ASTM A313/A313M-98

(Specification)Standard Specification for Stainless Steel Spring Wire

Standard Specification for Stainless Steel Spring Wire

SCOPE

1.1 This specification covers austenitic and age-hardenable stainless steel round spring wire intended especially for the manufacture of springs.

1.2 The values stated in inch-pound units or SI units are to be regarded separately as the standard. Within the text and tables, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 Unless the order specifies an "M" designation, the material shall be furnished to inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 313/A 313M – 98

Standard Specification for

Stainless Steel Spring Wire

This standard is issued under the fixed designation A 313/A 313M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.5 Type designation (Table 1),

3.1.6 ASTM designation and date of issue,

1.1 This specification covers austenitic and age-hardenable

3.1.7 Supplementay requirements for government procure-

stainless steel round spring wire intended especially for the

ment, and

manufacture of springs.

3.1.8 Special requirements.

1.2 The values stated in inch-pound units or SI units are to

be regarded separately as the standard. Within the text and

NOTE 1—A typical ordering description is as follows:

tables, the SI units are shown in brackets. The values stated in

2000 lb (1000 kg) Stainless Steel Spring Wire, cold-drawn Class 1,

bright finish, 0.032-in. (0.82 mm) diameter, in 100-lb (50 kg) 16-in. (0.4

each system are not exact equivalents; therefore, each system

m) coils, Type 302 to ASTM A 313, dated ____.

must be used independently of the other. Combining values

from the two systems may result in nonconformance with the

4. General Requirements for Delivery

specification.

4.1 In addition to the requirements of this specification, all

1.3 Unless the order specifies an “M” designation, the

requirements of the current edition of Specification A 555/

material shall be furnished to inch-pound units.

A 555M shall apply. Failure to comply with the general

2. Referenced Documents requirements of Specification A 555/A 555M constitutes non-

conformance with this specification.

2.1 ASTM Standards:

A 555/A555M Specification for General Requirements for

5. Manufacture

Stainless Steel Wire and Wire Rods

5.1 Types 302 Class 1, 304, 305, 316, 321, 347, and Grades

A 751 Test Methods, Practices, and Terminology for

S20430 and XM-28 shall be cold drawn to produce the

Chemical Analysis of Steel Products

3 required mechanical properties.

E 527 Practice for Numbering Metals and Alloys (UNS)

5.2 Type 631, Type 302 Class 2, and Grade XM-16 shall be

2.2 Society of Automotive Engineers Standard:

4 furnished in the cold-drawn condition ready for fabrication.

J 1086 Numbering Metals and Alloys

Following fabrication Type 631 and Grade XM-16 shall be age

3. Ordering Information or precipitation hardened to produce their maximum strength

properties. The tensile strengths to be obtained following the

3.1 It is the responsibility of the purchaser to specify all

prescribed heat treatment are shown in Table 2 and Table 3 for

requirements that are necessary for material ordered under this

hardened wire. Type 302 Class 2 shall be stress relieved

specification. Such requirements may include, but are not

following fabrication and meet the requirements shown in

limited to the following:

Table 4. The nominal as-drawn tensile strengths are provided

3.1.1 Quantity (weight),

as a guide for the spring manufacturer.

3.1.2 Name of material (stainless steel spring wire),

3.1.3 Finish (see 8.1),

6. Chemical Composition

3.1.4 Dimension (diameter),

6.1 The steel shall conform to the requirements as to

chemical composition prescribed in Table 1.

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, 6.2 Methods and practices relating to chemical analysis

Stainless Steel and Related Alloys, and is the direct responsibility of Subcommittee

required by this specification shall be in accordance with Test

A01.17 on Flat Stainless Steel Products.

Methods, Practices, and Terminology A 751.

Current edition approved Sept. 10, 1998. Published December 1998. Originally

published as A 313 – 47 T. Last previous edition A 313/A 313M – 95a.

2 7. Mechanical Requirements

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.01.

