ASTM D128-98(2014)

(Test Method)Standard Test Methods for Analysis of Lubricating Grease

Standard Test Methods for Analysis of Lubricating Grease

SIGNIFICANCE AND USE

4.1 These test methods can be used to identify and estimate the amount of some of the constituents of lubricating greases. These test methods are applicable to many, but not all, greases.

4.2 Composition should not be considered as having any direct bearing on service performance unless such correlation is established.

Note 2: Details on other test methods for grease analysis can be found in other reference material.4,5,6

SCOPE

1.1 These test methods for analysis cover greases of the conventional type, which consist essentially of petroleum oil and soap. The constituents that can be determined are soap, unsaponifiable matter (petroleum oil, and so forth), water, free alkalinity, free fatty acid, fat, glycerin, and insolubles.

Note 1: Any of the test methods described herein are best used by an experienced grease analyst who may also be able to make appropriate adaptations of the techniques as occasion requires.

1.2 A supplementary test method is provided in Appendix X1. This test method is intended primarily for application to greases containing thickeners that are essentially insoluble in n-hexane, and to greases that cannot be analyzed by conventional methods because of the presence of such constituents as nonpetroleum fluids or nonsoap-type thickeners, or both. In some cases, these constituents can react with strong acid or alkaline solutions.

1.3 These test methods appear in the following order:

Sections

Ash Determination

7 – 11

Insolubles, Soap, Fat, Petroleum Oil,

and Unsaponifiable Matter

12 – 20

Free Alkali and Free Acid

21 – 23

Water

24

Glycerin (Quantitative)

25 – 29

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D128 − 98(Reapproved 2014)

Standard Test Methods for

Analysis of Lubricating Grease

This standard is issued under the fixed designation D128; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods for analysis cover greases of the 2.1 ASTM Standards:

conventional type, which consist essentially of petroleum oil D95 Test Method for Water in Petroleum Products and

and soap. The constituents that can be determined are soap, Bituminous Materials by Distillation

unsaponifiable matter (petroleum oil, and so forth), water, free D156 Test Method for Saybolt Color of Petroleum Products

alkalinity, free fatty acid, fat, glycerin, and insolubles. (Saybolt Chromometer Method)

D217 Test Methods for Cone Penetration of Lubricating

NOTE 1—Any of the test methods described herein are best used by an

Grease

experienced grease analyst who may also be able to make appropriate

D445 Test Method for Kinematic Viscosity of Transparent

adaptations of the techniques as occasion requires.

and Opaque Liquids (and Calculation of Dynamic Viscos-

1.2 A supplementary test method is provided in Appendix

ity)

X1. This test method is intended primarily for application to

D473 Test Method for Sediment in Crude Oils and Fuel Oils

greases containing thickeners that are essentially insoluble in

by the Extraction Method

n-hexane, and to greases that cannot be analyzed by conven-

D804 Terminology Relating to Pine Chemicals, Including

tional methods because of the presence of such constituents as

Tall Oil and Related Products

nonpetroleum fluids or nonsoap-type thickeners, or both. In

D1078 Test Method for Distillation Range of Volatile Or-

some cases, these constituents can react with strong acid or

ganic Liquids

alkaline solutions.

D1193 Specification for Reagent Water

1.3 These test methods appear in the following order:

D1353 Test Method for Nonvolatile Matter in Volatile Sol-

Sections

vents for Use in Paint, Varnish, Lacquer, and Related

Ash Determination 7–11

Products

Insolubles, Soap, Fat, Petroleum Oil, 12–20

and Unsaponifiable Matter

3. Terminology

Free Alkali and Free Acid 21–23

Water 24

3.1 Definitions:

Glycerin (Quantitative) 25–29

3.1.1 asphalt, n—a dark brown-to-black cementitious mate-

1.4 The values stated in SI units are to be regarded as

rial in which the predominating constituents are bitumens.

standard. No other units of measurement are included in this

3.1.1.1 Discussion—Asphalt can be a natural product or a

standard.

material obtained from petroleum processing.

1.5 This standard does not purport to address all of the

3.1.2 candle pitch, n—a dark brown-to-black, tarry or solid,

safety concerns, if any, associated with its use. It is the

by-product residue from soap and candle stock manufacture,

responsibility of the user of this standard to establish appro-

refiningofvegetableoils,refiningofwoolgrease,orrefiningof

priate safety and health practices, and determine the applica-

refuse animal fats.

bility of regulatory limitations prior to use.

