ASTM D608-90(2001)

(Specification)Standard Specification for Dibutyl Phthalate

Standard Specification for Dibutyl Phthalate

SCOPE

1.1 This specification covers dibutyl phthalate (99% grade).

1.2 For specific hazard information and guidance, see the supplier's Material Safety Data Sheet for materials listed in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 608 – 90 (Reapproved 2001)

Standard Specification for

Dibutyl Phthalate

This standard is issued under the fixed designation D 608; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

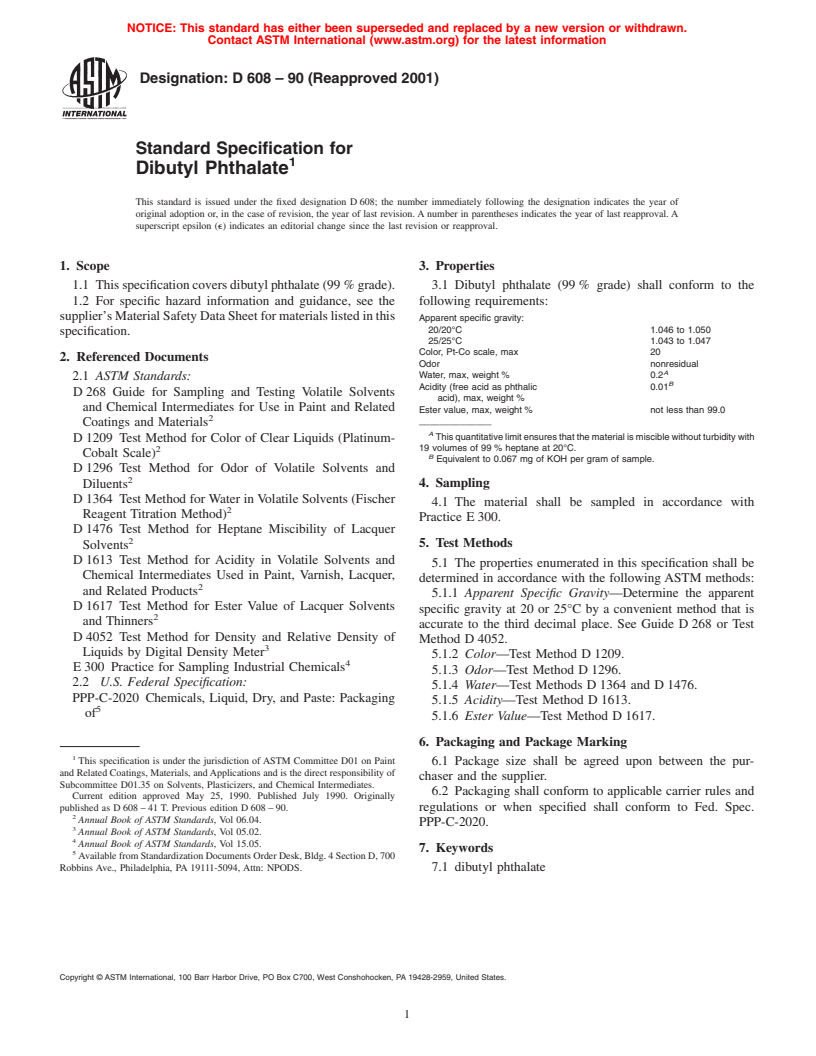

1. Scope 3. Properties

1.1 Thisspecificationcoversdibutylphthalate(99 %grade). 3.1 Dibutyl phthalate (99 % grade) shall conform to the

1.2 For specific hazard information and guidance, see the following requirements:

supplier’sMaterialSafetyDataSheetformaterialslistedinthis

Apparent specific gravity:

20/20°C 1.046 to 1.050

specification.

25/25°C 1.043 to 1.047

Color, Pt-Co scale, max 20

2. Referenced Documents

Odor nonresidual

A

Water, max, weight % 0.2

2.1 ASTM Standards:

B

Acidity (free acid as phthalic 0.01

D 268 Guide for Sampling and Testing Volatile Solvents

acid), max, weight %

and Chemical Intermediates for Use in Paint and Related

Ester value, max, weight % not less than 99.0

______________

Coatings and Materials

A

Thisquantitativelimitensuresthatthematerialismisciblewithoutturbiditywith

D 1209 Test Method for Color of Clear Liquids (Platinum-

2 19 volumes of 99 % heptane at 20°C.

