ASTM F855-14

(Specification)Standard Specifications for Temporary Protective Grounds to Be Used on De-energized Electric Power Lines and Equipment

Standard Specifications for Temporary Protective Grounds to Be Used on De-energized Electric Power Lines and Equipment

ABSTRACT

These specifications cover the equipment making up the temporary grounding system used on de-energized electric power lines, electric supply stations, and equipment. These specifications for a system of protective grounding utilizing copper cables are covered in four parts, as follows: clamps, ferrules, cables, and temporary protective grounds. Each of the four parts is an entity of itself, but is listed as a part of the system for completeness and clarification. The clamps shall be subject to design tests for determining mechanical torque strength and electrical short circuit capacity. The ferrules shall be tested for electrical short-circuit capacity and continuous current rating. The elastomer or thermoplastic making up the jacket of the flexible cable shall be tested according to the specified methods.

SCOPE

1.1 These specifications cover the equipment making up the temporary grounding system used on de-energized electric power lines, electric supply stations, and equipment.

1.2 It is common practice for the users of protective grounding equipment to prepare complete instructions and regulations to govern in detail the correct use and maintenance of such equipment.

1.3 The uses and maintenance of this equipment are beyond the scope of these specifications.

1.4 These specifications for a system of protective grounding utilizing copper cables are covered in four parts, as follows:

Sections

Clamps for Temporary Protective Grounds

4 – 16

Ferrules for Temporary Protective Grounds

17 – 30

Cables for Temporary Protective Grounds

31 – 39

Protective Grounds (Complete Assembly With Clamps, Ferrules, and Cable)

40 – 52

1.5 Each of the four parts is an entity of itself, but is listed as a part of the system for completeness and clarification.

1.6 Currents presented in Table 1 are based upon cable melting times, as determined from equations by I. M. Onderdonk and are to used in situations involving an asymmetry value less than 20 % (X/R ≤ 1.8). See Appendix X3. (A) Withstand and ultimate short circuit properties are based on performance with surges not exceeding 20 % asymmetry factor (see 9.1 and 12.3.4.2).(B) Yield shall mean no permanent deformation such that the clamp cannot be reused throughout its entire range of application.(C) Ultimate rating represents a symmetrical current which the assembly or individual components shall carry for the specified time.(D) Ultimate values are based upon application of Onderdonk's equation to 98 % of nominal circular mil area allowed by Specifications B172 and B173.

