ASTM D6564-00

(Guide)Standard Guide for Field Filtration of Ground-Water Samples

Standard Guide for Field Filtration of Ground-Water Samples

SCOPE

1.1 This guide covers methods for field filtration of ground-water samples collected from ground-water monitoring wells, excluding samples that contain non-aqueous phase liquids (either Dense Non-Aqueous Phase Liquids (DNAPLs) or Light Non-Aqueous Phase Liquids (LNAPLs)). Methods of field filtration described herein could also be applied to samples collected from wells used for other purposes. Laboratory filtration methods are not described in this guide.

1.2 This guide provides procedures available for field filtration of ground-water samples. The need for sample filtration for specific analytes should be defined prior to the sampling event and documented in the site-specific sampling and analysis plan in accordance with Guide D5903. The decision should be made on a parameter-specific basis with consideration of the data quality objectives of the sampling program, any applicable regulatory agency guidelines, and analytical method requirements.

1.3 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This guide cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this guide may be applicable in all circumstances. This guide is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this guide be applied without consideration of the many unique aspects of a project. The word "Standard" in the title of this guide means only that the guide has been approved through the ASTM consensus process.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6564–00

Standard Guide for

Field Filtration of Ground-Water Samples

This standard is issued under the fixed designation D 6564; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 653 Terminology Relating to Soil, Rock, and Contained

Fluids

1.1 This guide covers methods for field filtration of ground-

D 5088 Practice for Decontamination of Field Equipment

water samples collected from ground-water monitoring wells,

Used at Non-Radioactive Waste Sites

excluding samples that contain non-aqueous phase liquids

D 5092 Practice for Design and Installation of Ground-

(either Dense Non-Aqueous Phase Liquids (DNAPLs) or Light

Water Monitoring Wells in Aquifers

Non-Aqueous Phase Liquids (LNAPLs)). Methods of field

D 5903 Guide for Planning and Preparing for a Ground-

filtration described herein could also be applied to samples

Water Sampling Event

collected from wells used for other purposes. Laboratory

D 6089 Guide for Documenting a Ground-Water Sampling

filtration methods are not described in this guide.

Event

1.2 This guide provides procedures available for field filtra-

F 740 Terminology Relating to Filtration

tion of ground-water samples. The need for sample filtration

for specific analytes should be defined prior to the sampling

3. Terminology

event and documented in the site-specific sampling and analy-

3.1 filter, v—to pass a fluid containing particles through a

sis plan in accordance with Guide D 5903.The decision should

filter medium whereby particles are separated from the fluid.

bemadeonaparameter-specificbasiswithconsiderationofthe

(F 740)

dataqualityobjectivesofthesamplingprogram,anyapplicable

3.2 filter, n—a device for carrying out filtration which

regulatory agency guidelines, and analytical method require-

consists of the combination of the filter medium and suitable

ments.

hardware for constraining and supporting it in the path of the

1.3 This guide offers an organized collection of information

fluid. (F 740)

oraseriesofoptionsanddoesnotrecommendaspecificcourse

3.3 filter medium—the permeable material used for a filter

of action. This guide cannot replace education or experience

that separates particles from a fluid passing through it.

and should be used in conjunction with professional judgment.

(F 740)

Not all aspects of this guide may be applicable in all circum-

3.4 filter preconditioning—the process of preparing a filter

stances. This guide is not intended to represent or replace the

medium for filtration

standard of care by which the adequacy of a given professional

3.5 filter system—the combination of one or more filter with

service must be judged, nor should this guide be applied

all the associated process hardware required for filtration.

without consideration of the many unique aspects of a project.

(F 740)

The word “Standard” in the title of this guide means only that

3.6 filtrate—the fluid that has passed through the filter.

the guide has been approved through the ASTM consensus

(F 740)

process.

3.7 filtration—the process by which particles are separated

1.4 This standard does not purport to address all of the

from a fluid by passing the fluid through a permeable material.

safety concerns, if any, associated with its use. It is the

(F 740)

responsibility of the user of this standard to establish appro-

3.8 filtered sample—a ground-water sample which has

priate safety and health practices and determine the applica-

passed through a filter medium.

bility of regulatory limitations prior to use.