Cobalt Scale)

B

Equivalent to 0.067 mg of KOH per gram of sample.

D 1296 Test Method for Odor of Volatile Solvents and

Diluents 4. Sampling

D 1364 Test Method for Water in Volatile Solvents (Fischer

4.1 The material shall be sampled in accordance with

Reagent Titration Method)

Practice E 300.

D 1476 Test Method for Heptane Miscibility of Lacquer

5. Test Methods

Solvents

D 1613 Test Method for Acidity in Volatile Solvents and

5.1 The properties enumerated in this specification shall be

Chemical Intermediates Used in Paint, Varnish, Lacquer,

determined in accordance with the following ASTM methods:

and Related Products

5.1.1 Apparent Specific Gravity—Determine the apparent

D 1617 Test Method for Ester Value of Lacquer Solvents

specific gravity at 20 or 25°C by a convenient method that is

and Thinners

accurate to the third decimal place. See Guide D 268 or Test

D 4052 Test Method for Density and Relative Density of

Method D 4052.

Liquids by Digital Density Meter

5.1.2 Color—Test Method D 1209.

E 300 Practice for Sampling Industrial Chemicals

5.1.3 Odor—Test Method D 1296.

2.2 U.S. Feder

...

This May Also Interest You

SIGNIFICANCE AND USE

5.1 Earlier methods for characterizing turpentine and related terpene products were based on physical properties, such as those in Specification D13 and Test Methods D801 and D802, and packed column gas chromatography for the major constituents (for example, α-pinene, β-pinene) as in Test Method D3009. As terpene products became widely used as chemical raw material, the separation and quantitation of compounds present at lower concentrations in the product became more important. The capillary gas chromatographic technique described in these test methods is a rapid and convenient means to perform these analyses.

SCOPE

1.1 These test methods describe the determination of the amounts of α-pinene, β-pinene, dipentene, terpene alcohols, and other terpene compounds in turpentine and related terpene products using capillary gas chromatography. The two methods for determining the amount of the individual terpene compounds are the “internal standard” method, which yields absolute values, and the “area percent” method, which yields relative values.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of the standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: Overall this test method gives excellent repeatability but only moderate reproducibility. This greater than normal differential is a consequence of the variety of gas chromatography (GC) columns and other variables used by participants. These variables, coupled with the complex composition of the test products, enabled some workers to separate peaks that others reported as one peak; thus, this test method gives excellent precision within a given laboratory on a given GC. When laboratory to laboratory comparison have to be made, however, it is essential that the GC operating conditions be defined closely.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method is useful for determining low levels of acidity, below 0.05 %, in organic compounds and hydrocarbon mixtures. The total acidity is calculated as acetic acid or milligrams of sodium hydroxide per gram of sample.

4.2 Acidity may be present as a result of contamination, decomposition during storage or distribution, or manufacture. This test method may be used in assessing compliance with a specification.

SCOPE

1.1 This test method covers the determination of total acidity as acetic acid, in concentrations below 0.05 %, in organic compounds and hydrocarbon mixtures used in paint, varnish, and lacquer solvents and diluents. It is known to be applicable to such mixtures as low molecular weight saturated and unsaturated alcohols, ketones, ethers, esters, hydrocarbon diluents, naphtha, and other light distillate petroleum fractions.

1.2 For purposes of determining conformance of an observed value or a calculated value using this test method to relevant specifications, test result(s) shall be rounded off “to the nearest unit” in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E29.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 For specific hazard information and guidance consult supplier’s Safety Data Sheet.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Since the desired specifications and compositions of soluble nitrocellulose base solutions vary greatly, these methods are used to establish whether limits that shall be as agreed upon between the producer and the user have been met.

