ASTM A322-06

(Specification)Standard Specification for Steel Bars, Alloy, Standard Grades

Standard Specification for Steel Bars, Alloy, Standard Grades

SCOPE

1.1 This specification covers hot-wrought alloy steel bars. Bar applications include forging, heat treating, cold drawing, machining and many structural components (Note 0). Note 0A guide for the selection of steel bars is contained in Practice A 400.

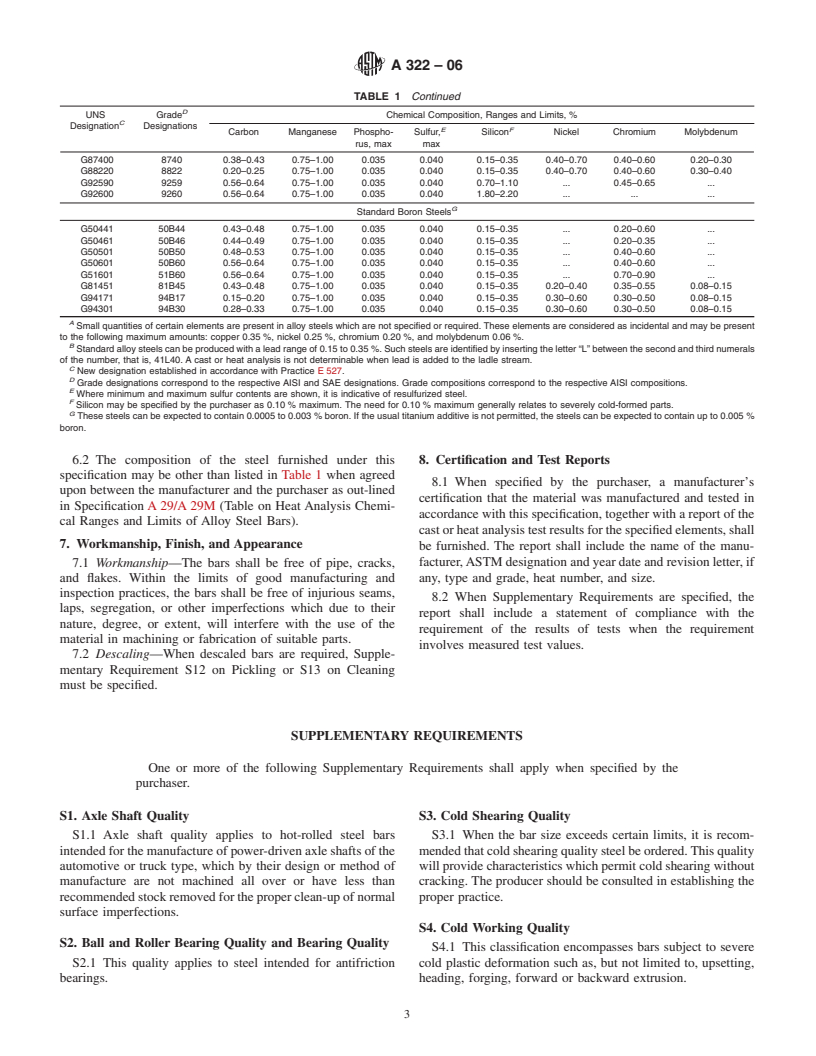

1.2 The bars shall be furnished in the grades specified in . Sections and sizes of bar steel available are covered in Specification A 29/A 29M. Hot-wrought alloy steel bars are produced in cut lengths and coils; the manufacturer should be consulted regarding sections and sizes available in coils, produced to a chemical composition.

1.3 Some applications may require superior surface quality, or special chemical restrictions, metallurgical characteristics, heat treatment, or surface finishes which the purchaser may obtain by designating one or more of the available Supplementary Requirements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 322 – 06

Standard Specification for

1

Steel Bars, Alloy, Standard Grades

This standard is issued under the fixed designation A 322; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Ordering Information

1.1 This specification covers hot-wrought alloy steel bars. 3.1 Orders under this specification should include the fol-

Bar applications include forging, heat treating, cold drawing, lowing as required to describe adequately the desired material:

machining and many structural components (Note 1). 3.1.1 Quantity (weight or number of bars),

3.1.2 Name of material (hot-wrought alloy steel bars),

NOTE 1—Aguide for the selection of steel bars is contained in Practice

3.1.3 Dimensions,

A 400.

3.1.4 ASTM designation,

1.2 The bars shall be furnished in the grades specified in

3.1.5 Deoxidation practice (see 5.3),

Table 1. Sections and sizes of bar steel available are covered in

3.1.6 Gradedesignationorchemicalcompositionlimits(see

Specification A 29/A 29M. Hot-wrought alloy steel bars are

6.1 and Table 1),

produced in cut lengths and coils; the manufacturer should be

3.1.7 Grain size if required,

consulted regarding sections and sizes available in coils,

3.1.8 Test reports, if required (Section 8),

produced to a chemical composition.

3.1.9 Additions to the specification and Supplementary

1.3 Some applications may require superior surface quality,

Requirements, if required, and

or special chemical restrictions, metallurgical characteristics,

3.1.10 Application.

heat treatment, or surface finishes which the purchaser may

obtain by designating one or more of the available Supplemen-

4. General Requirements

tary Requirements.

4.1 Material furnished under this specification shall con-

form to the applicable requirements of the current edition of

2. Referenced Documents

Specification A 29/A 29M, unless otherwise provided herein.

2

2.1 ASTM Standards:

A 29/A 29M SpecificationforSteelBars,CarbonandAlloy,

5. Materials and Manufacture

Hot-Wrought, General Requirements for

5.1 The steel shall be made by one or more of the following

A 304 Specification for Carbon and Alloy Steel Bars Sub-

primary processes: open-hearth, basic-oxygen, or electric-

ject to End-Quench Hardenability Requirements

furnace. The primary melting may incorporate separate degas-

A 400 Practice for Steel Bars, Selection Guide, Composi-

sing or refining and may be followed by secondary melting

tion, and Mechanical Properties

using electro-slag remelting or vacuum arc remelting. Where

E112 Test Methods for Determining Average Grain Size

secondary melting is employed, the heat shall be defined as all

E 381 Method of Macroetch Testing Steel Bars, Billets,

of the ingots remelted from a single primary heat.

Blooms, and Forgings

5.2 The steel shall be furnished as strand cast or ingot cast,

E 527 Practice for Numbering Metals and Alloys (UNS)

unless otherwise specified.

5.3 Deoxidation—Killed steel is required.

5.3.1 The purchaser may designate that the steel be made to

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

coarse or fine austenitic grain size. (See Supplementary Re-

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.15 on Bars.

quirement S9 or S10.)

Current edition approved May 1, 2006. Published May 2006. Originally

5.4 Slow Cooling—Immediately after hot forming, the bars

e1

approved in 1947. Last previous edition approved in 2001 as A 322 – 91 (2001) .

2 shall be allowed to cool to a temperature below the critical

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM range under suitable conditions to prevent imperfections

Standards volume information, refer to the standard’s Document Summary page on

caused by too rapid cooling.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 322–06

5.5 ThermalTreatment—Variousthermaltreatmentssuchas 6. Chemical Composition

annealing, stress relief, quench and temper, normalize, etc., are

6.1 The heat analysis shall conform to the requirements for

available. Such treatments must be specified as a Supplemen-

chemical composition in Table 1 for the grade specified.

tary Requirement.

A,B

TABLE 1 Grade Designations and Chemical Compositions of Hot-Wrought Alloy Steel Bars

D

UNS Grade Chemical Composition, Ranges and Limits

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.