3.1.3 cup grease, n—any lubricating grease having physical

properties, such as consistency and texture, suitable for its use

in spring-loaded or screw-type lubricating cups.

These test methods are under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and are the direct responsibility

of Subcommittee D02.G0.01 on Chemical and General Laboratory Tests. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2014. Published November 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1922. Last previous edition approved in 2008 as D128 – 98(2008). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D0128-98R14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D128 − 98 (2014)

3.1.3.1 Discussion—Cup greases are predominantly NLGI expressed as equivalent milligrams of potassium hydroxide per

No. 3 or 4 calcium greases, but grease types other than calcium gram of sample. D804

are also used.

3.1.12 NLGI, n—National Lubricating Grease Institute.

3.1.4 degras(woolfat,woolgrease,woolwax),n—afat-like

3.1.13 NLGI number, n—a numerical scale for classifying

material comprised primarily of sterols, other higher alcohols,

the consistency range of lubricating greases and based on the

and fatty acids, obtained from the solvent extraction of sheep’s

Test Methods D217 worked penetration.

wool.

NLGI Lubricating Grease Guide

3.1.5 free alkali, n— in lubricating grease, unreacted basic

3.1.14 non-soap thickener (synthetic thickener, inorganic

(alkaline) material present in the product.

thickener, organic thickener), n—in lubricating grease, any of

3.1.5.1 Discussion—Many greases are made with a slight

several specially treated or synthetic materials, excepting

excess of alkali to ensure complete saponification. Free alkali

metallicsoaps,thatcanbethermallyormechanicallydispersed

is determined by acidification of a solvent-thinned specimen

in liquid lubricants to form the lubricating grease structure.

and back titration with standardized, alcoholic potassium

NLGI Lubricating Grease Guide

hydroxide. It is expressed in terms of the predominating alkali

3.1.15 residuum, n—a liquid or semi-liquid product ob-

and a mass % of the total grease composition (for example,

tained as residue from the distillation of petroleum and

mass % lithium hydroxide).

consisting primarily of asphaltic hydrocarbons.

3.1.6 free fatty acid, n—in lubricating grease, unreacted

3.1.15.1 Discussion—Also known as asphaltic oil, asphal-

carboxylic acid(s) present in the product.

tum oil, liquid asphalt, black oil, petroleum tailings, and

3.1.6.1 Discussion—Some greases are made with a slight

residual oil.

excess of carboxylic acid to ensure a non-alkaline product.

Free fatty acid is determined by neutralization of a solvent-

3.1.16 rosin oil, n—a viscous, oily liquid obtained as a

thinned specimen with standardized, alcoholic potassium hy-

condensate when the residue (rosin) from turpentine produc-

droxide.Regardlessoftheactualcompositionofthecarboxylic

tion is subjected to dry, destructive distillation.

acid(s), it is expressed as free oleic acid and as a mass % of the

3.1.16.1 Discussion—Also used to describe specially com-

total grease composition.

pounded oils having a rosin base.

3.1.7 insolubles, n—in lubricating greases analysis, the

3.1.17 saponification, n—the interaction of fats, fatty acids,

material remaining after the acid hydrolysis, water extraction,

or esters generally with an alkali to form the metallic salt,

and solvent extraction of soap-thickened greases.

which is commonly called soap.

3.1.7.1 Discussion—Consisting of such products as

3.1.17.1 Discussion—Soap thickeners are most often made

graphite, molybdenum disulfide, insoluble polymers, and so

by in situ saponification in the lubricating grease base oil.

forth.

However, the use of pre-formed soaps is also common;

3.1.8 lubricating grease, n—a semi-fluid to solid product of

dispersion is effected by mechanical means and usually with

a dispersion of a thickener in a liquid lubricant.

heat. NLGI Lubricating Grease Guide

3.1.8.1 Discussion—The qualifying term, lubricating,

3.1.18 single base, adj— in lubricating grease, relating to a

should always be used. The term, grease, used without the

thickener comprised of soaps of only one metal.

qualifier refers to a different product, namely certain natural or

3.1.19 soap, n—in lubricating grease, a product formed in

processed animal fats, such as tallow, lard, and so forth.

the saponification (neutralization) of fats, fatty acids, or esters

3.1.9 mixed base, adj—in lubricating grease, the description

by inorganic bases.

of a thickener system composed of soaps of two metals.