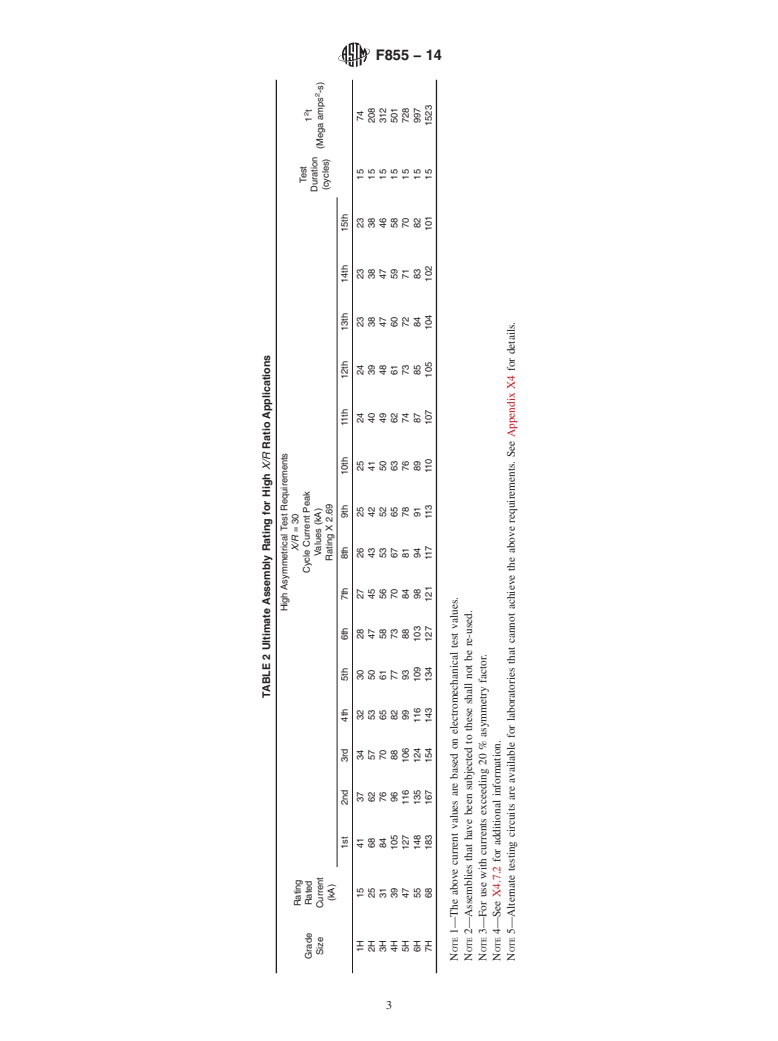

1.6.1 Currents presented in Table 2 are based upon the values from EPRI Project RP2446 Computer Program RTGC “A Desktop Computer Program for Calculating Rating of Temporary Grounding Cables” and are to be used in situations involving an asymmetry value greater then 20 % (X/R ≧ 1.8), see Appendix X4.

Note 1: The above current values are based on electromechanical test values.

Note 2: Assemblies that have been subjected to these shall not be re-used.

Note 3: For use with currents exceeding 20 % asymmetry factor.

Note 4: See X4.7.2 for additional information.

Note 5: Alternate testing circuits are available for laboratories that cannot achieve the above requirements. See Appendix X4 for details.

Note 1: Table 1 represents the clamp and assembly ratings that existed prior to this revision. Table 2 represents new ratings now required for high X/R situations.

1.6.2 See Appendix X3 and Appendix X4 for a discussion of these topics.

1.7 The values stated in Newton-Meter units are to be regarded as the standard. The values in parentheses are the inch-pound units.

1.8 The following precautionary caveat pertains to the test method portions, Sections 12 and 25 of these specifications: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the respon...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F855 −14

StandardSpecifications for

Temporary Protective Grounds to Be Used on De-energized

Electric Power Lines and Equipment

ThisstandardisissuedunderthefixeddesignationF855;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The values stated in Newton-Meter units are to be

regarded as the standard. The values in parentheses are the

1.1 Thesespecificationscovertheequipmentmakingupthe

inch-pound units.

temporary grounding system used on de-energized electric

1.8 The following precautionary caveat pertains to the test

power lines, electric supply stations, and equipment.

method portions, Sections 12 and 25 of these specification-

1.2 It is common practice for the users of protective

s:This standard does not purport to address all of the safety

grounding equipment to prepare complete instructions and

concerns, if any, associated with its use. It is the responsibility

regulations to govern in detail the correct use and maintenance

of the user of this standard to establish appropriate safety and

of such equipment.

health practices and determine the applicability of regulatory

1.3 Theusesandmaintenanceofthisequipmentarebeyond

limitations prior to use.

the scope of these specifications.

2. Referenced Documents

1.4 These specifications for a system of protective ground-

ingutilizingcoppercablesarecoveredinfourparts,asfollows:

2.1 ASTM Standards:

B172Specification for Rope-Lay-Stranded Copper Conduc-

Sections

torsHavingBunch-StrandedMembers,forElectricalCon-

Clamps for Temporary Protective Grounds 4–16

ductors

Ferrules for Temporary Protective Grounds 17–30

Cables for Temporary Protective Grounds 31–39

B173Specification for Rope-Lay-Stranded Copper Conduc-

Protective Grounds (Complete Assembly With Clamps, Ferrules, 40–52

tors Having Concentric-Stranded Members, for Electrical

and Cable)

Conductors

1.5 Each of the four parts is an entity of itself, but is listed

D470Test Methods for Crosslinked Insulations and Jackets

as a part of the system for completeness and clarification.

for Wire and Cable

1.6 Currents presented in Table 1 are based upon cable D753Specification for General Purpose Polychloroprene

melting times, as determined from equations by I. M. Onder-

Jacket for Wire and Cable (Withdrawn 1984)

donk and are to used in situations involving an asymmetry D2219Specification for Poly(Vinyl Chloride) Insulation for

value less than 20 % (X/R ≤ 1.8). See Appendix X3.

Wire and Cable, 60°C Operation

1.6.1 Currents presented in Table 2 are based upon the D2633Test Methods for Thermoplastic Insulations and

values from EPRI Project RP2446 Computer Program RTGC

Jackets for Wire and Cable

“A Desktop Computer Program for Calculating Rating of

D2768 Specification for General-Purpose Ethylene-

Temporary Grounding Cables” and are to be used in situations

Propylene Rubber Jacket for Wire and Cable (Withdrawn

involving an asymmetry value greater then 20 % (X/R^ 1.8),

2007)

see Appendix X4.