7.1 Tensile Properties:

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Dr., Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 313/A 313M – 98

TABLE 1 Chemical Requirements

B

UNS Desig- Type Composition, %

A

nation

Carbon Manganese Phosphorus Sulfur Silicon Chromium Nickel Molybdenum Nitrogen Other Elements

Austenitic Grades

S 24100 XM-28 0.15 11.0–14.0 0.060 0.030 1.00 16.5–19.0 0.50– 2.50 0.20–0.45

S 30200 302 0.12 2.00 0.045 0.030 1.00 17.0–19.0 8.0– 9.5 0.10

S 30400 304 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–10.5 0.10

S 30500 305 0.12 2.00 0.045 0.030 1.00 17.0–19.0 10.5–13.0

S 31600 316 0.07 2.00 0.045 0.030 1.00 16.5–18.0 10.5–13.5 2.00–2.50 0.10

S 32100 321 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 Ti 53C min

S 34700 347 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 (Cb + Ta) 103C min

Age-Hardenable Grades

S 17700 631 0.09 1.00 0.040 0.030 1.00 16.0–18.0 6.50– 7.8 Al 0.75–1.50

S 45500 XM-16 0.05 0.50 0.040 0.030 0.50 11.0–12.5 7.50– 9.5 0.50 max Ti 0.80–1.40

Cu 1.50–2.50

(Cb + Ta) 0.10–0.50

S 20430 . . . 0.15 6.5–9.0 0.060 0.030 1.00 15.5–17.5 1.50– 3.50 0.05–0.25 Cu 2.0–4.0

A

New designations established in accordance with Practice E 527 and SAE J 1086, Practice for Numbering Metals and Alloys (UNS).

B

Maximum unless range is shown.