SCOPE

1.1 This guide covers the testing of soluble nitrocellulose base solutions that are made by dispersing various kinds and concentrations of soluble nitrocellulose (cellulose nitrate) in various solvent mixtures.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 11.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide4 pagesEnglish languagesale 15% off

- Guide4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The comparative odor characteristics can be used, combined with other tests, for product identification and assessing compliance with a specification.

3.2 The residual odor characteristics can be used to judge the presence of relatively nonvolatile materials that may be associated with manufacture or contamination during distribution. Since volatile solvents and diluents are used in a wide variety of chemical processes and residual materials may affect the efficiency of such processes, this test method provides a comparative test for manufacturing control and assessing compliance with a specification.

SCOPE

1.1 This test method covers a comparative procedure for observing the characteristic and residual odors of volatile organic solvents and diluents to determine their odor acceptability in a solvent system.

1.2 It is not intended that this test method be employed to determine subtle odor differences between materials or to determine odor intensity.

1.3 It is recommended that this test method not be employed to determine the residual odor of a liquid if its time for evaporation to dryness at room temperature exceeds 30 min or as agreed upon.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 4.

1.6 For specific hazard information, see the supplier's Material Safety Data Sheet (MSDS).

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 VAM is an organic vinyl ester compound. This colorless liquid is the precursor to polyvinyl acetate, an important industrial polymer. VAM may be subject to rapid spontaneous polymerization if the inhibitor is not present or becomes depleted during prolonged storage.

4.2 VAM is typically shipped with a HQ inhibitor as free radical scavenger. VAM should be evaluated to ensure that appropriate systems (for example, temperature and inhibitor quantity) are assured during storage, transportation, and getting prolonged shelf life.

4.3 Most VAM shipped from the manufacturer will contain an inhibitor, typically 3 to 5 ppm HQ for regional shipments and up to 25 ppm HQ for long-range shipments.

SCOPE

1.1 This test method covers the determination of hydroquinone (HQ) in colorless vinyl acetate monomer (VAM). This test method is applicable to the determination of HQ in the concentration range from 1 to 25 ppm.

1.2 For purposes of determining conformance of an observed or a calculated value using this test method to relevant specifications, test result(s) shall be rounded off “to the nearest unit” in the last right-hand digit used in expressing the specification limit in accordance with Practice E29.

1.3 For ensuring safety, hazard information and guidance, follow the manufacturer’s material safety data sheet.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SCOPE

1.1 Although the pine chemical industry has been a continuing producer of chemical products for many centuries, the nature of the industry, its products, and its terminology have changed. In particular, the original practice of recovering pine chemical through the processing of the exudate from pine trees has been supplemented by their extraction by solvent products of the wood pulping industry. For many years the industry was known as the Naval Stores industry but that term has gradually been replaced by the more descriptive and meaningful term, Pine Chemicals Industry. Thus, this terminology contains some old terms now mostly of historic value, together with the terms of the modern pine chemical industry.2

1.2 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The testing procedures described in these test methods have been in use for many years and emphasize the physical properties rather than the chemical composition of dipentene. These procedures were sufficient when dipentene was used primarily as a solvent. Currently, however, dipentene finds application as a chemical raw material and a knowledge of its chemical composition is therefore important. Test Methods D6387 describe a capillary gas chromatography method which is suitable for determining both the major and minor components found in dipentene.

SCOPE

1.1 These test methods cover procedures for sampling and testing dipentene and related terpene solvents, consisting chiefly of monocyclic terpene hydrocarbons distilling above the range for turpentine.

1.2 The procedures given in these test methods appear in the following order:

Section

Sampling

4

Detection and Removal of Separated Water

5

Appearance

6

Color

7

Odor

8

Specific Gravity

9

Refractive Index

10

Composition

11

Flash Point

12

Moisture

13

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The test procedures described in this standard were developed when the chief use for turpentine was as a solvent. Currently however, the chief use for turpentine (and pinenes) is as raw materials for the production of resins and synthetic organic chemicals. Thus the chemical composition of turpentines and pinenes is extremely important and tests, in addition to the ones described in these test methods, are required in order to fully characterize turpentines and pinenes. The most widely used technique for determining the chemical composition of turpentines (and pinenes) is gas chromatography (see Test Methods D6387).