3.8.1 Discussion—This type of sample may also be referred

2. Referenced Documents to as a “dissolved” sample. An unfiltered sample containing

dissolved, sorbed, coprecipitated and all suspended particles

2.1 ASTM Standards:

may be referred to as a “total” sample.

This guide is under the jurisdiction ofASTM Committee D18 on Soil and Rock

and is the direct responsibility of Subcommittee D18.21 on Ground Water and Annual Book of ASTM Standards, Vol 04.08.

Vadose Zone Investigations. Annual Book of ASTM Standards, Vol 04.09.

Current edition approved June 10, 2000. Published August 2000. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6564–00

TABLE 1 Examples of Equipment Options for Positive and

3.9 particle—a small discrete mass of solid or liquid matter.

Negative Pressure Filtration of Ground Water Samples

(F 740)

Positive Pressure Filtration Equipment:

In-line capsules

4. Significance and Use

attached directly to a pumping device discharge hose

4.1 A properly designed, installed and developed ground-

attached to a pressurized transfer vessel

attached to a pressurized bailer

water monitoring well, constructed in accordance with Practice

Free-standing disk filter holders

D 5092, should facilitate collection of samples of ground water

Syringe filters

that can be analyzed to determine both the physical and

Zero headspace extraction vessels

Negative Pressure Filtration Equipment:

chemical properties of that sample. Samples collected from

Glass funnel support assembly

these wells that require analysis for dissolved constituents

shouldbefilteredinthefieldpriortochemicalpreservationand

shipment to the laboratory for analysis.

7.1.2.1 Effect on sample integrity considering the potential

for the following to occur:

5. Purpose of Ground-Water Sample Filtration

7.1.2.2 Sample aeration (Note 2),

5.1 Ground-water samples may be filtered to separate a

7.1.2.3 Sample agitation (Note 2),

defined fraction of the sample for analysis.

NOTE 2—Sample aeration and increased agitation may result in sample

6. Timing of Ground-Water Sample Filtration

chemical alteration.

6.1 Ground-water samples should be filtered immediately

7.1.2.4 Change in partial pressure of sample constituents

upon collection and prior to chemical preservation of the

resulting from application of negative pressure to the sample

sample. (1) Filtration should be completed in as short a time

during filtration,

as possible while minimizing sample aeration, agitation, pres-

7.1.2.5 Sorptive losses of components from the sample onto

sure changes, temperature changes and prolonged contact with

the filter medium or components of the filtration equipment

ambient air.

(for example, flasks, filter holders etc.); and

7.1.2.6 Leaching of components from the filter medium or

NOTE 1—The pressure change that occurs when the sample is brought

to the surface may cause changes in sample chemistry which include

components of the filtration equipment into the sample.

losses of dissolved gases and precipitation of dissolved constituents such

7.1.2.7 Volume of sample to be filtered;

as metals. When handling samples during filtration operations, additional

7.1.2.8 Chemical compatibility of filter medium with

turbulence and mixing of the sample with air can cause aeration and

ground water sample chemistry;

oxidation of dissolved ferrous to ferric iron. Ferric iron rapidly precipi-

7.1.2.9 Anticipated amount of suspended solids and the

tates as amorphous iron hydroxide and can adsorb other dissolved trace

attendant effects of particulate loading (reduction in effective

metals (2).

filter pore size);

7. Ground-Water Sample Filtration Procedures

7.1.2.10 Time required to filter samples (Note 3);

7.1 Preparation for Ground-Water Sample Filtration—The

NOTE 3—Short filtration times are recommended to minimize the time

ground-watersamplefiltrationprocessconsistsofthreephases:

available for chemical changes to occur in the sample.

selection of filtration method; selection and pretreatment of

7.1.2.11 Ease of use;

filter media; and ground-water sample filtration prior to trans-

7.1.2.12 Availability of an appropriate medium in the de-

fer into the sample container.

sired filter pore size

7.1.1 Filtration Method Selection Criteria—A wide variety

7.1.2.13 Filter surface area;

of methods are available for field filtration of ground-water

7.1.2.14 Use of disposable versus non-disposable equip-

samples. In general, filtration equipment can be divided into

ment;

positive pressure filtration and vacuum (negative pressure)

