rounded to the desired num-

14.3 Start the electrolysis and increase the voltage until the

ber of places as directed in 3.4 to 3.6 of Practice E 29.

ammeter indicates a current which is equivalent to about 1.0

A/dm and electrolyze overnight. Alternatively electrolyze at a

8. Interlaboratory Studies

current density of 4 A/dm for 1.5 h. (The more rapid procedure

8.1 These test methods have been evaluated in accordance

requires the use of gauze electrodes).

with Practice E 173 unless otherwise noted in the precision

14.4 Slowly withdraw the electrodes (or lower the beaker)

section.

with the current still flowing, and rinse with a stream of water

from a wash bottle. Quickly remove the cathode, rinse it in

COPPER BY THE COMBINED

water, and then dip into two successive baths of ethanol or

ELECTRODEPOSITION GRAVIMETRIC AND

methanol. Dry in an oven at 110°C for 3 to 5 min.

OXALYLDIHYDRAZIDE PHOTOMETRIC TEST

14.5 Return the voltage to zero, and turn off the switch.

METHOD

Reserve the electrolyte.

14.6 Allow the electrode to cool to room temperature, and

9. Scope

weigh.

9.1 This test method covers the determination of copper in

concentrations greater than 50 %.

15. Calculation

10. Summary of Test Method 15.1 Calculate the percentage of copper as follows:

Copper, % 5 A 1 B/C 3 100 (1)

10.1 After dissolution of the sample in nitric and hydrof- @~ #

luoric acids, the oxides of nitrogen are reduced with hydrogen

peroxide, and the copper deposited electrolytically. Loss of

where:

platinum from the anode is minimized by the addition of lead.

A = deposited copper, g,

The copper oxalyldihydrazide complex is formed with the

B = copper in the electrolyte as calculated in 16.10, g, and

copper remaining in the electrolyte. Photometric measurement

C = sample used, g.

is made at approximately 540 nm.

16. Photometric Determination of the Residual Copper in

11. Interferences

the Electrolyte

11.1 The elements ordinarily present do not interfere if their

16.1 Interferences—The elements ordinarily present do not

concentrations are under the maximum limits shown in 1.1.

interfere if their concentrations are under the maximum limits

shown in 1.1.

12. Apparatus

16.2 Concentration Range—The recommended concentra-

12.1 Apparatus No. 9—Gauze cathodes are recommended

tion range is from 0.0025 to 0.07 mg of copper per 50 mL of

where rapid electrolysis is used.

solution, using a 2-cm cell.

12.2 Polytetrafluoroethylene or Polypropylene Beakers,

NOTE 1—This procedure has been written for cells having a 2-cm light

250-mL capacity.

path. Cells having other dimensions may be used, provided suitable

12.3 Polytetrafluoroethylene or Polypropylene Split Covers.

adjustments can be made in the amounts of sample and reagents used.

13. Reagents

16.3 Stability of Color—The color fully develops in 20 min,

13.1 Ammonium Chloride Solution (0.02 g/L)—Dissolve and is stable for 1 h.

0.02 g of ammonium chloride (NH Cl) in water and dilute to 1 16.4 Reagents:

L. 16.4.1 Acetaldehyde Solution (40 %)—Dilute 400 mL of

13.2 Hydrogen Peroxide (3 %)—Dilute 100 mL of 30 % acetaldehyde to 1 L with water.

hydrogen peroxide to 1 L. 16.4.2 Boric Acid Solution—Reagent No. 136.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 478 – 89a (1996)

16.4.3 Citric Acid Solution (200 g/L)—Dissolve 200 g of 16.10 Calculation—Convert the net photometric reading of

citric acid in water and dilute to 1 L. the test solution to milligrams of copper by means of the

16.4.4 Copper, Standard Solution A (1 mL = 1.0 mg Cu)— calibration curve. Calculate the grams of copper in the total

Transfer a 1.000-g sample of electrolytic copper (purity: electrolyte as follows:

99.9 % minimum) to a 250-mL beaker and add 10 mL of HNO

Copper, g 5 ~A 3 25!/1000 (2)

(1 + 1). Evaporate till nearly to dryness. Add 5 mL of water to

dissolve the residue. Transfer to a 1-L volumetric flask, dilute

where:

to volume, and mix.