D2770 Specification for Ozone-Resisting Ethylene-

Propylene Rubber Integral Insulation and Jacket for Wire

NOTE1—Table1representstheclampandassemblyratingsthatexisted

and Cable (Withdrawn 2007)

priortothisrevision.Table2representsnewratingsnowrequiredforhigh

X/R situations. E8/E8MTest Methods for Tension Testing of Metallic Ma-

terials

1.6.2 See Appendix X3 and Appendix X4 for a discussion

of these topics.

1 2

These specifications are under the jurisdiction of ASTM Committee F18 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Protective Equipment for Workers and are the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee F18.45 on Mechanical Apparatus. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2014. Published November 2014. Originally the ASTM website.

approved in 1983. Last previous edition approved in 2009 as F855–09. DOI: The last approved version of this historical standard is referenced on

10.1520/F0855-14. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F855−14

TABLE 1 Protective Ground Cable, Ferrule, Clamp and Assembly Ratings for Symmetrical Current

Grounding Clamp Torque

A

Short Circuit Properties

Strength, min

CD

Withstand Rating, Symmetrical Continuous

Ultimate Rating Capacity , Symmetrical

B

Yield Ultimate kA kA Current

RMS, 60 Hz

Grade RMS, 60 Hz Rating, A

RMS, 60

15 30

15 30 cycles 60 Maximum

Hz

Copper Cable cycles cycles

lbf·in. n·m lbf·in. n·m cycles (500 cycles Copper Test

Size (250 (500

(250 ms) ms) (1 s) Cable Size

ms) ms)

1 280 32 330 37 14 10 #2 18 13 9 2/0 200

2 280 32 330 37 21 15 1/0 29 21 14 4/0 250

3 280 32 330 37 27 20 2/0 37 26 18 4/0 300

4 330 37 400 45 34 25 3/0 47 33 23 250 kcmil 350

5 330 37 400 45 43 30 4/0 59 42 29 250 kcmil 400

6 330 37 400 45 54 39 250 kcmil or 70 49 35 350 kcmil 450

22/0

7 330 37 400 45 74 54 350 kcmil or 98 69 48 550 kcmil 550

24/0

A

Withstand and ultimate short circuit properties are based on performance with surges not exceeding 20 % asymmetry factor (see 9.1 and 12.3.4.2).

B

Yield shall mean no permanent deformation such that the clamp cannot be reused throughout its entire range of application.

C

Ultimate rating represents a symmetrical current which the assembly or individual components shall carry for the specified time.

D

Ultimate values are based upon application of Onderdonk’s equation to 98 % of nominal circular mil area allowed by Specifications B172 and B173.

2.2 ANSI Standard: 3.1.3 protective grounding equipment—devices installed

C 37.09 Standard Test Procedure for AC High-Voltage temporarily on de-energized electric power circuits for the

Circuit Breakers Rated on a Symmetrical Basis purposesofpotentialequalizationandtoconductashortcircuit

current for a specified duration (time).

2.3 ICEA/NEMA Standard:

ICEAS-19-81/NEMAWC 3-80 (R1986) Rubber Insulated

3.1.4 time to failure—failure time of the cable is the time

Wire and Cable for the Transmission and Distribution of

between the initiation of current flow and the instant at which

Electrical Energy

arcing begins.

2.4 IEC Standard:

3.1.5 ultimate capacity—thisrepresentsacurrentwhichitis

IEC61230Ed. 2, 2008, Portable Equipment for Earthing or

calculated the component is capable of conducting for the

Earthing and Short-Circuiting

specified time. It is expected that component damage may

2.5 IEEE Standard:

result. The component shall not be reused, except in test

IEEE386Standard for Separable Insulated Connector Sys-

situations.

tems for Power Distribution Systems Above 600V

3.1.6 withstand rating—this represents a near symmetrical

IEEE1048Guide for Protective Grounding of Power Lines

currentwhichshallbeconductedwithoutanycomponentbeing

IEEE1246Guide for Temporary Protective Grounding Sys-

damaged sufficiently to prevent being operable and reusable.

tems Used in Substations

Theprotectivegroundshallbecapableofpassingasecondtest

at this current after being cooled to ambient temperature.

3. Terminology

3.1 Definitions of Terms Specific to This Standard: CLAMPS FOR TEMPORARY PROTECTIVE

GROUNDS

3.1.1 continuous current rating—designated RMS current

which can be carried continuously under specified conditions.

4. Scope

3.1.2 protective ground assembly—a temporary electrical

4.1 This specification covers clamps used with ferrules and

connection between a source of potential energization and the

elastomer or thermoplastic covered flexible cable in the manu-

earth, rated for the maximum anticipated fault current or

facture of protective grounds installed temporarily for protec-

continuous induced current, or both.

tive grounding of de-energized circuits.