7.1.2.15 Ease of cleaning equipment if not disposable;

filtrationmethods,eachwithseveraldifferentfiltrationmedium

7.1.2.16 Potential for sample bias associated with ambient

configurations. Ground-water samples undergo pressure

air contact during sample filtration; and

changes as they are brought from the saturated zone (where

7.1.2.17 Cost, evaluating the costs associated with: equip-

ground water is under pressure greater than atmospheric) to the

ment purchase price, expendable supplies and their disposal,

surface (where it is under atmospheric pressure), resulting in

time required for filtration, time required for decontamination

changes in sample chemistry. Vacuum filtration methods fur-

of non-disposable equipment and quality control measures.

ther exacerbate pressure changes. For this reason, positive

7.1.2.18 The filtration method used for any given sampling

pressure filtration methods are preferred. Table 1 presents

program should be documented in the site-specific sampling

equipment options available for positive pressure and vacuum

and analysis plan and should be consistent throughout the life

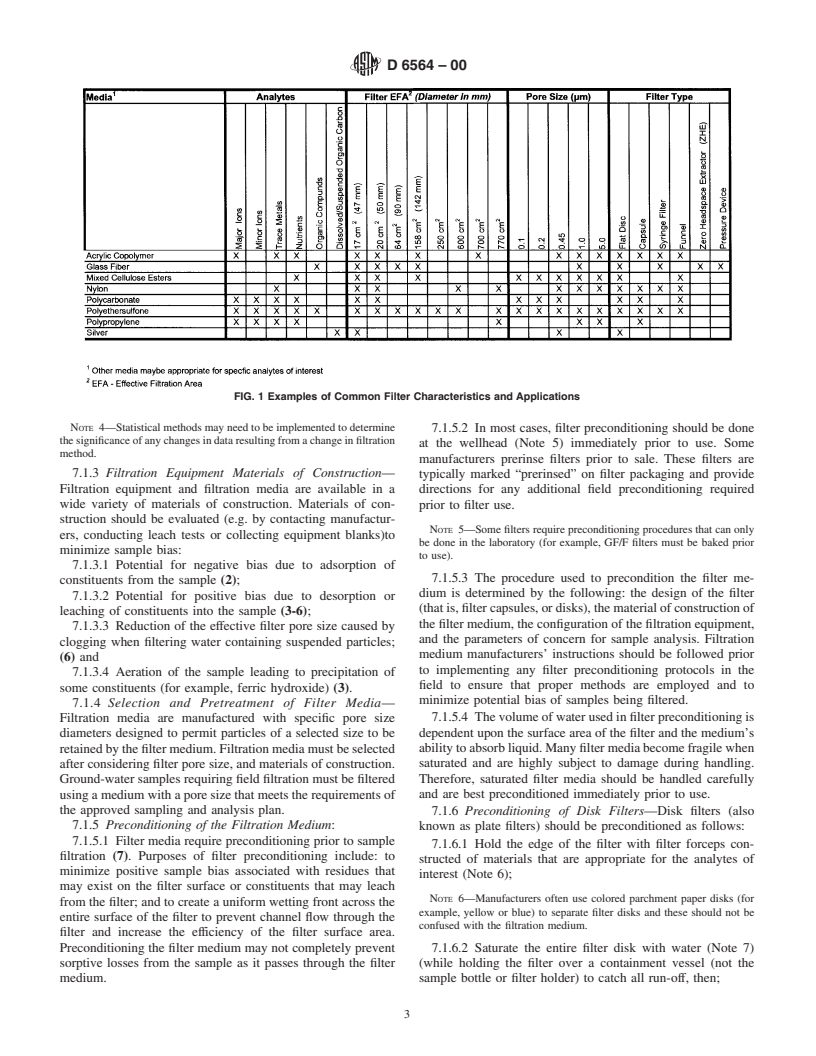

filtration of ground-water samples. Fig. 1 presents examples of

of the sampling program to permit comparison of data gener-

common filter characteristics and applications.

ated. If an improved method of filtration is determined to be

7.1.2 When selecting a filtration method, the following

appropriate for a sampling program, the sampling and analysis

criteria should be evaluated on a site-by-site basis:

plan should be revised and implemented in lieu of continuation

of the existing filtration method. In this event, the effect on

comparability of data needs to be examined and quantified to

The boldface numbers given in parentheses refer to a list of references at the

end of the text. allow proper data analysis and interpretation (Note 4).

