ASTM F1164-97

(Test Method)Standard Test Method for Evaluation of Transparent Plastics Exposed to Accelerated Weathering Combined with Biaxial Stress

Standard Test Method for Evaluation of Transparent Plastics Exposed to Accelerated Weathering Combined with Biaxial Stress

SCOPE

1.1 This test method evaluates the resistance of transparent plastics exposed to environmental conditioning (accelerated weathering) under a biaxial stress state induced by a pressure cell/test fixture.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in acceptable metric units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1164 – 97

Standard Test Method for

Evaluation of Transparent Plastics Exposed to Accelerated

Weathering Combined with Biaxial Stress

This standard is issued under the fixed designation F 1164; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope determine any changes in value. Coating adhesion is measured

when applicable.

1.1 This test method evaluates the resistance of transparent

3.2 The resistance of the plastic to stress-during-weathering

plastics exposed to environmental conditioning (accelerated

is determined by the onset of crazing, the change in haze and

weathering) under a biaxial stress state induced by a pressure

luminous transmittance, and adhesion of coating.

cell/test fixture.

1.2 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 The degradation of optical properties of transparent

responsibility of the user of this standard to establish appro-

plastics is the single greatest cause for in-service removal and

priate safety and health practices and determine the applica-

replacement. Some optical qualities are inherent in the geom-

bility of regulatory limitations prior to use.

etry, manufacturing process, and materials, and remain rela-

1.3 The values stated in acceptable metric units are to be

tively unchanged after manufacture, while others are subject to

regarded as the standard.

gradual change during exposure to the service environment.

2. Referenced Documents Factors having an influence on the crazing of transparent

plastics include stress, ultraviolet (UV), moisture, and tempera-

2.1 ASTM Standards:

ture. Sufficient data has been generated to make it evident that

D 1003 Test Method for Haze and Luminous Transmittance

2 real-world conditioning must be experienced by developmental

of Transparent Plastics

test specimens, as opposed to testing new unexposed material

D 3359 Test Methods for Measuring by Tape Test

to determine durability, prior to in-service usage. However, the

G 26 Practice for Operating Light-Exposure Apparatus

laboratory simulation of natural weathering, and especially

(Xenon-Arc Type) With and Without Water for Exposure

accelerated simulation, is imprecise and correlation of results

of Nonmetallic Materials

obtained for different plastics or from using different exposure

G 53 Practice for Operating Light- and Water-Exposure

apparatus should not be attempted until a valid database has

Apparatus (Fluorescent UV-Condensation Type) for Expo-

been generated for such cross-correlation.