A = copper found in 50 mL of the final test solution, mg.

16.4.5 Copper, Standard Solution B (1 mL = 0.010 mg

Cu)—Using a pipet, transfer 10 mL of copper solution A (1

mL = 1.0 mg Cu) to a 1-L volumetric flask, dilute to volume

17. Precision

and mix.

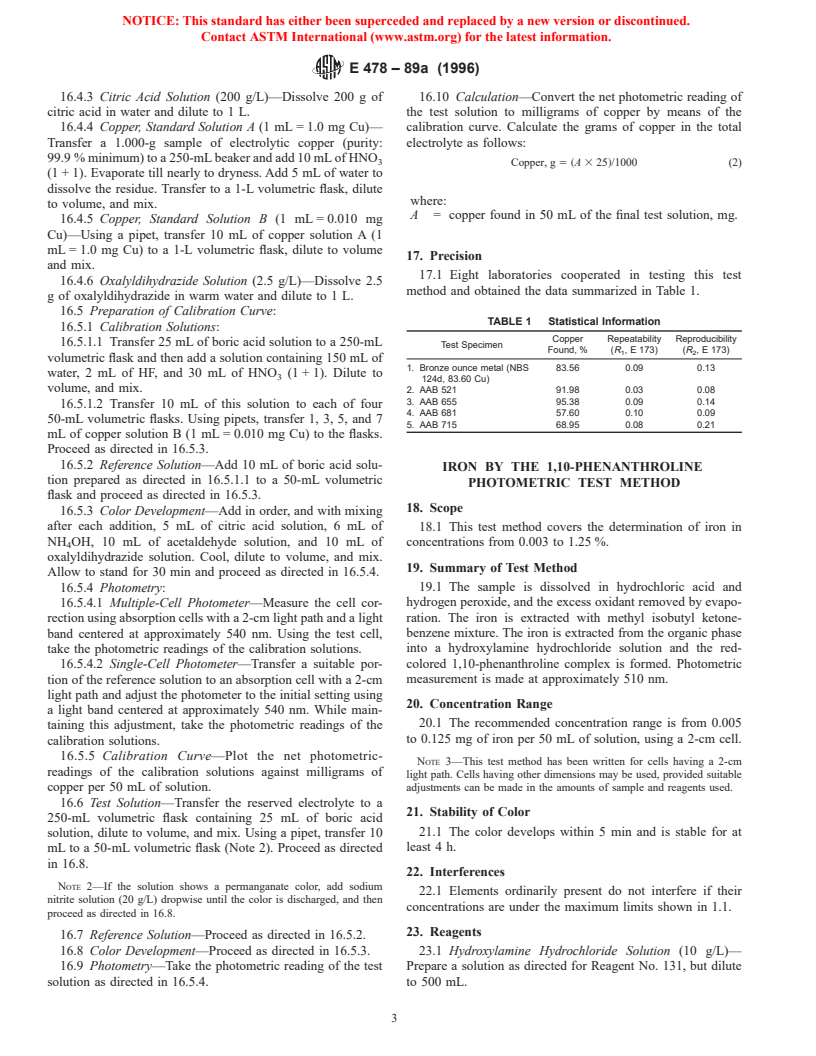

17.1 Eight laboratories cooperated in testing this test

16.4.6 Oxalyldihydrazide Solution (2.5 g/L)—Dissolve 2.5

method and obtained the data summarized in Table 1.

g of oxalyldihydrazide in warm water and dilute to 1 L.

16.5 Preparation of Calibration Curve:

TABLE 1 Statistical Information

16.5.1 Calibration Solutions:

Copper Repeatability Reproducibility

16.5.1.1 Transfer 25 mL of boric acid solution to a 250-mL

Test Specimen

Found, % (R , E 173) (R , E 173)

1 2

volumetric flask and then add a solution containing 150 mL of

1. Bronze ounce metal (NBS 83.56 0.09 0.13

water, 2 mL of HF, and 30 mL of HNO (1 + 1). Dilute to

124d, 83.60 Cu)

volume, and mix.