A

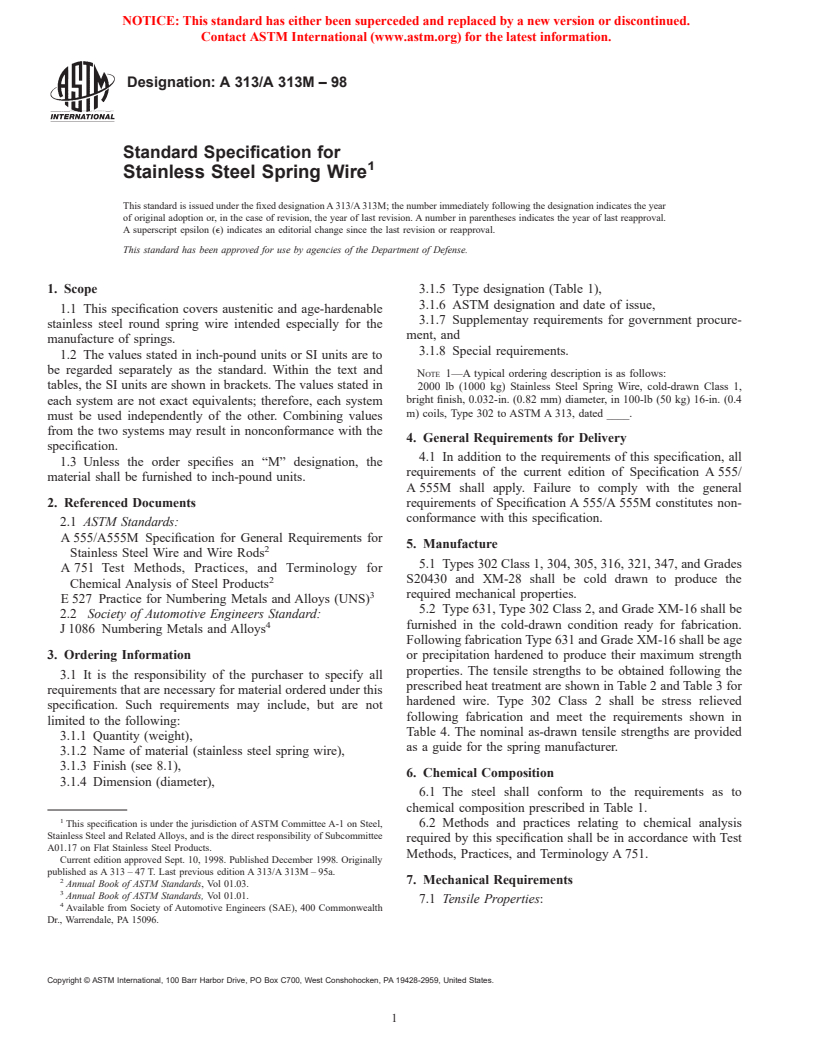

TABLE 2 Tensile Strength Requirements for Type 631

B

Diameter, in. [mm] Cold Drawn Condition Condition CH-900 , ksi [MPa]

C, ksi [MPa]

min max

Nominal

0.010 [0.25] to 0.015 [0.38], incl 295 [2035] 335 [2310] 365 [2515]

Over 0.015 [0.38] to 0.020 [0.51], incl 290 [2000] 330 [2275] 360 [2480]

Over 0.020 [0.51] to 0.029 [0.74], incl 285 [1965] 325 [2240] 355 [2450]

Over 0.029 [0.74] to 0.041 [1.04], incl 275 [1895] 320 [2205] 350 [2415]

Over 0.041 [1.04] to 0.051 [1.30], incl 270 [1860] 310 [2135] 340 [2345]

Over 0.051 [1.30] to 0.061 [1.55], incl 265 [1825] 305 [2100] 335 [2310]

Over 0.061 [1.55] to 0.071 [1.80], incl 257 [1770] 297 [2050] 327 [2255]

Over 0.071 [1.80] to 0.086 [2.18], incl 255 [1760] 292 [2015] 322 [2220]

Over 0.086 [2.18] to 0.090 [2.29], incl 245 [1690] 282 [1945] 312 [2150]

Over 0.090 [2.29] to 0.100 [2.54], incl 242 [1670] 279 [1925] 309 [2130]

Over 0.100 [2.54] to 0.106 [2.69], incl 238 [1640] 274 [1890] 304 [2095]

Over 0.106 [2.69] to 0.130 [3.30], incl 236 [1625] 272 [1875] 302 [2080]

Over 0.130 [3.30] to 0.138 [3.50], incl 230 [1585] 260 [1795] 290 [2000]

Over 0.138 [3.50] to 0.146 [3.71], incl 228 [1570] 258 [1780] 288 [1985]

Over 0.146 [3.71] to 0.162 [4.11], incl 226 [1560] 256 [1765] 286 [1970]

Over 0.162 [4.11] to 0.180 [4.57], incl 224 [1545] 254 [1750] 284 [1960]

Over 0.180 [4.57] to 0.207 [5.26], incl 222 [1530] 252 [1740] 282 [1945]

Over 0.207 [5.26] to 0.225 [5.72], incl 218 [1505] 248 [1710] 278 [1915]

Over 0.225 [5.72] to 0.306 [7.77], incl 213 [1470] 242 [1670] 272 [1875]

Over 0.306 [7.77] to 0.440 [11.2], incl 207 [1425] 235 [1620] 265 [1825]

Over 0.440 [11.2] to 0.625 [15.88], incl 203 [1400] 230 [1585] 260 [1795]

A

When wire is specified in straightened and cut lengths, the minimum tensile strength shall be 90 % of the values listed in the table.

B

Aged at 900°F [482°C] for 1 h and air cooled.

7.1.1 Types 302 Class 1 and 304 shall conform to the 7.2.1 Wire 0.162 in. [4.11 mm] and smaller in diameter shall

requirements shown in Table 5. wind on itself as an arbor without breaking.