3.1.20 Soxhlet apparatus, n—a device, usually of glass,

3.1.9.1 Discussion—Although mixed-base grease can be

used to extract soluble material from a mixture of soluble and

made with soaps of more than two metals, in practice, such is

insoluble (generally solid) materials, by passing a volatile

rarely, if ever, encountered. All of the soaps need not be

solvent through the sample and recirculating the solvent by

thickeners, although the major soap constituent will be one

refluxing.

capable of forming a lubricating grease structure. Because the

mixed soaps are seldom present in equal amounts. The pre-

3.1.21 tar, n—a brown or black, bituminous, liquid or

dominant soap is referred to first.

semi-solid comprised primarily of bitumens condensed in the

NLGI Lubricating Grease Guide

processingofcoal,petroleum,oil-shale,wood,orotherorganic

materials.

3.1.10 montan wax, n—a wax-like material comprised pri-

marily of montanic acid and its ester, higher aliphatic alcohols,

3.1.22 thickener, n—in lubricating grease, a substance com-

and resins obtained from the solvent extraction of lignite.

posed of finely divided solid particles dispersed in a liquid

3.1.11 neutralization number, n—of petroleum oil, the quan- lubricant to form the product’s structure.

tity of acid or base required to titrate to neutrality and

3.1.22.1 Discussion—The thickener can be fibers (such as

various metallic soaps) or plates or spheres (such as certain

non-soapthickeners),whichareinsolubleor,atmost,onlyvery

slightly soluble in the liquid lubricant. The general require-

Available from National Lubricating Grease Institute, 4635 Wyandotte St.,

Kansas City, MO 64112-1596. ments are that the solid particles be extremely small, uniformly

D128 − 98 (2014)