D6564–00

FIG. 1 Examples of Common Filter Characteristics and Applications

NOTE 4—Statistical methods may need to be implemented to determine

7.1.5.2 In most cases, filter preconditioning should be done

thesignificanceofanychangesindataresultingfromachangeinfiltration

at the wellhead (Note 5) immediately prior to use. Some

method.

manufacturers prerinse filters prior to sale. These filters are

7.1.3 Filtration Equipment Materials of Construction—

typically marked “prerinsed” on filter packaging and provide

Filtration equipment and filtration media are available in a directions for any additional field preconditioning required

wide variety of materials of construction. Materials of con-

prior to filter use.

struction should be evaluated (e.g. by contacting manufactur-

NOTE 5—Some filters require preconditioning procedures that can only

ers, conducting leach tests or collecting equipment blanks)to

be done in the laboratory (for example, GF/F filters must be baked prior

minimize sample bias:

to use).

7.1.3.1 Potential for negative bias due to adsorption of

7.1.5.3 The procedure used to precondition the filter me-

constituents from the sample (2);

dium is determined by the following: the design of the filter

7.1.3.2 Potential for positive bias due to desorption or

(thatis,filtercapsules,ordisks),thematerialofconstructionof

leaching of constituents into the sample (3-6);

the filter medium, the configuration of the filtration equipment,

7.1.3.3 Reduction of the effective filter pore size caused by

and the parameters of concern for sample analysis. Filtration

clogging when filtering water containing suspended particles;

medium manufacturers’ instructions should be followed prior

(6) and

to implementing any filter preconditioning protocols in the

7.1.3.4 Aeration of the sample leading to precipitation of

field to ensure that proper methods are employed and to

some constituents (for example, ferric hydroxide) (3).

minimize potential bias of samples being filtered.

7.1.4 Selection and Pretreatment of Filter Media—

Filtration media are manufactured with specific pore size 7.1.5.4 The volume of water used in filter preconditioning is

dependent upon the surface area of the filter and the medium’s

diameters designed to permit particles of a selected size to be

retainedbythefiltermedium.Filtrationmediamustbeselected abilitytoabsorbliquid.Manyfiltermediabecomefragilewhen

saturated and are highly subject to damage during handling.

after considering filter pore size, and materials of construction.

Therefore, saturated filter media should be handled carefully

Ground-water samples requiring field filtration must be filtered

using a medium with a pore size that meets the requirements of and are best preconditioned immediately prior to use.

the approved sampling and analysis plan.

7.1.6 Preconditioning of Disk Filters—Disk filters (also

7.1.5 Preconditioning of the Filtration Medium:

known as plate filters) should be preconditioned as follows:

7.1.5.1 Filter media require preconditioning prior to sample

7.1.6.1 Hold the edge of the filter with filter forceps con-

filtration (7). Purposes of filter preconditioning include: to

structed of materials that are appropriate for the analytes of

minimize positive sample bias associated with residues that

interest (Note 6);

may exist on the filter surface or constituents that may leach

NOTE 6—Manufacturers often use colored parchment paper disks (for

from the filter; and to create a uniform wetting front across the

example, yellow or blue) to separate filter disks and these should not be

entire surface of the filter to prevent channel flow through the

confused with the filtration medium.

filter and increase the efficiency of the filter surface area.

Preconditioning the filter medium may not completely prevent 7.1.6.2 Saturate the entire filter disk with water (Note 7)

sorptive losses from the sample as it passes through the filter (while holding the filter over a containment vessel (not the

medium. sample bottle or filter holder) to catch all run-off, then;

D6564–00

NOTE 7—Filter manufacturers should be consulted to determine filter-

7.2.2.9 Decontaminate any equipment used for filtration of

specific volumes of water or medium-specific aqueous solution to be used

the next sample following procedures described in Practice

for optimum filter preconditioning.

D 5088.

7.1.6.3 Place the saturated filter on the appropriate filter 7.2.3 Independent Pressure Filtration Method—Ground-

stand or holder in preparation for sample filtra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.