7.1.2 Types 305, 316, 321, and 347 shall conform to the 7.2.2 Wire larger than 0.162 in. [4.11 mm] in diameter shall

requirements shown in Table 6. wind without breaking on a mandrel having a diameter twice

7.1.3 Type 631 shall conform to the requirements shown in the diameter of the wire.

Table 2 when heat treated 900°F [482°C] for 1 h and air cooled. 7.3 Uniformity (Coil Test):

7.1.4 Grade XM-16 shall conform to the requirements

7.3.1 In the as-cold drawn condition, a specimen coil shall

shown in Table 3 when heat treated 850°F [454°C] for ⁄2h and be wound on an arbor of the size specified in Table 9 to form

air cooled.

a tightly wound coil.

7.1.5 Grade XM-28 shall conform to the requirements 7.3.2 After winding, the specimen coil shall be stretched to

shown in Table 7. a permanent set four times its as-wound length. After this

7.1.6 Type 302 Class 2 shall conform to the requirements treatment, the specimen coil shall show uniform pitch with no

shown in Table 4. splits or fractures.

7.1.7 Grade S20430 shall conform to the requirements

7.4 Cast—A loop or ring shall be cut from the bundle and

shown in Table 8. allowed to fall on the floor. The wire shall lie flat and not spring

7.2 Wrap Test: up or show a wavy condition.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 313/A 313M – 98

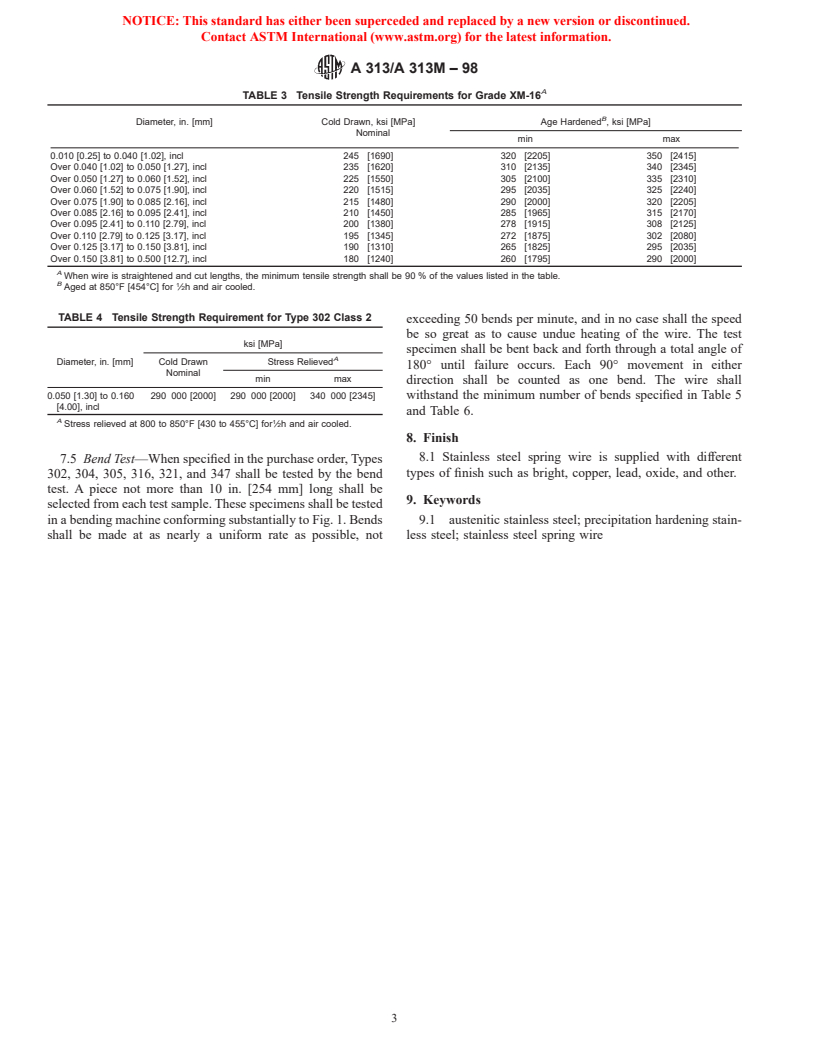

A

TABLE 3 Tensile Strength Requirements for Grade XM-16

B

Diameter, in. [mm] Cold Drawn, ksi [MPa] Age Hardened , ksi [MPa]