sure of Nonmetallic Materials

G 90 Practice for Performing Accelerated Outdoor Weath-

5. Apparatus

ering of Nonmetallic Materials Using Concentrated Natu-

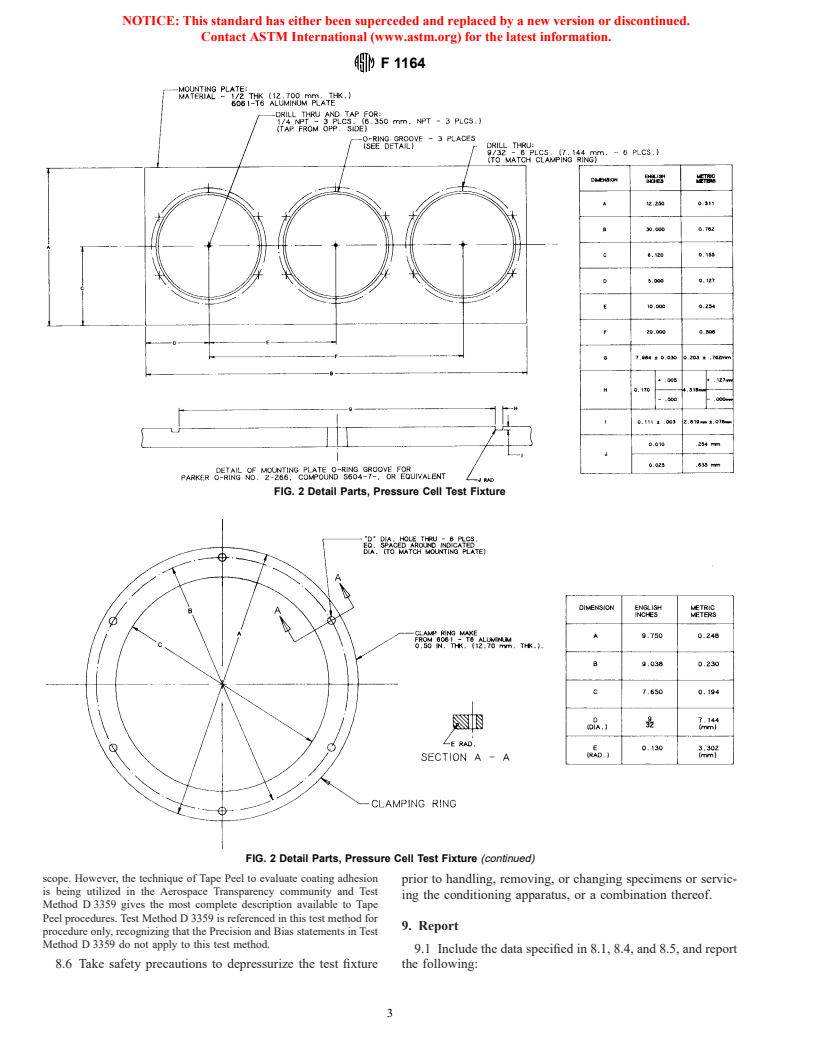

4 5.1 Manifold Test Fixture—An exploded view of the

ral Sunlight

pressure-cell/test-fixture used to induce a biaxial stress state in

3. Summary of Test Method a clamped specimen is illustrated in Fig. 1. The mounting plate

and clamping ring for a 76.2 mm (30-in.) wide three-cell test

3.1 This test method consists of measuring and recording

fixture are detailed in Fig. 2. A 254 mm (10 in.) wide

the haze and light transmittance of an unexposed circular plate

single-cell fixture or a 508 mm (20-in.) wide double-cell fixture

test specimen; mounting the specimen in the test fixture;

are also acceptable.

pressurizing the fixture to induce the desired biaxial stress in

5.2 Accelerated Weathering Apparatus:

the specimen; and exposing the stressed specimen to specific

5.2.1 Operating procedures for using water- or light-

accelerated weathering conditions. After conditioning, the

exposure apparatus, or both, employing a Xenon-arc light

specimen is removed and haze/transmittance are measured to

source to simulate the deterioration caused by accelerated

weathering exposure, shall comply with Practice G 26.

This test method is under the jurisdiction of ASTM Committee F-7 on

5.2.2 Operating procedures for using fluorescent UV and

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

condensation apparatus to simulate the deterioration caused by

Transparent Enclosures and Materials.

Current edition approved April 10, 1997. Published August 1997. Originally accelerated weathering exposure shall comply with Practice

published as F 1164 – 88. Last previous edition F 1164 – 88.

G 53.

Annual Book of ASTM Standards, Vol 08.01.

5.2.3 Operating procedures for using Fresnel-reflecting con-

Annual Book of ASTM Standards, Vol 06.01.

Annual Book of ASTM Standards, Vol 14.02. centrators employing the sun as source, with or without water

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1164

6 2

13.8 3 10 ! t

~

SI Units: M 5 (1)

2000 t

Inch2Pound Units: M 5 (2)

where:

M 5 bending moment at plate center (lb-in./in. or N-m/m)

and

t 5 plate thickness, in. or m.

The desired pressure is as follows:

16 M

P 5 (3)

a ~11y!

where: a 5 distance from plate center to clamped

edge 5 0.0984 m (3.875 in.) or

1652 M

SI Units: P 5 (4)

11y

1.065 M

Inch2Pound Units: P 5 (5)

11y

FIG. 1 Stress Weathering Test Apparatus

8.3 In accordance with the procedures in 5.2, condition the

specimens under stress for 1, 2, 3, 4, and 5 equivalent years of

spray cycles, to simulate the deterioration caused by acceler-

accelerated weathering. Using a fluorescent ultraviolet conden-

ated weathering exposure, shall comply with Practice G 90.

sation test chamber with UV B-313 lamps, an operating

5.3 Hazemeter—The Hazemeter shall conform to the re-

temperature of 48.89°C (120°F), alternate cycles of7hUV

quirements of Test Method D 1003.

followed by5hof condensation, each equivalent year of

6. Test Specimens

natural weathering may be simulated by 168 h of run time.

6.1 Use at least three specimens for each material being Using the Fresnel-reflector accelerated outdoor exposure test

tested and for each specified exposure. The specimens shall be

machines, parameters to establish an equivalent year of real-

as follows: clean, transparent circular plates, 0.216 m (8.500 time weathering shall comply with the guidelines presented in

in.) in diameter, having both sides substantially plane and

Practice G 90.

parallel; specimen nominal thickness being 0.00508 m (0.200 8.4 After each equivalent year of conditioning under stress,

in.).

measure haze and transmittance at the plate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.