3.1.2.1 Discussion—Throughout this specification, kc

mil=1000 circular mils.

5. Classification

5.1 Clamps are furnished in, but not limited to, three types

Available from American National Standards Institute, 11 West 42nd St., 13th

according to their function and method of installation, as

Floor, New York, NY 10036.

5 follows:

AvailablefromInsulatedCableEngineersAssoc.,P.O.BoxP,SouthYarmouth,

5.1.1 Type I—Clamps for installation on de-energized con-

MA 02664.

Available from International Electrotechnical Commission (IEC), 3 rue de

ductors equipped with eyes for installation with removable hot

Varembé, Case postale 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

sticks.

5.1.2 Type II—Clamps for installation on de-energized con-

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org. ductors having permanently mounted hot sticks.

F855−14

TABLE 2 Ultimate Assembly Rating for High X/R Ratio Applications

High Asymmetrical Test Requirements

X/R =30

Rating

Test

Cycle Current Peak

Grade Rated 1 t

Duration

Values (kA)

Size Current (Mega amps -s)

(cycles)

Rating X 2.69

(kA)

1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th 12th 13th 14th 15th

1H 15 41 37 34 32 30 28 27 26 25 25 24 24 23 23 23 15 74

2H 25 68 62 57 53 50 47 45 43 42 41 40 39 38 38 38 15 208

3H 31 84 76 70 65 61 58 56 53 52 50 49 48 47 47 46 15 312

4H 39 105 96 88 82 77 73 70 67 65 63 62 61 60 59 58 15 501

5H 47 127 116 106 99 93 88 84 81 78 76 74 73 72 71 70 15 728

6H 55 148 135 124 116 109 103 98 94 91 89 87 85 84 83 82 15 997

7H 68 183 167 154 143 134 127 121 117 113 110 107 105 104 102 101 15 1523

NOTE 1—The above current values are based on electromechanical test values.

NOTE 2—Assemblies that have been subjected to these shall not be re-used.

NOTE 3—For use with currents exceeding 20 % asymmetry factor.

NOTE 4—See X4.7.2 for additional information.

NOTE 5—Alternate testing circuits are available for laboratories that cannot achieve the above requirements. See Appendix X4 for details.

F855−14

5.1.3 Type III—Clamps for installation on permanently

Copper Base Alloy Aluminum Base Alloy

grounded conductors or metal structures with tee handles, and

Tensile strength, min 207 MPa (30 000 psi) 207 MPa (30 000 psi)

eyes or square or hexagon head screw(s), or both.

Yield strength, min 90 MPa (13 000 psi) 138 MPa (20 000 psi)

5.1.4 Othertypesofspecialclamps,suchasthoseforcluster

Elongation, min 6 % 3 %

grounds or for underground equipment grounding, may be

8.2 Type II clamps shall be equipped with an insulating

made, tested, and certified by the manufacturer as meeting the

handle (hot stick) appropriate for the nominal voltage of the

requirements of this specification.

circuit to be grounded.

5.1.5 Separable insulated connectors used in manufacturing

underground equipment grounding assemblies shall meet the

9. Electrical and Mechanical Properties

requirements of IEEE 386.

9.1 Electrical and mechanical properties shall conform to

5.2 Clampsarefurnishedingradesaccordingtomechanical

the requirements prescribed in Table 1 or Table 2,as

strengths, short circuit capabilities, and duration of faults, as

appropriate, and the following paragraphs. See Appendix X3

indicated in Table 1.

for a discussion and derivation of the current levels in Table 1.

5.3 Clamps are furnished in two classes according to the See Appendix X4 for a discussion of the effects of asymmetri-

characteristics of the main contact jaws: cal current and the derivation of the currents in Table 2.

5.3.1 Class A—Clamp jaws with smooth contact surfaces.

9.1.1 Types I and II stick installed clamps shall be designed

5.3.2 Class B—Clamp jaws with serrations, or cross

such that a failure does not increase the risk of injury to the

hatching, or other means intended to abrade or bite through user or have excess mechanical strength to prevent failure,

corrosion products on the surfaces of the conductor being

defined as follows:

clamped.

9.1.1.1 In the event the clamp is over-torqued during

installation, normal fracture shall be such that the attached

6. Sizes

cable remains under control by being retained with the stick.