Nominal

min max

0.010 [0.25] to 0.040 [1.02], incl 245 [1690] 320 [2205] 350 [2415]

Over 0.040 [1.02] to 0.050 [1.27], incl 235 [1620] 310 [2135] 340 [2345]

Over 0.050 [1.27] to 0.060 [1.52], incl 225 [1550] 305 [2100] 335 [2310]

Over 0.060 [1.52] to 0.075 [1.90], incl 220 [1515] 295 [2035] 325 [2240]

Over 0.075 [1.90] to 0.085 [2.16], incl 215 [1480] 290 [2000] 320 [2205]

Over 0.085 [2.16] to 0.095 [2.41], incl 210 [1450] 285 [1965] 315 [2170]

Over 0.095 [2.41] to 0.110 [2.79], incl 200 [1380] 278 [1915] 308 [2125]

Over 0.110 [2.79] to 0.125 [3.17], incl 195 [1345] 272 [1875] 302 [2080]

Over 0.125 [3.17] to 0.150 [3.81], incl 190 [1310] 265 [1825] 295 [2035]

Over 0.150 [3.81] to 0.500 [12.7], incl 180 [1240] 260 [1795] 290 [2000]

A

When wire is straightened and cut lengths, the minimum tensile strength shall be 90 % of the values listed in the table.

B

Aged at 850°F [454°C] for ⁄2h and air cooled.

TABLE 4 Tensile Strength Requirement for Type 302 Class 2

exceeding 50 bends per minute, and in no case shall the speed

be so great as to cause undue heating of the wire. The test

ksi [MPa]

specimen shall be bent back and forth through a total angle of

A

Diameter, in. [mm] Cold Drawn Stress Relieved

180° until failure occurs. Each 90° movement in either

Nominal

min max

direction shall be counted as one bend. The wire shall

0.050 [1.30] to 0.160 290 000 [2000] 290 000 [2000] 340 000 [2345]

withstand the minimum number of bends specified in Table 5

[4.00], incl

and Table 6.

A

Stress relieved at 800 to 850°F [430 to 455°C] for ⁄2h and air cooled.

8. Finish

7.5 Bend Test—When specified in the purchase order, Types 8.1 Stainless steel spring wire is supplied with different

types of finish such as bright, copper, lead, oxide, and other.

302, 304, 305, 316, 321, and 347 shall be tested by the bend

test. A piece not more than 10 in. [254 mm] long shall be

9. Keywords

selected from each test sample. These specimens shall be tested

in a bending machine conforming substantially to Fig. 1. Bends 9.1 austenitic stainless steel; precipitation hardening stain-

shall be made at as nearly a uniform rate as possible, not less steel; stainless steel spring wire

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 313/A 313M – 98

A

TABLE 5 Tensile Strength Requirements for Types 302 Class 1 and 304

Bend Test Minimum Number of ksi [MPa]

Diameter, in. [mm]

Bends

min max

Up to 0.009 [0.23], incl . . . 325 [2240] 355 [2450]

Over 0.009 [0.23] to 0.010 [0.25], incl . . . 320 [2205] 350 [2415]

Over 0.010 [0.25] to 0.011 [0.28], incl . . . 318 [2190] 348 [2400]

Over 0.011 [0.28] to 0.012 [0.30], incl . . . 316 [2180] 346 [2385]

Over 0.012 [0.30] to 0.013 [0.33], incl . . . 314 [2165] 344 [2370]

Over 0.013 [0.33] to 0.014 [0.36], incl . . . 312 [2150] 342 [2360]

Over 0.014 [0.36] to 0.015 [0.38], incl . . . 310 [2135] 340 [2345]

