ASTM G92-86(2003)

(Practice)Standard Practice for Characterization of Atmospheric Test Sites

Standard Practice for Characterization of Atmospheric Test Sites

SIGNIFICANCE AND USE

This practice gives suggested procedures for characterization of atmospheric test sites. It can be useful to researchers, manufacturers, engineering firms, architects, and construction contractors to provide corrosion and environmental data, materials selection information, and a materials storage practice.

This practice does not give specific parameters for classifying the type of test site. PROCEDURES Top

SCOPE

1.1 This practice gives suggested procedures for the characterization of atmospheric test sites. Continuous characterization can provide corrosion data, environmental data, or both which will signal changes in corrosivity of the atmospheric environment. This practice can also provide guidance for classification of future test sites.

1.2 Two methods are defined in this practice for the characterization of atmospheric test sites. The methods are identified as characterization Methods A and B. The preferred characterization technique would require using both Method A and B for concurrent data collection.

1.2.1 Method A is to be used when atmospheric corrosion is monitored on a continuing basis at a test site using specified materials and exposure configurations.

1.2.2 Method B is specified when atmospheric factors are monitored on a continuing basis.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G92 – 86 (Reapproved 2003)

Standard Practice for

Characterization of Atmospheric Test Sites

This standard is issued under the fixed designation G92; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G84 Practice for Measurement of Time-of-Wetness on Sur-

faces Exposed to Wetting Conditions as in Atmospheric

1.1 This practice gives suggested procedures for the char-

Corrosion Testing

acterization of atmospheric test sites. Continuous characteri-

G91 Practice for Monitoring Atmospheric SO Using the

ization can provide corrosion data, environmental data, or both 2

Sulfation Plate Technique

which will signal changes in corrosivity of the atmospheric

environment. This practice can also provide guidance for

3. Summary of Methods

classification of future test sites.

3.1 Characterization Method A is to be used when atmo-

1.2 Two methods are defined in this practice for the char-

spheric corrosion data are to be obtained.

acterization of atmospheric test sites. The methods are identi-

3.1.1 Corrosion tests to measure the corrosivity of the test

fied as characterization Methods A and B. The preferred

site should follow the procedure established by Practice G50.

characterization technique would require using both MethodA

Additional special instructions are identified in this procedure

and B for concurrent data collection.

relating to types of materials for corrosion characterization

1.2.1 MethodAis to be used when atmospheric corrosion is

tests, time of test exposure, positioning of test specimens,

monitored on a continuing basis at a test site using specified

removal of test specimens and proper identification, cleaning

materials and exposure configurations.

practices, and reporting of data.

1.2.2 Method B is specified when atmospheric factors are

3.2 Characterization Method B is to be used when atmo-

monitored on a continuing basis.

spheric climatological factors influencing the corrosion of

1.3 This standard does not purport to address all of the

metals are to be monitored.

safety concerns, if any, associated with its use. It is the

3.2.1 Several atmospheric factors which have been identi-

responsibility of the user of this standard to establish appro-

fied as having significant bearing on the corrosion of metals

priate safety and health practices and determine the applica-

include, but are not limited to, sulfur dioxide, chlorides,

bility of regulatory limitations prior to use.

temperature, humidity, precipitation, time of wetness, and

2. Referenced Documents atmospheric particulate matter.

3.3 The preferred technique utilizes both Methods A and B

2.1 ASTM Standards:

for concurrent data to be collected.

A36/A36M Specification for Carbon Structural Steel

3.3.1 Should either Method A or B be singled out as the

B6 Specification for Zinc

primary technique to be used on a continuing basis, both

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

should be used at some point in time to establish a data base.

sion Test Specimens

The availability of computerized weather stations greatly

G50 Practice for Conducting Atmospheric Corrosion Tests

facilitates the collection of reliable atmospheric data.

on Metals

4. Significance and Use

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

4.1 This practice gives suggested procedures for character-

of Metals and is the direct responsibility of Subcommittee G01.04 on Atmospheric

ization of atmospheric test sites. It can be useful to researchers,

Corrosion.

manufacturers, engineering firms, architects, and construction

Current edition approved Nov. 21, 1986. Published January 1987. DOI: 10.1520/

G0092-86R03.

contractors to provide corrosion and environmental data, ma-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

terials selection information, and a materials storage practice.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 This practice does not give specific parameters for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. classifying the type of test site.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G92 – 86 (2003)

PROCEDURES 5.2.2 An identifying code should be assigned to each

specimen. Locating a permanent code on each test specimen

5. Method A can be accomplished easily by using a code template (Fig. 1).

5.2.2.1 Pre-assignment of codes for a definite test period is

5.1 Materials:

suggested. After a temporary mark is placed on the specimen,

5.1.1 The materials recommended for conducting atmo-

a permanent drilled code (a series of 2.5 mm holes) should

spheric corrosion characterization studies are copper-bearing

perforate the test specimen.