SCOPE

1.1 These test methods cover procedures for sampling and testing turpentine, as defined by the Code of Federal Regulations and Terminology D804. These test methods are also used for the sampling and testing of pinenes, the major components of most turpentines.

1.2 These test methods primarily measure the physical rather than the chemical properties of turpentines and pinenes. As turpentines and pinenes are currently used chiefly as chemical raw materials for the production of resins and synthetic organic chemicals, chemical composition is also very important. Consequently, testing the chemical composition of turpentines and pinenes by gas chromatography has displaced these test methods to a large extent. (See for example Test Methods D6387.)

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Many pine chemical products contain water as a result of the processes used for their production. Typically refined products such as terpenes, pine oil, tall oil fatty acids, and distilled tall oil contain only traces of water, but crude tall oil might contain 0.5 % to 2.5 % of water. Although the Karl Fischer and coulometric methods are most applicable to low levels of moisture, these can be and are used at higher levels. The azeotropic distillation method is generally used at higher levels.

SCOPE

1.1 These test methods cover the quantitative determination of dissolved or occluded water present in any proportion in liquid pine chemicals, such as turpentine, pinene, dipentene, pine oil, tall oil, and tall oil fatty acids. Three methods of moisture testing are included. The Karl Fisher titration method is the preferred method for testing tall oil, Test Methods D803.

1.1.1 The Karl Fischer Titration method is based on the reaction between water and a complex reagent2 consisting of iodine, sulfur dioxide, pyridine, and methanol, whereby the iodine is converted to a colorless compound. The appearance of a persistent iodine color in the reaction mixture indicates the complete removal of free water by reaction with the reagent, and the endpoint may be measured colorimetrically. Automatic titrators find this endpoint by the restoration of a current strength when the resistance provided by the presence of water is eliminated. Amperometric automatic titrators find this endpoint by detecting the current flow that occurs once water is eliminated.

1.1.2 The coulometric titration method determines water content by electronic integration of a current sufficient to generate the precise amount of iodine from the required reagent to react with the water in the sample.

1.1.3 The azeotropic method utilizes the relatively low boiling point of water, as compared with other sample constituents, in a toluene or xylene matrix so that water is collected in a trap and measured.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 In order to calculate the volatile organic content (VOC) of paints containing EPA exempt solvents, it is necessary to know the acetone, methyl acetate, or parachlorobenzotrifluoride content. This gas chromatographic test method provides a simple and direct way for measuring these solvents. Each analyte is measured with respect to a unique internal standard. For acetone, the internal standard used is acetone-d6, for methyl acetate it is methyl acetate-d3, and for PCBTF it is metachlorobenzotrifluoride (MCBTF). These unique analyte/internal standard pairs behave very nearly as single solvents with respect to evaporation rate and adsorption rate onto a coated silica fiber (SPME) but are separable on a gas chromatograph (GC) capillary column. The only critical analytical technique required for successfully performing this test method is the ability of an analyst to weigh a paint sample and internal standard, corresponding to the analyte of interest, into a septum capped vial. After weighing, solvent evaporation has no effect on the final value of the determination. Since whole paint is not injected into the gas chromatograph, the analytical system is never compromised.

SCOPE

1.1 This test method is for the determination of acetone, methyl acetate, or parachlorobenzotrifluoride (PCBTF), or combination of any of the three, in paints and coatings, by solid phase microextraction (SPME) headspace sampling, and subsequent injection into a gas chromatograph. It has been evaluated for cellulose nitrate, acrylic, and urethane solvent-borne systems. The established working range of this test method is: acetone, 28 to 90 %; methyl acetate, 12 to 22 %; parachlorobenzotrifluoride, 10 to 17 %. There is no reason to believe that it will not work outside these ranges. A minor modification of this test method would make it suitable for the analysis of the same analytes in water-borne coatings (see Note 1).

Note 1: Water-borne paints are internally standardized and diluted with water followed by addition of solid sodium chloride.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.