Over 0.015 [0.38] to 0.016 [0.41], incl . . . 308 [2125] 338 [2330]

Over 0.016 [0.41] to 0.017 [0.43], incl . . . 306 [2110] 336 [2315]

Over 0.017 [0.43] to 0.018 [0.46], incl . . . 304 [2095] 334 [2300]

Over 0.018 [0.46] to 0.020 [0.51], incl . . . 300 [2070] 330 [2275]

Over 0.020 [0.51] to 0.022 [0.56], incl . . . 296 [2040] 326 [2250]

Over 0.022 [0.56] to 0.024 [0.61], incl . . . 292 [2015] 322 [2220]

Over 0.024 [0.61] to 0.026 [0.66], incl 8 291 [2005] 320 [2205]

Over 0.026 [0.66] to 0.028 [0.71], incl 8 289 [1995] 318 [2190]

Over 0.028 [0.71] to 0.031 [0.79], incl 8 285 [1965] 315 [2170]

Over 0.031 [0.79] to 0.034 [0.86], incl 8 282 [1945] 310 [2135]

Over 0.034 [0.86] to 0.037 [0.94], incl 8 280 [1930] 308 [2125]

Over 0.037 [0.94] to 0.041 [1.04], incl 8 275 [1895] 304 [2095]

Over 0.041 [1.04] to 0.045 [1.14], incl 8 272 [1875] 300 [2070]

Over 0.045 [1.14] to 0.050 [1.27], incl 8 267 [1840] 295 [2035]

Over 0.050 [1.27] to 0.054 [1.37], incl 8 265 [1825] 293 [2020]

Over 0.054 [1.37] to 0.058 [1.47], incl 7 261 [1800] 289 [1990]

Over 0.058 [1.47] to 0.063 [1.60], incl 7 258 [1780] 285 [1965]

Over 0.063 [1.60] to 0.070 [1.78], incl 7 252 [1735] 281 [1935]

Over 0.070 [1.78] to 0.075 [1.90], incl 7 250 [1725] 278 [1915]

Over 0.075 [1.90] to 0.080 [2.03], incl 7 246 [1695] 275 [1895]

Over 0.080 [2.03] to 0.087 [2.21], incl 7 242 [1670] 271 [1870]

Over 0.087 [2.21] to 0.095 [2.41], incl 7 238 [1640] 268 [1850]

Over 0.095 [2.41] to 0.105 [2.67], incl 5 232 [1600] 262 [1805]

Over 0.105 [2.67] to 0.115 [2.92], incl 5 227 [1565] 257 [1770]

Over 0.115 [2.92] to 0.125 [3.17], incl 5 222 [1530] 253 [1745]

Over 0.125 [3.17] to 0.135 [3.43], incl 3 217 [1495] 248 [1710]

Over 0.135 [3.43] to 0.148 [3.76], incl 3 210 [1450] 241 [1660]

Over 0.148 [3.76] to 0.162 [4.11], incl 3 205 [1415] 235 [1620]

Over 0.162 [4.11] to 0.177 [4.50], incl 3 198 [1365] 228 [1570]

Over 0.177 [4.50] to 0.192 [4.88], incl 1 194 [1335] 225 [1550]

Over 0.192 [4.88] to 0.207 [5.26], incl 1 188 [1295] 220 [1515]

Over 0.207 [5.26] to 0.225 [5.72], incl 1 182 [1255] 214 [1475]

Over 0.225 [5.72] to 0.250 [6.35], incl 1 175 [1205] 205 [1415]

Over 0.250 [6.35] to 0.278 [7.06], incl 1 168 [1160] 198 [1365]

Over 0.278 [7.06] to 0.306 [7.77], incl 1 161 [1110] 192 [1325]

Over 0.306 [7.77] to 0.331 [8.41], incl 1 155 [1070] 186 [1280]

Over 0.331 [8.41] to 0.362 [9.19], incl 1 150 [1035] 180 [1240]

Over 0.362 [9.19] to 0.394 [10.00], i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.