structural carbon steel (such as Specification A36/A36M with

5.2.3 All test specimens of the same alloy should be cleaned

0.2 % copper min) and high-purity zinc (Specification B6 high

by the same procedure to ensure a comparative surface finish

grade).

following the guidance of Practice G1. The recommended

5.1.2 Materials recommended are the absolute minimum

practice suggested for cleaning is (a) degrease and pickle, if

required to serve as a characterization base for test sites.

necessary, to remove grease, mill scale, or other impurities; (b)

Additional materials should be added to meet individual needs.

scrub with pumice and britle brush until free of water-break;

Sufficient material should be obtained at the start to insure that

(c) dry with towels; and (d) place in a desiccator for 2 h before

an ample supply of the same heat is available to complete the

weighing.

characterization test. If tests are on-going and additional

materials must be obtained, care should be taken in attempting

5.2.4 Specimens should be weighed (61.0 mg) and original

to match material compositions. mass recorded on a data sheet (Table 1). Specific information,

such as nominal composition, density, and exposed area should

5.1.3 Sufficient specimens should be prepared to comply

with the specific criteria for the planned characterization test. also be recorded.

5.2.5 Specimensshouldbestoredinadesiccatororsealedin

5.2 Material Preparation:

airtight storage bags until the time of exposure.

5.2.1 Testspecimensshouldbeshearedtosize,forexample,

100 3 150 mm. 5.3 Exposure of Test Specimens:

* Template contains 126 drilled holes

FIG. 1 Sample Atmospheric Specimen Drill Code Identification Template

G92 – 86 (2003)

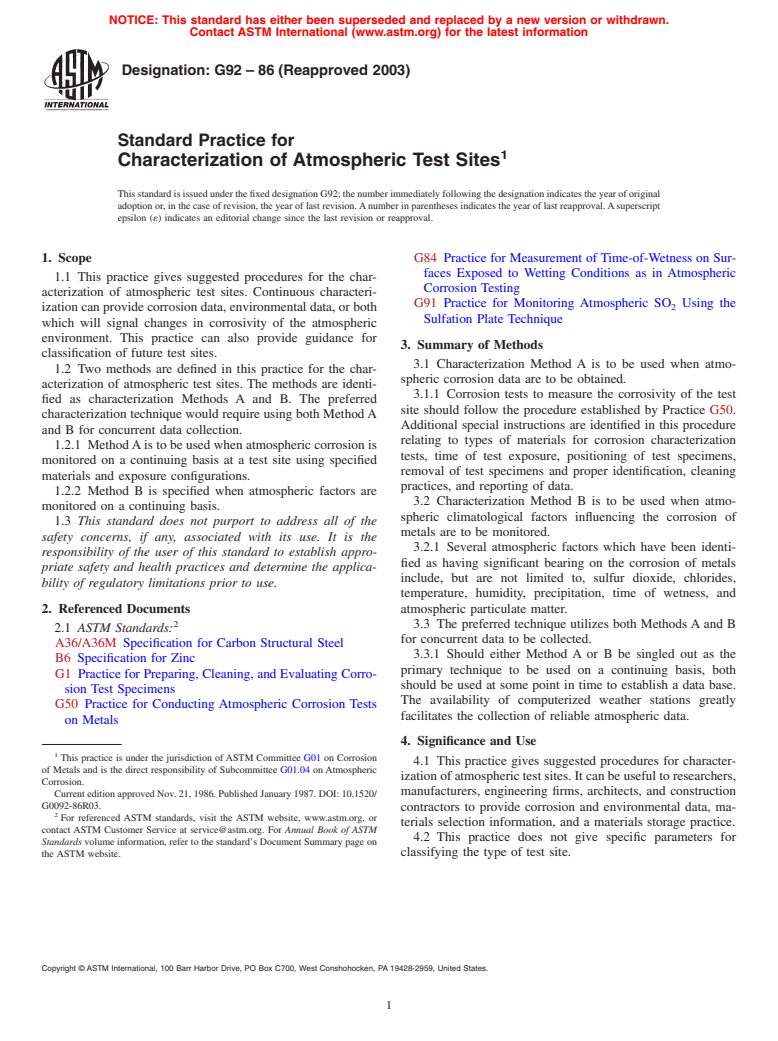

TABLE 1 Sample Data Sheet for Atmospheric Corrosion Data

Test Site: Kure Beach (250m lot) Latitude: 34° 008 N

Exposure Dates: 10/7/61 to 10/6/62 Longitude: 77° 558 W

Mass (g) Mass Loss Per Corrosion

Exposure

Material Code Unit Area Rate

Period (days)

Original Final Loss

(mg/m ) (mm/y)