9.1.1.2 Clamps with an ultimate torque strength exceeding

6.1 Clamp size is the combination of the main contact and

45N·m(400lbf·in.)areexemptfromtheprovisionsof9.1.1.1.

cable size ranges as listed by the manufacturers. It should be

noted that the main contact may connect to a cable or bus bar 9.1.2 Resistancefromthemaincontacttotheattachedcable

contact shall be less than that for an equal length of maximum

or be used at the “ground end” to connect to a variety of

conductive grounded objects. size cable(s) for which the clamp is rated.

9.1.3 Maincontactsshallacceptandclampallconductorsor

7. Ordering Information structural members in accordance with the manufacturer’s

rating.

7.1 Orders for clamps under this specification shall include

9.1.4 Clamp shall accept hand assembly of all cables fitted

this ASTM designation and the following information:

with compatible ferrules as rated per Table 3.

7.1.1 Quantity,

9.1.5 Cable termination shall include a cable support or

7.1.2 Name (grounding clamp),

shallbemadetoacceptacablesupportingferrule.Thissupport

7.1.3 Main contact size ranges, conductor descriptions, and

shall secure the entire cable over the jacket and is provided in

materials which are to be clamped by main contact,

addition to the electrical connection to the strand.

7.1.4 Cable size, material, and description by which clamps

9.1.6 Type I clamps shall be operable with clamp sticks and

are to be assembled,

shall fit securely inside a nominal 13 mm ( ⁄2 in.) wide slot in

7.1.5 Type (see 5.1),

the head of the stick.

7.1.6 Grade (see 5.2 and Table 1 or Table 2),

7.1.7 Class (see 5.3),

10. Workmanship, Finish, and Appearance

7.1.8 Asymmetrical current or other supplementary

requirements, if applicable. (See Supplementary Requirements

10.1 Components shall be free of structural porosity, fins,

S1 to S10 for styles and designs.)

sharp edges, splits, cracks, and other defects that affect

handling or performance.

NOTE 2—A typical ordering description is as follows: 100 Grounding

Clamps, Main contact range #2 to 350 kcmil for 2/0 Copper flexible

10.2 All parts shall be formed, machined, and assembled

grounding cable,ASTM F855, Type 1, Grade 3, ClassA, Design C, Style

with sufficient accuracy for smooth operation by hand, and

7.

shallbefreeofexcessiveloosenesstotheextentdetrimentalto

NOTE 3—It is expected that manufacturers will publish catalog data

repeated applications at the recommended installing torque.

conforming to this specification that will combine the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F855 − 09 F855 − 14

Standard Specifications for

Temporary Protective Grounds to Be Used on De-energized

Electric Power Lines and Equipment

This standard is issued under the fixed designation F855; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These specifications cover the equipment making up the temporary grounding system used on de-energized electric power

lines, electric supply stations, and equipment.

1.2 It is common practice for the users of protective grounding equipment to prepare complete instructions and regulations to

govern in detail the correct use and maintenance of such equipment.

1.3 The uses and maintenance of this equipment are beyond the scope of these specifications.

1.4 These specifications for a system of protective grounding utilizing copper cables are covered in four parts, as follows:

Sections

Clamps for Temporary Protective Grounds 4 – 16

Ferrules for Temporary Protective Grounds 17 – 30

Cables for Temporary Protective Grounds 31 – 39

Protective Grounds (Complete Assembly With Clamps, Ferrules, 40 – 52

and Cable)

1.5 Each of the four parts is an entity of itself, but is listed as a part of the system for completeness and clarification.

1.6 Currents presented in Table 1 are based upon cable melting times, as determined from equations by I. M. Onderdonk and

are to used in situations involving an asymmetry value less than 20 % (X/R ≤ 1.8). See Appendix X3.

1.6.1 Currents presented in Table 2 are based upon the values from EPRI Project RP2446 Computer Program RTGC “A Desktop

Computer Program for Calculating Rating of Temporary Grounding Cables” and are to be used in situations involving an

asymmetry value greater then 20 % (X/R ^ 1.8), see Appendix X4.

NOTE 1—Table 1 represents the clamp and assembly ratings that existed prior to this revision. Table 2 represents new ratings now required for high

X/R situations.

1.6.2 See Appendix X3 and Appendix X4 for a discussion of these topics.

1.7 The values stated in Newton-Meter units are to be regarded as the standard. The values in parentheses are the inch-pound

units.

1.8 The following precautionary caveat pertains to the test method portions, Sections 12 and 25 of these specifications:This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2.1 ASTM Standards:

B172 Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

B173 Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conduc-

tors

These specifications are under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and are the direct responsibility of Subcommittee

F18.45 on Mechanical Apparatus.

