ASTM B474-03

(Specification)Standard Specification for Electric Fusion Welded Nickel and Nickel Alloy Pipe

Standard Specification for Electric Fusion Welded Nickel and Nickel Alloy Pipe

ABSTRACT

This specification covers electric fusion welded pipe suitable for high-temperature or corrosive service. The pipes are designated into five classes namely Class 1, Class 2, Class 3, Class 4 and Class 5, according to how they are to be welded. The joints shall be full penetration double-welded or single-welded butt joints employing fusion welding processes. The furnished pipe shall undergo heat treatment and a chemical analysis shall be employed for both plate and weld. Each pipe shall be subjected to transverse tension test, transverse guided weld bend test and hydrostatic pressure test.

SCOPE

1.1 This specification covers electric fusion welded pipe suitable for high-temperature or corrosive service as listed in . (Although no restrictions are placed on the sizes of pipe that may be furnished under this specification, commercial practice is commonly limited to sizes not less than 8 in. (203 mm) nominal diameter.)

1.2 Five classes of pipe are covered as follows:

1.2.1 Class 1 -- Pipe shall be double welded by processes employing filler metal in all passes and shall be completely radiographed.

1.2.2 Class 2--Pipe shall be double welded by processes employing filler metal in all passes. No radiography is required.

1.2.3 Class 3 -- Pipe shall be single welded by processes employing filler metal in all passes and shall be completely radiographed.

1.2.4 Class 4 -- Same as Class 3 except that the weld pass exposed to the inside pipe surface may be made without the addition of filler metal.

1.2.5 Class 5 -- Pipe shall be double welded by processes employing filler metal in all passes and shall be spot radiographed.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 474 – 03

Standard Specification for

1

Electric Fusion Welded Nickel and Nickel Alloy Pipe

This standard is issued under the fixed designation B 474; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 370 Test Methods and Definitions for MechanicalTesting

2

of Steel Products

1.1 This specification covers electric fusion welded pipe

B 127 Specification for Nickel-Copper Alloy (UNS

suitable for high-temperature or corrosive service as listed in

2

N04400) Plate, Sheet, and Strip

Table 1. (Although no restrictions are placed on the sizes of

2

B 162 Specification for Nickel Plate, Sheet, and Strip

pipethatmaybefurnishedunderthisspecification,commercial

B 168 Specification for Nickel-Chromium-Iron Alloys

practice is commonly limited to sizes not less than 8 in. (203

(UNS N06600, N06601, N06603, N06690, N06025 and

mm) nominal diameter.)

N06045) and Nickel-Chromium-Cobalt-Molybdenum Al-

1.2 Five classes of pipe are covered as follows:

2

loy (UNS N06617) Plate, Sheet, and Strip

1.2.1 Class 1—Pipe shall be double welded by processes

B 333 Specification for Nickel-Molybdenum Alloy Plate,

employing filler metal in all passes and shall be completely

2

Sheet, and Strip

radiographed.

B 424 Specification for Ni-Fe-Cr-Mo-Cu-Alloy (UNS

1.2.2 Class 2—Pipe shall be double welded by processes

2

N08825 and UNS N08221) Plate, Sheet, and Strip

employing filler metal in all passes. No radiography is re-

B 435 Specification for UNS N06002, UNS N06230, UNS

quired.

2

N12160, and UNS R30556 Plate, Sheet, and Strip

1.2.3 Class 3—Pipe shall be single welded by processes

B 443 Specification for Nickel-Chromium-Molybdenum-

employing filler metal in all passes and shall be completely

2

Columbium Alloy (UNS N06625) Plate, Sheet, and Strip

radiographed.

B 463 Specification for UNS N08020, UNS N08026, and

1.2.4 Class 4—Same as Class 3 except that the weld pass

3

UNS N08024 Alloy Plate, Sheet, and Strip

exposed to the inside pipe surface may be made without the

B 536 Specification for Nickel-Iron-Chromium-Silicon Al-

addition of filler metal.

2

loys (UNS N08330 and N08332) Plate, Sheet, and Strip

1.2.5 Class 5—Pipe shall be double welded by processes

B 575 Specification for Low-Carbon Nickel-Molybdenum-

employing filler metal in all passes and shall be spot radio-

Chromium, Low-Carbon Nickel-Chromium-Molybdenum,

graphed.

Low-Carbon Nickel-Chromium-Molybdenum-Copper,

1.3 The values stated in inch-pound units are to be regarded

Low-Carbon Nickel-Chromium-Molybdenum-Tantalum,

as the standard. The values given in parentheses are for

and Low-Carbon Nickel-Chromium-Molybdenum-

information only.