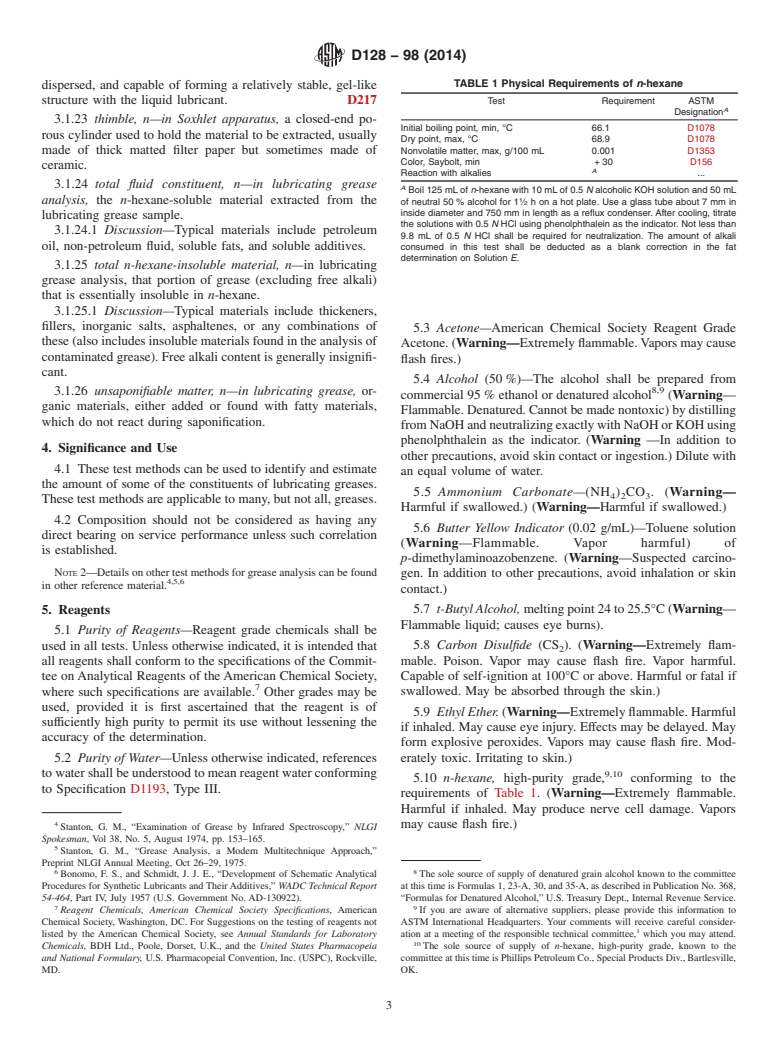

TABLE 1 Physical Requirements of n-hexane

dispersed, and capable of forming a relatively stable, gel-like

structure with the liquid lubricant. D217 Test Requirement ASTM

A

Designation

3.1.23 thimble, n—in Soxhlet apparatus, a closed-end po-

Initial boiling point, min, °C 66.1 D1078

rous cylinder used to hold the material to be extracted, usually

Dry point, max, °C 68.9 D1078

made of thick matted filter paper but sometimes made of Nonvolatile matter, max, g/100 mL 0.001 D1353

Color, Saybolt, min + 30 D156

ceramic.

A

Reaction with alkalies .

3.1.24 total fluid constituent, n—in lubricating grease

A

Boil 125 mL of n-hexane with 10 mL of 0.5 N alcoholic KOH solution and 50 mL

analysis, the n-hexane-soluble material extracted from the of neutral 50 % alcohol for 1 ⁄2 h on a hot plate. Use a glass tube about 7 mm in

inside diameter and 750 mm in length as a reflux condenser. After cooling, titrate

lubricating grease sample.

the solutions with 0.5 N HCl using phenolphthalein as the indicator. Not less than

3.1.24.1 Discussion—Typical materials include petroleum

9.8mL of0.5 N HCl shall be required for neutralization. The amount of alkali

oil, non-petroleum fluid, soluble fats, and soluble additives. consumed in this test shall be deducted as a blank correction in the fat

determination on Solution E.

3.1.25 total n-hexane-insoluble material, n—in lubricating

grease analysis, that portion of grease (excluding free alkali)

that is essentially insoluble in n-hexane.

3.1.25.1 Discussion—Typical materials include thickeners,

fillers, inorganic salts, asphaltenes, or any combinations of

5.3 Acetone—American Chemical Society Reagent Grade

these(alsoincludesinsolublematerialsfoundintheanalysisof

Acetone.(Warning—Extremelyflammable.Vaporsmaycause

contaminated grease). Free alkali content is generally insignifi-

flash fires.)

cant.

5.4 Alcohol (50 %)—The alcohol shall be prepared from

8,9

3.1.26 unsaponifiable matter, n—in lubricating grease, or-

commercial 95 % ethanol or denatured alcohol (Warning—

ganic materials, either added or found with fatty materials,

Flammable.Denatured.Cannotbemadenontoxic)bydistilling

which do not react during saponification.

fromNaOHandneutralizingexactlywithNaOHorKOHusing

phenolphthalein as the indicator. (Warning —In addition to

4. Significance and Use

other precautions, avoid skin contact or ingestion.) Dilute with

4.1 These test methods can be used to identify and estimate

an equal volume of water.

the amount of some of the constituents of lubricating greases.

5.5 Ammonium Carbonate—(NH ) CO.(Warning—

4 2 3

These test methods are applicable to many, but not all, greases.

Harmful if swallowed.) (Warning—Harmful if swallowed.)

4.2 Composition should not be considered as having any

5.6 Butter Yellow Indicator (0.02 g/mL)—Toluene solution

direct bearing on service performance unless such correlation

(Warning—Flammable. Vapor harmful) of

is established.

p-dimethylaminoazobenzene. (Warning—Suspected carcino-

NOTE 2—Details on other test methods for grease analysis can be found

gen. In addition to other precautions, avoid inhalation or skin

4,5,6

in other reference material.

contact.)

5. Reagents 5.7 t-ButylAlcohol,meltingpoint24to25.5°C(Warning—

Flammable liquid; causes eye burns).

5.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that 5.8 Carbon Disulfide (CS ). (Warning—Extremely flam-

mable. Poison. Vapor may cause flash fire. Vapor harmful.

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society, Capable of self-ignition at 100°C or above. Harmful or fatal if

swallowed. May be absorbed through the skin.)

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

5.9 EthylEther.(Warning—Extremelyflammable.Harmful

sufficiently high purity to permit its use without lessening the

if inhaled. May cause eye injury. Effects may be delayed. May

accuracy of the determination.

form explosive peroxides. Vapors may cause flash fire. Mod-

erately toxic. Irritating to skin.)