Cu-steel A1-B2 365 196.583 187.332 9.251 2.86 3 10 0.0365

Zinc A2-B2 365 67.521 66.938 0.583 1.84 3 10 0.0026

Test Method Documentation

Steel Zinc

1. Composition (weight %) 0.15 C, 1.0 Mn, 0.01 P, 0.027 S, 0.24 Si, 0.01 Cu, 0.012 Cd, 0.03 Pb, 0.02 Fe,

0.21 Cu, 0.05 Ni, 0.03 Cr, Balance Fe Balance Zn

3 3 3

2. Density (g/cm ) 7.85 g/cm 7.13 g/cm

3. Dimensions (mm) 100 3 150 3 2.00 mm 100 3 150 3 2.00 mm

2 2 2

4. Exposed area (cm ) 322.9 cm 317.7 cm

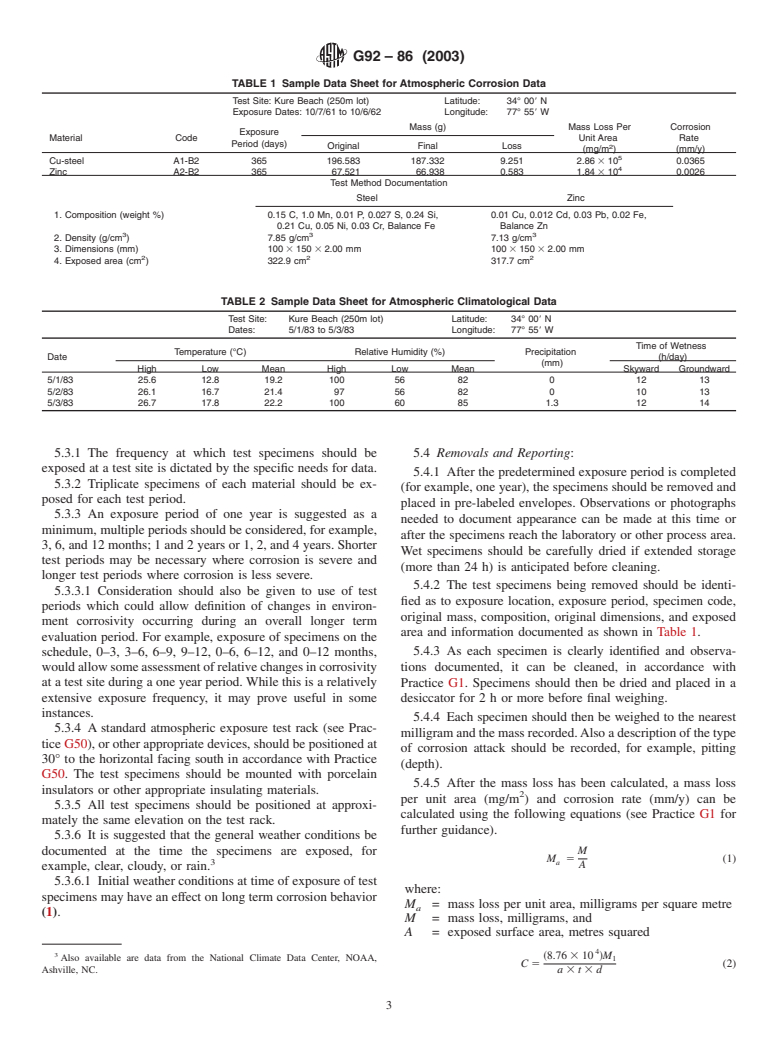

TABLE 2 Sample Data Sheet for Atmospheric Climatological Data

Test Site: Kure Beach (250m lot) Latitude: 34° 008 N

Dates: 5/1/83 to 5/3/83 Longitude: 77° 558 W

Time of Wetness

Temperature (°C) Relative Humidity (%) Precipitation

Date (h/day)

(mm)

High Low Mean High Low Mean Skyward Groundward

5/1/83 25.6 12.8 19.2 100 56 82 0 12 13

5/2/83 26.1 16.7 21.4 97 56 82 0 10 13

5/3/83 26.7 17.8 22.2 100 60 85 1.3 12 14

5.3.1 The frequency at which test specimens should be 5.4 Removals and Reporting:

exposed at a test site is dictated by the specific needs for data.

5.4.1 After the predetermined exposure period is completed

5.3.2 Triplicate specimens of each material should be ex-

(for example, one year), the specimens should be removed and

posed for each test period.

placed in pre-labeled envelopes. Observations or photographs

5.3.3 An exposure period of one year is suggested as a

needed to document appearance can be made at this time or

minimum, multiple periods should be considered, for example,

after the specimens reach the laboratory or other process area.

3, 6, and 12 months; 1 and 2 years or 1, 2, and 4 years. Shorter

Wet specimens should be carefully dried if extended storage

test periods may be necessary where corrosion is severe and

(more than 24 h) is anticipated before cleaning.

longer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.