2

Tungsten Alloy Plate, Sheet, and Strip

1.4 This standard does not purport to address all of the

B 582 Specification for Nickel-Chromium-Iron-

safety concerns, if any, associated with its use. It is the

2

Molybdenum-Copper Alloy, Plate, Sheet, and Strip

responsibility of the user of this standard to become familiar

B 880 Specification for General Requirements for Chemical

with all hazards including those identified in the appropriate

Check Analysis Limits for Nickel, Nickel Alloys and

Material Safety Data Sheet for this product/material as pro-

2

Cobalt Alloys

vided by the manufacturer, to establish appropriate safety and

B 899 Terminology Relating to Non-ferrous Metals and

health practices, and determine the applicability of regulatory

2

Alloys

limitations prior to use.

4

E 8 Test Methods forTensionTesting of Metallic Materials

2. Referenced Documents

E 29 Practice for Using Significant Digits in Test Data to

5

Determine Conformance with Specifications

2.1 ASTM Standards:

E 1473 Test Method for Chemical Analysis of Nickel,

6

Cobalt, and High Temperature Alloys

1

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

2

B02.07on Refined Nickel and Cobalt and Their Alloys. Annual Book of ASTM Standards, Vol 01.03.

3

Current edition approved March 10, 2003. Published May 2003. Originally Annual Book of ASTM Standards, Vol 02.04.

4

approved in 1968. Last previous edition approved in 1999 as B 474 – 99. Annual Book of ASTM Standards, Vol 03.01.

5

* NewdesignationestablishedinaccordancewithASTME 527andSAEJ 1086, Annual Book of ASTM Standards, Vol 14.02.

6

Practice for Numbering Metals and Alloys (UNS). Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

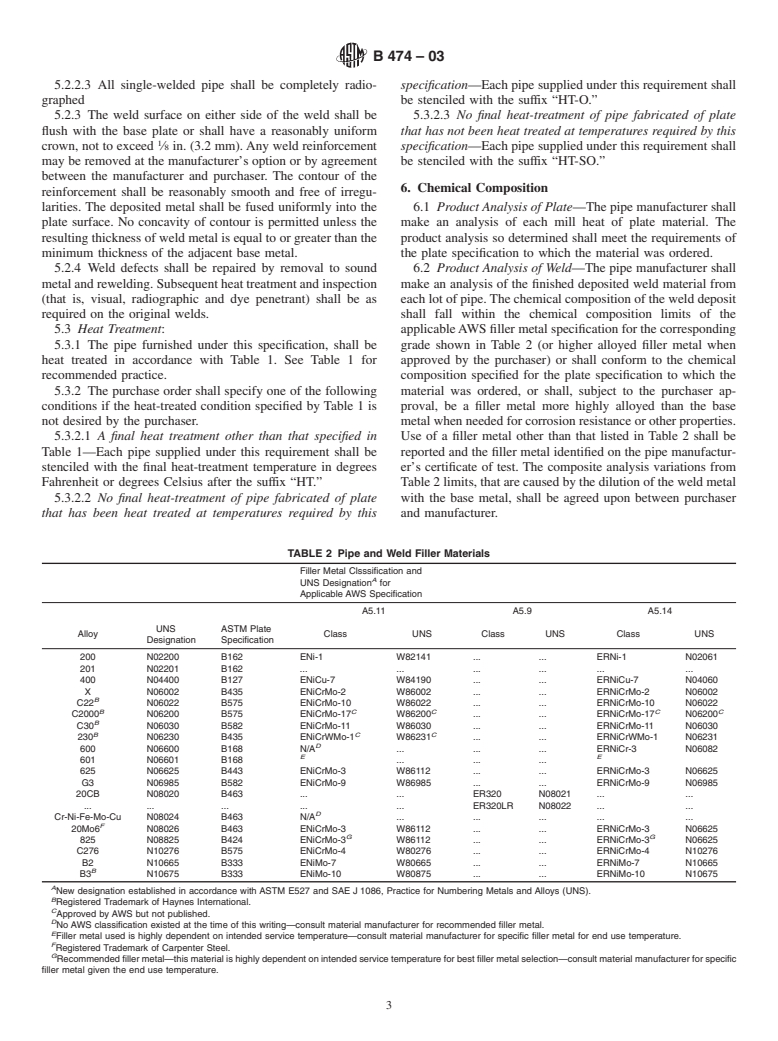

B474–03

TABLE 1 Recommended Heat Treatment

A,B

PWHT

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.