5.2 Purity of Water—Unless otherwise indicated, references

towatershallbeunderstoodtomeanreagentwaterconforming 9,10

5.10 n-hexane, high-purity grade, conforming to the

to Specification D1193, Type III.

requirements of Table 1.(Warning—Extremely flammable.

Harmful if inhaled. May produce nerve cell damage. Vapors

may cause flash fire.)

Stanton, G. M., “Examination of Grease by Infrared Spectroscopy,” NLGI

Spokesman, Vol 38, No. 5, August 1974, pp. 153–165.

Stanton, G. M., “Grease Analysis, a Modern Multitechnique Approach,”

Preprint NLGI Annual Meeting, Oct 26–29, 1975.

6 8

Bonom

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D128 − 98 (Reapproved 2008) D128 − 98 (Reapproved 2014)

Standard Test Methods for

Analysis of Lubricating Grease

This standard is issued under the fixed designation D128; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods for analysis cover greases of the conventional type, which consist essentially of petroleum oil and soap.

The constituents that can be determined are soap, unsaponifiable matter (petroleum oil, and so forth), water, free alkalinity, free

fatty acid, fat, glycerin, and insolubles.

NOTE 1—Any of the test methods described herein are best used by an experienced grease analyst who may also be able to make appropriate adaptations

of the techniques as occasion requires.

1.2 A supplementary test method is provided in Appendix X1. This test method is intended primarily for application to greases

containing thickeners that are essentially insoluble in n-hexane, and to greases that cannot be analyzed by conventional methods

because of the presence of such constituents as nonpetroleum fluids or nonsoap-type thickeners, or both. In some cases, these

constituents can react with strong acid or alkaline solutions.

1.3 These test methods appear in the following order:

Sections

Ash Determination 7 – 11

Insolubles, Soap, Fat, Petroleum Oil, 12 – 20

and Unsaponifiable Matter

Free Alkali and Free Acid 21 – 23

Water 24

Glycerin (Quantitative) 25 – 29

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices, and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D95 Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

D156 Test Method for Saybolt Color of Petroleum Products (Saybolt Chromometer Method)

D217 Test Methods for Cone Penetration of Lubricating Grease

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D473 Test Method for Sediment in Crude Oils and Fuel Oils by the Extraction Method

D804 Terminology Relating to Pine Chemicals, Including Tall Oil and Related Products

D1078 Test Method for Distillation Range of Volatile Organic Liquids

D1193 Specification for Reagent Water

D1353 Test Method for Nonvolatile Matter in Volatile Solvents for Use in Paint, Varnish, Lacquer, and Related Products

3. Terminology

3.1 Definitions:

3.1.1 asphalt, n—a dark brown-to-black cementitious material in which the predominating constituents are bitumens.

These test methods are under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and are the direct responsibility

of Subcommittee D02.G0.01 on Chemical and General Laboratory Tests.

Current edition approved May 1, 2008Oct. 1, 2014. Published July 2008 November 2014. Originally approved in 1922. Last previous edition approved in 20032008 as

ε1

D128–98(2003)D128 – 98 .(2008). DOI: 10.1520/D0128-98R08.10.1520/D0128-98R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D128 − 98 (2014)

3.1.1.1 Discussion—

Asphalt can be a natural product or a material obtained from petroleum processing.

3.1.2 candle pitch, n—a dark brown-to-black, tarry or solid, by-product residue from soap and candle stock manufacture,

refining of vegetable oils, refining of wool grease, or refining of refuse animal fats.

3.1.3 cup grease, n—any lubricating grease having physical properties, such as consistency and texture, suitable for its use in

spring-loaded or screw-type lubricating cups.

3.1.3.1 Discussion—

Cup greases are predominantly NLGI No. 3 or 4 calcium greases, but grease types other than calcium are also used.

3.1.4 degras (wool fat, wool grease, wool wax), n—a fat-like material comprised primarily of sterols, other higher alcohols, and

fatty acids, obtained from the solvent extraction of sheep’s wool.

3.1.5 free alkali, n— in lubricating grease, unreacted basic (alkaline) material present in the product.

3.1.5.1 Discussion—

Many greases are made with a slight excess of alkali to ensure complete saponification. Free alkali is determined by acidification

of a solvent-thinned specimen and back titration with standardized, alcoholic potassium hydroxide. It is expressed in terms of the

predominating alkali and a mass % of the total grease composition (for example, mass % lithium hydroxide).