Current edition approved May 1, 2009Oct. 1, 2014. Published July 2009November 2014. Originally approved in 1983. Last previous edition approved in 20042009 as

F855 – 04.F855 – 09. DOI: 10.1520/F0855-09.10.1520/F0855-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F855 − 14

TABLE 1 Protective Ground Cable, Ferrule, Clamp and Assembly Ratings for Symmetrical Current

Grounding Clamp Torque

A

Short Circuit Properties

Strength, min

CD

Withstand Rating, Symmetrical Continuous

Ultimate Rating Capacity , Symmetrical

B

Yield Ultimate kA kA Current

RMS, 60 Hz

Grade RMS, 60 Hz Rating, A

RMS, 60

15 30

15 30 cycles 60 Maximum

Hz

Copper Cable cycles cycles

lbf·in. n·m lbf·in. n·m cycles (500 cycles Copper Test

Size (250 (500

(250 ms) ms) (1 s) Cable Size

ms) ms)

1 280 32 330 37 14 10 #2 18 13 9 2/0 200

2 280 32 330 37 21 15 1/0 29 21 14 4/0 250

3 280 32 330 37 27 20 2/0 37 26 18 4/0 300

4 330 37 400 45 34 25 3/0 47 33 23 250 kcmil 350

5 330 37 400 45 43 30 4/0 59 42 29 250 kcmil 400

6 330 37 400 45 54 39 250 kcmil or 70 49 35 350 kcmil 450

2 2/0

7 330 37 400 45 74 54 350 kcmil or 98 69 48 550 kcmil 550

2 4/0

A

Withstand and ultimate short circuit properties are based on performance with surges not exceeding 20 % asymmetry factor (see 9.1 and 12.3.4.2).

B

Yield shall mean no permanent deformation such that the clamp cannot be reused throughout its entire range of application.

C

Ultimate rating represents a symmetrical current which the assembly or individual components shall carry for the specified time.

D

Ultimate values are based upon application of Onderdonk’s equation to 98 % of nominal circular mil area allowed by Specifications B172 and B173.

D470 Test Methods for Crosslinked Insulations and Jackets for Wire and Cable

D753 Specification for General Purpose Polychloroprene Jacket for Wire and Cable (Withdrawn 1984)

D2219 Specification for Poly(Vinyl Chloride) Insulation for Wire and Cable, 60°C Operation

D2633 Test Methods for Thermoplastic Insulations and Jackets for Wire and Cable

D2768 Specification for General-Purpose Ethylene-Propylene Rubber Jacket for Wire and Cable (Withdrawn 2007)

D2770 Specification for Ozone-Resisting Ethylene-Propylene Rubber Integral Insulation and Jacket for Wire and Cable

(Withdrawn 2007)

E8/E8M Test Methods for Tension Testing of Metallic Materials

2.2 ANSI Standard:

C 37.09 Standard Test Procedure for AC High-Voltage Circuit Breakers Rated on a Symmetrical Basis

2.3 ICEA/NEMA Standard:

ICEA S-19-81/NEMA WC 3-80 (R 1986) Rubber Insulated Wire and Cable for the Transmission and Distribution of Electrical

Energy

2.4 IEC Standard:

IEC 61230 Ed. 2, 2008, Portable Equipment for Earthing or Earthing and Short-Circuiting

2.5 IEEE Standard:

IEEE 386 Standard for Separable Insulated Connector Systems for Power Distribution Systems Above 600V

IEEE 1048 Guide for Protective Grounding of Power Lines

IEEE 1246 Guide for Temporary Protective Grounding Systems Used in Substations

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 continuous current rating—designated RMS current which can be carried continuously under specified conditions.

3.1.2 protective ground assembly—a temporary electrical connection between a source of potential energization and the earth,

rated for the maximum anticipated fault current or continuous induced current, or both.

The last approved version of this historical standard is referenced on www.astm.org.

Available from American National Standards Institute, 11 West 42nd St., 13th Floor, New York, NY 10036.

Available from Insulated Cable Engineers Assoc., P.O. Box P, South Yarmouth, MA 02664.

Available from International Electrotechnical Commission (IEC), 3 rue de Varembé, Case postale 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

3.1.2.1 Discussion—

Throughout this specification, kc mil = 1000 circular mils.

3.1.3 protective grounding equipment—devices installed temporarily on de-energized electric power circuits for the purposes of

potential equalization and to conduct a short circuit current for a specified duration (time).