2. AAB 521 91.98 0.03 0.08

3. AAB 655 95.38 0.09 0.14

16.5.1.2 Transfer 10 mL of this solution to each of four

4. AAB 681 57.60 0.10 0.09

50-mL volumetric flasks. Using pipets, transfer 1, 3, 5, and 7

5. AAB 715 68.95 0.08 0.21

mL of copper solution B (1 mL = 0.010 mg Cu) to the flasks.

Proceed as directed in 16.5.3.

16.5.2 Reference Solution—Add 10 mL of boric acid solu-

IRON BY THE 1,10-PHENANTHROLINE

tion prepared as directed in 16.5.1.1 to a 50-mL volumetric

PHOTOMETRIC TEST METHOD

flask and proceed as directed in 16.5.3.

18. Scope

16.5.3 Color Development—Add in order, and with mixing

after each addition, 5 mL of citric acid solution, 6 mL of

18.1 This test method covers the determination of iron in

NH OH, 10 mL of acetaldehyde solution, and 10 mL of concentrations from 0.003 to 1.25 %.

oxalyldihydrazide solution. Cool, dilute to volume, and mix.

19. Summary of Test Method

Allow to stand for 30 min and proceed as directed in 16.5.4.

16.5.4 Photometry: 19.1 The sample is dissolved in hydrochloric acid and

hydrogen peroxide, and the excess oxidant removed by evapo-

16.5.4.1 Multiple-Cell Photometer—Measure the cell cor-

rection using absorption cells with a 2-cm light path and a light ration. The iron is extracted with methyl isobutyl ketone-

benzene mixture. The iron is extracted from the organic phase

band centered at approximately 540 nm. Using the test cell,

take the photometric readings of the calibration solutions. into a hydroxylamine hydrochloride solution and the red-

colored 1,10-phenanthroline complex is formed. Photometric

16.5.4.2 Single-Cell Photometer—Transfer a suitable por-

tion of the reference solution to an absorption cell with a 2-cm measurement is made at approximately 510 nm.

light path and adjust the photometer to the initial setting using

20. Concentration Range

a light band centered at approximately 540 nm. While main-

20.1 The recommended concentration range is from 0.005

taining this adjustment, take the photometric readings of the

to 0.125 mg of iron per 50 mL of solution, using a 2-cm cell.

calibration solutions.

16.5.5 Calibration Curve—Plot the net photometric-

NOTE 3—This test method has been written for cells having a 2-cm

readings of the calibration solutions against milligrams of

light path. Cells having other dimensions may be used, provided suitable

copper per 50 mL of solution. adjustments can be made in the amounts of sample and reagents used.

16.6 Test Solution—Transfer the reserved electrolyte to a

21. Stability of Color

250-mL volumetric flask containing 25 mL of boric acid

21.1 The color develops within 5 min and is stable for at

solution, dilute to volume, and mix. Using a pipet, transfer 10

least 4 h.

mL to a 50-mL volumetric flask (Note 2). Proceed as directed

in 16.8.

22. Interferences

NOTE 2—If the solution shows a permanganate color, add sodium

22.1 Elements ordinarily present do not interfere if their

nitrite solution (20 g/L) dropwise until the color is discharged, and then

concentrations are under the maximum limits shown in 1.1.

proceed as directed in 16.8.

23. Reagents

16.7 Reference Solution—Proceed as directed in 16.5.2.

16.8 Color Development—Proceed as directed in 16.5.3. 23.1 Hydroxylamine Hydrochloride Solution (10 g/L)—

16.9 Photometry—Take the photometric reading of the test Prepare a solution as directed for Reagent No. 131, but dilute

solution as directed in 16.5.4. to 500 mL.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 478 – 89a (1996)

23.2 Iron, Standard Solution A (1 mL = 0.125 mg Fe)— 25.1.2 Carry a reagent blank through the entire procedure,

Prepare a solution as directed for Reagent No. 4, but use using the same amounts of all

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.