3.1.6 free fatty acid, n—in lubricating grease, unreacted carboxylic acid(s) present in the product.

3.1.6.1 Discussion—

Some greases are made with a slight excess of carboxylic acid to ensure a non-alkaline product. Free fatty acid is determined by

neutralization of a solvent-thinned specimen with standardized, alcoholic potassium hydroxide. Regardless of the actual

composition of the carboxylic acid(s), it is expressed as free oleic acid and as a mass % of the total grease composition.

3.1.7 insolubles, n—in lubricating greases analysis, the material remaining after the acid hydrolysis, water extraction, and

solvent extraction of soap-thickened greases.

3.1.7.1 Discussion—

Consisting of such products as graphite, molybdenum disulfide, insoluble polymers, and so forth.

3.1.8 lubricating grease, n—a semi-fluid to solid product of a dispersion of a thickener in a liquid lubricant.

3.1.8.1 Discussion—

The qualifying term, lubricating, should always be used. The term, grease, used without the qualifier refers to a different product,

namely certain natural or processed animal fats, such as tallow, lard, and so forth.

3.1.9 mixed base, adj—in lubricating grease, the description of a thickener system composed of soaps of two metals.

3.1.9.1 Discussion—

Although mixed-base grease can be made with soaps of more than two metals, in practice, such is rarely, if ever, encountered. All

of the soaps need not be thickeners, although the major soap constituent will be one capable of forming a lubricating grease

structure. Because the mixed soaps are seldom present in equal amounts. The predominant soap is referred to first.

NLGI Lubricating Grease Guide

3.1.10 montan wax, n—a wax-like material comprised primarily of montanic acid and its ester, higher aliphatic alcohols, and

resins obtained from the solvent extraction of lignite.

3.1.11 neutralization number, n—of petroleum oil, the quantity of acid or base required to titrate to neutrality and expressed as

equivalent milligrams of potassium hydroxide per gram of sample. D804

Available from National Lubricating Grease Institute, 4635 Wyandotte St., Kansas City, MO 64112-1596.

D128 − 98 (2014)

3.1.12 NLGI, n—National Lubricating Grease Institute.

3.1.13 NLGI number, n—a numerical scale for classifying the consistency range of lubricating greases and based on the Test

Methods D217 worked penetration.

NLGI Lubricating Grease Guide

3.1.14 non-soap thickener (synthetic thickener, inorganic thickener, organic thickener), n—in lubricating grease, any of several

specially treated or synthetic materials, excepting metallic soaps, that can be thermally or mechanically dispersed in liquid

lubricants to form the lubricating grease structure. NLGI Lubricating Grease Guide

3.1.15 residuum, n—a liquid or semi-liquid product obtained as residue from the distillation of petroleum and consisting

primarily of asphaltic hydrocarbons.

3.1.15.1 Discussion—

Also known as asphaltic oil, asphaltum oil, liquid asphalt, black oil, petroleum tailings, and residual oil.

3.1.16 rosin oil, n—a viscous, oily liquid obtained as a condensate when the residue (rosin) from turpentine production is

subjected to dry, destructive distillation.

3.1.16.1 Discussion—

Also used to describe specially compounded oils having a rosin base.

3.1.17 saponification, n—the interaction of fats, fatty acids, or esters generally with an alkali to form the metallic salt, which

is commonly called soap.

3.1.17.1 Discussion—

Soap thickeners are most often made by in situ saponification in the lubricating grease base oil. However, the use of pre-formed

soaps is also common; dispersion is effected by mechanical means and usually with heat. NLGI Lubricating Grease Guide

3.1.18 single base, adj— in lubricating grease, relating to a thickener comprised of soaps of only one metal.

3.1.19 soap, n—in lubricating grease, a product formed in the saponification (neutralization) of fats, fatty acids, or esters by

inorganic bases.

3.1.20 Soxhlet apparatus, n—a device, usually of glass, used to extract soluble material from a mixture of soluble and insoluble

(generally solid) materials, by passing a volatile solvent through the sample and recirculating the solvent by refluxing.

3.1.21 tar, n—a brown or black, bituminous, liquid or semi-solid comprised primarily of bitumens condensed in the processing

of coal, petroleum, oil-shale, wood, or other organic materials.