F855 − 14

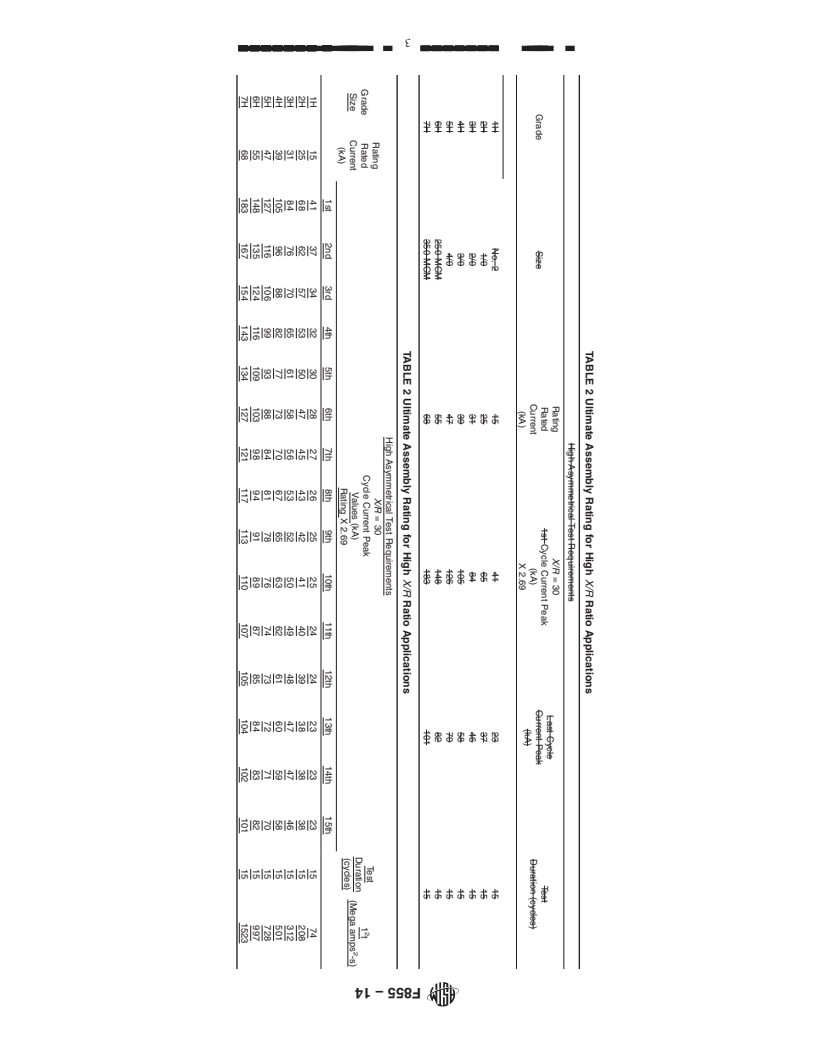

TABLE 2 Ultimate Assembly Rating for High X/R Ratio Applications

High Asymmetrical Test Requirements

Rating X/R = 30

Last Cycle

Rated 1st Cycle Current Peak Test

Grade Size Current Peak

Current (kA) Duration (cycles)

(kA)

(kA) X 2.69

1H No. 2 15 41 23 15

2H 1/0 25 65 37 15

3H 2/0 31 84 46 15

4H 3/0 39 105 58 15

5H 4/0 47 126 70 15

6H 250 MCM 55 148 82 15

7H 350 MCM 68 183 101 15

TABLE 2 Ultimate Assembly Rating for High X/R Ratio Applications

High Asymmetrical Test Requirements

X/R = 30

Rating

Test

Cycle Current Peak

Grade Rated 1 t

Duration

Values (kA)

Size Current (Mega amps -s)

(cycles)

Rating X 2.69

(kA)

1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th 12th 13th 14th 15th

1H 15 41 37 34 32 30 28 27 26 25 25 24 24 23 23 23 15 74

2H 25 68 62 57 53 50 47 45 43 42 41 40 39 38 38 38 15 208

3H 31 84 76 70 65 61 58 56 53 52 50 49 48 47 47 46 15 312

4H 39 105 96 88 82 77 73 70 67 65 63 62 61 60 59 58 15 501

5H 47 127 116 106 99 93 88 84 81 78 76 74 73 72 71 70 15 728

6H 55 148 135 124 116 109 103 98 94 91 89 87 85 84 83 82 15 997

7H 68 183 167 154 143 134 127 121 117 113 110 107 105 104 102 101 15 1523

F855 − 14

NOTE 1—The above current values are based on electromechanical test values.

F855 − 14

NOTE 2—Assemblies that have been subjected to these shall not be re-used.

F855 − 14

NOTE 3—For use with currents exceeding 20 % asymmetry factor.