3.1.22 thickener, n—in lubricating grease, a substance composed of finely divided solid particles dispersed in a liquid lubricant

to form the product’s structure.

3.1.22.1 Discussion—

The thickener can be fibers (such as various metallic soaps) or plates or spheres (such as certain non-soap thickeners), which are

insoluble or, at most, only very slightly soluble in the liquid lubricant. The general requirements are that the solid particles be

extremely small, uniformly dispersed, and capable of forming a relatively stable, gel-like structure with the liquid lubricant. D217

3.1.23 thimble, n—in Soxhlet apparatus, a closed-end porous cylinder used to hold the material to be extracted, usually made

of thick matted filter paper but sometimes made of ceramic.

3.1.24 total fluid constituent, n—in lubricating grease analysis, the n-hexane-soluble material extracted from the lubricating

grease sample.

3.1.24.1 Discussion—

Typical materials include petroleum oil, non-petroleum fluid, soluble fats, and soluble additives.

3.1.25 total n-hexane-insoluble material, n—in lubricating grease analysis, that portion of grease (excluding free alkali) that is

essentially insoluble in n-hexane.

3.1.25.1 Discussion—

D128 − 98 (2014)

Typical materials include thickeners, fillers, inorganic salts, asphaltenes, or any combinations of these (also includes insoluble

materials found in the analysis of contaminated grease). Free alkali content is generally insignificant.

3.1.26 unsaponifiable matter, n—in lubricating grease, organic materials, either added or found with fatty materials, which do

not react during saponification.

4. Significance and Use

4.1 These test methods can be used to identify and estimate the amount of some of the constituents of lubricating greases. These

test methods are applicable to many, but not all, greases.

4.2 Composition should not be considered as having any direct bearing on service performance unless such correlation is

established.

4,5,6

NOTE 2—Details on other test methods for grease analysis can be found in other reference material.

5. Reagents

5.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

5.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water conforming to

Specification D1193, Type III.

5.3 Acetone—American Chemical Society Reagent Grade Acetone. (Warning—Extremely flammable. Vapors may cause flash

fires.)

8,9

5.4 Alcohol (50 %)—The alcohol shall be prepared from commercial 95 % ethanol or denatured alcohol (Warning—

Flammable. Denatured. Cannot be made nontoxic) by distilling from NaOH and neutralizing exactly with NaOH or KOH using

phenolphthalein as the indicator. (Warning —In addition to other precautions, avoid skin contact or ingestion.) Dilute with an

equal volume of water.

5.5 Ammonium Carbonate—(NH ) CO . (Warning—Harmful if swallowed.) (Warning—Harmful if swallowed.)

4 2 3

5.6 Butter Yellow Indicator (0.02 g/mL)—Toluene solution (Warning—Flammable. Vapor harmful) of

p-dimethylaminoazobenzene. (Warning—Suspected carcinogen. In addition to other precautions, avoid inhalation or skin

contact.)

5.7 t-Butyl Alcohol, melting point 24 to 25.5°C (Warning—Flammable liquid; causes eye burns).

5.8 Carbon Disulfide (CS ). (Warning—Extremely flammable. Poison. Vapor may cause flash fire. Vapor harmful. Capable of

self-ignition at 100°C or above. Harmful or fatal if swallowed. May be absorbed through the skin.)

5.9 Ethyl Ether. (Warning—Extremely flammable. Harmful if inhaled. May cause eye injury. Effects may be delayed. May

form explosive peroxides. Vapors may cause flash fire. Moderately toxic. Irritating to skin.)

9,10

5.10 n-hexane, high-purity grade, conforming to the requirements of Table 1. (Warning—Extremely flammable. Harmful

if inhaled. May produce nerve cell damage. Vapors may cause flash fire.)

5.11 Hydrochloric Acid (37 %) —Concentrated acid (HCl). (Warning—Poison. Corrosive. May be fatal if swallowed. Liquid

and vapor cause severe burns. Harmful if inhaled.)

5.12 Hydrochloric Acid, Standard Solution (0.5 N)—Prepare and standardize a 0.5 N solution of HCl.

5.13 Hydrochloric Acid (10 %), a solution containing 10 % by weight of concentrated HCl in water, with a permissible variation

of 0.5 %.

5.14 Hydrochloric Acid (1 + 3) —Mix one volume of concentrated HCl (37 %) wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.