F855 − 14

NOTE 4—See X4.7.2 for additional information.

F855 − 14

NOTE 5—Alternate testing circuits are available for laboratories that cannot achieve the above requirements. See Appendix X4 for details.

F855 − 14

3.1.4 time to failure—failure time of the cable is the time between the initiation of current flow and the instant at which arcing

begins.

3.1.5 ultimate capacity—this represents a current which it is calculated the component is capable of conducting for the specified

time. It is expected that component damage may result. The component shall not be reused, except in test situations.

3.1.6 withstand rating—this represents a near symmetrical current which shall be conducted without any component being

damaged sufficiently to prevent being operable and reusable. The protective ground shall be capable of passing a second test at

this current after being cooled to ambient temperature.

CLAMPS FOR TEMPORARY PROTECTIVE GROUNDS

4. Scope

4.1 This specification covers clamps used with ferrules and elastomer or thermoplastic covered flexible cable in the manufacture

of protective grounds installed temporarily for protective grounding of de-energized circuits.

5. Classification

5.1 Clamps are furnished in, but not limited to, three types according to their function and method of installation, as follows:

5.1.1 Type I—Clamps for installation on de-energized conductors equipped with eyes for installation with removable hot sticks.

5.1.2 Type II—Clamps for installation on de-energized conductors having permanently mounted hot sticks.

5.1.3 Type III—Clamps for installation on permanently grounded conductors or metal structures with tee handles, and eyes or

square or hexagon head screw(s), or both.

5.1.4 Other types of special clamps, such as those for cluster grounds or for underground equipment grounding, may be made,

tested, and certified by the manufacturer as meeting the requirements of this specification.

5.1.5 Separable insulated connectors used in manufacturing underground equipment grounding assemblies shall meet the

requirements of IEEE 386.

5.2 Clamps are furnished in grades according to mechanical strengths, short circuit capabilities, and duration of faults, as

indicated in Table 1.

5.3 Clamps are furnished in two classes according to the characteristics of the main contact jaws:

5.3.1 Class A—Clamp jaws with smooth contact surfaces.

5.3.2 Class B—Clamp jaws with serrations, or cross hatching, or other means intended to abrade or bite through corrosion

products on the surfaces of the conductor being clamped.

6. Sizes

6.1 Clamp size is the combination of the main contact and cable size ranges as listed by the manufacturers. It should be noted

that the main contact may connect to a cable or bus bar or be used at the “ground end” to connect to a variety of conductive

grounded objects.

7. Ordering Information

7.1 Orders for clamps under this specification shall include this ASTM designation and the following information:

7.1.1 Quantity,

7.1.2 Name (grounding clamp),

7.1.3 Main contact size ranges, conductor descriptions, and materials which are to be clamped by main contact,

7.1.4 Cable size, material, and description by which clamps are to be assembled,

7.1.5 Type (see 5.1),

7.1.6 Grade (see 5.2 and Table 1 or Table 2),

7.1.7 Class (see 5.3),

7.1.8 Asymmetrical current or other supplementary requirements, if applicable. (See Supplementary Requirements S1 to S10

for styles and designs.)

NOTE 2—A typical ordering description is as follows: 100 Grounding Clamps, Main contact range #2 to 350 kcmil for 2/0 Copper flexible grounding

cable, ASTM F855, Type 1, Grade 3, Class A, Design C, Style 7.

NOTE 3—It is expected that manufacturers will publish catalog data conforming to this specification that will combine the requirements of 7.1.1 – 7.1.8

in a single product number. With that system, a typical order description is: 100 (Smith Manufacturing Co. Product No. XXXX) grounding clamps ASTM

F855, Grade 2 or 2H.

8. Materials

8.1 Current carrying parts made of copper base or aluminum base alloy shall have the following material properties in

accordance with Test Methods E8/E8M:

F855 − 14

Copper Base Alloy Aluminum Base Alloy

Tensile strength, min 207 MPa (30 000 psi) 207 MPa (30 000 psi)

Yield strength, min 90 MPa (13 000 psi) 138 MPa (20 000 psi)

Elongation, min 6 % 3 %

8.2 Type II clamps shall be equipped with an insulating handle (hot stick) appropriate for the nominal voltage of the circuit to

be grounded.

9. Electrical and Mechanical Properties

9.1 Electrical and mechanical properties shall conform to the requirements prescribed in Table 1 or Table 2, as appropriate, and

the following paragraphs. See Appendix X3 for a discussion and derivation of the current levels in Table 1. See Appendix X4 for

a discussion of the effects of asymmetrical current and the derivation of the currents in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.